ASSEMBLY

| ASSEMBLY |

| DIFFERENTIAL CASE ASSEMBLY |

Install the washer, differential bevel gear and differential bevel pinion in the differential case (RH). Insert the pinion shaft.

Install straight pin from reverse direction.

|

(A)

|

Differential

case (RH)

|

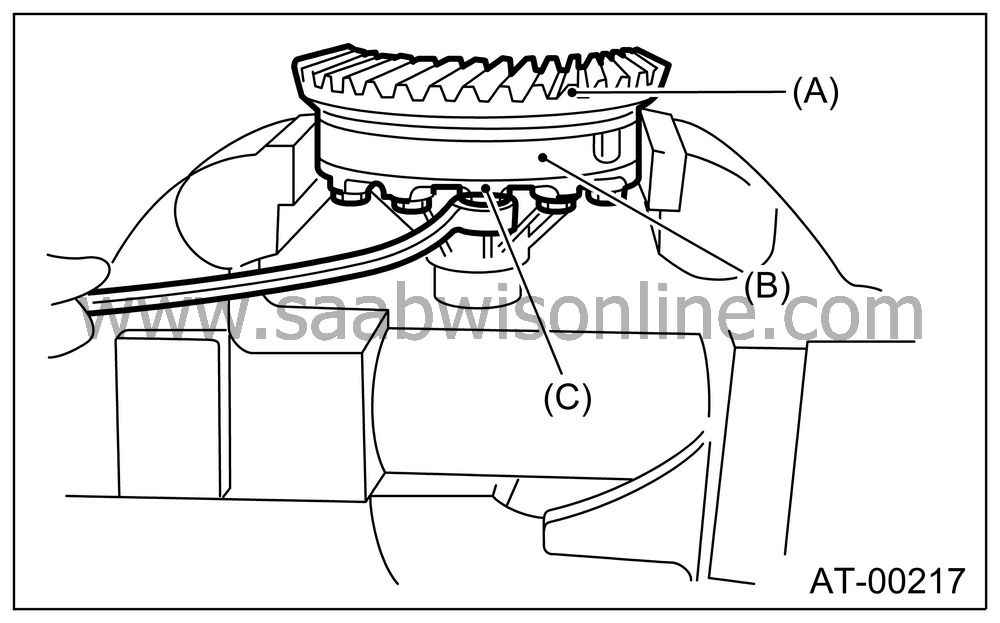

Install the washer and differential bevel gear to the differential case (LH). Then put the case over the differential case (RH), and connect both cases.

Install the hypoid driven gear and secure by tightening the bolt.

Standard tightening torque:

62 Nm (6.3 kgf-m, 45.6 ft-lb)

|

(A)

|

Hypoid

driven gear

|

|

(B)

|

Differential

case (RH)

|

|

(C)

|

Differential

case (LH)

|

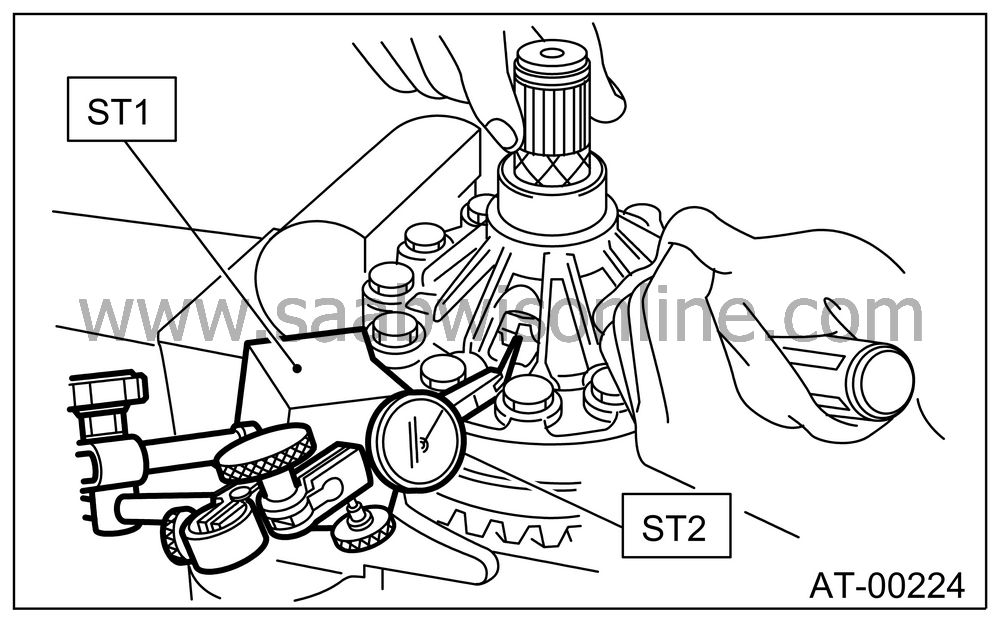

Measurement of backlash (Selection of washer)

Install the genuine axle shaft to differential case.

