INSPECTION

| INSPECTION |

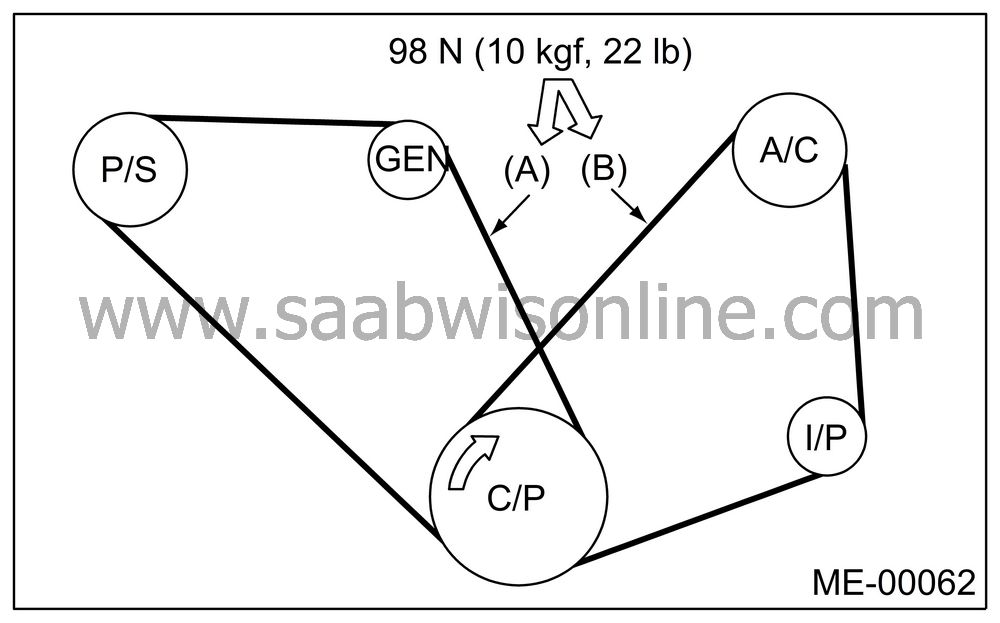

| WITHOUT USING BELT TENSION GAUGE |

Replace the belts, if cracks, fraying or wear is found.

Check the drive belt tension and adjust it if necessary by changing generator installing position and/or idler pulley installing position.

Belt tension:

(A)

replaced: 7 — 9 mm (0.276 — 0.354 in)

reused: 9 — 11 mm (0.354 — 0.433 in)

(B)*

replaced: 7.5 — 8.5 mm (0.295 — 0.335 in)

reused: 9.0 — 10.0 mm (0.354 — 0.394 in)

*: with air conditioner

|

(A)

|

Front side

belt

|

|

(B)

|

Rear side

belt

|

|

C/P

|

Crank pulley

|

|

GEN

|

Generator

|

|

P/S

|

Power steering

oil pump pulley

|

|

A/C

|

Air conditioning

compressor pulley

|

|

I/P

|

Idler pulley

|

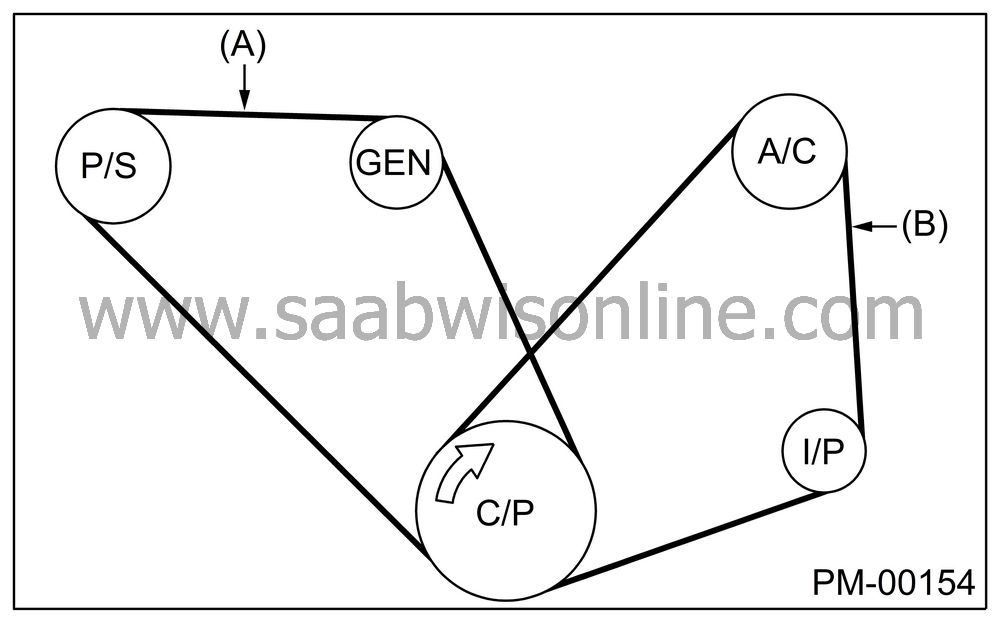

| WITH USING BELT TENSION GAUGE |

Replace the belts, if cracks, fraying or wear is found.

Check the belt tension using belt tension gauge. And adjust it if necessary by changing the generator installing position and/or idler pulley installing position.

Belt tension:

(A) 490 — 640 N (50 — 65 kgf, 110 — 144 lb)

(B) 350 — 450 N (36 — 46 kgf, 79 — 101 lb)

|

(A)

|

Front side

belt

|

|

(B)

|

Rear side

belt

|

|

C/P

|

Crank pulley

|

|

GEN

|

Generator

|

|

P/S

|

Power steering

oil pump pulley

|

|

A/C

|

A/C

compressor pulley

|

|

I/P

|

Idler pulley

|