INSPECTION

| INSPECTION |

| CYLINDER HEAD |

Make sure that no crack or other damage exists. In addition to visual inspection, inspect the important areas by means of red check.

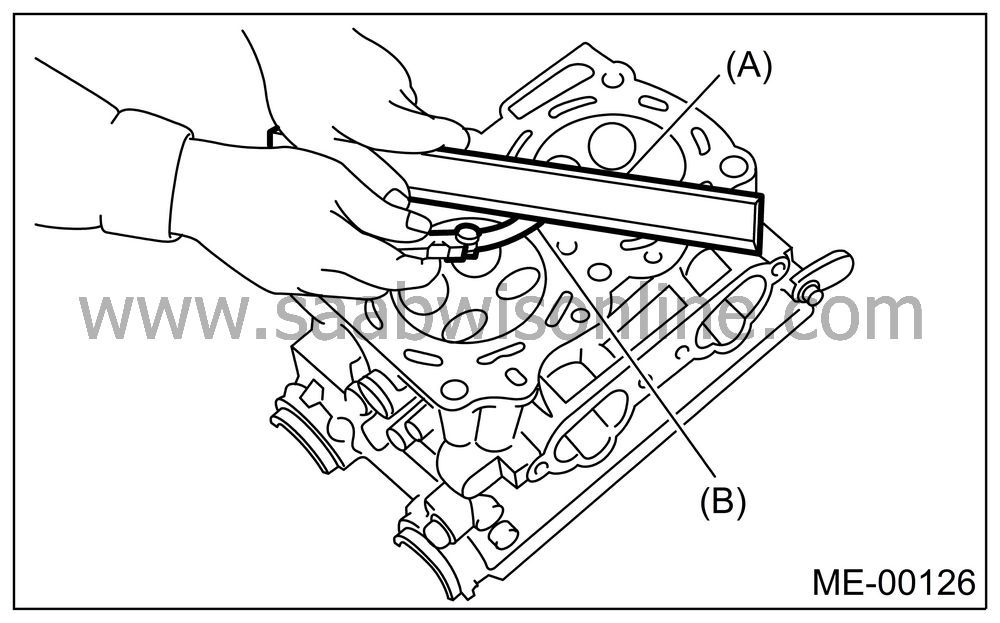

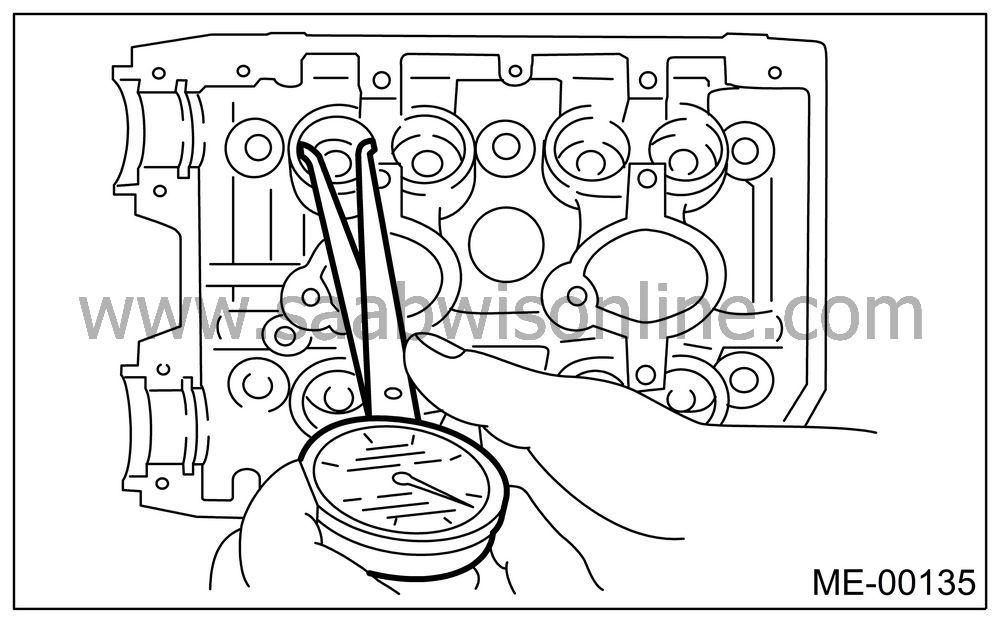

Measure the warping of the cylinder head surface that mates with crankcase by using a straight edge (A) and thickness gauge (B).

