ASSEMBLY

| ASSEMBLY |

Adjusting preload for front and rear bearings

Adjust the bearing preload with spacer and washer between front and rear bearings. Pinion height adjusting washer are not affected by this adjustment. The adjustment must be carried out without oil seal inserted.

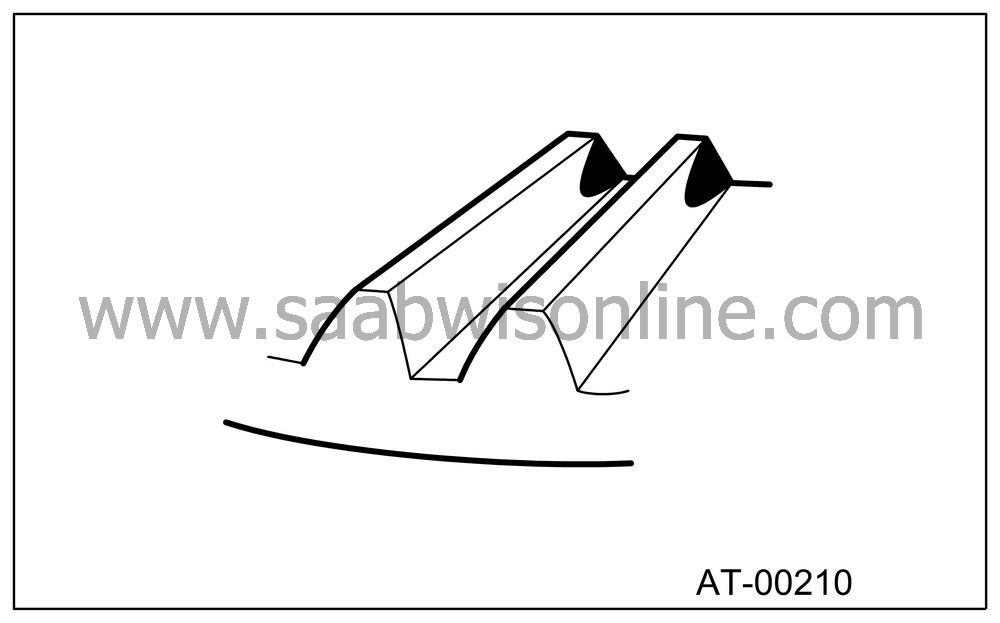

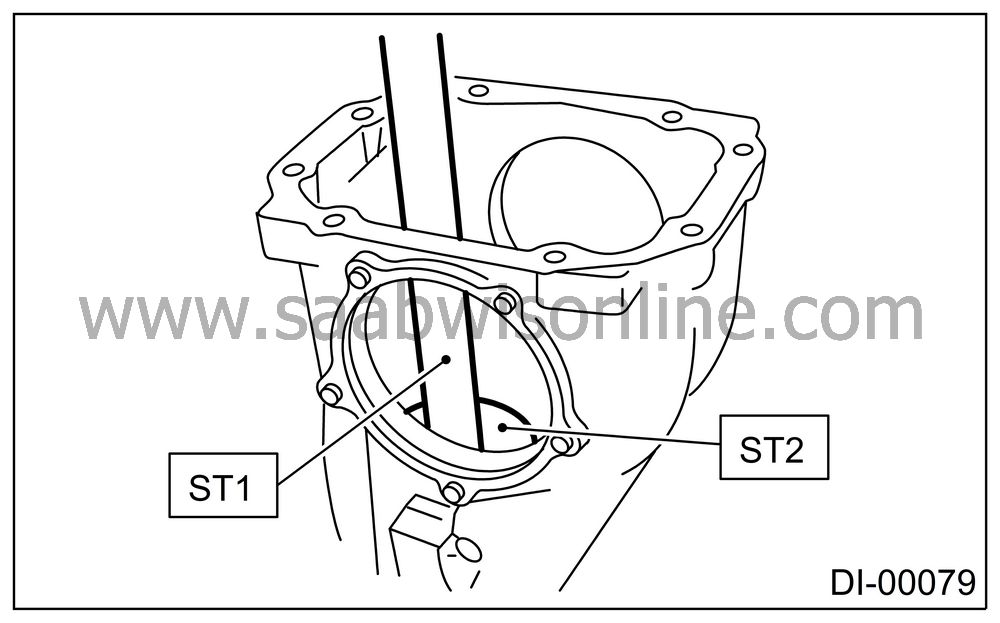

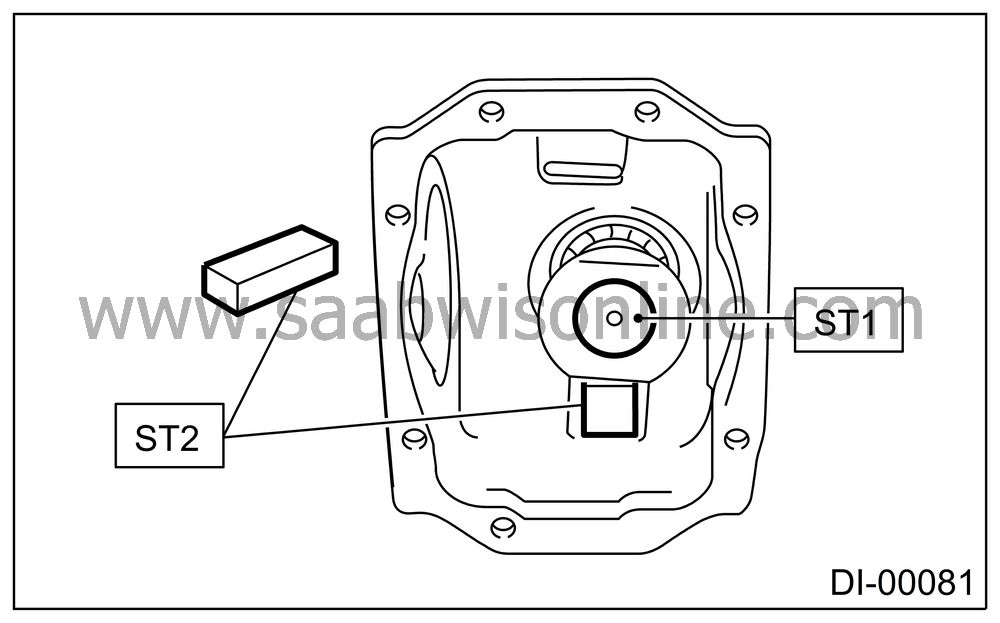

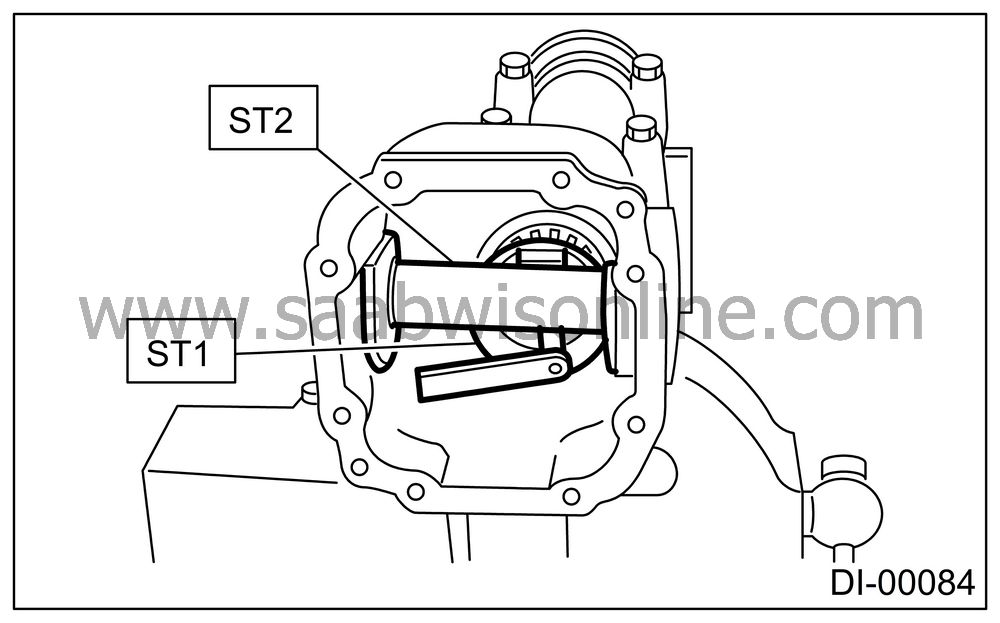

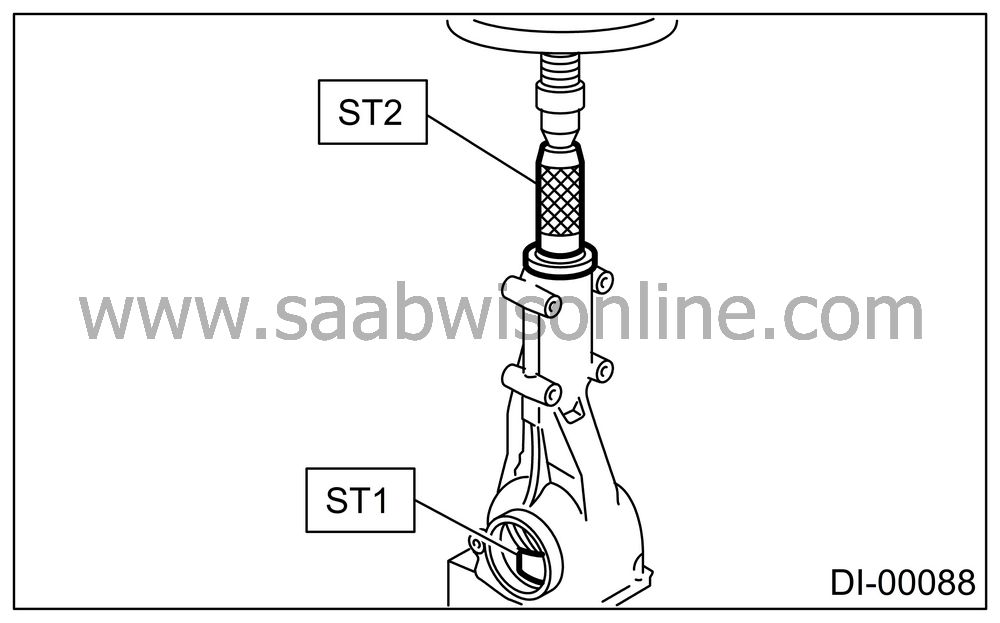

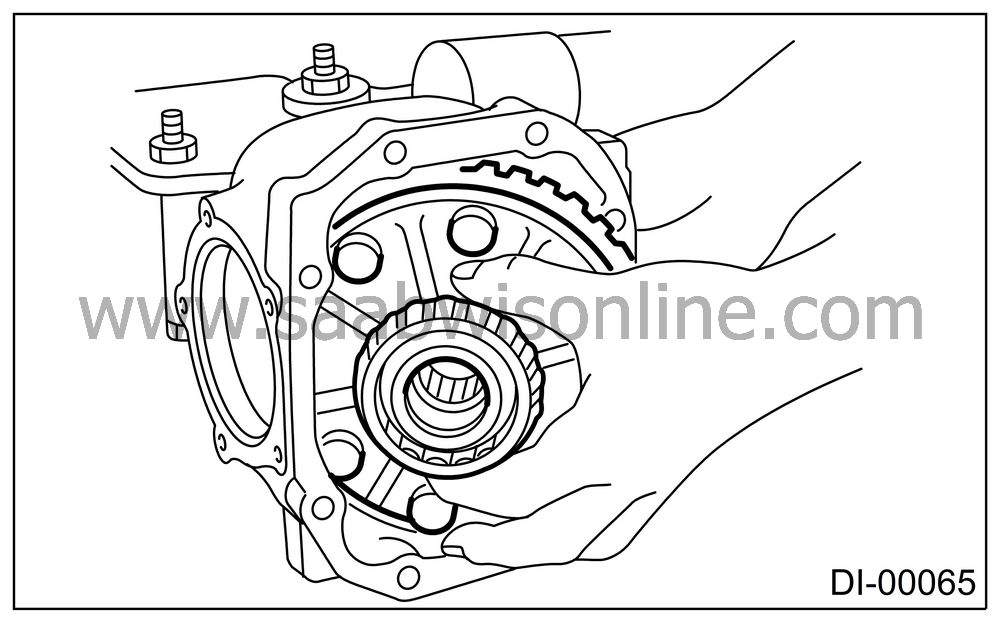