Measure the gear backlash with ST1 and ST2, and insert ST2 through the access window of the case.

ST1 32005094 MAGNET BASE

ST2 32005095 DIAL GAUGE

| Note | ||

| • |

Measure the backlash by applying a pinion tooth between

two bevel gear teeth.

|

|

| • |

Fix bevel pinion gear in place with a screwdriver or

similar tool when measuring.

|

|

Standard value:

0.13 — 0.18 mm (0.0051 — 0.0071 in)

If backlash is not as specified, select a washer from the table below.

|

Washer

|

|

|

Part

No.

|

Thickness

mm (in)

|

|

32008279

|

0.95

(0.037)

|

|

32008280

|

1.00

(0.039)

|

|

32008281

|

1.05

(0.041)

|

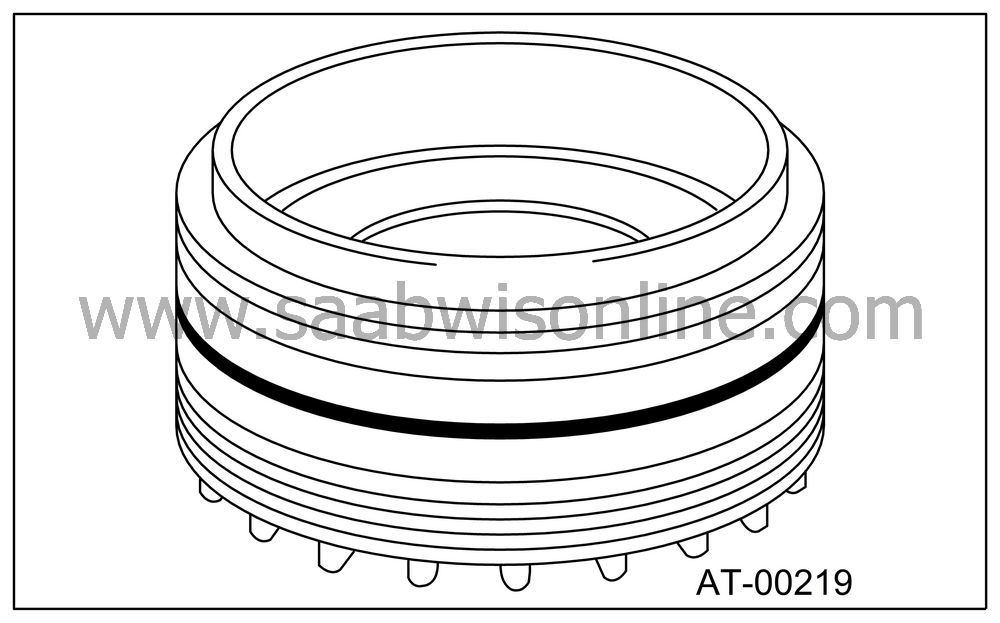

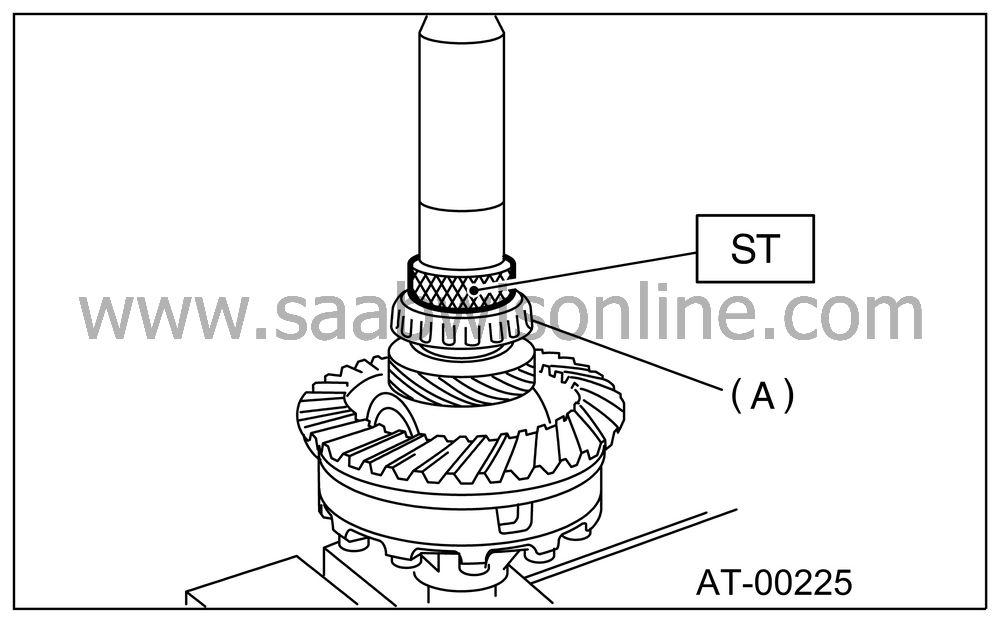

Using ST, install taper roller bearing.

