DTC P0442 EVAPORATIVE EMISSION CONTROL SYSTEM LEAK DETECTED (SMALL LEAK)

| DTC P0442 EVAPORATIVE EMISSION CONTROL SYSTEM LEAK DETECTED (SMALL LEAK) |

|

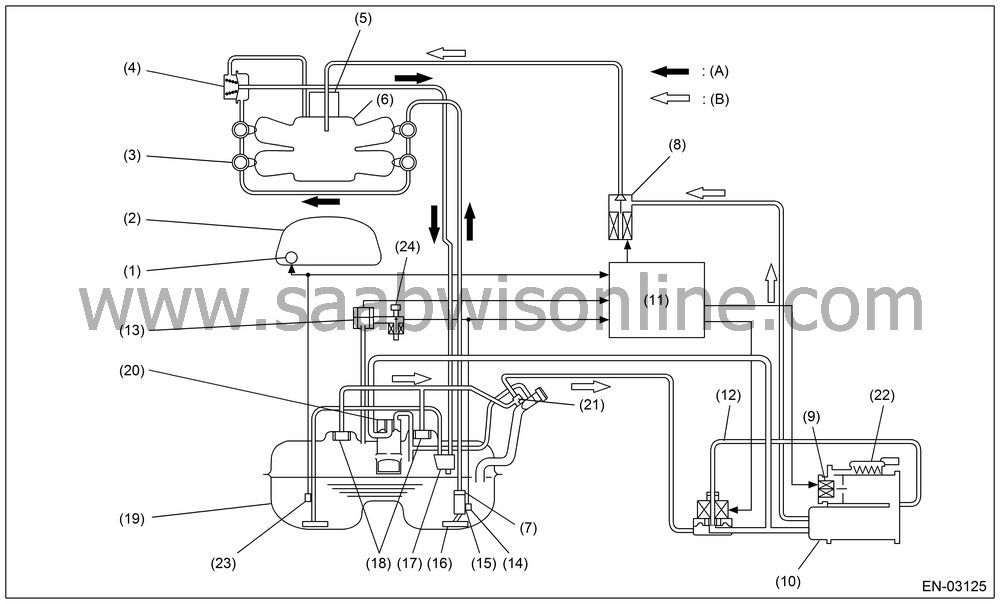

(1)

|

Fuel meter

|

(9)

|

Drain valve

|

(17)

|

Jet pump

|

|

(2)

|

Combination

meter

|

(10)

|

Canister

|

(18)

|

Fuel cut

valve

|

|

(3)

|

Fuel injector

|

(11)

|

Engine

control module (ECM)

|

(19)

|

Fuel tank

|

|

(4)

|

Pressure

regulator

|

(12)

|

Pressure

control solenoid valve

|

(20)

|

Vent valve

|

|

(5)

|

Throttle

body

|

(13)

|

Fuel tank

pressure sensor

|

(21)

|

Shut-off

valve

|

|

(6)

|

Intake

manifold

|

(14)

|

Fuel temperature

sensor

|

(22)

|

Drain filter

|

|

(7)

|

Fuel filter

|

(15)

|

Fuel level

sensor

|

(23)

|

Fuel sub

level sensor

|

|

(8)

|

Purge control

solenoid valve

|

(16)

|

Fuel pump

|

(24)