Press the rear bearing race into differential carrier using ST1 and ST2.

ST1 32005061 HANDLE

ST2 32005063 DRIFT 2

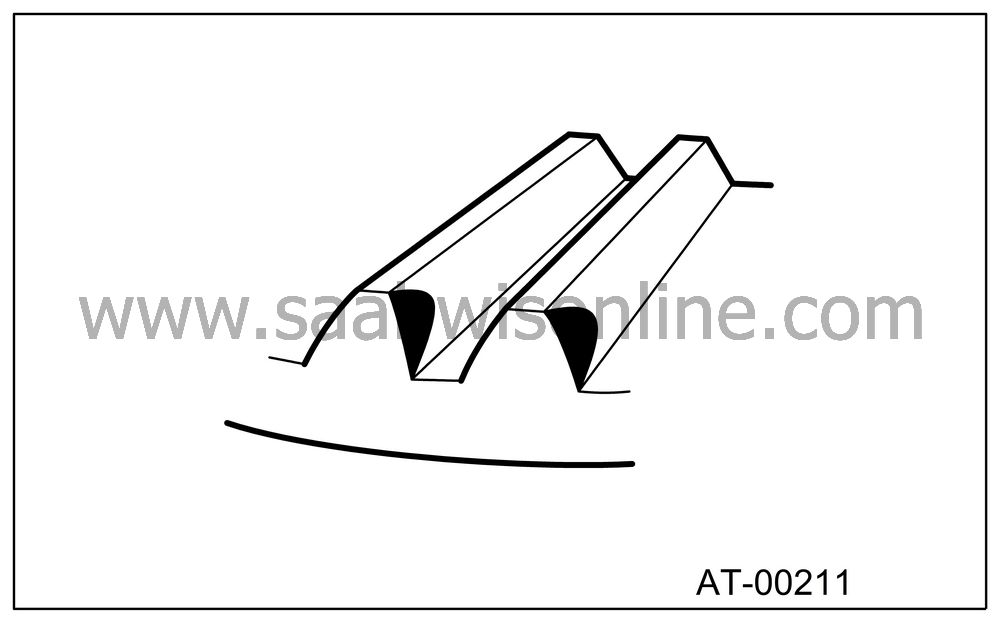

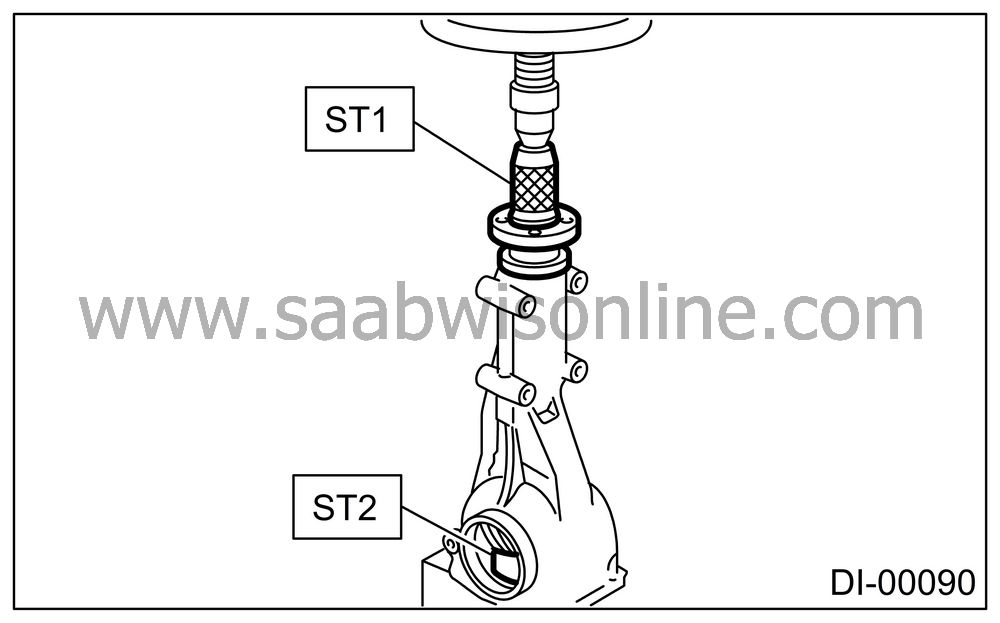

ST1 32005061 HANDLE

ST2 32005063 DRIFT 2

Insert the ST1 into carrier with pinion height adjusting washer and rear bearing cone fitted onto it.| Note | ||

| • |

If tooth contact (Drive pinion, Hypoid driven gear) is

normal in the inspection before disassembling, verify that the washer

is not deformed, and then re-use the used washer.

