DTC P0336 CRANKSHAFT POSITION SENSOR “A” CIRCUIT RANGE/PERFORMANCE

|

|

DTC P0336 CRANKSHAFT POSITION SENSOR “A” CIRCUIT

RANGE/PERFORMANCE

|

Detect the malfunction of crankshaft position

sensor output property. Judge NG when the number of crankshaft signal

every 1 revolution becomes abnormal.

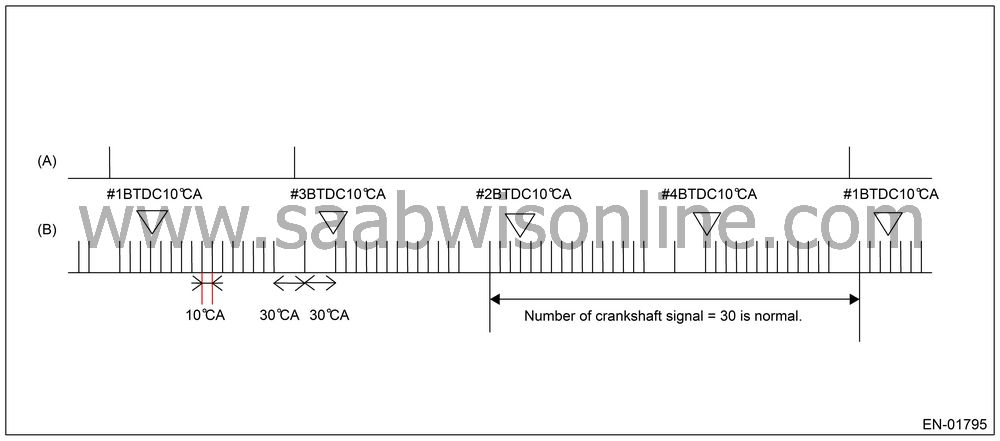

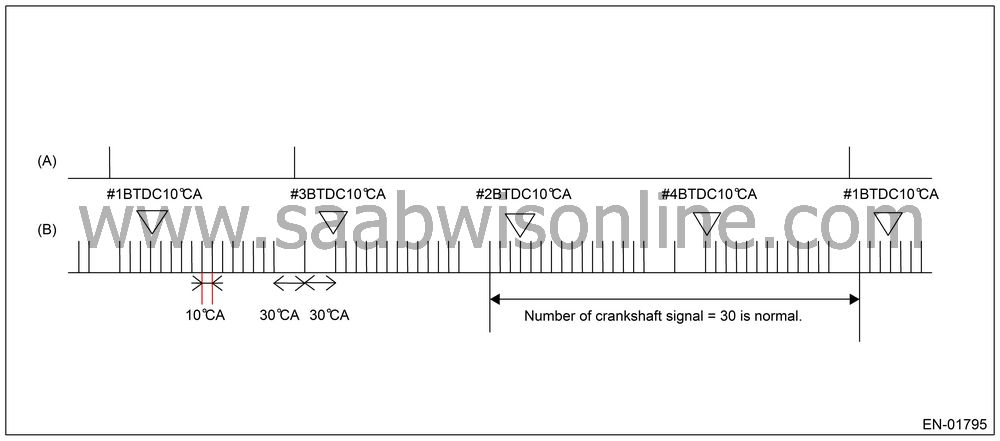

(A)

|

Camshaft

signal

|

(B)