|

Tank pressure

switching solenoid valve

|

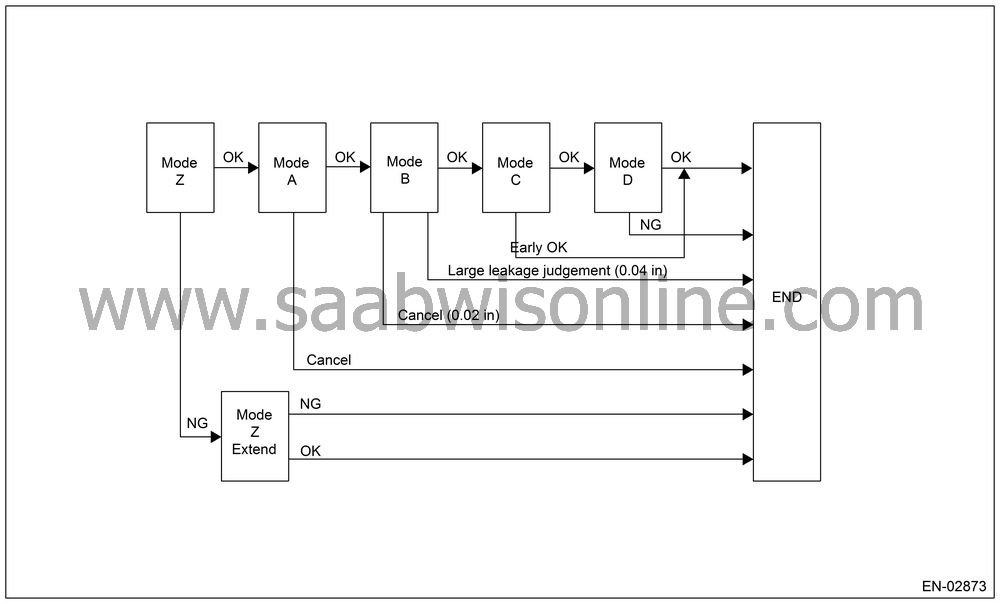

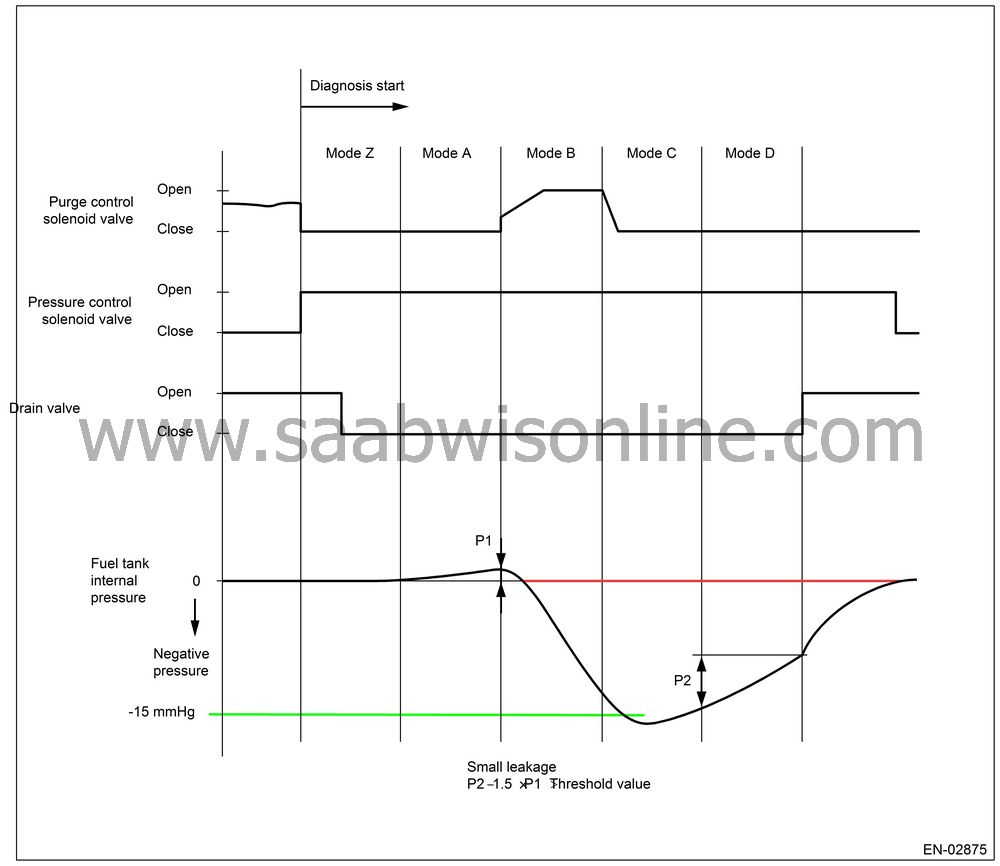

In this system diagnosis, filter tank pressure is changed. And leakage andnormality & abnormality of valve operation are judged by monitoring the pressure change status using the fuel tank pressure sensor. The diagnosis is performed for 0.04-inch diagnosis in the order of Mode A, Mode B, Mode C and Mode D. For 0.02-inch diagnosis, perform in the order of Mode Y, Mode A, Mode B, Mode C and Mode D.

0.04-inch Diagnosis

| Mode | Mode Description | Diagnosis Period |

|

Mode

Z

(Purge control solenoid valve open fail diagnosis) |

Perform

the diagnosis of purge control solenoid valve open fail depending

on the magnitude of the tank pressure change after diagnosis started.

|

3 — 16

seconds

|

|

Mode

A

(Evaluation of EVAP. generation amount) |

Calculate

the tank pressure change amount (P1).

|

16

seconds

|

|

Mode

B

(Negative pressure sealed/large leak judgment) |

Introduce

the intake manifold pressure into the fuel tank. If the tank pressure

cannot be reduced, diagnose that there is large leakage.

|

4 — 35

seconds

|

|

Mode

C

(Pressure increase check/premature OK judgment) |

Wait until

the tank pressure returns to the target value (Tank pressure when

P2 calculation started). If the pressure does not return, perform

the premature OK judgment.

|

4 — 15

seconds

|

|

Mode

D

(Negative pressure change amount measurement/EVAP. leakage diagnosis) |

Calculate

the tank pressure change amount (P2), and measure the diagnosis

value using P1 calculated in Mode A. Perform the EVAP. leakage diagnosis

using the diagnosis value.

|

12 — 16

seconds

|

0.02-inch Diagnosis

| Mode | Mode Description | Diagnosis Period |

|

Mode

A

(Evaluation of EVAP. generation amount) |

Calculate

the tank pressure change amount (P1).

|

29

seconds

|

|

Mode

B

(Negative pressure seal) |

Introduce

the intake manifold pressure into the fuel tank, and reduce the

tank pressure to the target pressure.

|

10 — 20

seconds

|

|

Mode

C

(Pressure increase check/premature OK judgment) |

Wait until

the tank pressure returns to the target value (Tank pressure when

P2 calculation started). If the tank pressure does not return, perform

the premature OK judgment.

|

5 — 20

seconds

|

|

Mode

D (Negative pressure change amount measurement/EVAP. leakage

diagnosis)

|

Calculate

the tank pressure change value (P2), measure the diagnosis value

using P1 calculated in Mode A. Perform the EVAP. leakage diagnosis

using the diagnosis value.

|

20 — 25

seconds

|

Mode table for Evaporative Emission Control System diagnosis

| Mode | Behavior of tank internal pressure under normal conditions | Diagnostic item | DTC |

|

Mode

Z

|

Nearly

same as atmospheric pressure (equivalent pressure of 0 kPa (0 mmHg, 0

inHg))

|

Purge

control solenoid valve is judged to be stuck open.

|

P0457

|

|

Mode

A

|

Pressure

is in proportion to amount of evaporative emission.

|

—

|

—

|

|

Mode

B

|

Negative

pressure is formed due to intake manifold negative pressure

|

Judged

as large leak

|

P0457

|

|

Mode

C

|

Target

pressure is reached.

|

—

|

—

|

|

Mode D

|

Pressure change is small.

|

EVAP

system is judged to have large leak [1.0 mm (0.04 in.)].

|

P0442

|

|

EVAP

system is judged to have small leak [0.5 mm (0.02 in.)].

|

P0456

|

| COMPONENT DESCRIPTION |

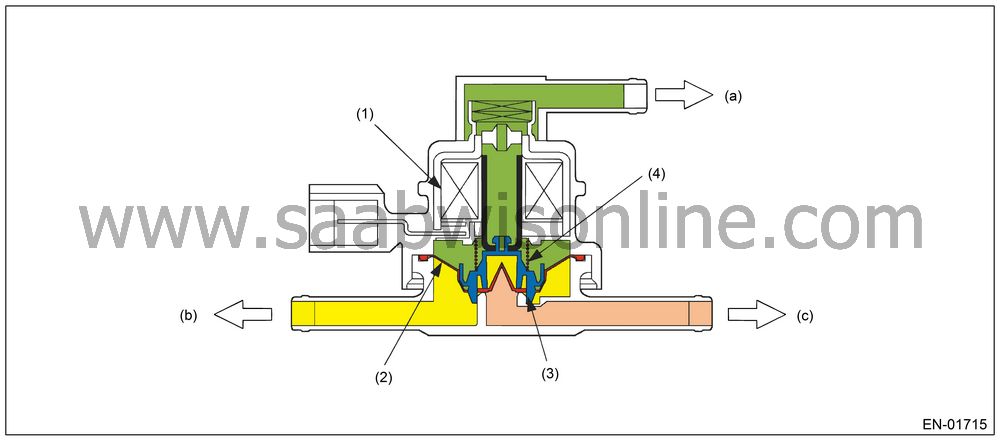

Pressure Control Solenoid Valve

Pressure control solenoid valve maintains the fuel tank pressure equal to the atmospheric air pressure. Normally, the solenoid is set to OFF, and the valve mechanically opens and closes in accordance with the difference between the tank pressure and atmospheric air pressure, and the tank pressure and canister pressure.The solenoid which is set to ON forces to open the valve.