|

|

| • |

Use a new rear bearing cone.

|

|

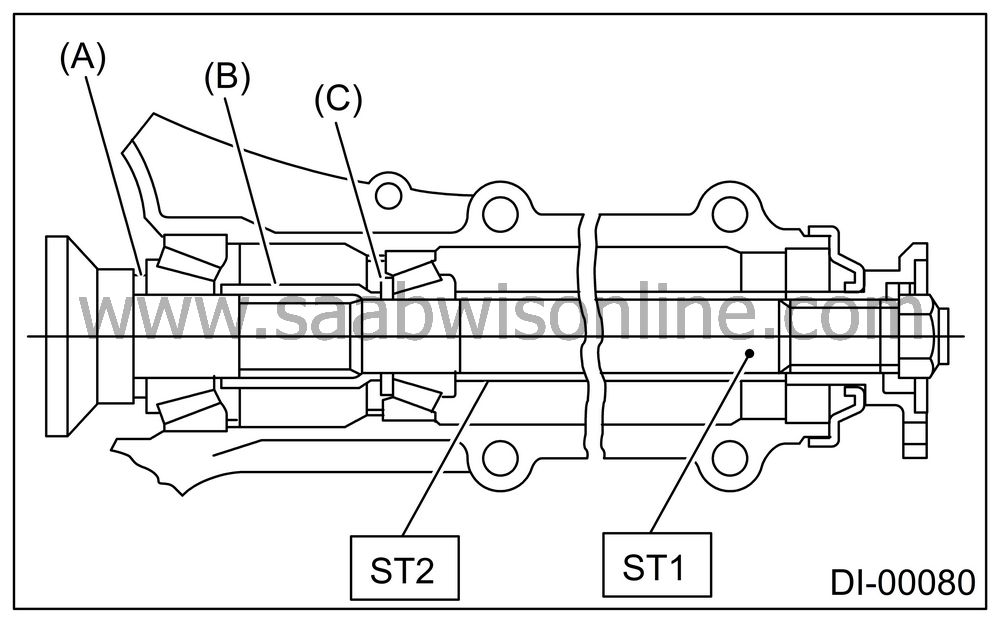

Then install the preload adjusting spacer and washer, front bearing cone, ST2, companion flange, and washer and drive pinion nut.

ST1 32005067 DUMMY SHAFT

ST2 32005068 DUMMY COLLAR

|

(A)

|

Pinion

height adjusting washer

|

|

(B)

|

Preload

adjusting spacer

|

|

(C)

