DTC P0758 SHIFT SOLENOID “B” ELECTRICAL

| DTC P0758 SHIFT SOLENOID “B” ELECTRICAL |

DIAGNOSIS:

The output signal circuit of 2-4 brake duty solenoid is open or shorted.

TROUBLE SYMPTOM:

Excessive shift shock.

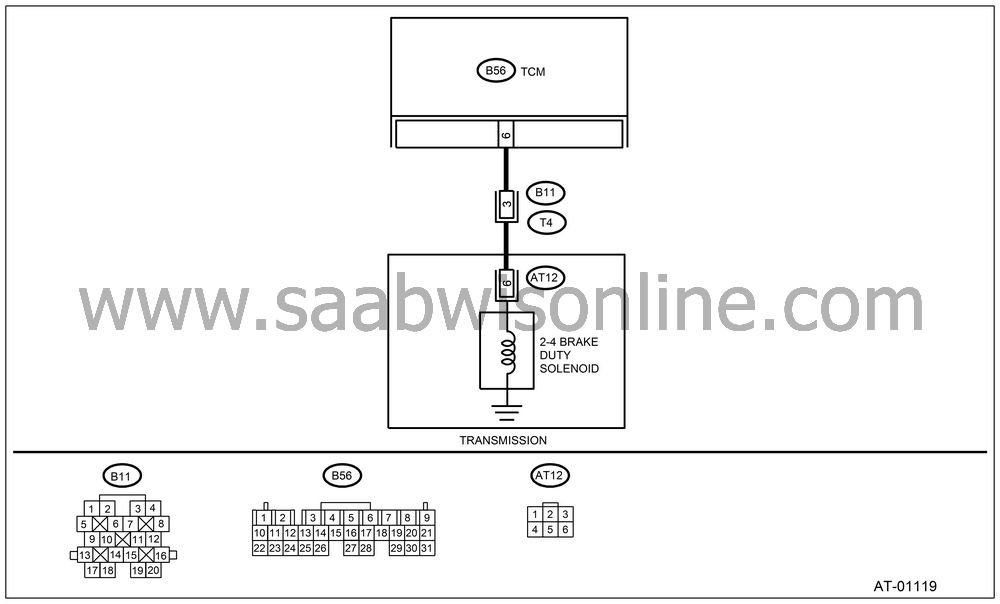

WIRING DIAGRAM:

CHECK HARNESS CONNECTOR BETWEEN TCM AND TRANSMISSION.

Turn the ignition switch to OFF.Disconnect the connector from TCM and transmission.

Measure the resistance of harness between TCM and shift transmission connector.

Connector & terminal

(B56) No. 6 — (B11) No. 3:

Is the resistance less than 1 Ω?

| Yes |

| No |

Repair the open circuit in harness between TCM and transmission connector.

CHECK HARNESS CONNECTOR BETWEEN TCM AND CHASSIS GROUND.

Measure the resistance of harness between TCM connector and chassis ground.Connector & terminal

(B56) No. 6 — Chassis ground:

Is the resistance more than 1 MΩ?

| Yes |

| No |

Repair the short circuit in harness between TCM and transmission connector.

CHECK 2-4 BRAKE DUTY SOLENOID.

Measure the resistance between transmission connector terminals.Connector & terminal

(T4) No. 3 — No. 20:

Is the resistance 2.0 — 6.0 Ω?

| Yes |

| No |

CHECK OUTPUT SIGNAL FROM TCM USING Vehicle Diagnostic Interface.

Connect all connectors.Connect the Vehicle Diagnostic Interface to data link connector.

Start the engine and turn Vehicle Diagnostic Interface switch to ON.

Warm-up the transmission until ATF temperature is above 80°C (176°F).

| Note | ||

|

If ambient temperature is below 0°C (32°F), drive the vehicle until ATF reaches its operating temperature. |

Stop the engine and turn ignition switch to ON (engine OFF).

Move the select lever to “N” range.

Read the data of 2-4 brake duty solenoid using Vehicle Diagnostic Interface.

| • |

2-4 brake

duty solenoid is indicated in “%”.

|

|

Is the value 100%?

| Yes |

| No |

CHECK OUTPUT SIGNAL FROM TCM USING Vehicle Diagnostic Interface.

Move the select lever to “2” range.Turn the HOLD switch to ON.

Is the value 0%?

| Yes |

Even if the POWER indicator blinks, the circuit has returned to a normal condition at this time. A temporary poor contact of the connector or harness may be the cause. Repair the harness or connector in TCM and transmission.

| No |

CHECK POOR CONTACT.

Is there poor contact in 2-4 brake duty solenoid circuit?

| Yes |

Repair the poor contact.

| No |

CHECK 2-4 BRAKE DUTY SOLENOID (IN TRANSMISSION).

Remove the transmission connector from bracket.Drain the ATF.

| Important | ||

|

Do not drain the ATF until it cools down. |

||

Remove the oil pan, and disconnect connector from 2-4 brake duty solenoid.

Measure the resistance between 2-4 brake duty solenoid connector and transmission ground.

Connector & terminal

(AT12) No. 6 — Transmission ground:

Is the resistance 2.0 — 6.0 Ω?

| Yes |

| No |

Replace the control valve body.

CHECK HARNESS CONNECTOR BETWEEN 2-4 BRAKE DUTY SOLENOID AND TRANSMISSION.

Measure the resistance of harness between 2-4 brake duty solenoid and transmission connector.Connector & terminal

(T4) No. 3 — (AT12) No. 6:

Is the resistance less than 1 Ω?

| Yes |

| No |

Repair the open circuit in harness between 2-4 brake duty solenoid and transmission connector.

CHECK HARNESS CONNECTOR BETWEEN 2-4 BRAKE DUTY SOLENOID AND TRANSMISSION.

Measure the resistance of harness between transmission connector and transmission ground.Connector & terminal

(T4) No. 3 — Transmission ground:

Is the resistance more than 1 MΩ?

| Yes |

Even if the POWER indicator blinks, the circuit has returned to a normal condition at this time. A temporary poor contact of the connector or harness may be the cause. Repair the harness or connector in high clutch duty solenoid and transmission.

| No |

Repair the short circuit harness between 2-4 brake duty solenoid and transmission connector.