|

(1)

|

Solenoid

|

(a)

|

Atmospheric

pressure

|

|

(2)

|

Diaphragm

|

(b)

|

Fuel tank

|

|

(3)

|

Valve

|

(c)

|

Canister

|

|

(4)

|

Spring

|

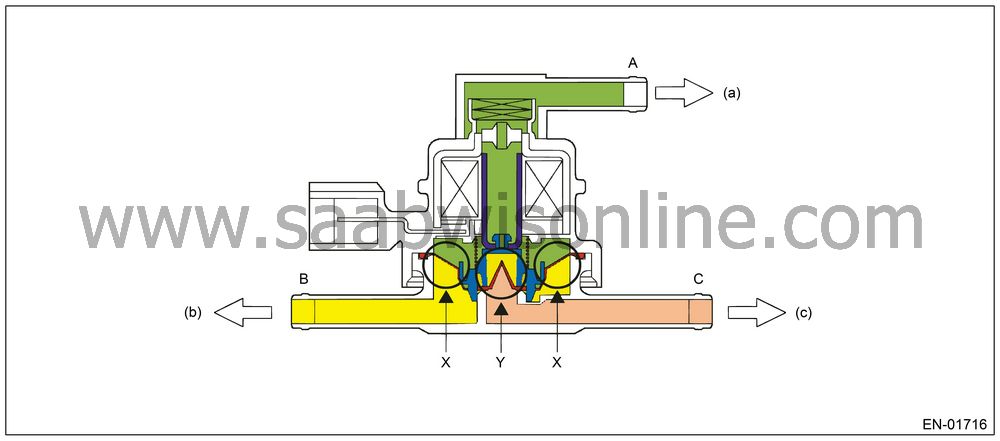

Valve Operation and Air Flow

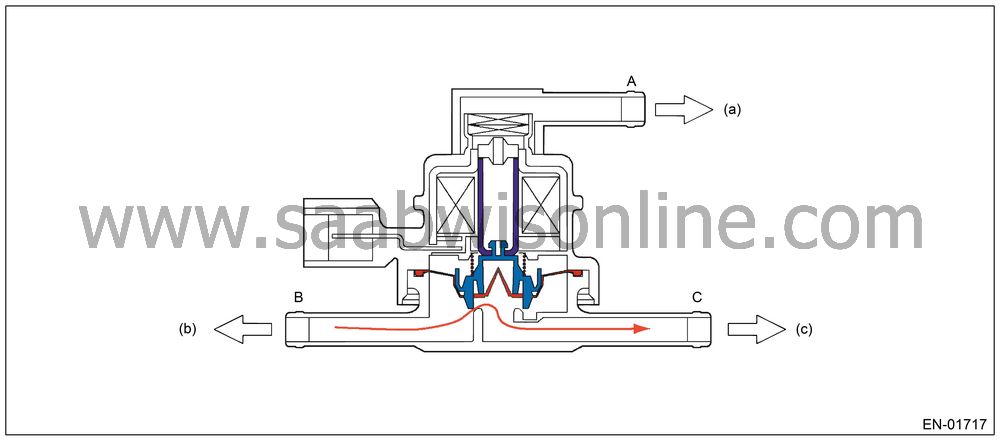

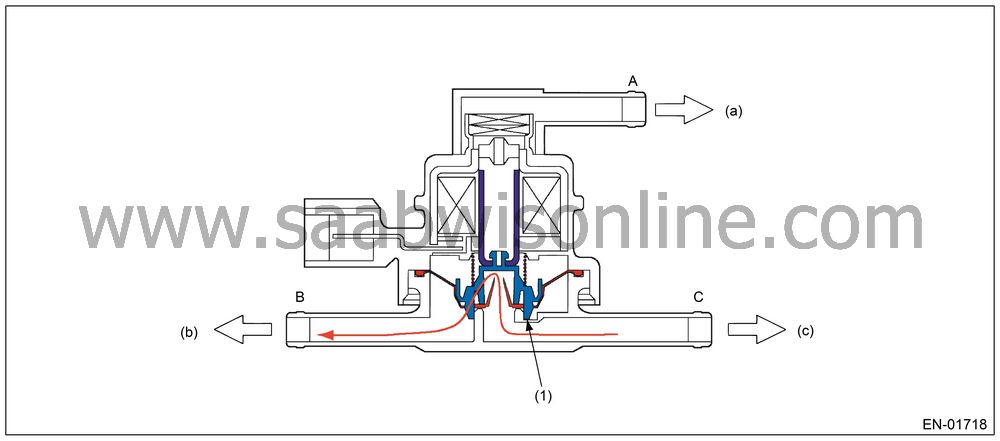

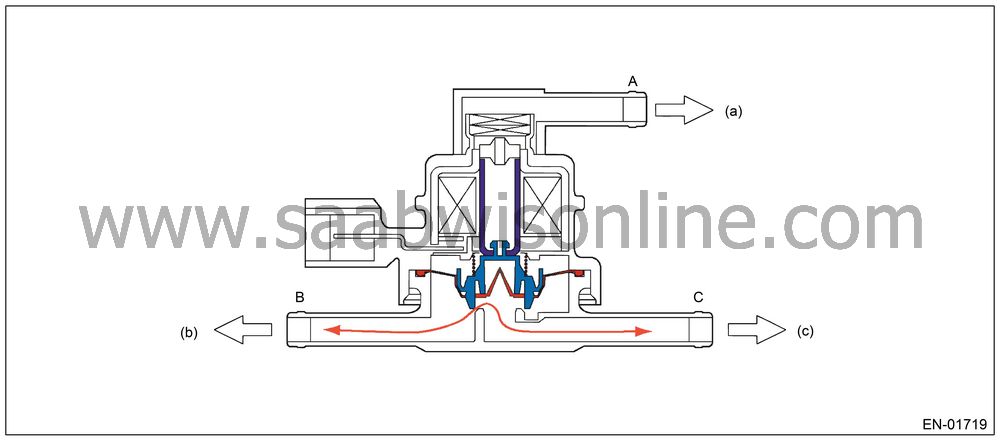

As in the X parts below, there are the area with atmospheric air pressure above the diaphragm and the area with tank pressure below the diaphragm. Also, as in the Y parts below, there are the area with tank pressure above the diaphragm and the area with canister pressure below the diaphragm. In the table below the air flow from each port in accordance with pressure difference is shown with the atmospheric air pressure port A, tank pressure port B and canister pressure port C.

