STEERING SYSTEM, INSPECTION

| STEERING SYSTEM, INSPECTION |

| STEERING WHEEL |

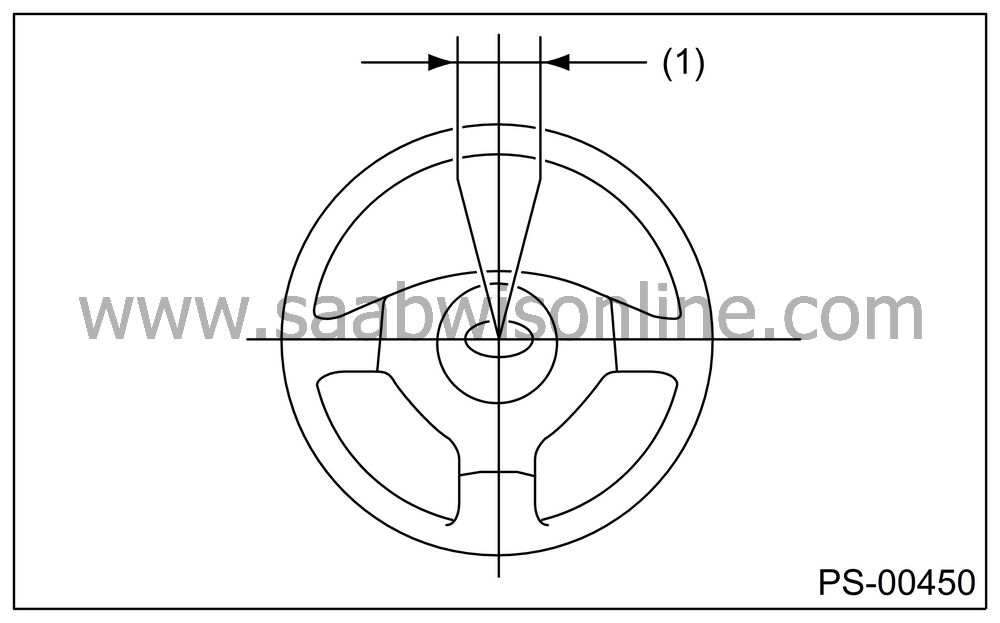

Set the steering wheel in a straight-ahead position, and check the wheel spokes to make sure they are correctly set in their specified positions.

Lightly turn the steering wheel to the right and left to determine the point where front wheels start to move.

Measure the distance of the movement of steering wheel at the outer periphery of wheel.

Steering wheel free play:

0 — 17 mm (0 — 0.67 in)

|

(1)

|

Steering

wheel free play

|

Move the steering wheel vertically toward the shaft to ascertain if there is play in the direction.

Maximum permissible play:

0.5 mm (0.020 in)

Drive the vehicle and check the following items during operation.

Steering force:

The effort required for steering should be smooth and even at all points, and should not vary.

Pull to one side:

Steering wheel should not be pulled to either side while driving on a level surface.

Wheel runout:

Steering wheel should not be runout.

Return factor:

Steering wheel should return to its original position after it has been turned and then released.

