ADJUSTMENT

| ADJUSTMENT |

Remove drive plate and driven plate from center differential carrier.

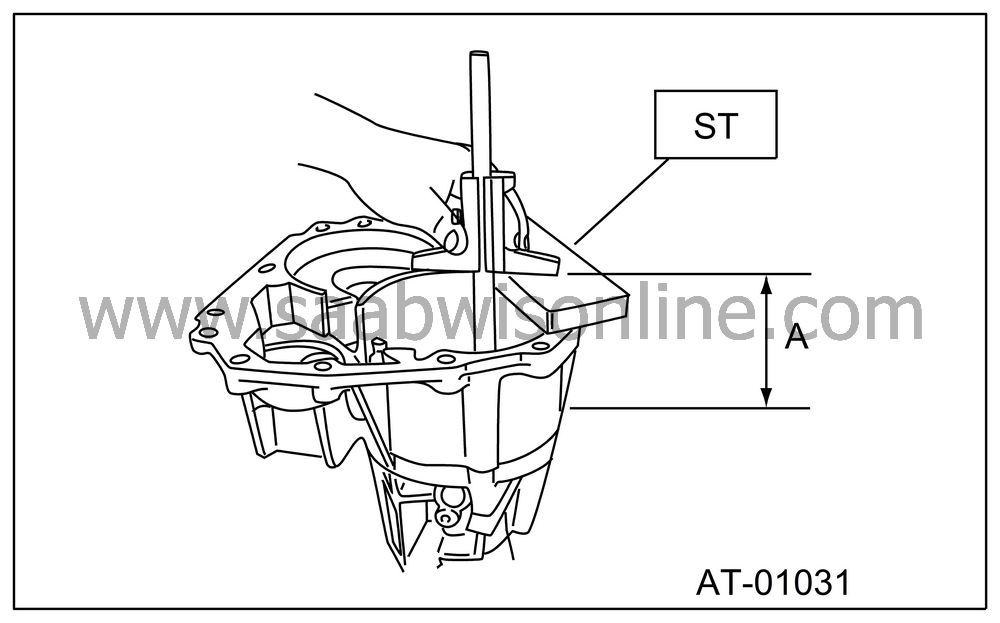

Using the special tool, measure distance “A” from extension case joining surface to multi-plate clutch (LSD) piston.

ST 32005073 GAUGE

|

A:

|

Measured

value

|

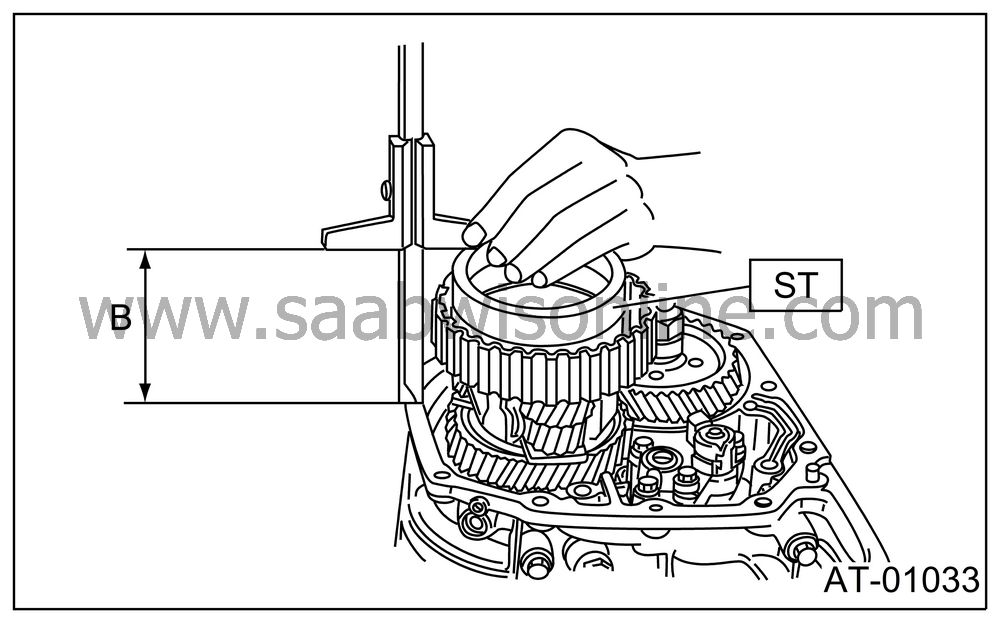

Using ST, measure height “B” from transmission case joining edge to center differential clutch drum edge.

ST 32005076 GAUGE

|

B:

|

Measured

value

|

Calculation formula

T = A − B + 0.45 mm

[T = A − B + 0.0177 in]

| Note | ||

| • |

Calculation formula for “T” is applied

when measuring using ST (32005073

GAUGE, 32005076 GAUGE). When not using

ST, apply

T = (A − α + 0.45 mm) − (B − β) [T = (A − α + 0.0177 in) − (B − β)]. T: Thrust needle bearing thickness A: Distance from end of extension case to end of reduction drive shaft B: Distance from end of transmission case to end of rear drive shaft α: Collar thickness used when measuring “A” β: Collar thickness used when measuring “B” 0.45: Gasket thickness (mm) |

|

| • |

Measure multi-plate clutch (LSD) driven and drive plate

thickness to find the clearance between measurement value and “T”.

|

|

Standard value:

0.2 — 0.6 mm (0.008 — 0.024 in)

Limit value:

1.6 mm (0.063 in)

If outside the standard value, replace the plate set (drive and driven plate). Select a multi-plate clutch (LSD) piston side adjustment plate that will bring clearance within the standard value.

|

Obtainable driven plate

|

|

|

Part

No.

|

Thickness

mm (in)

|

|

32006533

|

1.6 (0.063)

|

|

32006534

|

2.0 (0.079)

|

|

32006535

|

2.4 (0.094)

|

|

32006536

|

2.8 (0.110)

|