|

(a)

|

Atmospheric

pressure

|

|

(b)

|

Fuel tank

|

|

(c)

|

Canister

|

| Pressure Status | Flow |

|

A < B

(Solenoid OFF)

|

B → C

|

|

B < C

(Solenoid OFF)

|

C → B

|

|

Solenoid

ON

|

B ←→ C

|

|

(a)

|

Atmospheric

pressure

|

|

(b)

|

Fuel tank

|

|

(c)

|

Canister

|

|

(1)

|

Valve

|

(a)

|

Atmospheric

pressure

|

|

(b)

|

Fuel tank

|

||

|

(c)

|

Canister

|

|

(a)

|

Atmospheric

pressure

|

|

(b)

|

Fuel tank

|

|

(c)

|

Canister

|

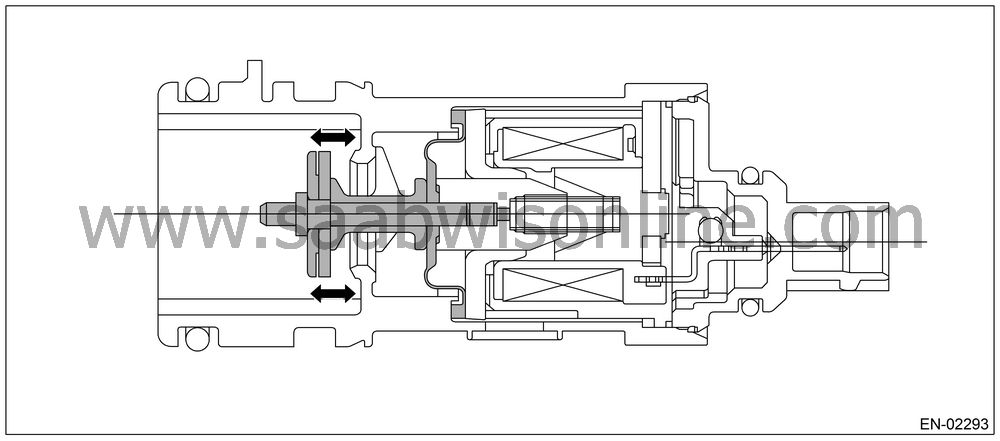

Drain valve

Drain valve controls the ambient air to be introduced to the canister.

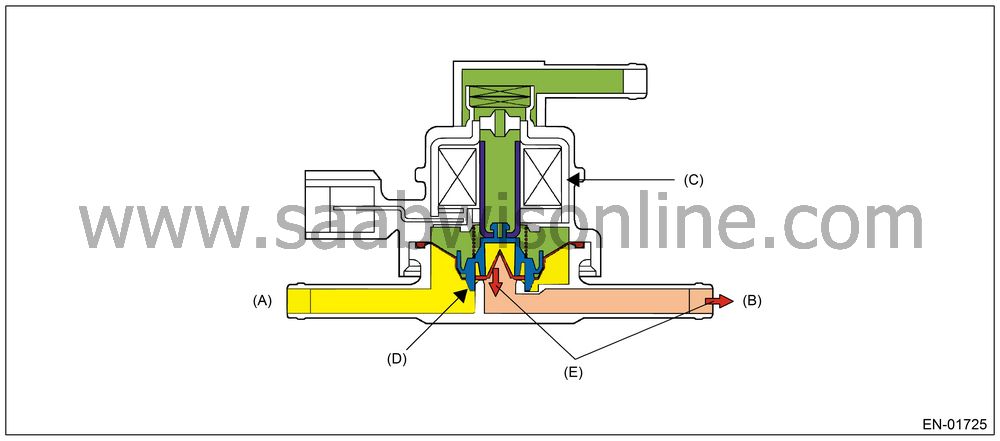

Tank Pressure Switching Solenoid

One of the atmospheric pressure switching solenoid valves is connected to fuel tank pressure sensor and the other is released to atmosphere. The passage to fuel tank pressure sensor is usually released to atmosphere because the solenoid is set to OFF, but the solenoid which is set to ON closes the passage open to atmosphere.

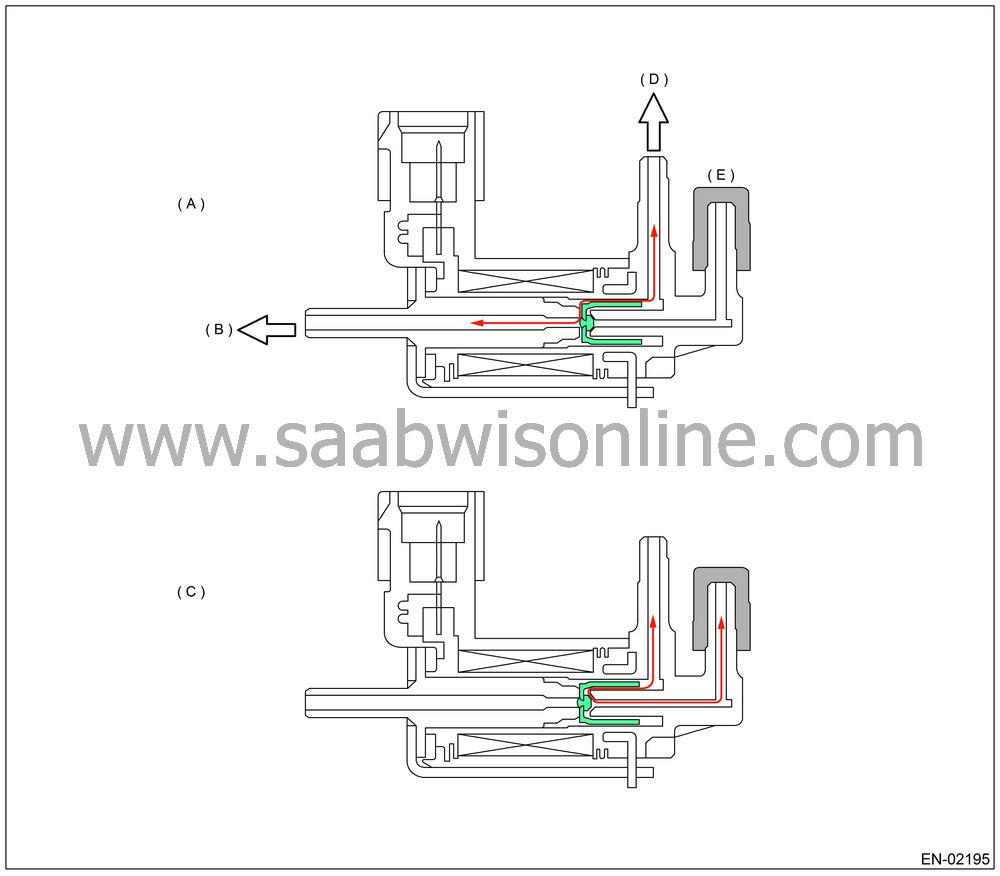

|

(A)

|

Released

to atmosphere (Solenoid OFF)

|

||

|

(B)

|

Ambient

air

|

||

|

(C)