|

Crankshaft

signal

|

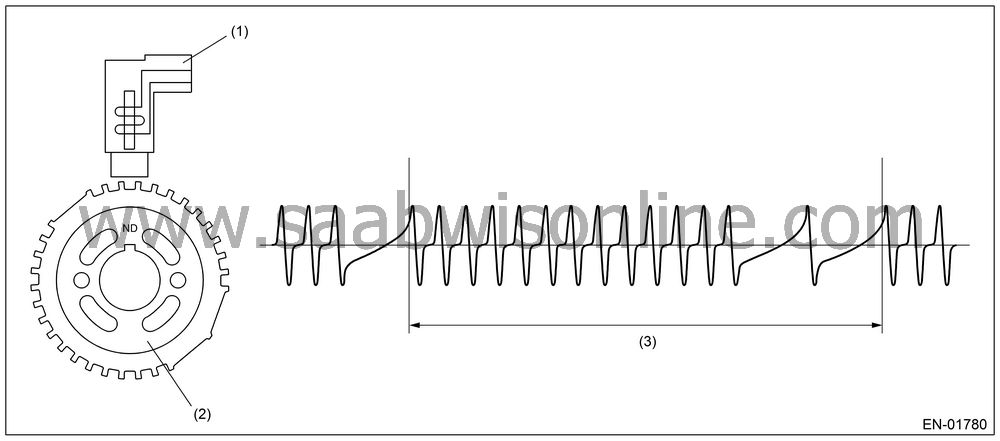

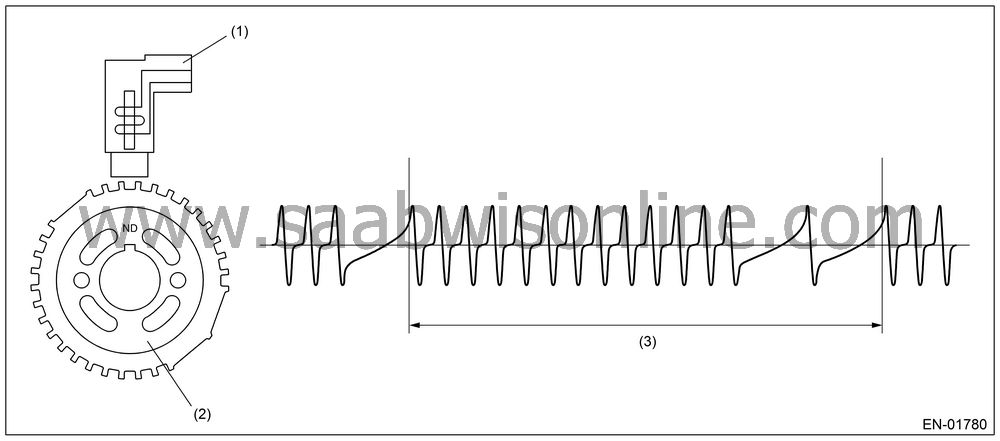

(1)

|

Crankshaft

position sensor

|

(2)

|

Crankshaft

sprocket

|

(3)

|

Crankshaft

half-turn

|

|

Secondary

Parameters

|

Enable

Conditions

|

Battery

voltage

|

≥ 8

V

|

Engine

speed

|

< 3,000

rpm

|

Perform the diagnosis continuously under

3,000 rpm engine speed.

Abnormality Judgment

Judge NG when all the malfunction criteria

below are completed more than 10 times in a row.

Judgment

Value

|

Malfunction

Criteria

|

Threshold

Value

|

Cylinder

number distinction

|

Completed

|

Amount

of crank sensor signal during 1 rev.

|

Not = 30

|

Time Needed for Diagnosis:

10

engine revs.

Malfunction Indicator

Light Illumination:

Illuminates when malfunction occurs in

2 continuous driving cycles.

Normality Judgment

Judge OK and clear the NG when the malfunction

criteria below are completed.

Judgment

Value

|

Malfunction

Criteria

|

Threshold

Value

|

Cylinder

number distinction

|

Completed

|

Amount

of crank sensor signal during 1 rev.

|

= 30

|

|

•

|

When the OK idling cycle was completed 40 times

in a row

|

|

•

|

When “Clear Memory” was

performed

|

|

MALFUNCTION

INDICATOR LIGHT CLEAR CONDITION

|

|

•

|

When the OK driving cycle was completed 3 times

in a row

|

|

•

|

When “Clear Memory” was

performed

|

None

|

ECM OPERATING

AT DTC SETTING

|

Memorize the freeze frame data. (For test

mode $02)