INSPECTION

| INSPECTION |

Inspection and adjustment of the valve clearance should be performed while engine is cold.

Set the vehicle on a lift.

Disconnect the ground cable from battery.

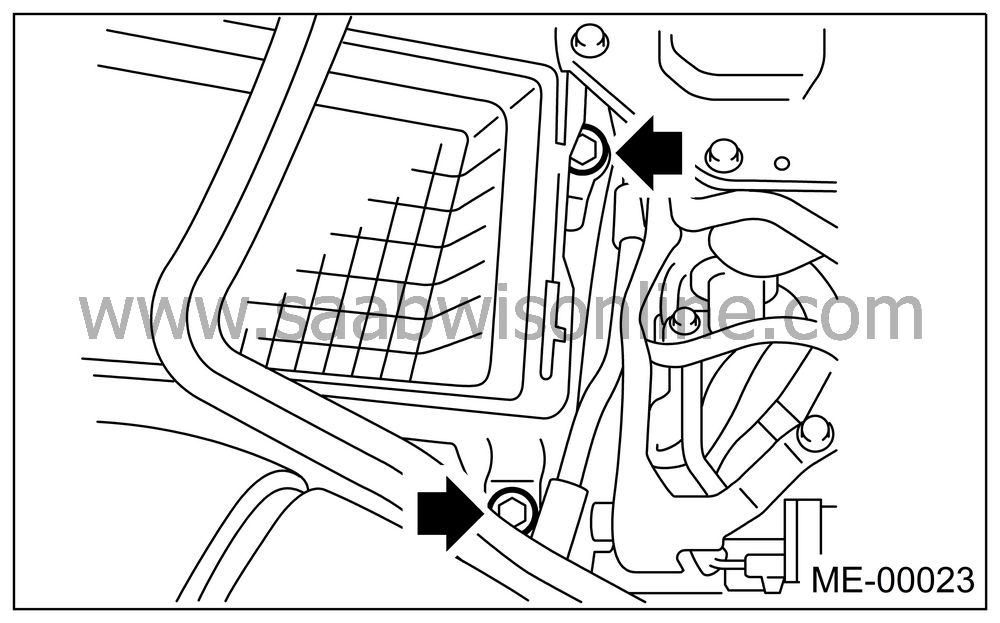

Remove the bolts which secure the timing belt cover (RH).

Lift-up the vehicle.

Remove the under cover.

Loosen the remaining bolts which secure the timing belt cover (RH), and then remove the timing belt cover.

Lower the vehicle.

When inspecting the #1 and #3 cylinders:

Pull out the engine harness connector with bracket from air cleaner upper cover.

Remove the air cleaner case.

Disconnect the ignition coil connector.

Remove the ignition coil.

Place a suitable container under the vehicle.

Disconnect the PCV hose from rocker cover (RH).

Remove the bolts, and then remove the rocker cover (RH).

When inspecting the #2 and #4 cylinders:

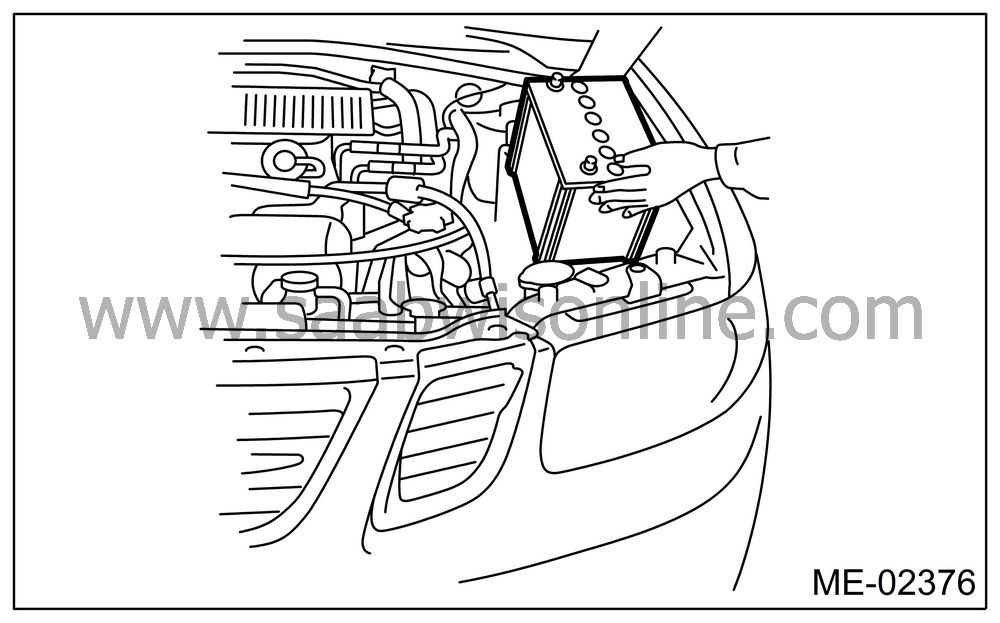

Disconnect the battery cable, and then remove the battery and battery carrier.

Remove the bolt which secures the engine harness bracket onto body.

Disconnect the ignition coil connector.

Remove the ignition coil.

Place a suitable container under the vehicle.

Disconnect the PCV hose from rocker cover (LH).

Remove the bolts, and then remove the rocker cover (LH).