| STEERING SHAFT JOINT |

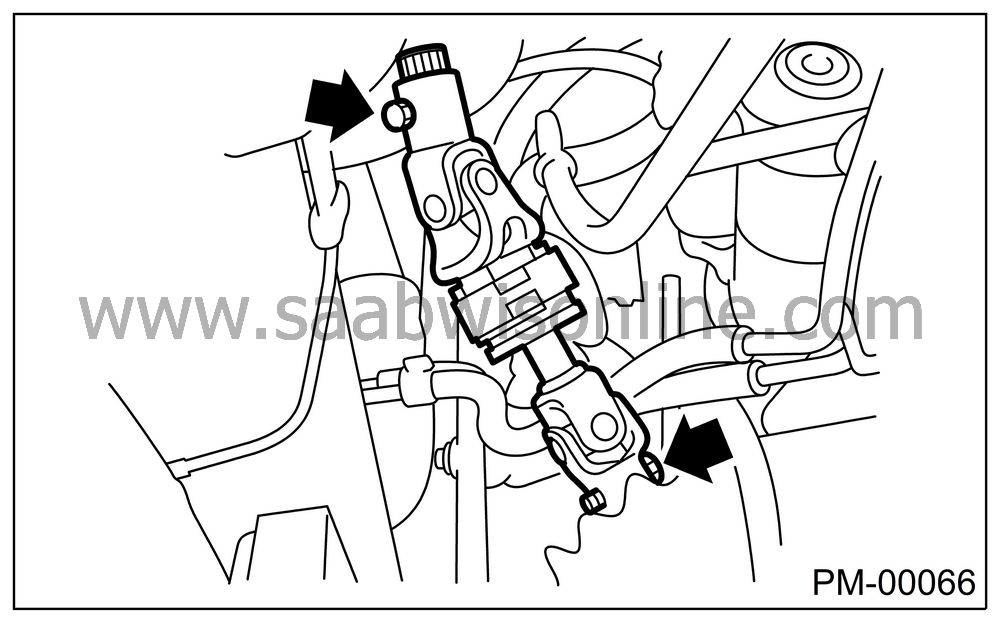

When the steering wheel free play is excessive, disconnect the universal joint of steering shaft and check it for any play and yawing torque (at the point of the crossing direction). Also inspect for any damage to sealing or worn serrations. If the joint is loose, retighten the mounting bolts to the specified torque.

Tightening torque:

24 Nm (2.4 kgf-m, 17.4 ft-lb)

| GEARBOX |

Saab 9-2X 2.5i Linear

With vehicle placed on a level surface, turn the steering wheel 90° in both the right and left directions.While the steering wheel is being rotated, reach under the vehicle and check for looseness in gearbox.

Tightening torque:

59 Nm (6.0 kgf-m, 43.4 ft-lb)

|

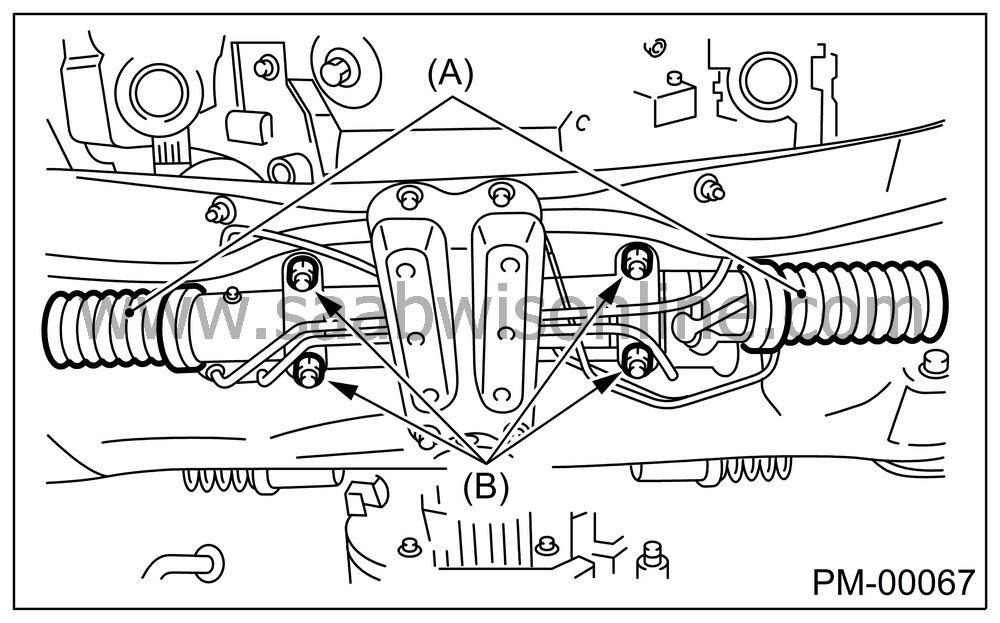

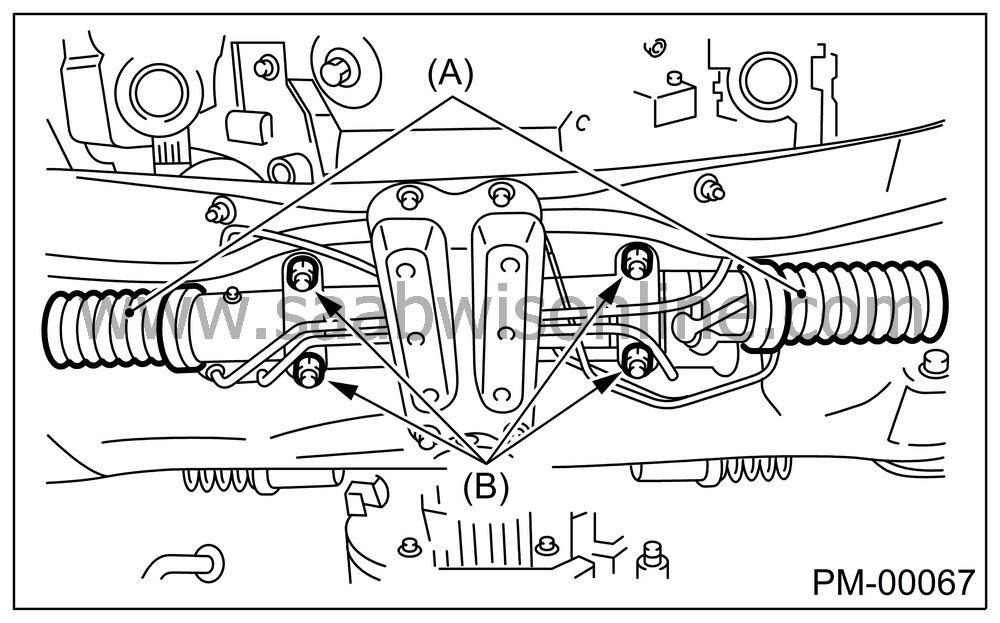

(A)

|

Boot

|

|

(B)

|

Gear box

mounting bolt

|

Check the boot for damage, cracks or deterioration.

With the vehicle on a level surface, quickly turn the steering wheel to the right and left.

While the steering wheel is being rotated, check the gear backlash. If any unusual noise is noticed, adjust the gear backlash in the following manner.

Tighten the adjusting screw to 7.4 Nm (0.75 kgf-m, 5.4 ft-lb) and then loosen. Repeat this operation twice.

Retighten the adjusting screw to 7.4 Nm (0.75 kgf-m, 5.4 ft-lb) and back off 25°.

Apply liquid packing to at least 1/3 of entire perimeter of adjusting screw thread.

