INSPECTION

| INSPECTION |

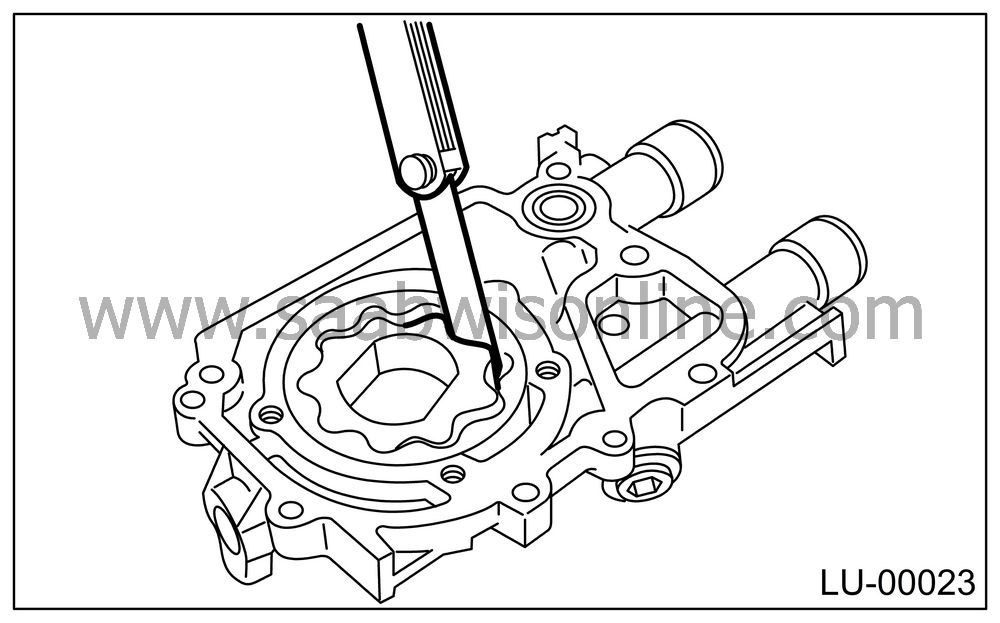

| TIP CLEARANCE |

Measure the tip clearance of rotors. If clearance exceeds the standard, replace the rotors as a matched set.

Tip clearance:

Standard

0.04 — 0.14 mm (0.0016 — 0.0055 in)

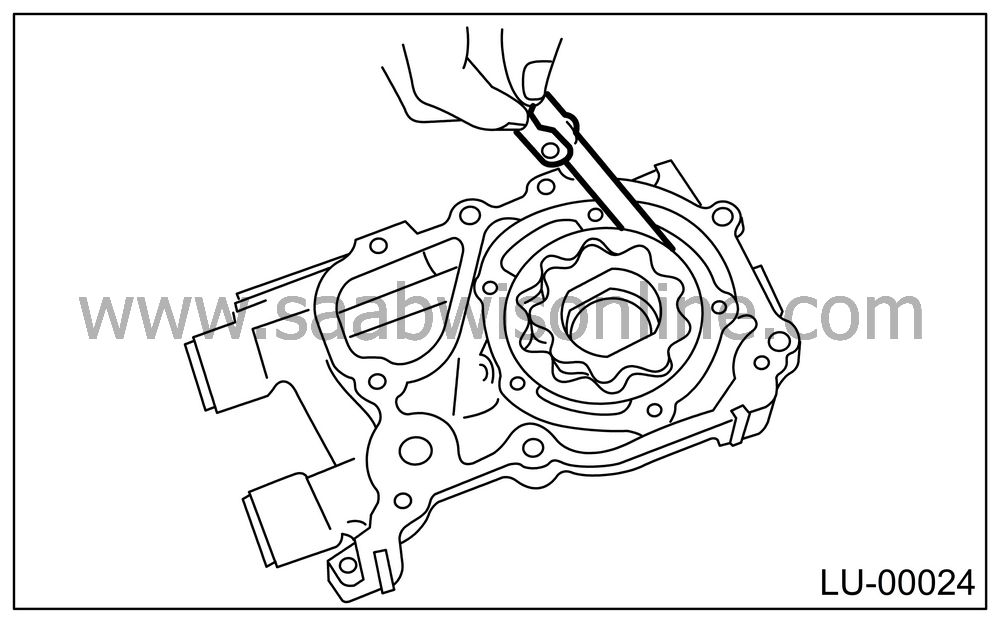

| CASE CLEARANCE |

Measure the clearance between the outer rotor and oil pump rotor housing. If clearance exceeds the standard, replace the rotor.

Case clearance:

Standard

0.10 — 0.175 mm (0.0039 — 0.0069 in)

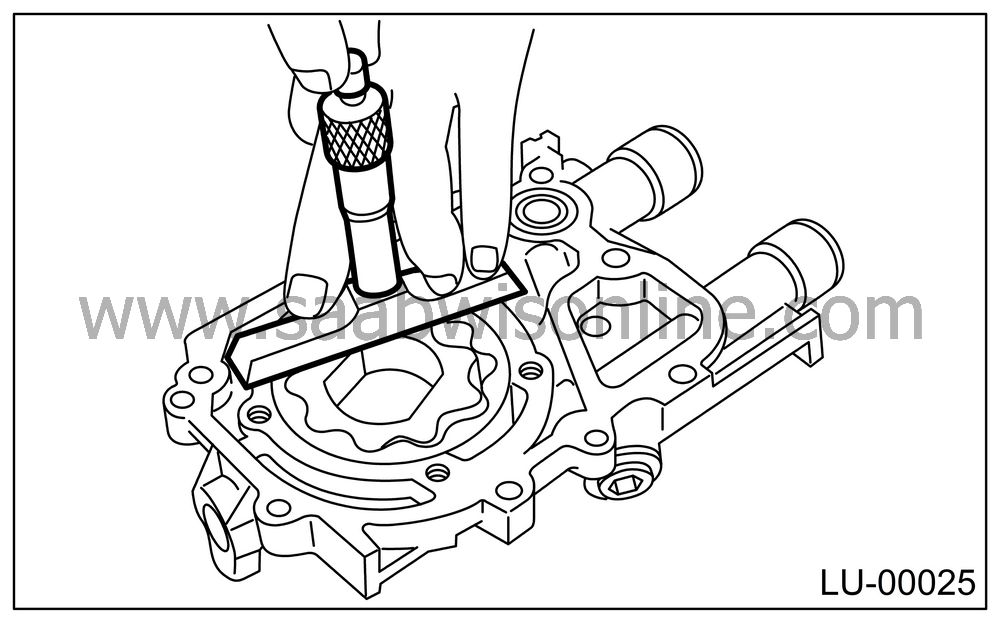

| SIDE CLEARANCE |

Measure the clearance between the oil pump inner rotor and pump cover. If clearance exceeds the standard, replace the rotor or pump body.

Side clearance:

Standard

0.02 — 0.07 mm (0.0008 — 0.0028 in)

| OIL RELIEF VALVE |

Check the valve for fitting condition and damage, and the relief valve spring for damage and deterioration. Replace the parts if defective.

Relief valve spring:

Free length

72.8 mm (2.866 in)Installed length

54.7 mm (2.154 in)Load when installed

81.3 N (8.29 kgf, 18.24 lb)| OIL PUMP CASE |

Check the oil pump case for worn shaft hole, clogged oil passage, worn rotor chamber, cracks, and other faults.

| OIL SEAL |

Check the oil seal lips for deformation, hardening, wear, etc. and replace if defective.