|

Preload

adjusting washer

|

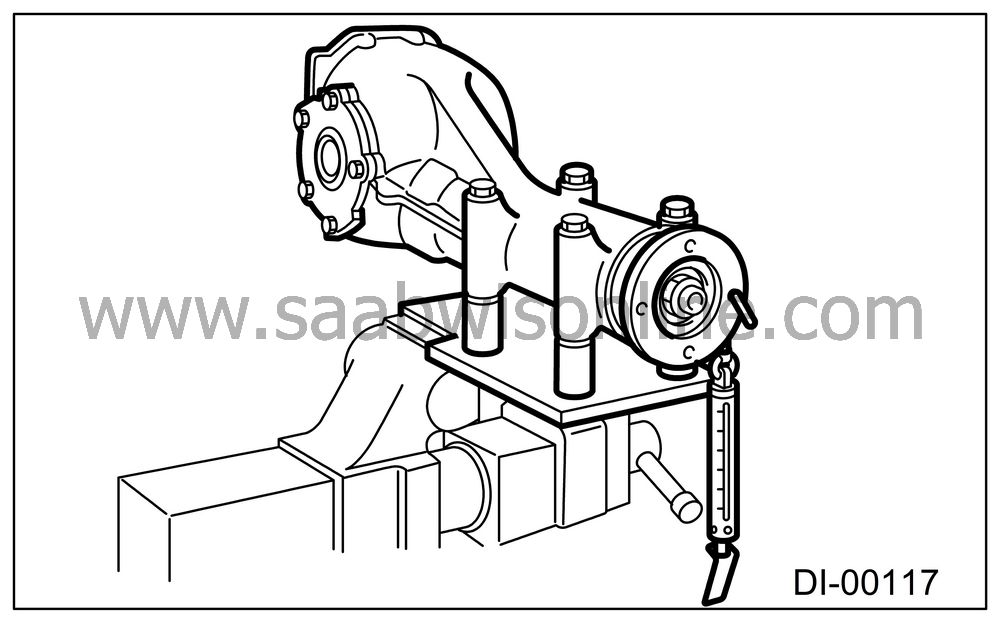

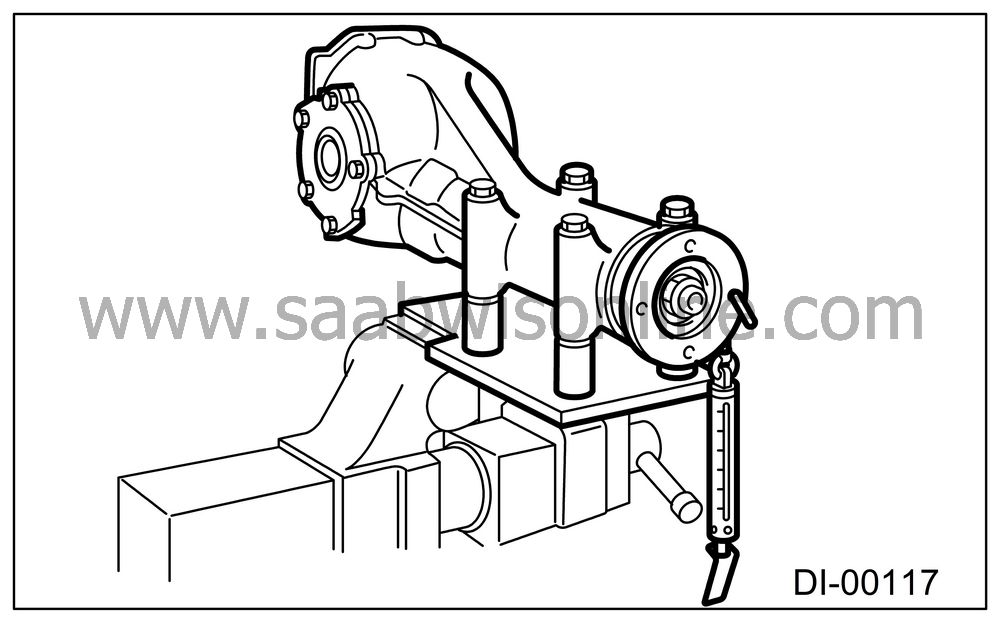

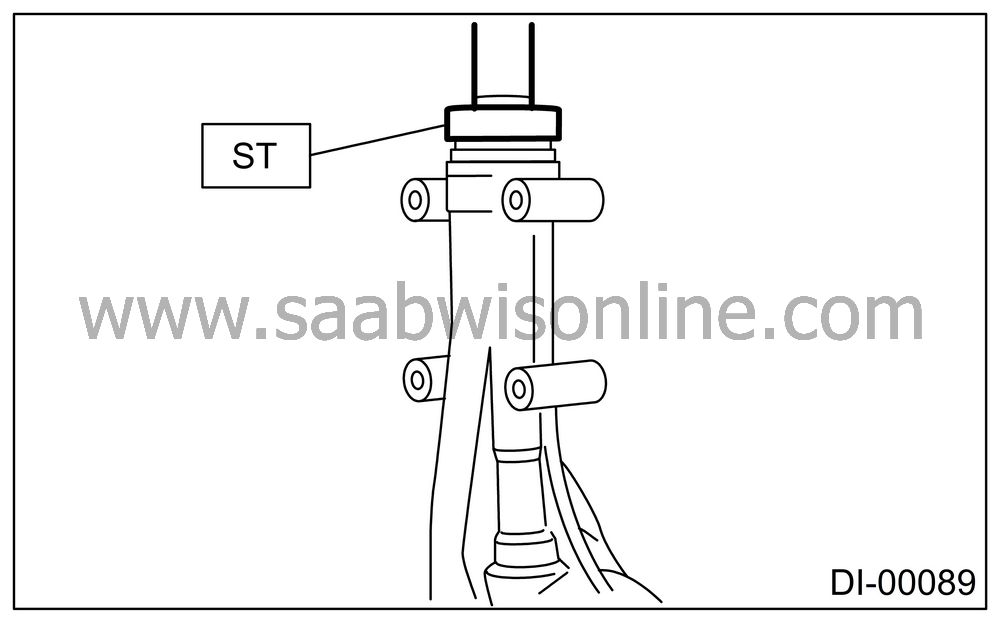

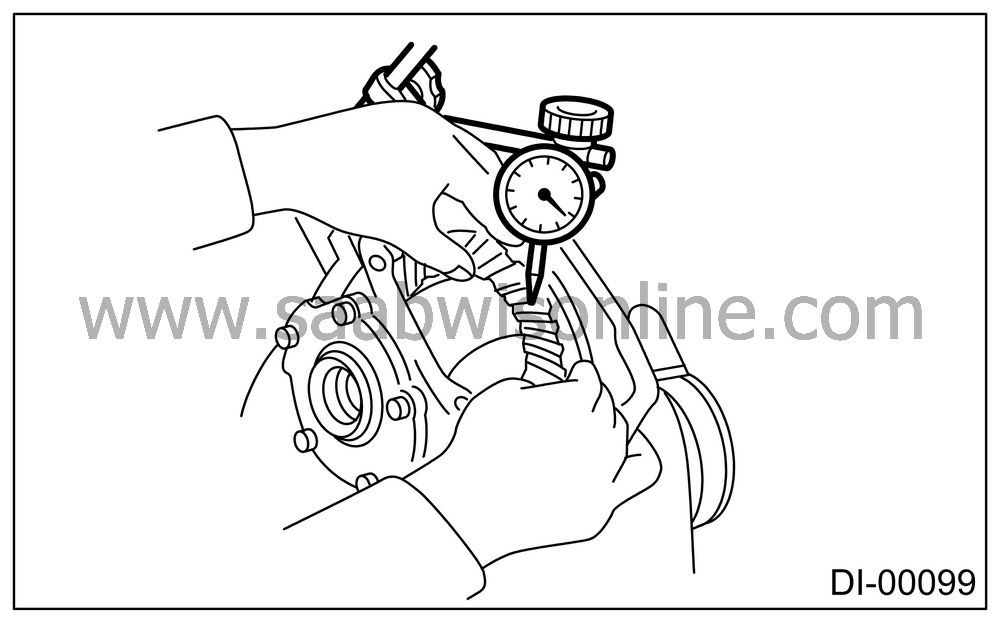

Turn the ST1 with hand to make it seated, and tighten the self-locking nut while measuring the preload with spring balance. Select the preload adjusting washer and spacer so that the specified preload is obtained when nut is tightened to the specified torque.

| Note | ||

| • |

Use a new self-locking nut.

|

|

| • |

Be careful not to give excessive preload.

|

|

| • |

When tightening the self-locking nut, lock ST1 with

ST2 as shown in the figure.

|

|

| • |

Measure the preload in direction of tangent to flange.

|

|

ST1 32005067 DUMMY SHAFT

ST2 32005069 BLOCK

Tightening torque:181 Nm (18.5 kgf-m, 134 ft-lb)

|

Drive pinion

bearing preload

|

|

18.1 — 38.8

N (1.8 — 4.0 kgf, 4.1 — 8.7 lb)

at companion flange bolt hole |

|

Preload adjusting washer

|

Part

No.

|

Thickness

mm (in) |

|

32007051

|

2.59

(0.1020)

|

|

|

32007052

|

2.57

(0.1012)

|

|

|

32007053

|

2.55

(0.1004)

|

|

|

32007054

|

2.53

(0.0996)

|

|

|

32007055

|

2.51

(0.0988)

|

|

|

32007056

|

2.49

(0.0980)

|

|

|

32007057

|

2.47

(0.0972)

|

|

|

32007058

|

2.45

(0.0965)

|

|

|

32007059

|

2.43

(0.0957)

|

|

|

32007060

|

2.41

(0.0949)

|

|

|

32007062

|

2.39

(0.0941)

|

|

|

32007063

|

2.37

(0.0933)

|

|

|

32007064

|

2.35

(0.0925)

|

|

|

32007065

|

2.33

(0.0917)

|

|

|

32007066

|

2.31

(0.0909)

|

|

|

Preload adjusting spacer

|

Part

No.

|

Length

mm (in)

|

|

32007045

|

56.2

(2.213)

|

|

|

32007046

|

56.4

(2.220)

|

|

|

32007047

|

56.6

(2.228)

|

|

|

32007048

|

56.8

(2.236)

|

|

|

32007049

|

57.0

(2.244)

|

|

|

32007050

|

57.2

(2.252)

|

Drive pinion height adjustment

Adjust the drive pinion height with shim installed between the rear bearing cone and back of pinion gear.

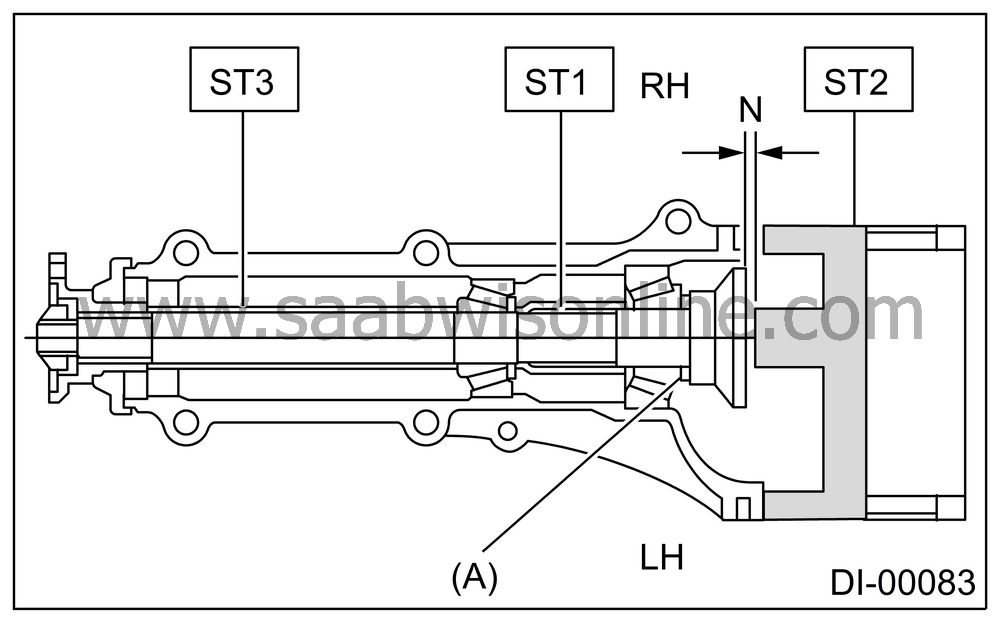

Install the ST2.

