INSPECTION

| INSPECTION |

Check seal ring and O-ring oil seal for breaks or damage.

Check other parts for dents or abnormalities.

Selection of oil pump rotor assembly

Tip clearance

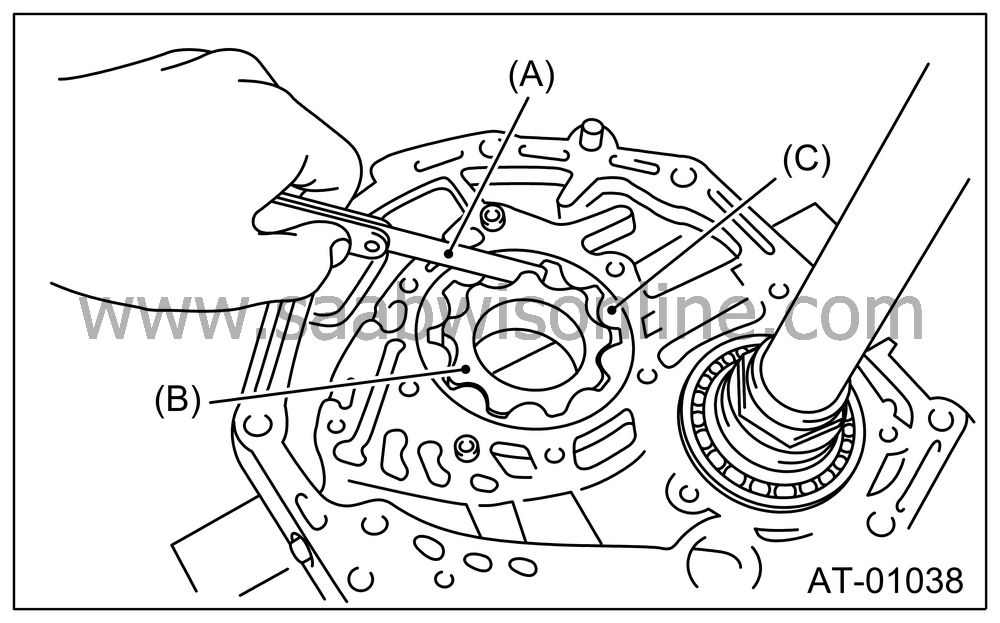

Install inner rotor and outer rotor to oil pump. With rotor gears facing each other, measure crest-to-crest clearance.

Tip clearance:

0.02 — 0.15 mm (0.0008 — 0.0059 in)

|

(A)

|

Thickness

gauge

|

|

(B)

|

Inner rotor

|

|

(C)

|

Outer rotor

|

Side clearance

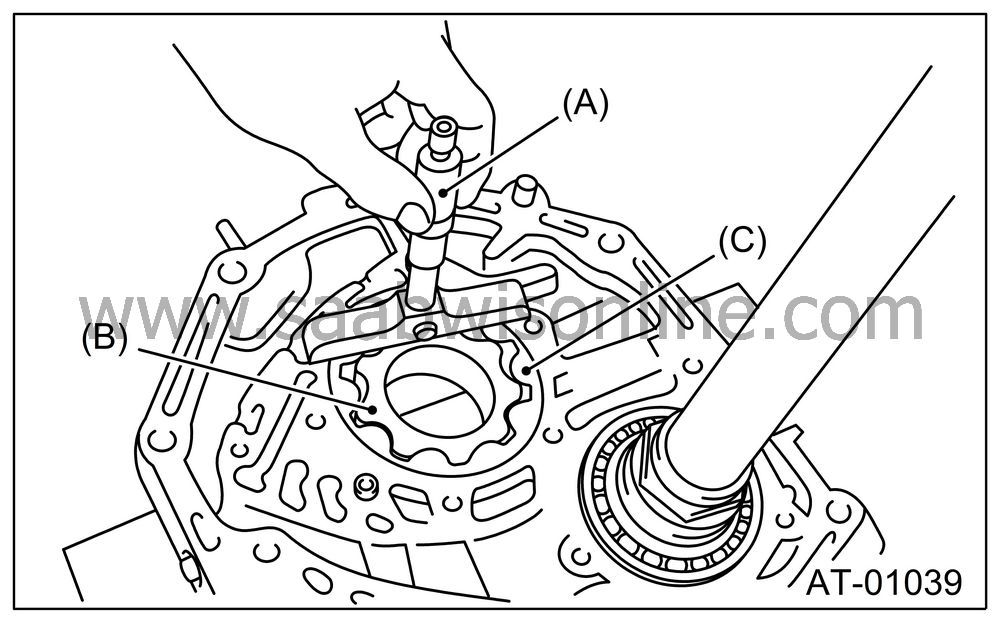

Set a depth gauge to oil pump housing, then measure oil pump housing-to-rotor clearances.

Side clearance:

0.02 — 0.04 mm (0.0008 — 0.0016 in)

|

(A)

|

Depth gauge

|

|

(B)

|

Inner rotor

|

|

(C)

|

Outer rotor

|

If depth and/or side clearances are outside specifications, replace rotor assembly.

| Oil pump rotor assembly | |

| Part No. | Thickness mm (in) |

|

32005739

|

11.37 — 11.38

(0.4476 — 0.4480)

|

|

32005740

|

11.38 — 11.39

(0.4480 — 0.4484)

|

|

32005741

|

11.39 — 11.40

(0.4484 — 0.4488)

|

Measure the total end play and adjust to within specifications.