If the warping exceeds 0.05 mm (0.0020 in), regrind the surface with a surface grinder.

Warping limit:

0.035 mm (0.0014 in)

Grinding limit:

0.3 mm (0.012 in)

Standard height of cylinder head:

127.5 mm (5.02 in)

| Note | ||

|

Uneven torque for the cylinder head nuts can cause warping. When reassembling, pay special attention to the torque so as to tighten evenly. |

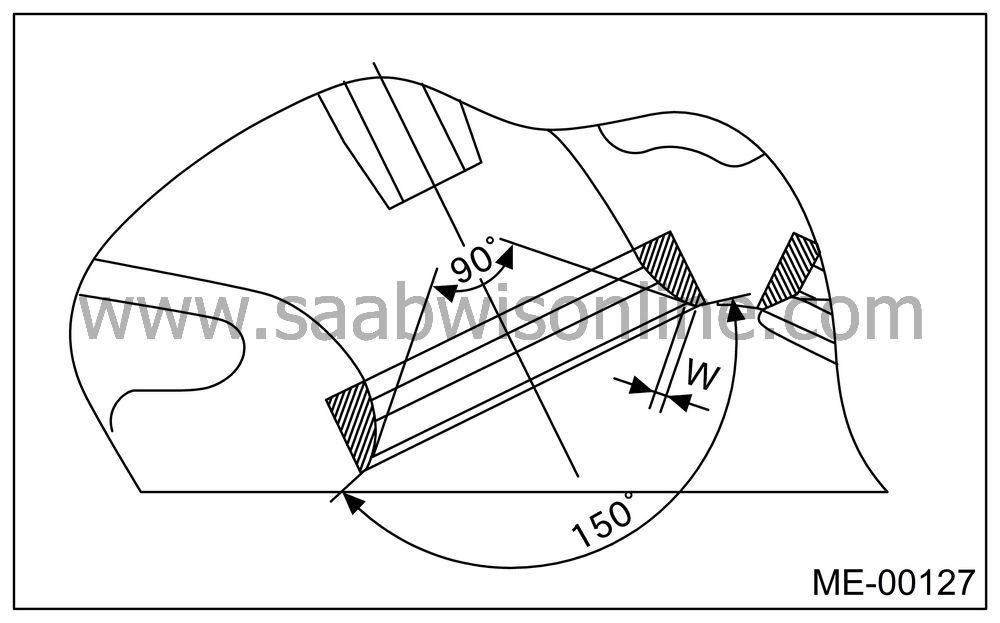

| VALVE SEAT |

Inspect the intake and exhaust valve seats, and then correct the contact surfaces with valve seat cutter if they are defective or when valve guides are replaced.

Valve seat width W:

Intake

Standard 0.85 — 1.15 mm (0.033 — 0.045 in)Exhaust

Standard 1.35 — 1.65 mm (0.053 — 0.064 in)

| VALVE GUIDE |

Check the clearance between valve guide and stem. The clearance can be checked by measuring the outside diameter of valve stem and the inside diameter of valve guide with outside and inside micrometers respectively.

Clearance between the valve guide and valve stem:

Standard:

Intake

0.030 — 0.057 mm (0.0012 — 0.0022 in)

Exhaust

0.040 — 0.067 mm (0.0016 — 0.0026 in)If the clearance between valve guide and stem exceeds the standard value, replace the valve guide or valve itself whichever shows greater amount of wear. See the following procedure for valve guide replacement.

Valve guide inner diameter:

6.000 — 6.012 mm (0.2362 — 0.2367 in)

Valve stem outer diameters:

Intake

5.955 — 5.970 mm (0.2344 — 0.2350 in)Exhaust

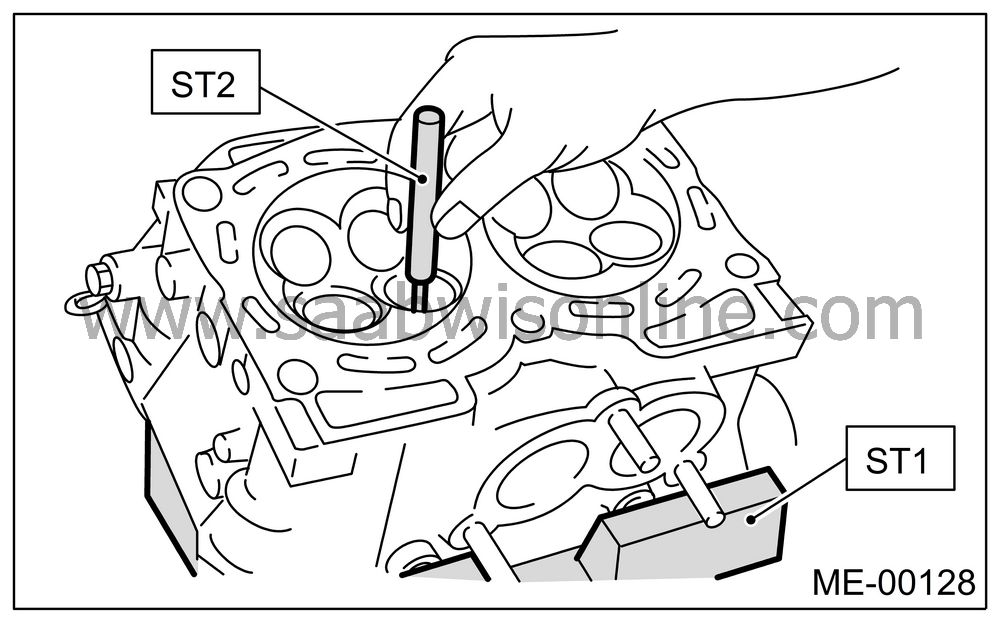

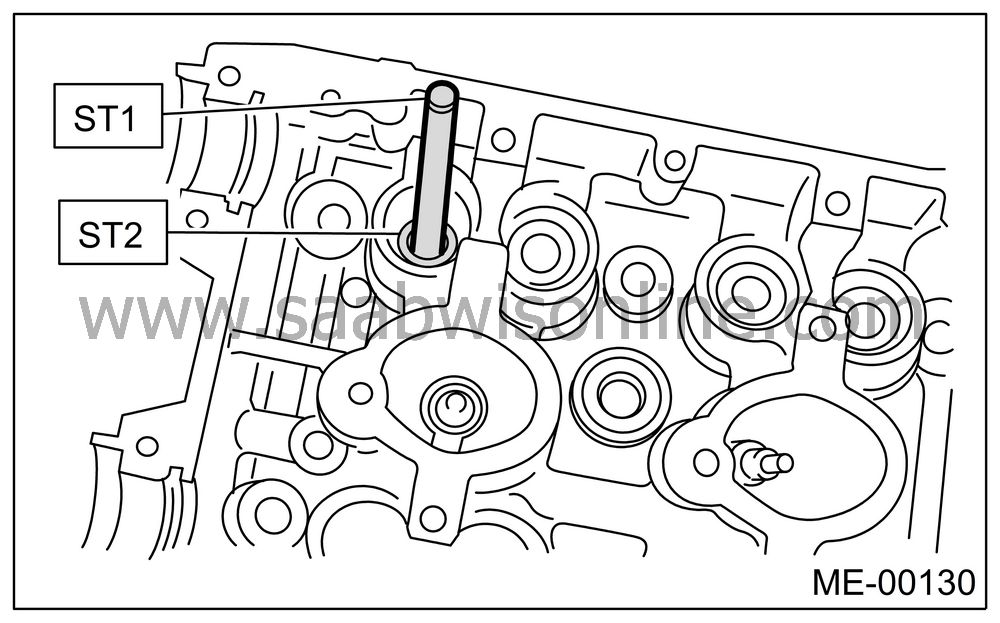

5.945 — 5.960 mm (0.2341 — 0.2346 in)Place the cylinder head on ST1 with the combustion chamber upward so that valve guides enter the holes in ST1.

Insert the ST2 into valve guide and press it down to remove the valve guide.