ST1 32005067 DUMMY SHAFT

ST2 32005066 DIFFERENTIAL CARRIER GAUGE

ST3 32005068 DUMMY COLLAR

| Note | ||

|

At this time, install a pinion height adjusting washer which is temporarily selected or the same as that used before. Measure and record the thickness. |

|

(A)

|

Pinion

height adjusting washer

|

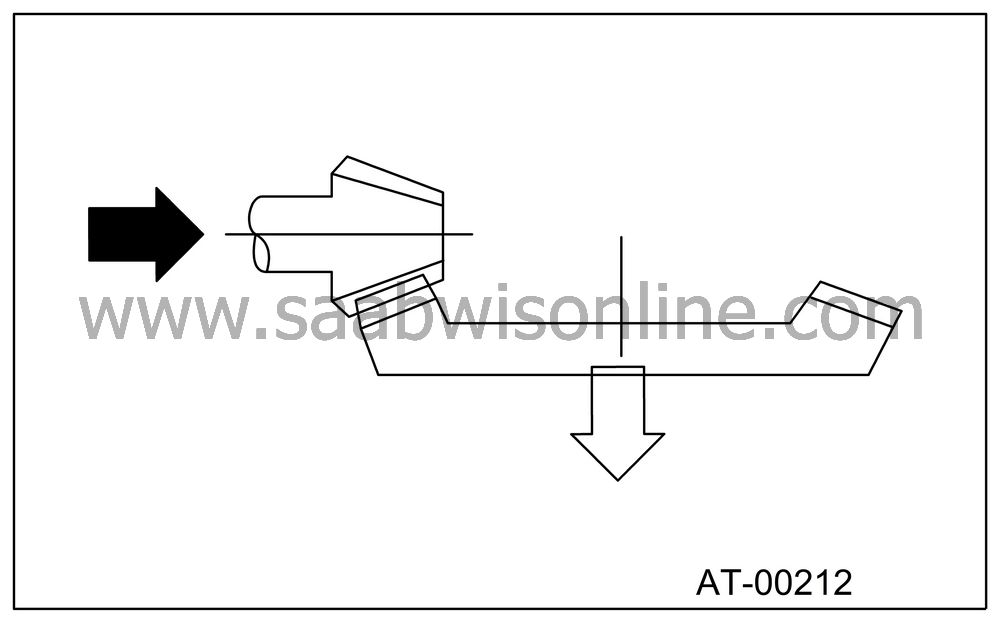

Measure the clearance N between the end of ST2 and end surface of ST1 by using a thickness gauge.

| Note | ||

|

Make sure there is no clearance between the case and ST2. |

ST1 32005067 DUMMY SHAFT

ST2 32005066 DIFFERENTIAL CARRIER GAUGE

Obtain the thickness of pinion height adjusting washer to be inserted from the following formula, and replace the temporarily installed shim with this one.

T = To + N − (H × 0.01) − 0.20 mm (0.0079 in)

| Note | ||

|

Use copies of this page. |

|

T

|

Thickness

of pinion height adjusting shim mm (in)

|

|

|

To

|

Thickness

of washer temporarily inserted mm (in)

|

|

|

N

|

Reading

of thickness gauge mm (in)

|

|

|

H

|

Figure

marked on drive pinion head

|

|

|

Memo:

|

||

(Example of calculation)

To = 2.20 + 1.20 = 3.40 mm

N = 0.23 mm

H = + 1

T = 3.40 + 0.23 − 0.01 − 0.20 = 3.42

Result: Thickness = 3.42 mm

Therefore use the washer 32007036.

| Pinion height adjusting washer | |

| Part No. | Thickness mm (in) |

|

32007021

|

3.09

(0.1217)

|

|

32007022

|

3.12

(0.1228)

|

|

32007023

|

3.15

(0.1240)

|

|

32007024

|

3.18

(0.1252)

|

|

32007026

|

3.21

(0.1264)

|

|

32007028

|

3.24

(0.1276)

|

|

32007029

|

3.27

(0.1287)

|

|

32007030

|

3.30

(0.1299)

|

|

32007031

|

3.33

(0.1311)

|

|

32007033

|

3.36

(0.1323)

|

|

32007035

|

3.39

(0.1335)

|

|

32007036

|

3.42

(0.1346)

|

|

32007037

|

3.45

(0.1358)

|

|

32007038

|

3.48

(0.1370)

|

|

32007039

|

3.51

(0.1382)

|

|

32007040

|

3.54

(0.1394)

|

|

32007041

|

3.57

(0.1406)

|

|

32007042

|

3.60

(0.1417)

|

|

32007043

|

3.63

(0.1429)

|

|

32007044

|

3.66

(0.1441)

|

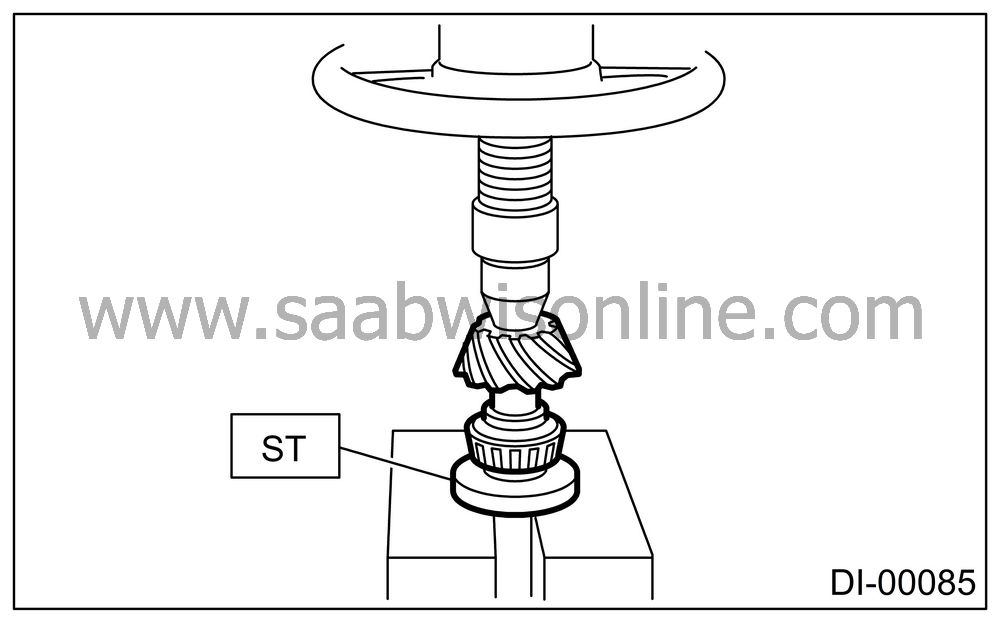

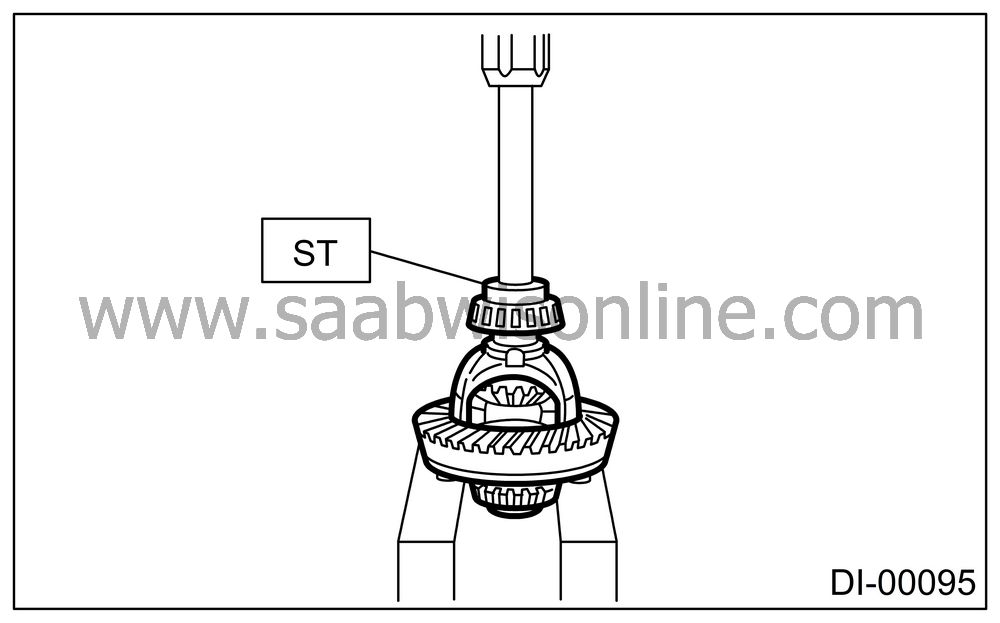

Install the selected pinion height adjusting washer on drive pinion, and press the rear bearing cone into position with ST.