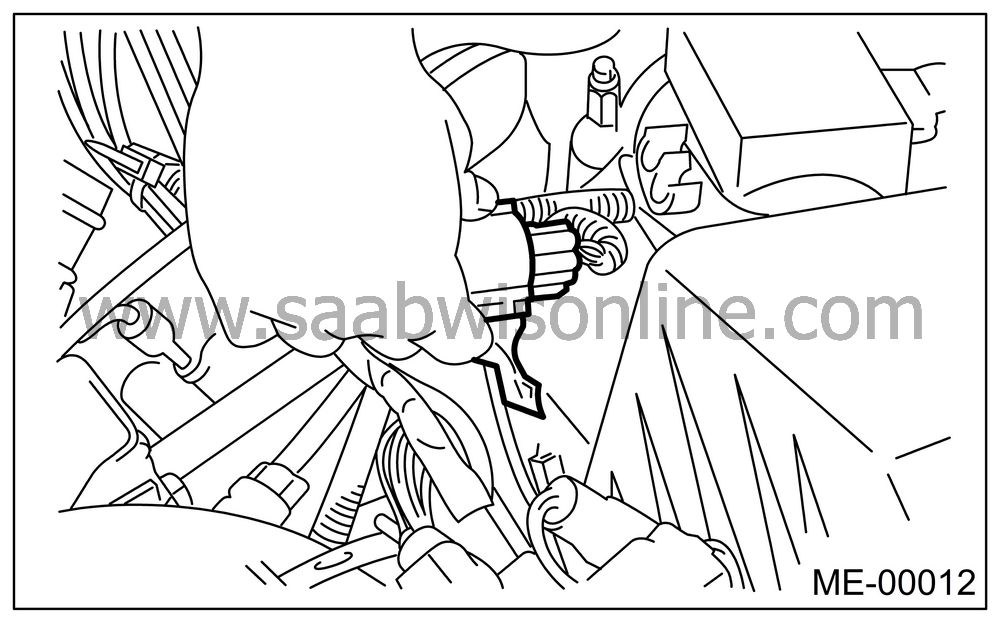

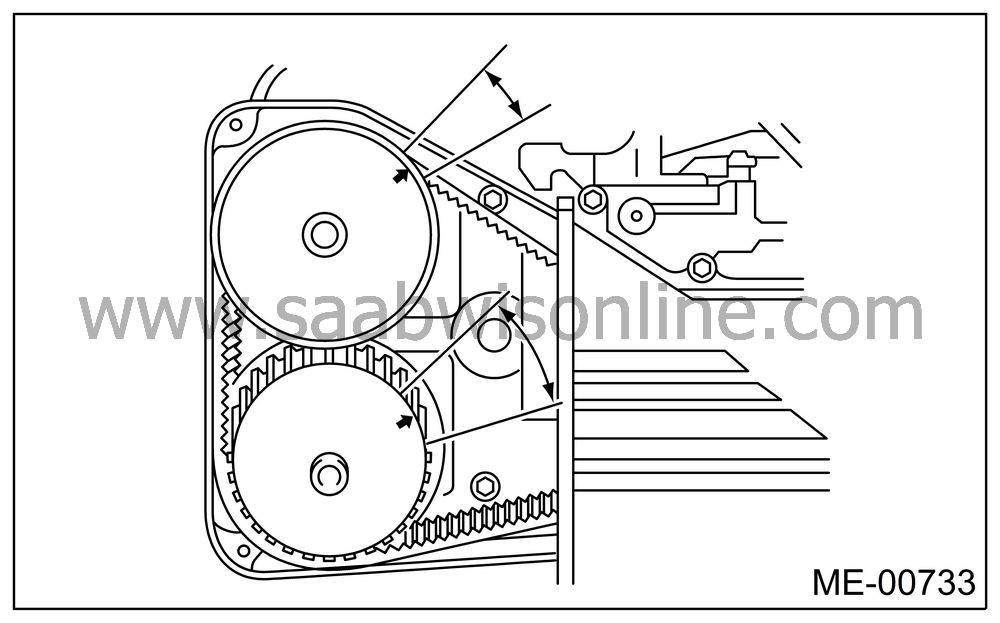

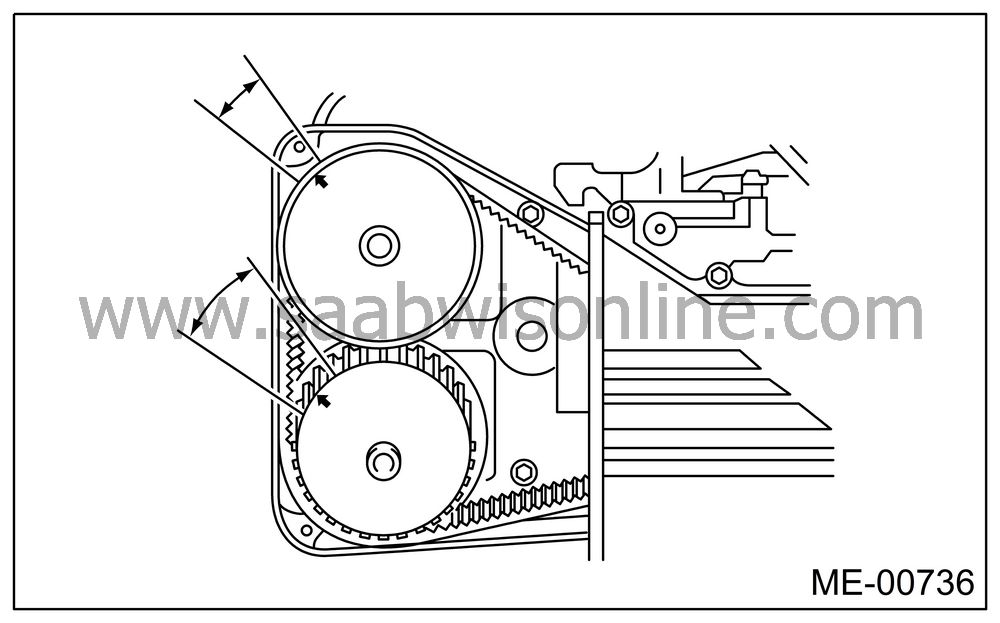

Turn the crank pulley clockwise until arrow mark on the cam sprocket is set to position shown in the figure.