|

During

diagnostics (Solenoid ON)

|

||

|

(D)

|

To pressure

sensor

|

||

|

(E)

|

Plug

|

Purpose of this solenoid

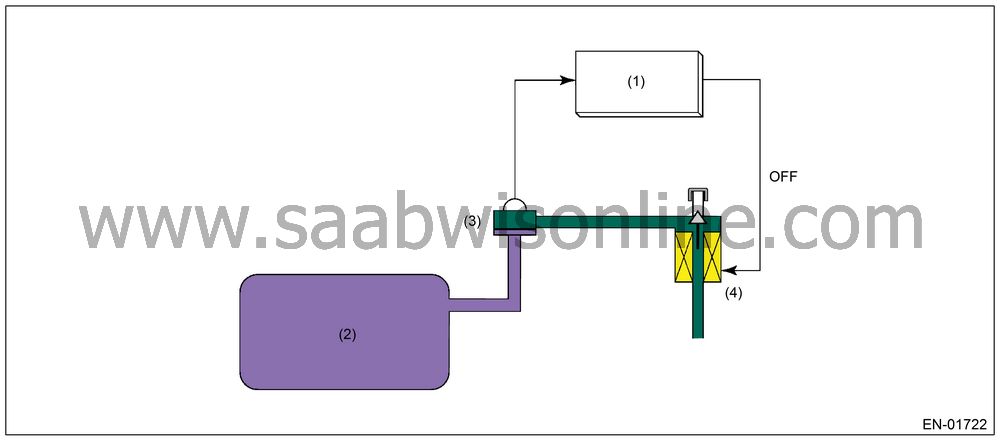

Fuel tank pressure sensor detects the difference between the atmospheric air pressure and the tank pressure, and the ECM monitors the pressure difference.

Even if the tank pressure is constant, the atmospheric air pressure varies depending on the driving height, and the pressure signal transmitted to ECM will change.

|

(1)

|

Engine

control module (ECM)

|

|

(2)

|

Fuel tank

|

|

(3)

|

Fuel tank

pressure sensor

|

|

(4)

|

Atmospheric

pressure switching solenoid

|

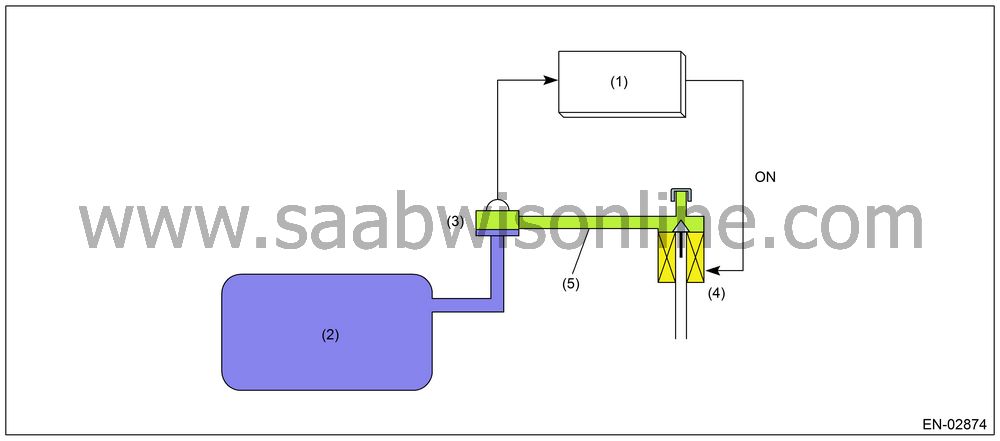

Especially, in the small leakage [0.5 mm (0.02 inch)], minute change in the tank pressure has to be detected. This diagnosis period is long (approx. 29 seconds). And if the driving height changes during the diagnosis, the atmospheric air pressure changes. In this case, it becomes difficult to precisely detect the tank pressure variation, causing erroneous diagnosis. Therefore, using the atmospheric pressure switching solenoid, atmospheric air is sealed between the fuel tank pressure sensor and atmospheric pressure switching solenoid, maintaining the air pressure constant and enabling the detection of minute variation of tank pressure.

|

(1)

|

Engine

control module (ECM)

|

|

(2)

|

Fuel tank

|

|

(3)

|

Fuel tank

pressure sensor

|

|

(4)

|

Atmospheric

pressure switching solenoid

|

|

(5)

|

Constant

pressure

|

| Note | ||

|

ECM also has the atmospheric air pressure sensor, and always monitors atmospheric air. However, as the monitoring range is large, that is, 53.3 to 107 kPa (400 to 800 mmHg, 15.7 to 31.6 inHg), it is not suitable for detection of minute pressure variation. |

||

|

In the case of small leakage diagnosis, the tank pressure variation is very small, that is, 0.13 to 0.26 kPa (1 to 2 mmHg, 0.04 to 0.08 inHg), and the fuel tank pressure sensor is equipped. |

| ENABLE CONDITION |

0.04-inch Diagnosis

| Secondary Parameters | Enable Conditions |

|

Evaporation

diagnosis

|

Incomplete

|

|

Battery

voltage

|

≥ 10.9

V

|

|

Barometric

pressure

|

≥ 75.1

kPa (563 mmHg, 22.2 inHg)

|

|

Total

time of canister purge operation

|

120

seconds or more

|

|

After

engine starting

|

856

seconds or more

|

|

Learning

value of evaporation gas density

|

≤ 0.08

|

|

Engine

speed

|

1,050 ←→ 6,500

rpm

|

|

Fuel

tank pressure

|

< 1.4 kPa

(10.7 mmHg, 0.4 inHg)

|

|

Atmospheric

pressure − Intake manifold vacuum (relative pressure)

|

≥ 13.3

kPa (100 mmHg, 3.92 inHg)

|

|

Vehicle

speed

|

≥ 32

km/h (20 MPH)

|

|

Fuel

level

|

9 ←→ 51 litres (2.38 ←→ 13.5

US gal, 1.98 ←→ 11.2 Imp gal)

|

|

Closed

air/fuel ratio control

|

In

operation

|

|

Fuel

temperature

|

−10 ←→ 45°C

(14 ←→ 113°F)

|

|

Intake

air temperature

|

≥ −10°C

(14°F)

|

|

Pressure

change per second

|

< 0.13

kPa (0.95 mmHg, 0.04 inHg)

|

|

Min.