ST 32005058 DRIFT

|

(A)

|

Taper roller

bearing

|

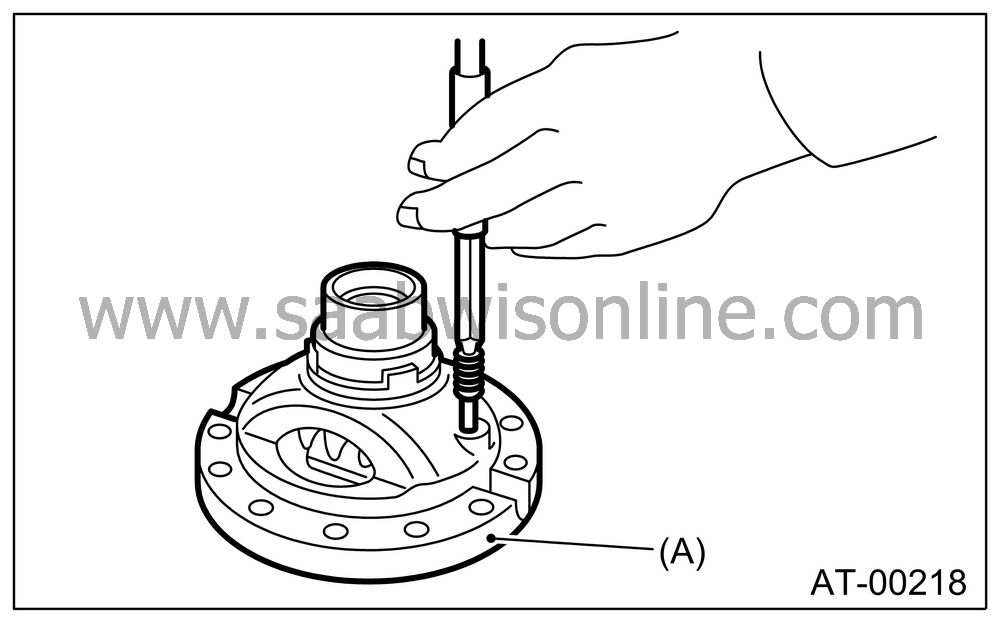

| SIDE RETAINER |

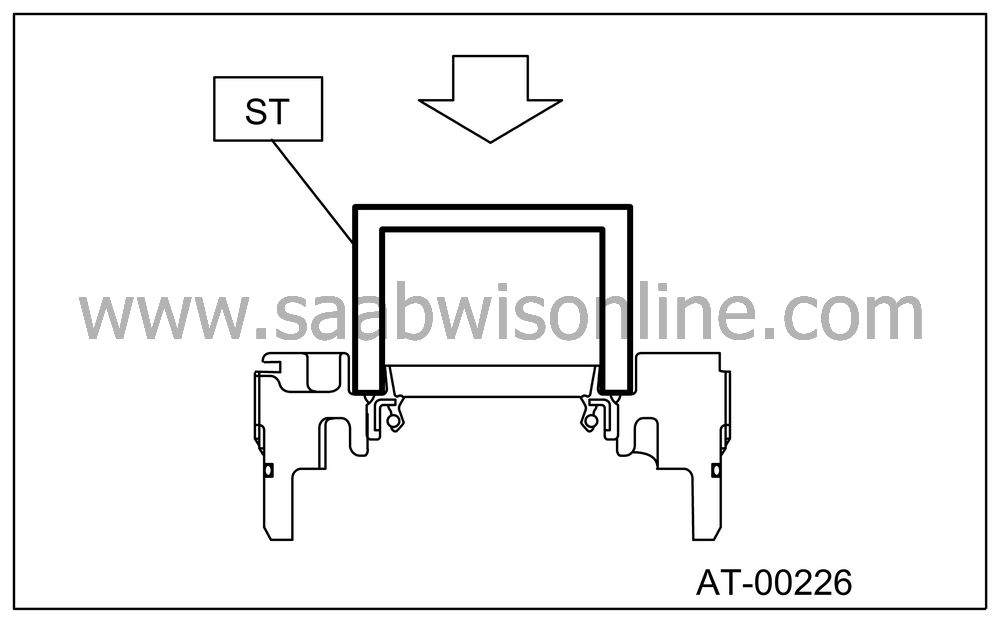

Install bearing outer race to side retainer.

Install a new oil seal using the ST and hammer.

ST 32005024 DIFFERENTIAL SIDE OIL SEAL INSTALLER

Apply gear oil to new O-ring and install it.