| Note | ||

|

Turn the crankshaft using socket wrench. |

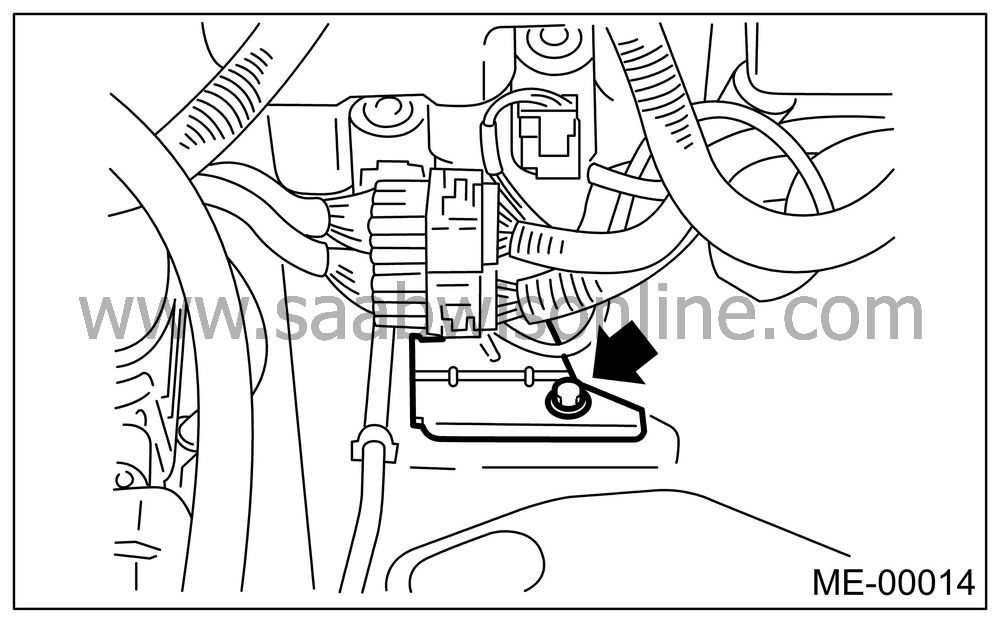

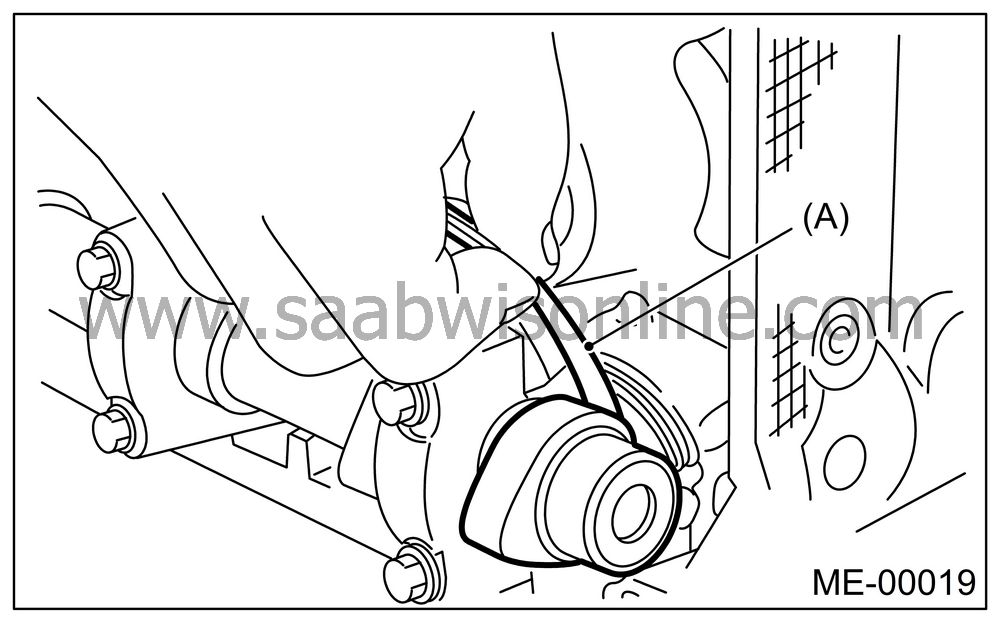

Measure the #1 cylinder intake valve and #3 cylinder exhaust valve clearance by using thickness gauge (A).

| Note | ||

| • |

Insert the thickness gauge in as horizontal a direction

as possible with respect to the shim.

|

|

| • |

Measure the exhaust valve clearances while lifting-up

the vehicle.

|

|

Valve clearance:

STD

Intake: 0.20±0.02 mm (0.0079±0.0008 in)Exhaust: 0.35±0.02 mm (0.0136±0.0008 in)

| Note | ||

|

If the measured value is not within specification, take notes of the value in order to adjust the valve clearance later on. |

If necessary, adjust the valve clearance.

Further turn the crank pulley clockwise. Using the same procedures described previously, and then measure the valve clearances again.