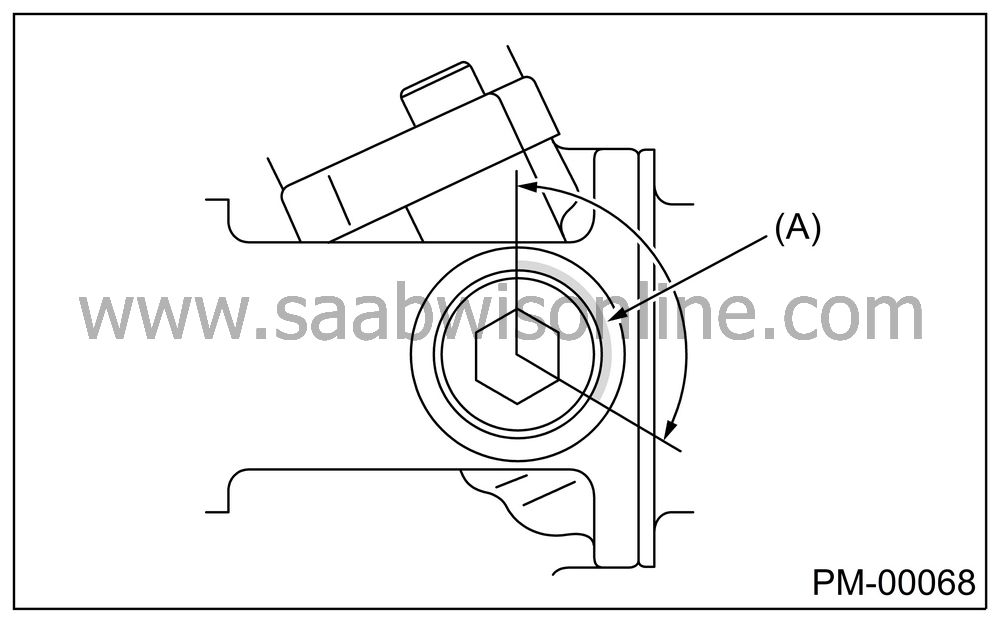

|

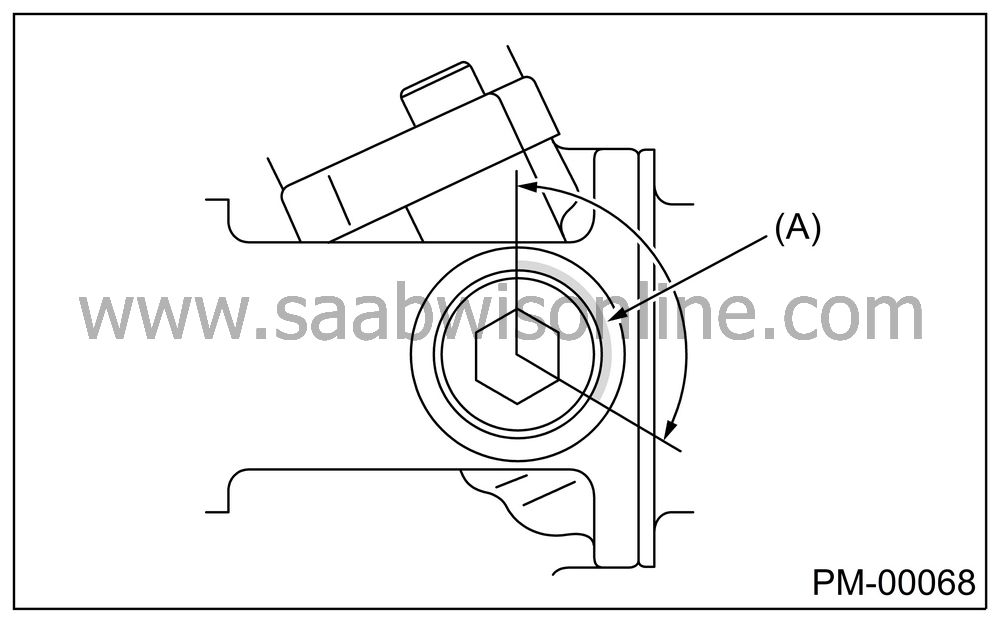

(A)

|

Apply liquid

packing to at least 1/3 of entire perimeter

|

Install the lock nut. While holding the adjusting screw with a wrench, tighten the lock nut using ST.

ST 32005191 SPANNER

Tightening torque (Lock nut):39 Nm (4.0 kgf-m, 29 ft-lb)

Hold the adjusting screw with a wrench to prevent it from turning, while tightening the lock nut.

Saab 9-2X 2.0T Aero

With vehicle placed on a level surface, turn the steering wheel 90° in both the right and left directions.While the steering wheel is being rotated, reach under the vehicle and check for looseness in gearbox.

Tightening torque:

59 Nm (6.0 kgf-m, 43.4 ft-lb)

|

(A)

|

Boot

|

|

(B)

|

Gear box

mounting bolt

|

Check the boot for damage, cracks or deterioration.

With the vehicle on a level surface, quickly turn the steering wheel to the right and left.

While the steering wheel is being rotated, check the gear backlash. If any unusual noise is noticed, adjust the gear backlash in the following manner.

Tighten the adjusting screw to 9.8 Nm (1.0 kgf-m, 7.2 ft-lb) and then loosen.

