INSPECTION

| INSPECTION |

| TIMING BELT |

Check the timing belt teeth for breaks, cracks and wear. If any fault is found, replace the belt.

Check the condition of the backside of belt. If cracks are found, replace the belt.

| Important | ||

| • |

Be careful not to let oil, grease

or coolant contact the belt. Remove quickly and thoroughly if this

happens.

|

|

| • |

Do not bend the timing belt sharply.

|

|

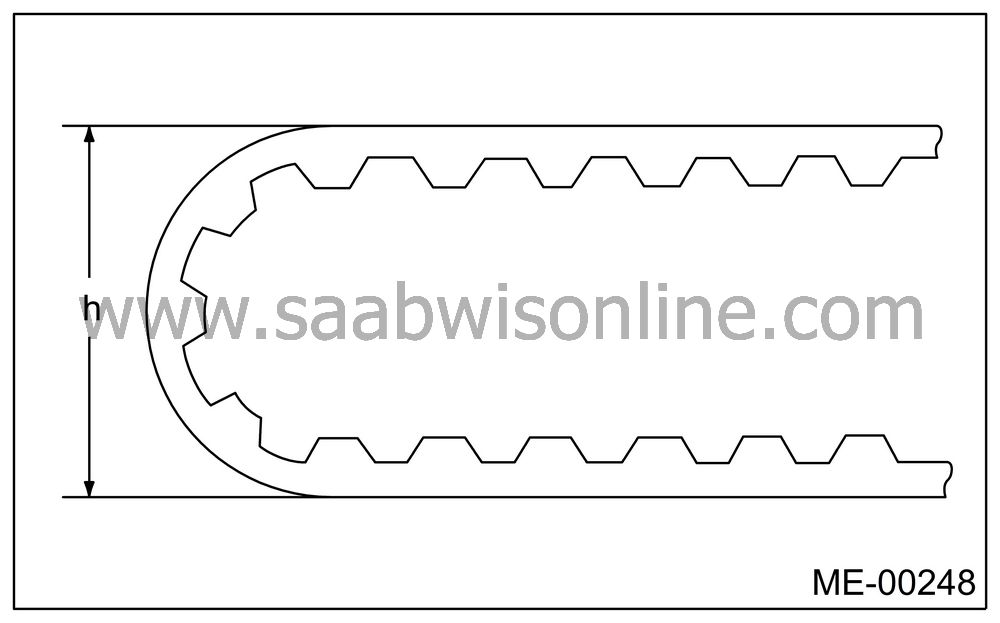

In radial diameter h:

60 mm (2.36 in) or more

| AUTOMATIC BELT TENSION ADJUSTER |

Visually check the oil seals for leaks, and rod ends for abnormal wear or scratches. If necessary, replace the automatic belt tension adjuster assembly.

| Note | ||

|

Slight traces of oil at rod’s oil seal does not indicate a problem. |

Check that the adjuster rod does not move when a pressure of 294 N (30 kgf, 66 lb) is applied to it. This is to check adjuster rod stiffness.

If the adjuster rod is not stiff and moves freely when applying 294 N (30 kgf, 66 lb), check it using the following procedures:

Slowly press the adjuster rod down to the end surface of the cylinder. Repeat this operation two to three times.

With the adjuster rod moved all the way up, apply a pressure of 294 N (30 kgf, 66 lb) to it. Check the adjuster rod stiffness.

If the adjuster rod is not stiff and moves down, replace the automatic belt tension adjuster assembly with a new one.

| Important | ||

| • |

Always use a vertical type pressing

tool to move the adjuster rod down.

|

|

| • |

Do not use a lateral type vise.

|

|

| • |

Push the adjuster rod vertically.

|

|

| • |

Press the adjuster rod gradually taking more than three

minutes.

|

|

| • |

Do not allow press pressure to exceed 9,807 N (1,000

kgf, 2,205 lb).

|

|

| • |

Press the adjuster rod as far as the end surface of

cylinder. Do not press the adjuster rod into cylinder. Doing so

may damage the cylinder.

|

|

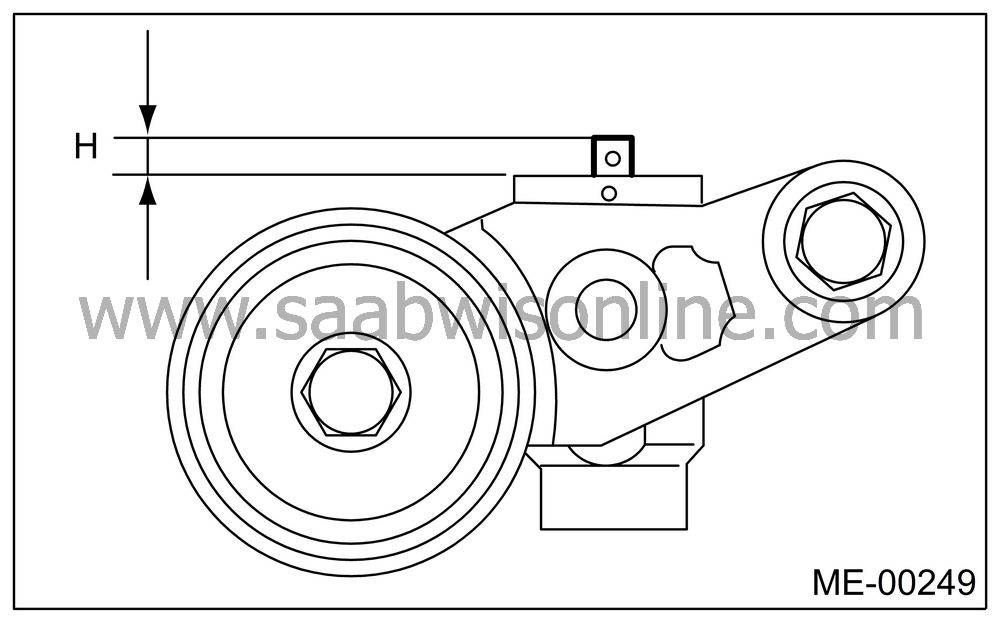

Measure the amount of rod protrusion beyond the body. If it is not within specifications, replace with a new one.

Amount of rod protrusion H:

5.7±0.5 mm (0.224±0.020 in)

| BELT TENSION PULLEY |

Check the mating surfaces of timing belt and contact point of adjuster rod for abnormal wear or scratches. Replace the automatic belt tension adjuster assembly if faulty.

Check the belt tension pulley for smooth rotation. Replace if noise or excessive play occurs.

Check the belt tension pulley for grease leakage.

| BELT IDLER |

Check the belt idler for smooth rotation. Replace if noise or excessive play occurs.

Check the outer contacting surfaces of idler pulley for abnormal wear and scratches.

Check the belt idler for grease leakage.