ST1 32005097 CYLINDER HEAD TABLE

ST2 32005148 VALVE GUIDE REMOVER

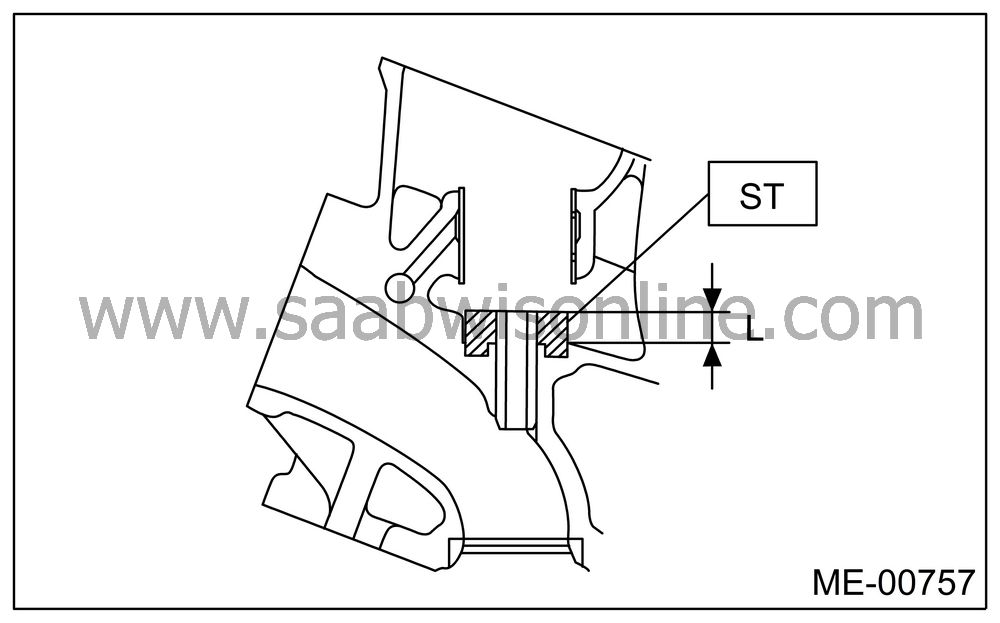

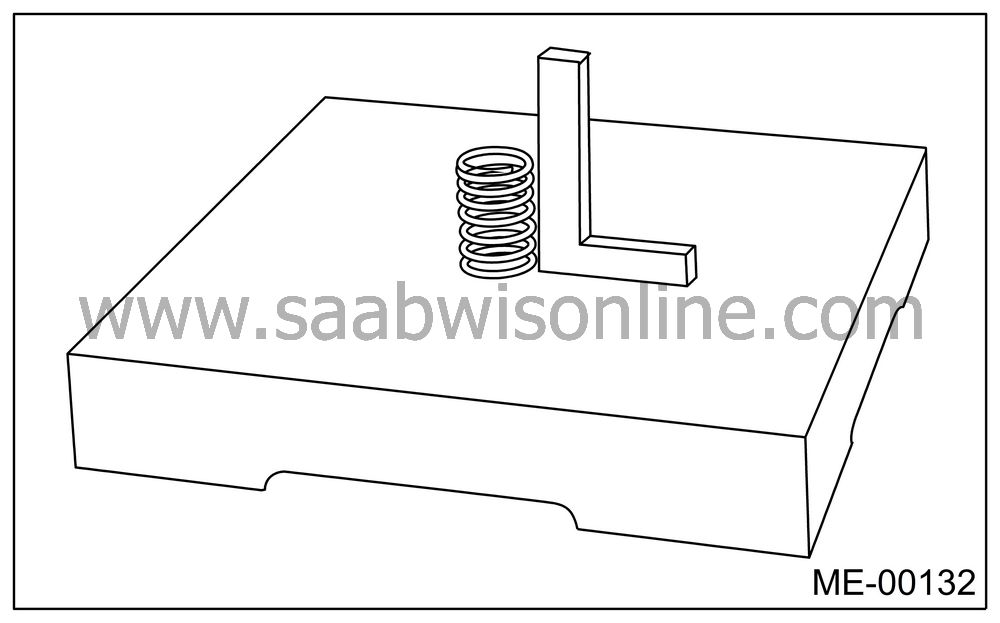

Turn the cylinder head upside down and place ST as shown in the figure.

ST 32005020 VALVE GUIDE ADJUSTER

Before installing a new valve guide, make sure that neither scratches nor damages exist on the inside surface of the valve guide holes in cylinder head.