pressure change per second − Max. pressure change per second

|

< 0.23

kPa (1.75 mmHg, 0.07 inHg)

|

|

Fuel

level change

|

< 3 litres(0.79

US gal, 0.66 Imp gal)/131 milliseconds

|

|

Air fuel

ratio

|

0.76 — 1.25

|

0.02-inch Diagnosis

| Secondary Parameters | Enable Conditions |

|

(At

starting a diagnosis)

|

|

|

Engine

speed

|

1,500 — 6,500

rpm

|

|

Battery

voltage

|

≥ 10.9 V

|

|

Atmospheric

pressure

|

≥ 75.7 kPa (568 mmHg, 22.4 inHg)

|

|

Since

last incomplete diagnosis event of 0.02-inch leakage

|

≥ 120

seconds

|

|

Total

time of canister purge operation

|

120

second or more

|

|

After

engine starting

|

335 second or more

|

|

Fuel

temperature, or the time after engine start with coolant temperature

of 40°C (104°F) or below

|

−10 ←→ 35°C

(14 ←→ 95°F)

< 2,400 seconds |

|

Fuel

level

|

9 ←→ 51 litres (2.38 ←→ 13.5

US gal, 1.98 ←→ 11.2 Imp gal)

|

|

(Ambient

(estimate) − fuel) temperature

|

< 1°C (34°F)

|

|

Fuel

tank pressure below −3.01 kPa (−22.8 mmHg, −0.88

inHg) (during same driving cycle, Intake manifold vacuum (relative

pressure))

|

Up

to 2 times

|

|

Atmospheric − Intake

manifold vacuum (relative pressure)

|

≥ 13.3

kPa (100 mmHg, 3.92 inHg)

|

|

Fuel

tank pressure

|

−0.67

to 1.20 kPa

(−5 to 9 mmHg, −0.20 to 0.35 inHg)

|

|

Vehicle

speed

|

≥ 68 km/h (42 MPH)

|

|

Closed

air/fuel ratio control

|

In operation

|

|

Ambient

temperature (estimate)

|

≥ −10°C (14°F)

|

|

(During

diagnosis)

|

|

|

P1

|

−0.07 ←→ 0.13 kPa

(−0.5 ←→ 1 mmHg,

−0.02 ←→ 0.04 inHg)

|

|

Pressure

change per second

|

< 0.13

kPa (0.95 mmHg, 0.04 inHg)

|

|

Fuel

level change

|

3litres / 128 milli-seconds

|

|

Min.

tank pressure change per second − Max. tank pressure change

per second

|

< 0.23

kPa (1.75 mmHg, 0.07 inHg)

|

|

Change

of atmospheric pressure during P1 calculation

|

−0.07 ←→ 0.15 kPa

(−0.5 ←→ 1.125 mmHg, −0.02 ←→ 0.04

inHg)

|

|

Change

of atmospheric pressure during P2 calculation

|

−0.15 ←→ 0.15

kPa

(−1.125 ←→ 1.125 mmHg, −0.04 ←→ 0.04

inHg)

|

| GENERAL DRIVING CYCLE |

0.04-inch Diagnosis

Perform the diagnosis only once in 856 seconds or more after starting the engine constantly at 32 km/h (20 MPH) or more.

Pay attention to the fuel temperature and fuel level.

0.02-inch Diagnosis

Perform the diagnosis in 335 seconds after starting the engine constantly at 68 km/h (42 MPH) or more, and perform OK/NG judgment.

If OK/NG judgment is not possible, repeat the diagnosis.

Pay attention to the fuel temperature and fuel level.

| DIAGNOSTIC METHOD |

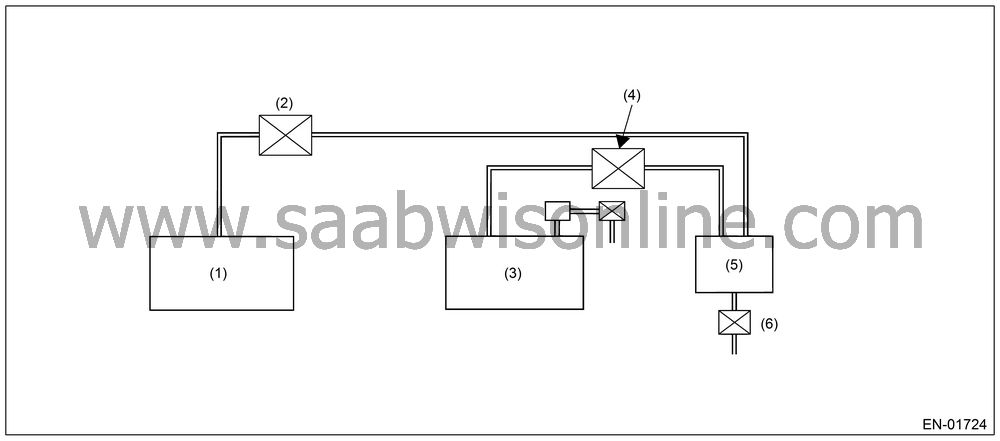

Diagnosing Function of Drain Valve and Purge Control Solenoid Valve

DTCP0457 Evaporative Emission Control System Leak Detected (Fuel Cap Loose/Off)