ST 32005054 INSTALLER

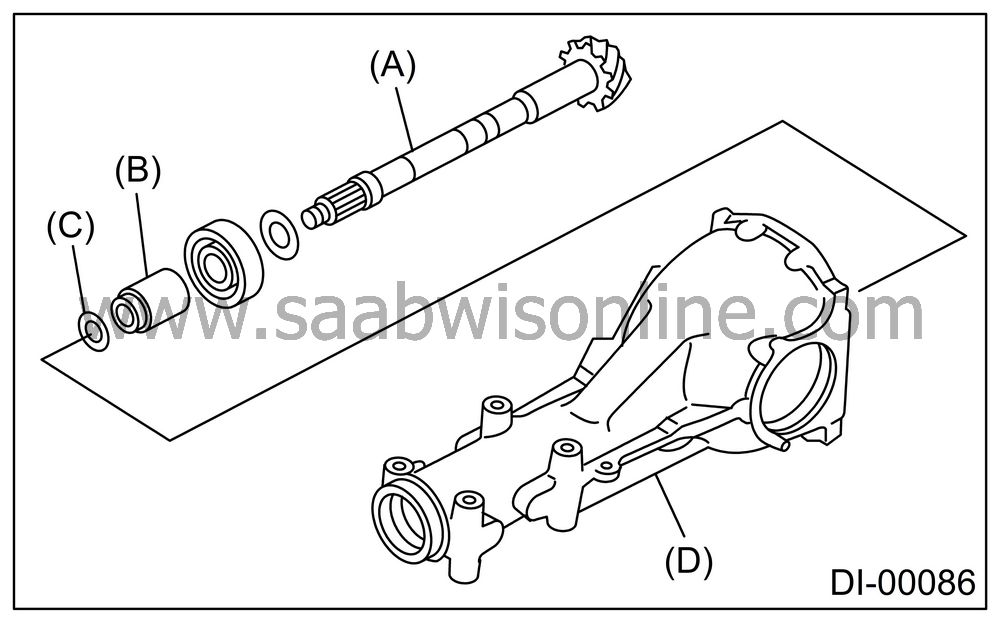

Insert the drive pinion into differential carrier, install the previously selected bearing preload adjusting spacer and washer.

|

(A)

|

Drive pinion

|

|

(B)

|

Bearing

adjusting spacer

|

|

(C)

|

Washer

|

|

(D)

|

Differential

carrier

|

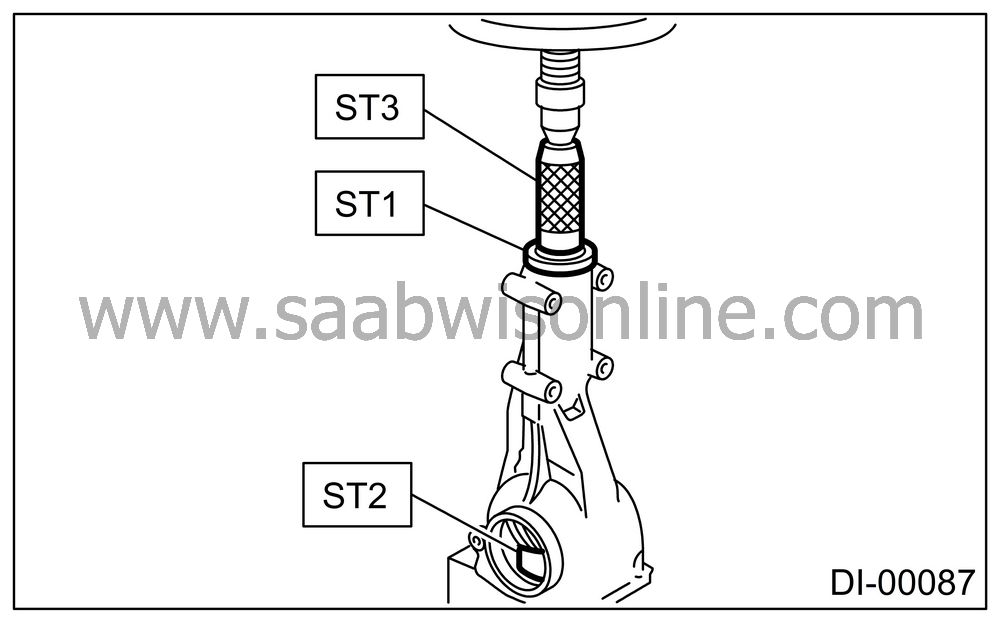

Press-fit the front bearing cone into case with ST1, ST2 and ST3.

ST1 32005068 DUMMY COLLAR

ST2 32005081 WEIGHT

ST3 32005175 INSTALLER

Insert the spacer, then press-fit the pilot bearing with ST1 and ST2.

ST1 32005081 WEIGHT

ST2 32005175 INSTALLER

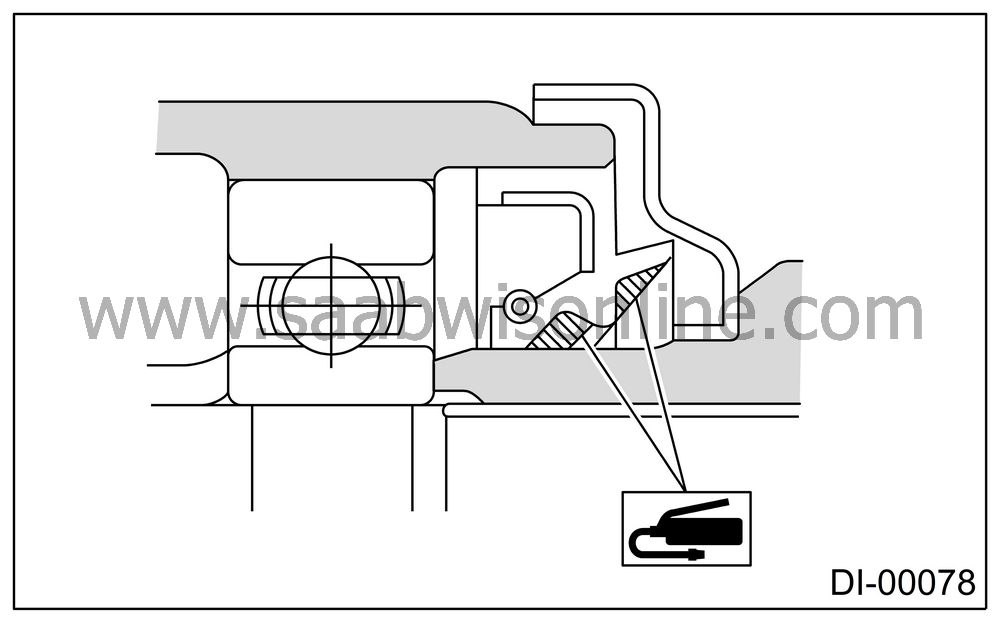

Fit a new oil seal with ST.

| Note | ||

| • |

Press-fit until the end of oil seal is 1 mm (0.04 in) inward

from end of carrier.

|

|

| • |

Apply grease between the oil seal lips.

|

|

ST 32005104 INSTALLER

Press-fit the companion flange with ST1 and ST2.