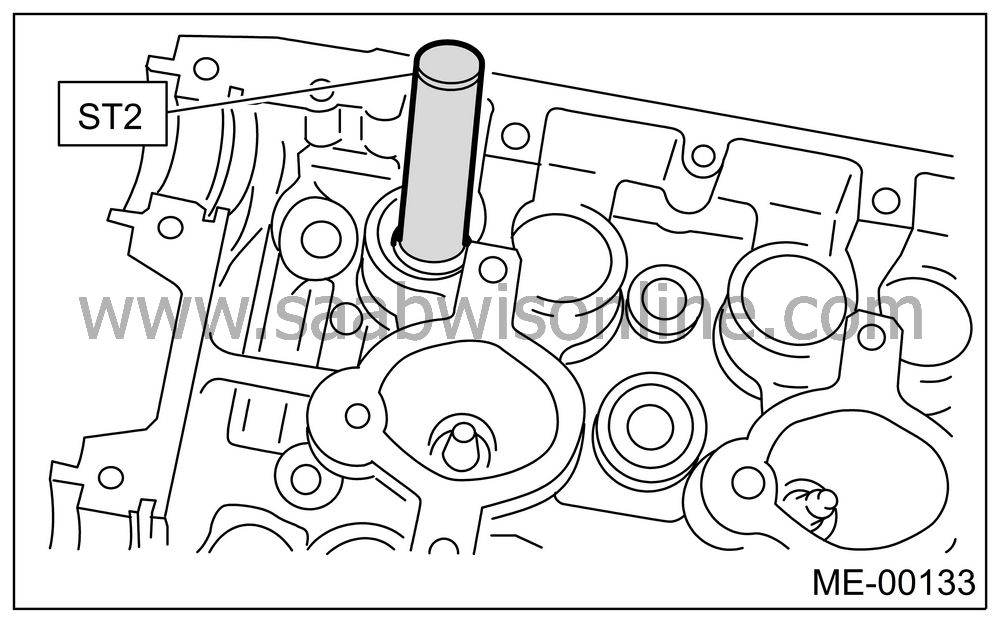

Put a new valve guide, coated with sufficient oil, in cylinder, and insert ST1 into valve guide. Press in until the valve guide upper end is flush with the upper surface of ST2.

ST1 32005148 VALVE GUIDE REMOVER

ST2 32005020 VALVE GUIDE ADJUSTER

Check the valve guide protrusion.

Valve guide protrusion L:

15.8 — 16.2 mm (0.622 — 0.638 in)

Ream the inside of valve guide with ST. Gently rotate the reamer clockwise while pressing it lightly into the valve guide, and return it also rotating clockwise. After reaming, clean the valve guide to remove chips.

ST 32005149 VALVE GUIDE REAMER

| Note | ||

| • |

Apply engine oil to the reamer when reaming.

|

|

| • |

If the inner surface of the valve guide is torn, the edge

of the reamer should be slightly ground with an oil stone.

|

|

| • |

If the inner surface of the valve guide becomes lustrous

and the reamer does not chip, use a new reamer or remedy the reamer.

|

|

Recheck the contact condition between valve and valve seat after replacing the valve guide.