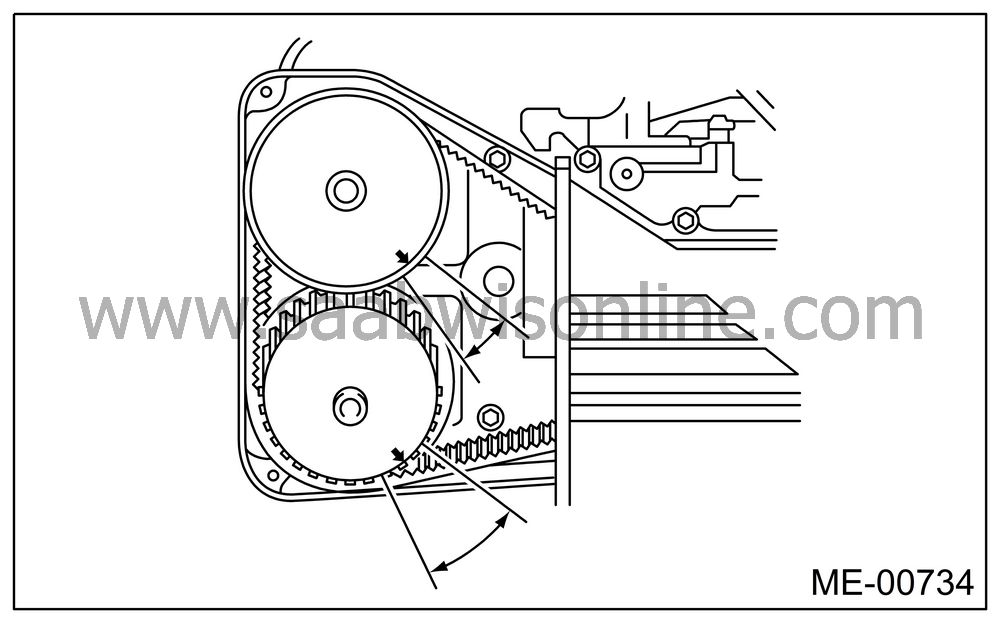

Set the arrow mark on cam sprocket to position shown in the figure, and then measure the #2 cylinder exhaust valve and #3 cylinder intake valve clearances.

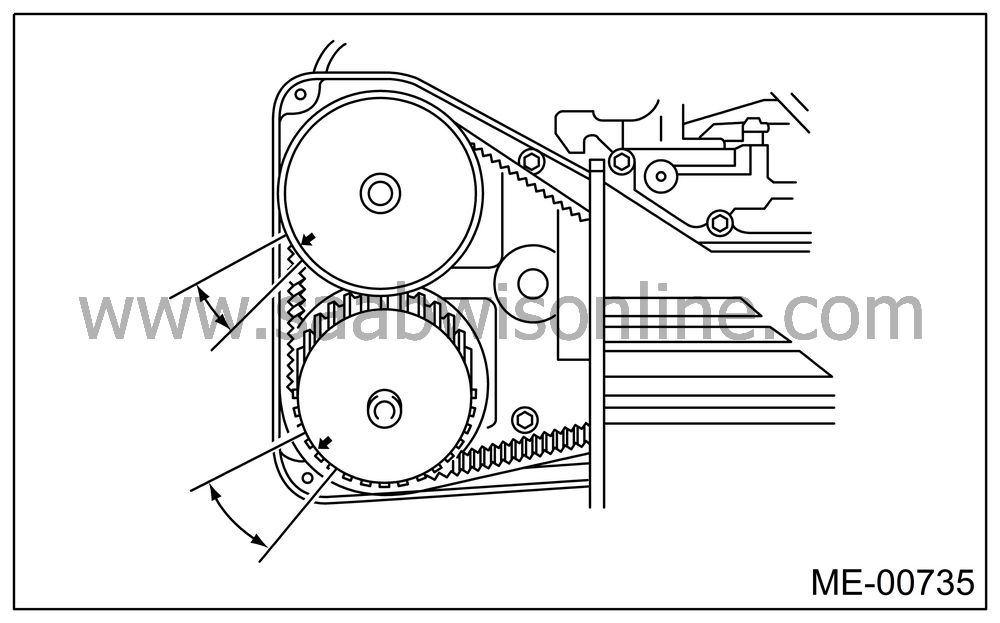

Set the arrow mark on cam sprocket to position shown in the figure, and then measure the #2 cylinder intake valve and #4 cylinder exhaust valve clearances.

Set the arrow mark on cam sprocket to position shown in the figure, and then measure the #1 cylinder exhaust valve and #4 cylinder intake valve clearances.

After inspection, install the related parts in the reverse order of removal.

Tightening torque:

33 Nm (3.4 kgf-m, 25 ft-lb)