| Note | ||

|

Be careful not to damage the bearing. |

ST1 32005179 INSTALLER

ST2 32005081 WEIGHT

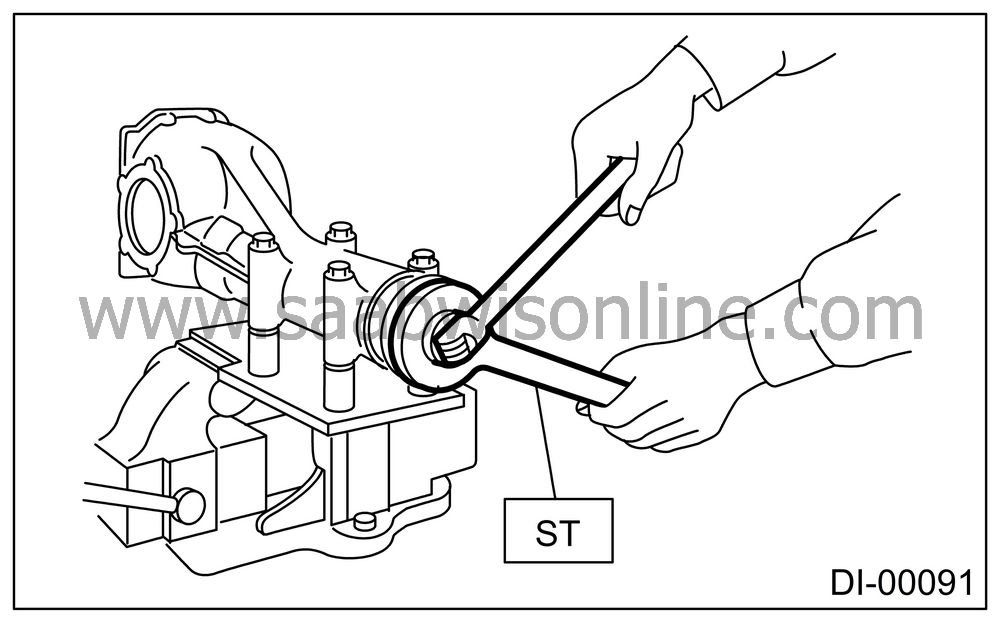

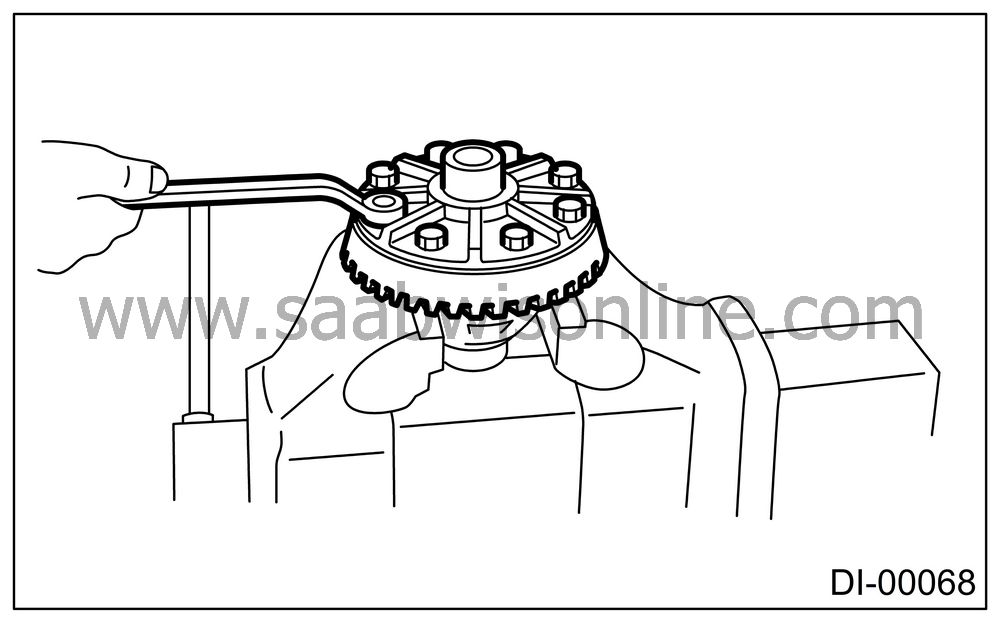

Install a new self-locking nut. Then tighten it with the ST.

ST 32005101 FLANGE WRENCH

Tightening torque:181 Nm (18.5 kgf-m, 134 ft-lb)

Assembling differential case

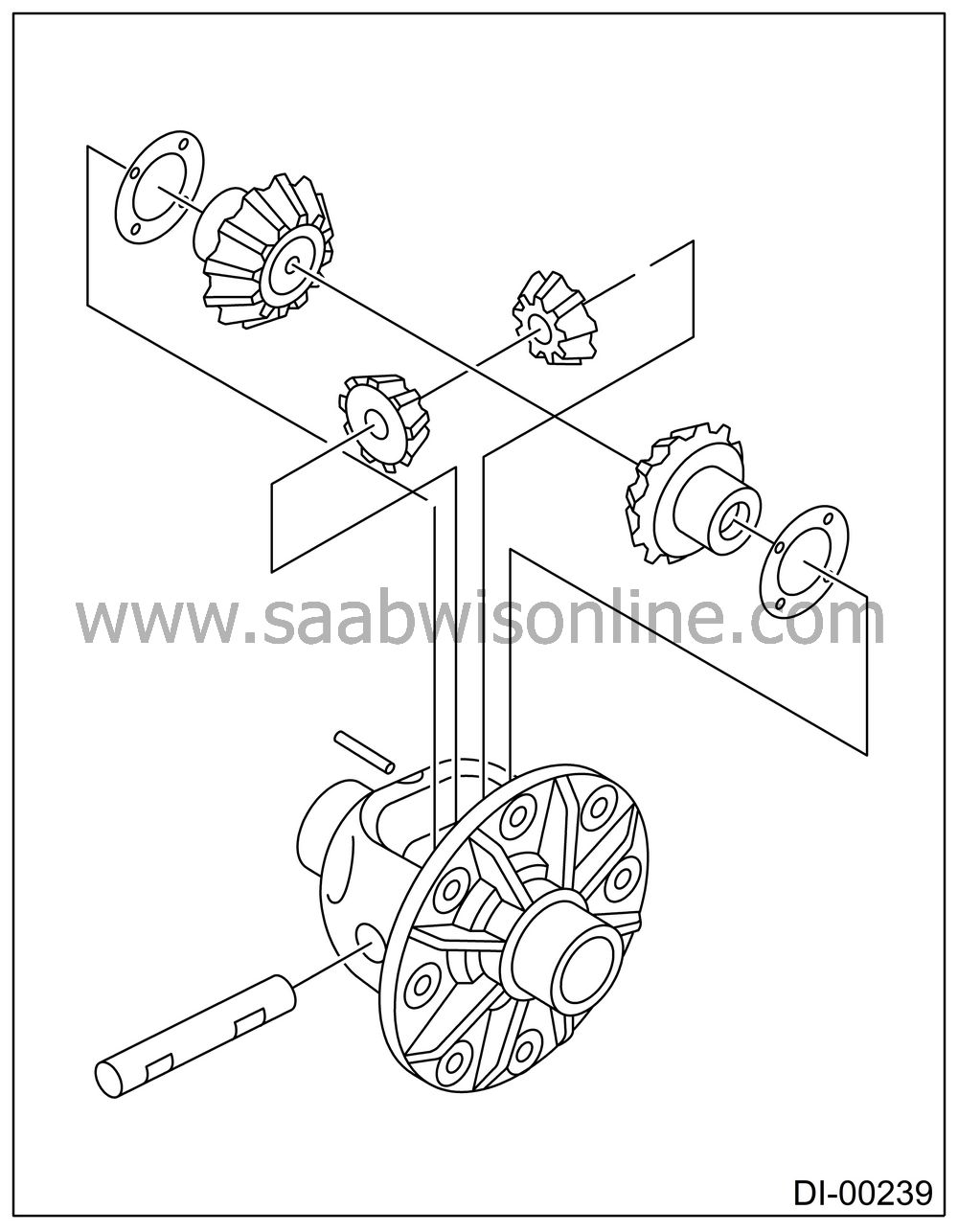

Install the side gears and pinion mate gears, with their thrust washers and pinion mate shaft, into differential case. (Model without LSD)

| Note | ||

| • |

Apply gear oil on both sides

of the washer and on the side gear shaft before installing.

|

|

| • |

Insert the pinion mate shaft into the differential case

by aligning the lock pin holes.

|

|

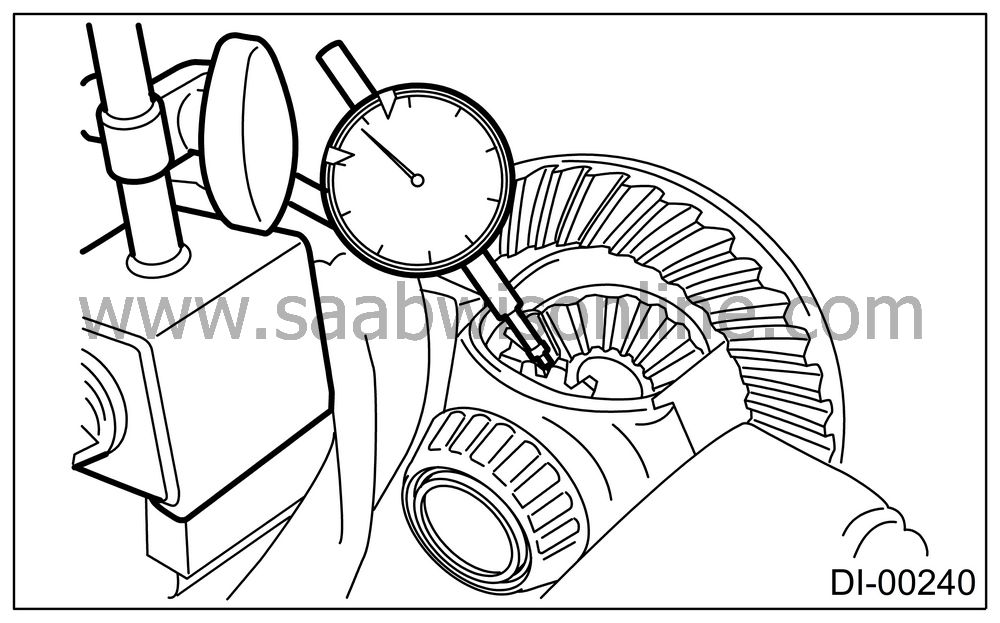

Measure the side gear backlash.