| INTAKE AND EXHAUST VALVE |

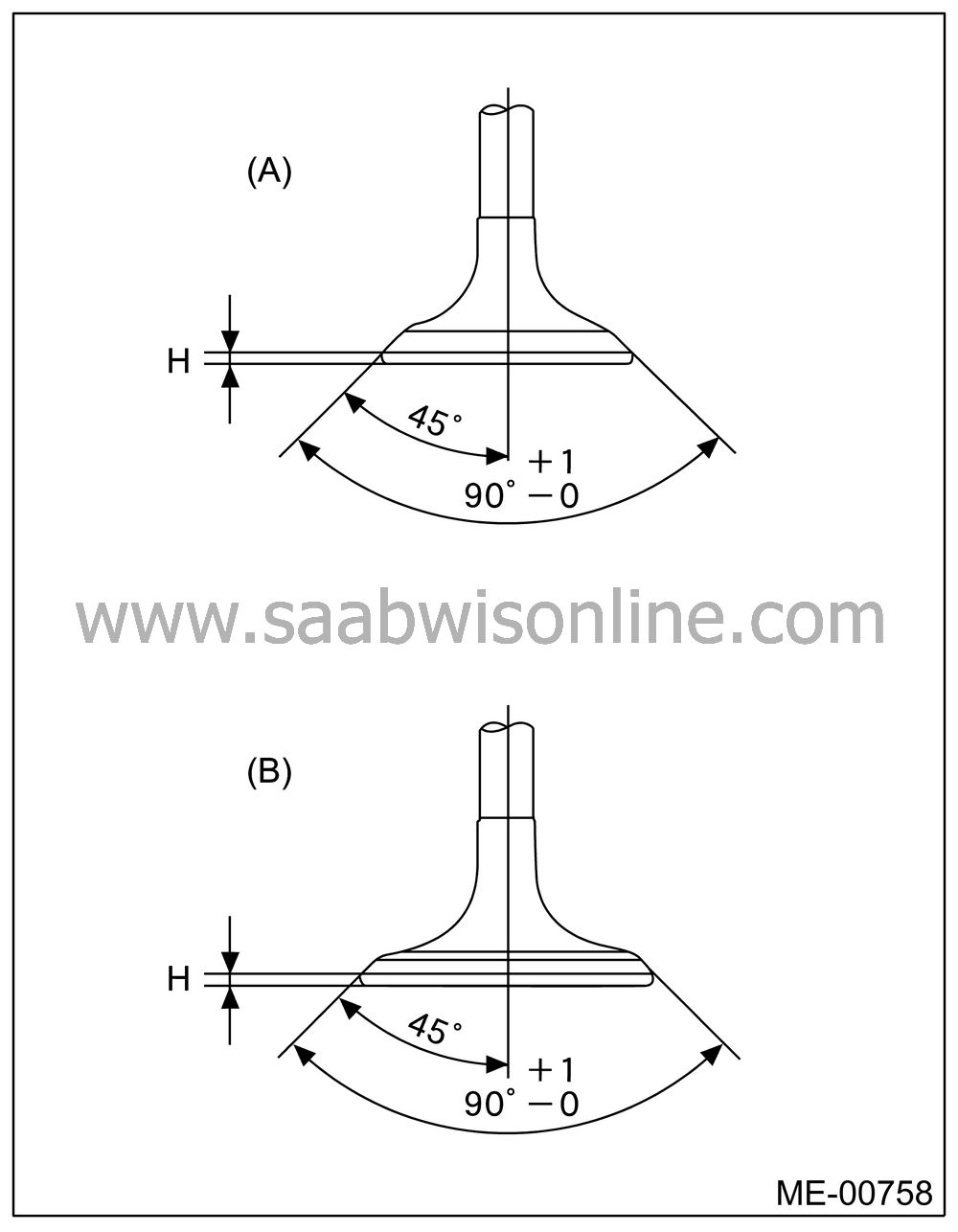

Inspect the flange and stem of valve, and replace if damaged, worn, or deformed, or if “H” is exceeds the standard value.

H:

Intake (A)

Standard 1.0 — 1.4 mm (0.039 — 0.055 in)Exhaust (B)

Standard 1.3 — 1.7 mm (0.051 — 0.067 in)Valve overall length:

Intake (A)

104.4 mm (4.110 in)Exhaust (B)

104.65 mm (4.120 in)

Put a small amount of grinding compound on the seat surface and lap the valve and seat surface. Install a new intake valve oil seal after lapping.

| VALVE SPRINGS |

Check the valve springs for damage, free length, and tension. Replace the valve spring if it is not within specifications presented in the table.

To measure the squareness of valve spring, stand the spring on a surface plate and measure its deflection at the top using a try square.

|

Valve

spring

|

||

|

Free length

|

44.67

mm (1.759 in)

|

|

|

Tension/spring height

|

Set

|

206 — 236

N

(21.0 — 24.1 kgf, 46.2 — 53.0 lb) /36.0 mm (1.417 in) |

|

Lift

|

485 — 537

N (49.5 — 54.8 kgf, 109 — 121 lb)/26.0

mm (1.024 in)

|

|

|

Squareness

|

2.5°, 1.9

mm (0.075 in)

|

|

| INTAKE AND EXHAUST VALVE OIL SEAL |

In the following case, pinch and remove the oil seal from valve using pliers, and then replace it with a new one.

| • |

When the

lip is damaged.

|

|

| • |

When the spring is out of the specified position.

|

|

| • |

When readjusting the surfaces of intake valve and valve

sheet.

|

|

| • |

When replacing the intake valve guide.

|

|

Place the cylinder head on ST1.

Using ST2, press-fit the oil seal.

| Important | ||

| • |

Apply engine oil to oil seal

before press-fitting.

|

|

| • |

When press-fitting the oil seal, do not use a hammer

or strike in.

|

|

| • |

Differentiate between the intake valve oil seal and

exhaust valve oil seal by noting their difference in color.

|

|

ST1 32005097 CYLINDER HEAD TABLE

ST2 32005116 VALVE OIL SEAL GUIDE

Color of rubber part:Intake [Black] Exhaust [Brown]

| VALVE LIFTER |

Visually check the valve lifter.

Measure the outer diameter of valve lifter.

Outer diameter:

34.959 — 34.975 mm (1.3763 — 1.3770 in)

Measure the inner diameter of valve lifter mating part on cylinder head.

Inner diameter:

34.994 — 35.016 mm (1.3777 — 1.3786 in)

| Note | ||

|

If difference between outer diameter of valve lifter and inner diameter of valve lifter mating part is over the standard, replace the cylinder head. |

Standard:

0.019 — 0.057 mm (0.0007 — 0.0022 in)