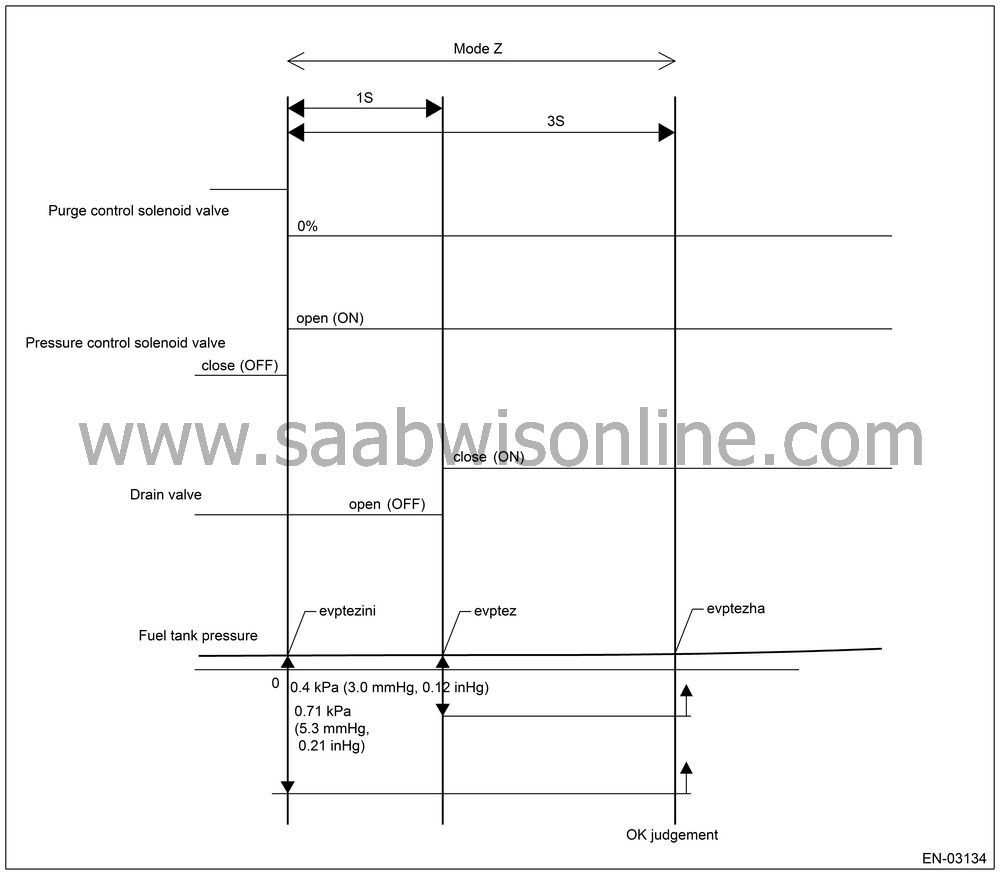

Purpose of Mode Z

When performing the leakage diagnosis of EVAP system, purge control solenoid valve have to operate normally. Therefore, mode Z is used to diagnose the purge control solenoid valve open fixation.

If purge control solenoid valve open fixation trouble is detected, the evaporation system leakage diagnosis is cancelled.

|

(1)

|

Engine

|

(4)

|

Pressure

control solenoid valve (Close)

|

|

(2)

|

Purge control

solenoid valve (Open)

|

(5)

|

Canister

|

|

(3)

|

Fuel tank

|

(6)

|

Drain valve

(Stuck close)

|

|

(A)

|

To fuel

tank

|

|

(B)

|

To canister

(Negative pressure)

|

|

(C)

|

Solenoid

ON

|

|

(D)

|

Valve cannot

be open.

|

|

(E)

|

Negative

pressure

|

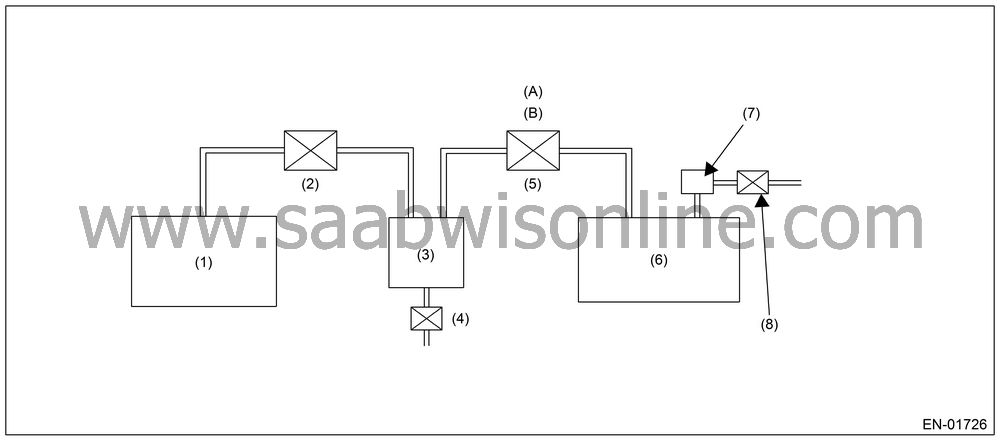

Diagnostic method

Purge control solenoid valve open fixation diagnosis is performed in mode Z as shown in the figure below.

|

(1)

|

Engine

|

(5)

|

Pressure

control solenoid valve

|

|

(2)

|

Purge control

solenoid valve

|

(6)

|

Fuel tank

|

|

(3)

|

Canister

|

(7)

|

Fuel tank

pressure sensor

|

|

(4)

|

Drain valve

|

(8)

|

Atmospheric

pressure switching solenoid

|

Diagnosing function of purge control solenoid valve [P0457]

Purge control solenoid valve functional diagnosis is performed by monitoring the tank pressure in Mode Z.Normality Judgment

Judge OK when the following criteria are satisfied in 3 seconds after Mode Z started, and change to Mode A.

Judgment Value

| Malfunction Criteria | Threshold Value | DTC |

|

(Tank pressure

when Mode Z started) — (Tank pressure when Mode Z finished)

|

≤ 0.4

kPa (3 mmHg, 0.12 inHg)

|

P0457

|

Normal

Judge normal when the following conditions are completed at once.

| • |

evptez − evptezha ≤ 0.4 kPa

(3.0 mmHg, 0.12 inHg)

|

|

| • |

evptezini − evptezha ≤ 0.71

kPa (5.3 mmHg, 0.21 inHg)

|

|

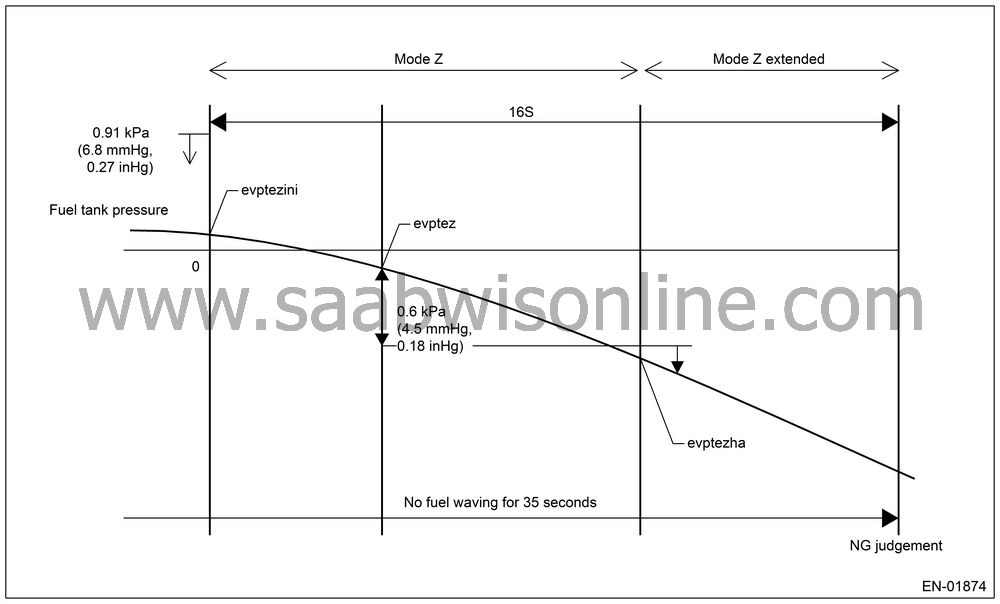

Abnormality Judgment

If OK judgment cannot be made, extend Mode Z 16 seconds more, and judge NG when all the criteria below are completed in 16 seconds.