Retighten the adjusting screw to 4.9 Nm (0.5 kgf-m, 3.6 ft-lb) and then loosen.

Retighten the adjusting screw to 4.9 Nm (0.5 kgf-m, 3.6 ft-lb) and back off 26°.

Apply liquid packing to at least 1/3 of entire perimeter of adjusting screw thread.

|

(A)

|

Apply liquid

packing to at least 1/3 of entire perimeter

|

Install the lock nut. While holding the adjusting screw with a wrench, tighten the lock nut using ST.

ST 32005191 SPANNER

Tightening torque (Lock nut):39 Nm (4.0 kgf-m, 29 ft-lb)

Hold the adjusting screw with a wrench to prevent it from turning, while tightening the lock nut.

| TIE-ROD |

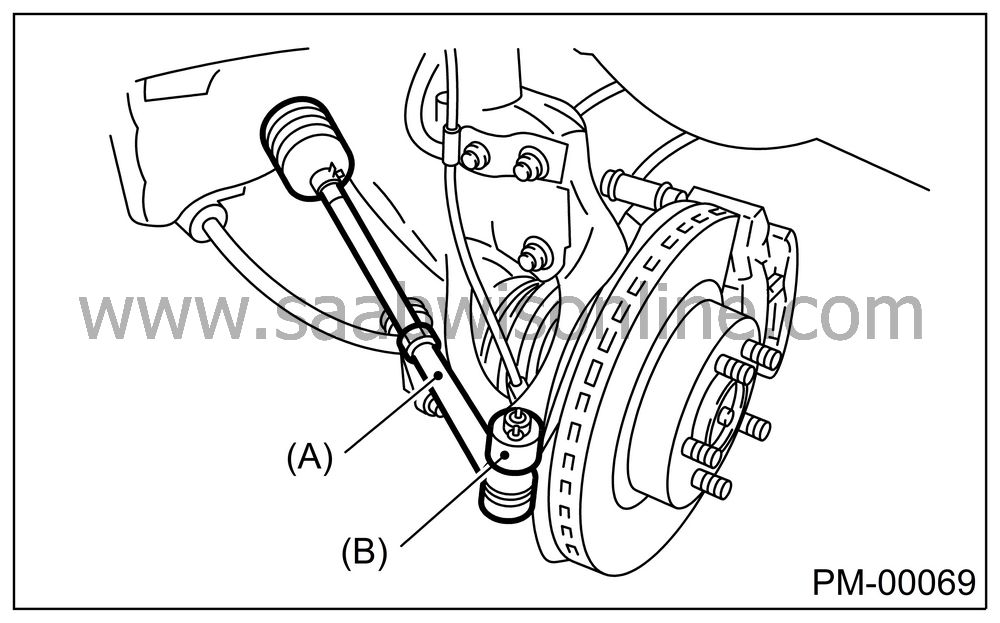

Check the tie-rod and tie-rod ends for bends, scratches or other damage.

|

(A)

|

Tie-rod

end

|

|

(B)

|

Knuckle

arm

|

Check the connections of knuckle ball joints for play, inspect for damage on dust seals, and check free play of ball studs. If the castle nut is loose, retighten it to the specified torque, then tighten further up to 60° until the cotter pin hole is aligned.

Tightening torque:

27 Nm (2.75 kgf-m, 19.9 ft-lb)

Check the lock nut on tie-rod end for tightness. If it is loose, retighten it to the specified torque.

Tightening torque:

83 Nm (8.5 kgf-m, 61.5 ft-lb)

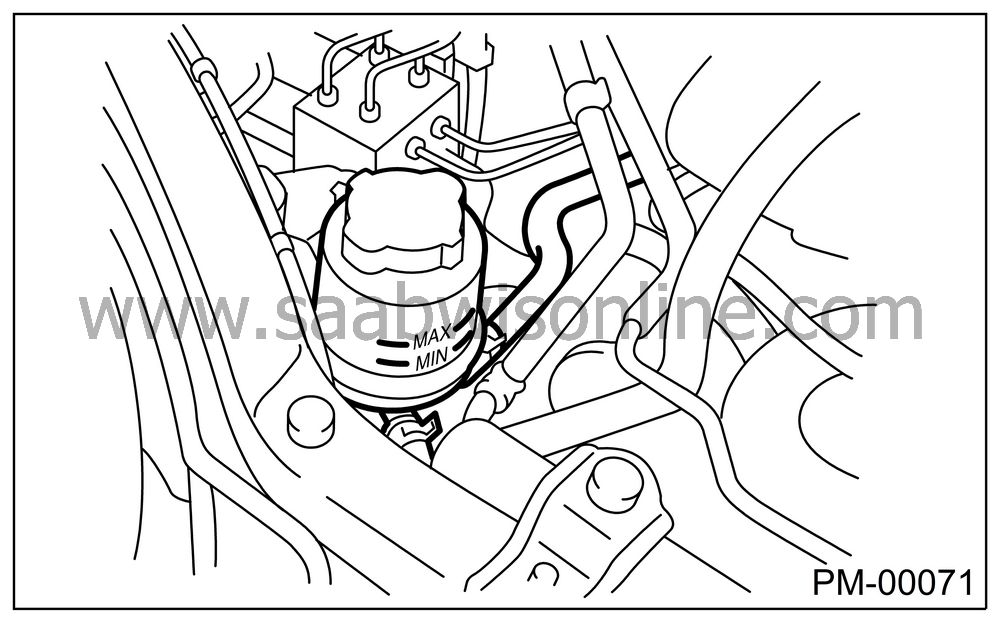

| POWER STEERING FLUID LEVEL |

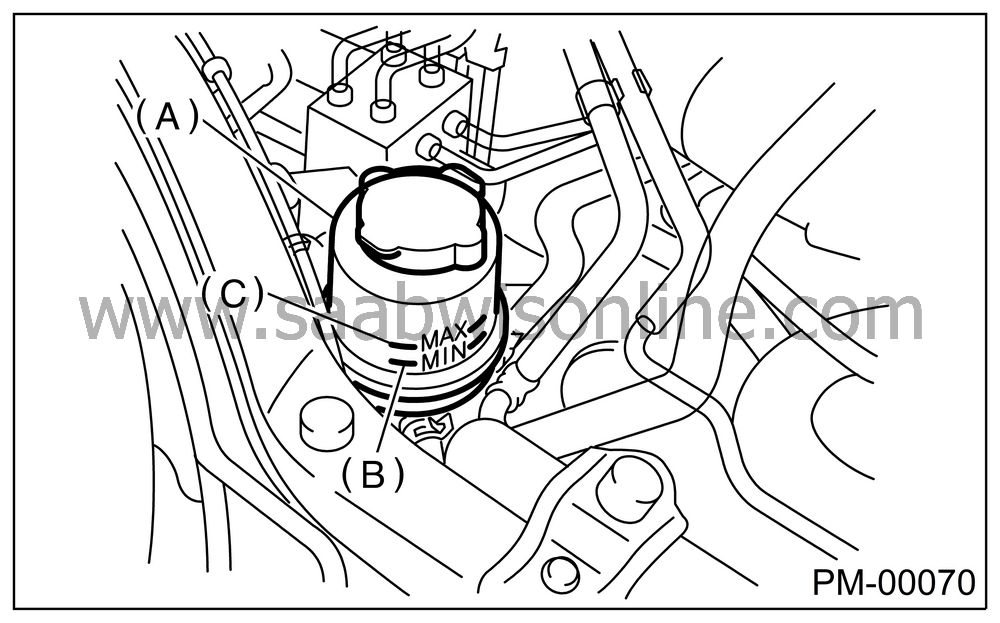

| Note | ||

| • |

Check at power steering fluid temperature 20°C (68°F);

read the fluid level on the “COLD” side.

|

|

| • |

Check at power steering fluid temperature 80°C (176°F);

read the fluid level on the “HOT” side.

|

|

Place the vehicle with engine “OFF” on a flat and level surface.

