ADJUSTMENT

| ADJUSTMENT |

| Important | ||

|

Adjustment of valve clearance should be performed while engine is cold. |

||

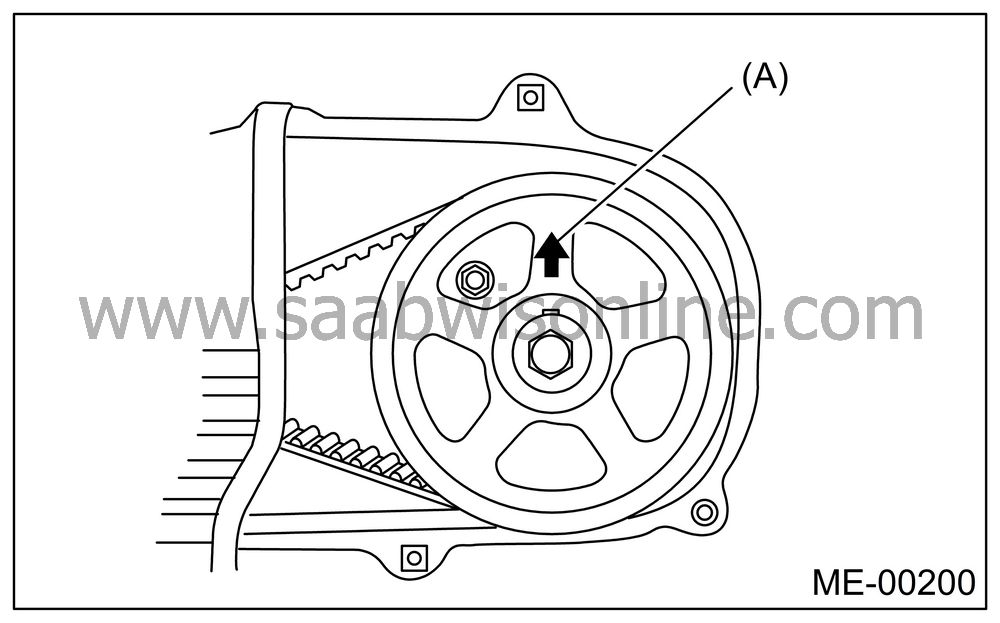

Set #1 cylinder piston to top dead center of compression stroke by rotating the crank pulley clockwise using the socket wrench.

| Note | ||

|

When the arrow mark (A) on cam sprocket (LH) comes exactly to the top, #1 cylinder piston is brought to the top dead center of compression stroke. |

Adjust the #1 cylinder valve clearance.

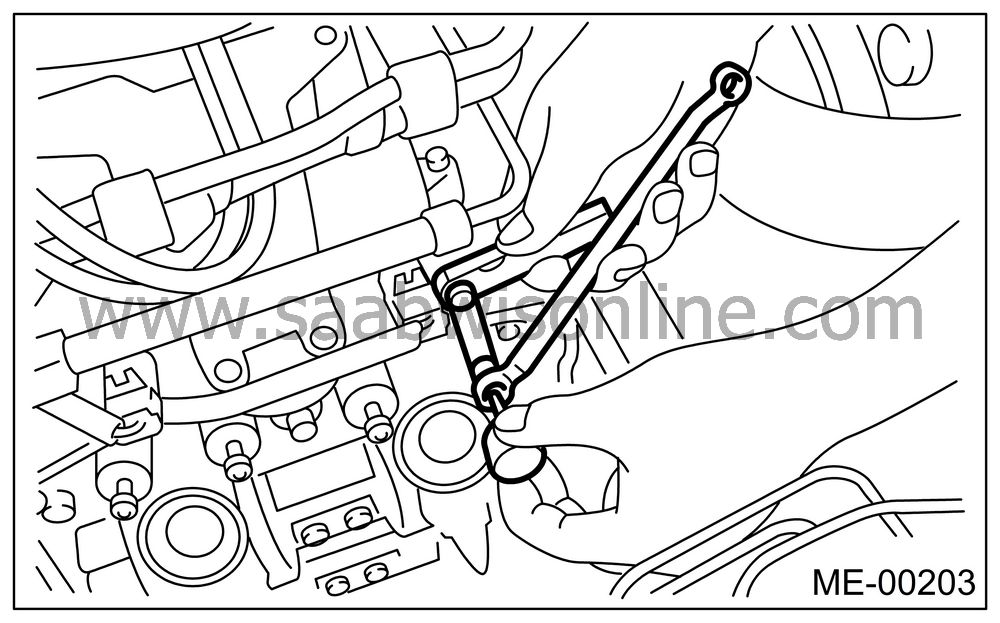

Loosen the valve rocker nut and screw.

Place a suitable thickness gauge.

While noting the valve clearance, tighten the valve rocker adjusting screw.

When the specified valve clearance is obtained, tighten the valve rocker nut.

Tightening torque:

10 Nm (1.0 kgf-m, 7.2 ft-lb)

| Important | ||

| • |

Insert the thickness gauge in

as horizontally as possible with respect to the valve stem end face.

|

|

| • |

Adjust the exhaust valve clearances while lifting-up

the vehicle.

|

|

Valve clearance

Intake:

0.20±0.04 mm (0.0079±0.0016 in)Exhaust:

0.25±0.04 mm (0.0098±0.0016 in)

| Note | ||

| • |

Be sure to set the cylinder pistons to their respective

top dead centers on compression stroke before adjusting valve clearances.

|

|

| • |

By rotating the crank pulley clockwise every 180° from

the state that #1 cylinder piston is on the top dead center

of compression stroke, #3, #2 and #4 cylinder

pistons come to the top dead center of compression stroke in this

order.

|

|

Ensure the valve clearances of each cylinder are within specifications. If necessary, readjust the valve clearances.