Judgment Value

| Malfunction Criteria | Threshold Value | DTC |

|

(Tank

pressure 1 second after Mode Z started) − (Tank pressure

when Mode Z finished)

|

> 0.6

kPa (4.5 mmHg, 0.18 inHg)

|

P0457

|

|

Tank

pressure when Mode Z started

|

≤ 0.91

kPa (6.8 mmHg, 0.27 inHg)

|

|

|

TIme for

no fuel rolling of 3litres or more

|

≥ 35

seconds

|

Time Needed for Diagnosis: 16 seconds

Malfunction Indicator Light Illumination: Illuminates when malfunction occurs in 2 continuous driving cycles.

Finish the Evap. diagnosis when making NG judgment for purge control solenoid valve open fixation.

Cancel the Evap. diagnosis when the OK/NG judgment for purge control solenoid valve open fixation cannot be made in Mode Z.

Purge control solenoid valve open fixation

Judge NG when the following conditions are completed at once.

| • |

evptez − evptezha > 0.6 kPa

(4.5 mmHg, 0.18 inHg)

|

|

| • |

evptezini ≤ 0.91 kPa (6.8

mmHg, 0.27 inHg)

|

|

| • |

Period without 3litres(0.79 US

gal, 0.67 Imp gal) or more fuel waving is 35 seconds or more.

|

|

Leakage Diagnosis

DTCP0442 Evaporative Emission Control System Leak Detected (Small Leak)

P0456 Evaporative Emission Control System Leak Detected (Very Small Leak)

P0457 Evaporative Emission Control System Leak Detected (Fuel Cap Loose/Off)

Diagnostic Method

| • |

The diagnostic method consists of creating

a sealed vacuum in the fuel tank and then determining the presence

of leakage from the speed at which the tank internal pressure returns

to atmospheric pressure.

|

|

| • |

The diagnosis is devided into the following

five phases.

|

|

Mode A; (Estimation of evaporation abundance)

Calculate the tank pressure variation amount (P1) at Mode A. Move to Mode B after calculating P1.

Mode B; (Seal negative pressure)

Introduce the negative pressure of the intake manifold into the tank.

Approx. 0 → −1.4 kPa (0 → −10.5 mmHg, 0 → −0.41 inHg) (0.04-inch diagnosis)

Approx. 0 → −3.05 kPa (0 → −22.875 mmHg, 0 → −0.9 inHg) (0.02-inch diagnosis)

Move to Mode C when reaching the pressure above (target pressure).

Then, if the tank pressure does not become negative, judge that there is large leakage in the system. In 0.04-inch diagnosis, judge that there is large leakage (10 seconds or 25 seconds) and terminate the EVAP. diagnosis. In 0.02-inch diagnosis, cancel the diagnosis (20 seconds).

Abnormality Judgment

Judge NG (large leakage) when the malfunction criteria below is completed.

Judgment Value

| Malfunction Criteria | Threshold Value | DTC |

|

(0.04-inch

diagnosis)

|

P0457

|

|

|

Period

until reaching target negative pressure

|

≥ 25

seconds

|

|

|

OR,

Mode B period

|

≥ 10

seconds

|

|

|

(Tank Pressure

Min. Value in Mode B) − (Tank Pressure when starting Mode

B)

|

> −0.53

kPa (−4 mmHg, −0.16 inHg)

|

Mode C; (Check increasing pressure)

Stop the introduction of negative pressure. (Wait until returning to the start level of P2 calculation)

When returning to the start level of P2 calculation, move to Mode D.

Judge premature OK and move to Mode E when not returning in the determined period of time.

| Tank pressure when P2 calculation started | Premature OK Judgment Period | |

|

0.04-inch

Diagnosis

|

−1.30 kPa (−9.75 mmHg, −0.38 inHg)

|

15

seconds

|

|

0.02-inch

Diagnosis

|

−3.00

kPa (−22.5 mmHg, −0.89 inHg)

|

20 seconds

|

Mode D; (Measurement of negative pressure variation)

Monitor the tank pressure variation in Mode D. In this case, the tank pressure increases (close to atmospheric pressure) because the evaporator is generated. However, if there is leakage, the pressure increases additionally. P2 means the variation amount of this tank pressure. After calculating P2, perform the small leakage diagnosis.

When Terminating Mode D

By assigning the variation values of tank pressure, P1 and P2, in the following formula, judge the system small leakage. If the calculated judgment value is larger than the threshold value, judge that there is a failure.

0.04-inch Diagnosis

Judge NG when the malfunction criteria below is completed.

Judgment Value

| Malfunction Criteria | Threshold Value | DTC |

|

P2 − 1.5 × P1

P2 = Change of tank pressure in 16 seconds at mode D. P1 = Change of tank pressure in 16 seconds at mode A. |

> 0.38 ←→ 0.81

kPa (2.86 ←→ 6.08 mmHg, 0.11 ←→ 0.24 inHg)

*Threshold value: Map (fuel level vs tank temperature) |

P0442

|

0.02-inch Diagnosis

Abnormality Judgment

Judge NG when the malfunction criteria below is completed.

Judgment Value

| Malfunction Criteria | Threshold Value | DTC |

|

P2 − 1.5 × P1

P2 = Change of tank pressure in 22 seconds at mode D. P1 = Change of tank pressure in 22 seconds at mode A. |

≥ 0.40 ←→ 0.97

kPa (3 ←→ 7.3 mmHg, 0.12 ←→ 0.29

inHg)

*Threshold value: Map (fuel level vs tank temperature) |

P0456

|

Normality Judgment

Judge OK when the malfunction criteria below is not completed.

Judgment Value

| Malfunction Criteria | Threshold Value | DTC |

|

P2 − 1.5 × P1

|

< 0.31 ←→ 0.60

kPa (2.3 ←→ 4.5 mmHg, 0.09 ←→ 0.18

inHg)

|

P0456

|

If OK/NG judgment is not possible, repeat the diagnosis.

Time Needed for Diagnosis:

|

0.04

inches:

|

30 to

100 seconds

|

|

0.02

inches:

|

30 to

100 seconds

|

Malfunction Indicator Light Illumination: Detect when malfunction occurs in two continuous drive cycles.

| DTC CLEAR CONDITION |

| • |

When the OK idling cycle was completed 40 times

in a row

|

|

| • |

When “Clear Memory” was

performed

|

|

| MALFUNCTION INDICATOR LIGHT CLEAR CONDITION |

| • |

When the OK driving cycle was completed 3 times

in a row

|

|

| • |

When “Clear Memory” was

performed

|

|

| FAIL SAFE |

None

| ECM OPERATION AT DTC SETTING |

| • |

Memorize the freeze frame data. (For test mode $02)

|

|

| • |

Memorize the diagnostic value and trouble

standard value. (For test mode $06)

|

|