Check the fluid level using the scale on the outside of reservoir tank (A). If the level is below “MIN” (B), add fluid to bring it up to “MAX” (C).

| Note | ||

|

If the fluid level is at MAX level or above, drain fluid to keep the level in specified range of indicator by using a syringe or the like. |

Recommended fluid:

Dexron III

Fluid capacity:

0.7 litres (0.7 US qt, 0.6 Imp qt)

| POWER STEERING FLUID FOR LEAKS |

Inspect the underside of oil pump and gearbox for power steering system, hoses, piping and their couplings for fluid leaks.

If fluid leaks are found, correct them by retightening their fitting bolts (or nuts) and/or replacing their parts.

| Note | ||

| • |

Wipe the leakage fluid off after correcting fluid leaks,

or a wrong diagnosis is taken later.

|

|

| • |

Also pay attention to clearances between hoses (or pipings)

and other parts when inspecting fluid leaks.

|

|

| HOSES OF OIL PUMP FOR DAMAGES |

Check the pressure hose and return hose of oil pump for crack, swell or damage. Replace the hose with a new one if necessary.

| Note | ||

|

Prevent the hoses from revolving and/or turning when installing hoses. |

| POWER STEERING PIPES FOR DAMAGE |

Check the power steering pipes for corrosion and damage.

Replace the pipes with a new one if necessary.

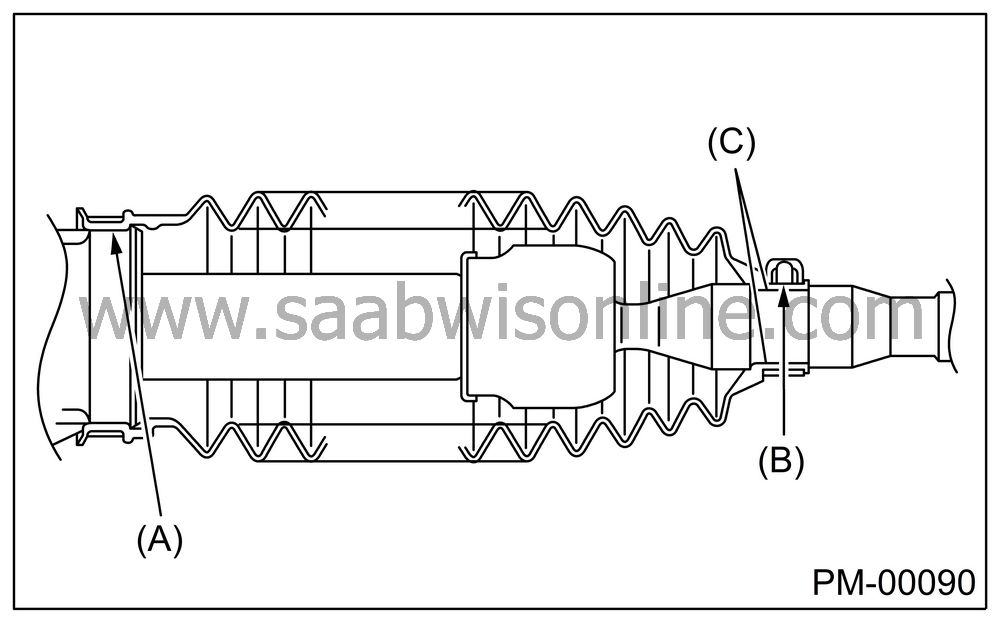

| GEARBOX BOOTS |

Inspect both sides of gearbox boots as follows, and correct the defects if necessary.

(A) and (B) positions of gearbox boot are fitted correspondingly in (A) and (B) grooves of gearbox and the rod (C).

Clips are fitted outside of (A) and (B) positions of boot.

Boot does not have crack and hole.

| Note | ||

|

Rotate (B) the position of gearbox boot against twist of it produced by adjustment of toe-in, etc. |

| FITTING BOLTS AND NUTS |

Inspect the fitting bolts and nuts of oil pump and bracket for looseness, and retighten them if necessary.

Inspect and/or retighten them when engine is cold.