Side gear backlash:

0.10 — 0.20 mm (0.0039 — 0.0079 in)

Adjust the backlash as specified by selecting the side gear thrust washer.

|

Side gear thrust washer

|

|

|

Part

No.

|

Thickness

mm (in)

|

|

32007010

|

0.75 — 0.80

(0.0295 — 0.0315)

|

|

32007011

|

0.80 — 0.85

(0.0315 — 0.0335)

|

|

32007012

|

0.85 — 0.90

(0.0335 — 0.0354)

|

Check the condition of rotation after applying oil to the gear tooth surfaces and thrust surfaces.

After inserting the pinion shaft lock pin into differential case, stake both sides of the hole to prevent pin from falling off.

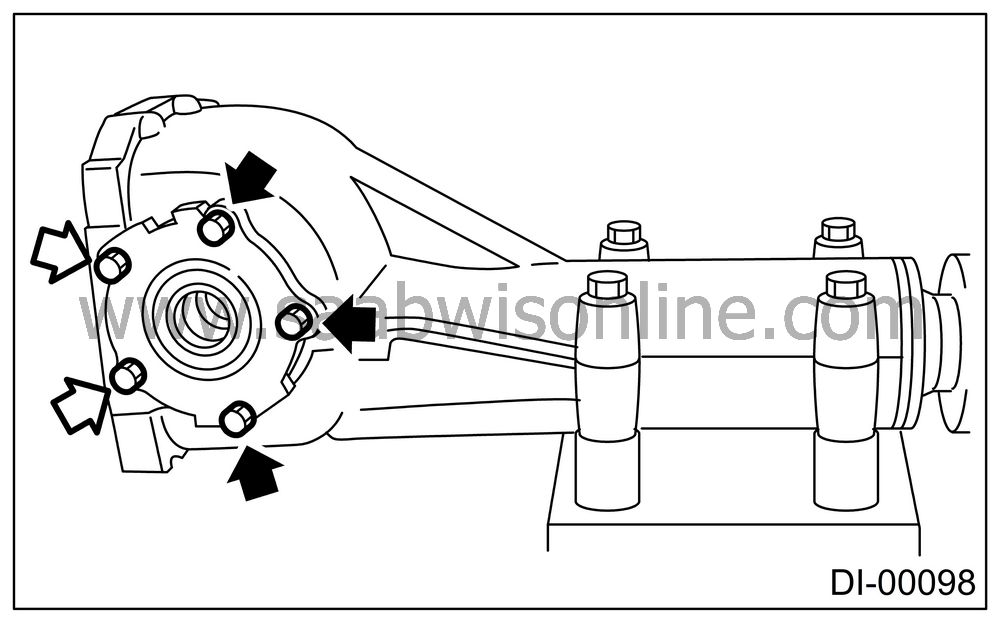

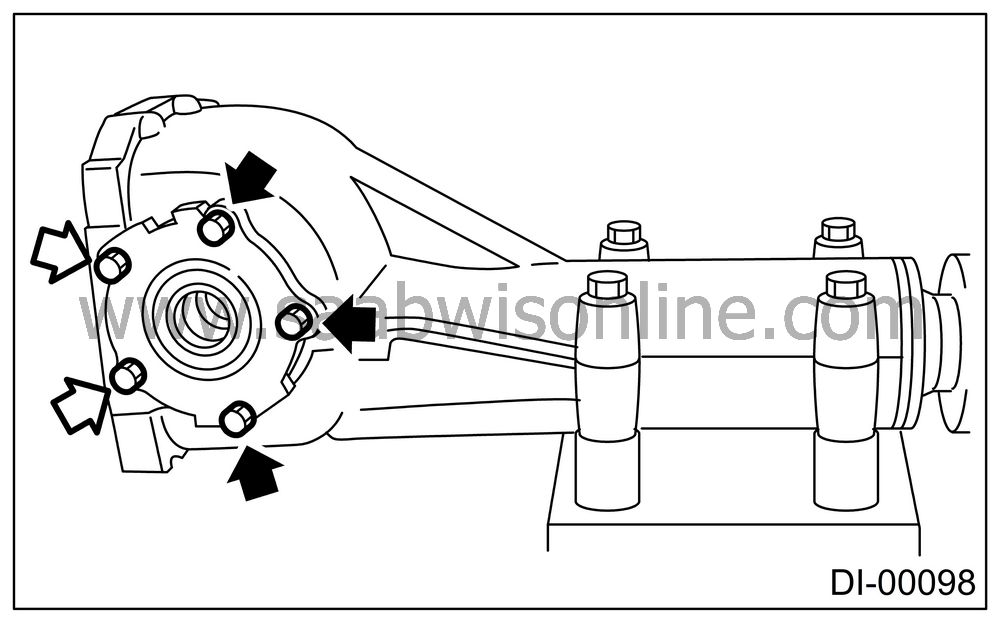

Install the hypoid driven gear on differential case.

| Note | ||

|

Before installing the bolts, apply Lock Tite to bolt threads. |

Lock Tite:

THREE BOND 1324 (Part No. 32005016) or equivalent

| Note | ||

|

Tighten diagonally while tapping the bolt heads. |

Tightening torque:

105 Nm (10.7 kgf-m, 77.4 ft-lb)

Press the side bearing into differential case using ST.

ST 32005057 DRIFT

Press the side bearing cone into side bearing retainer using ST.

ST 32005064 DRIFT

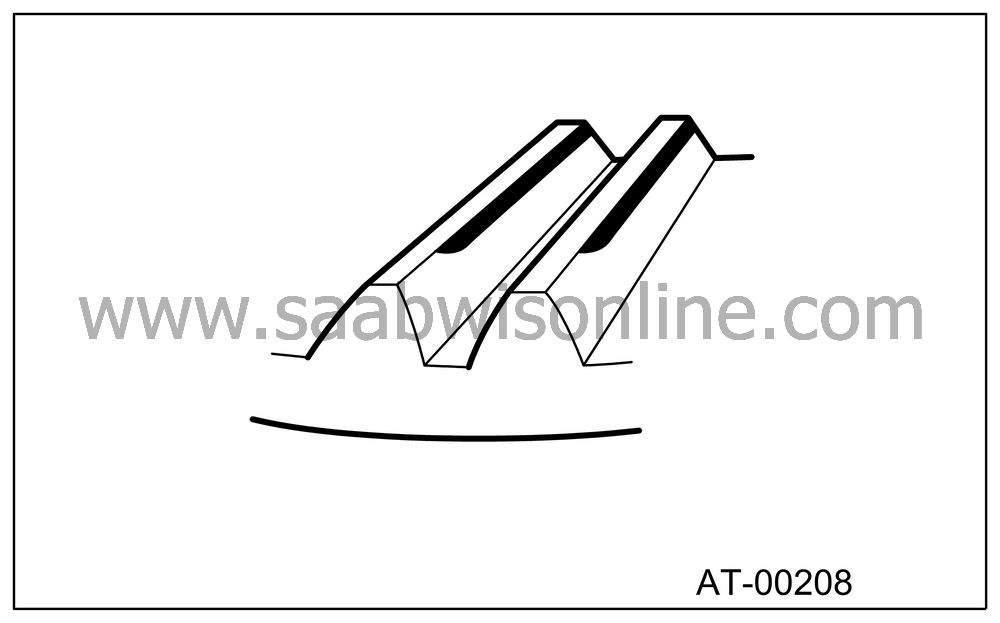

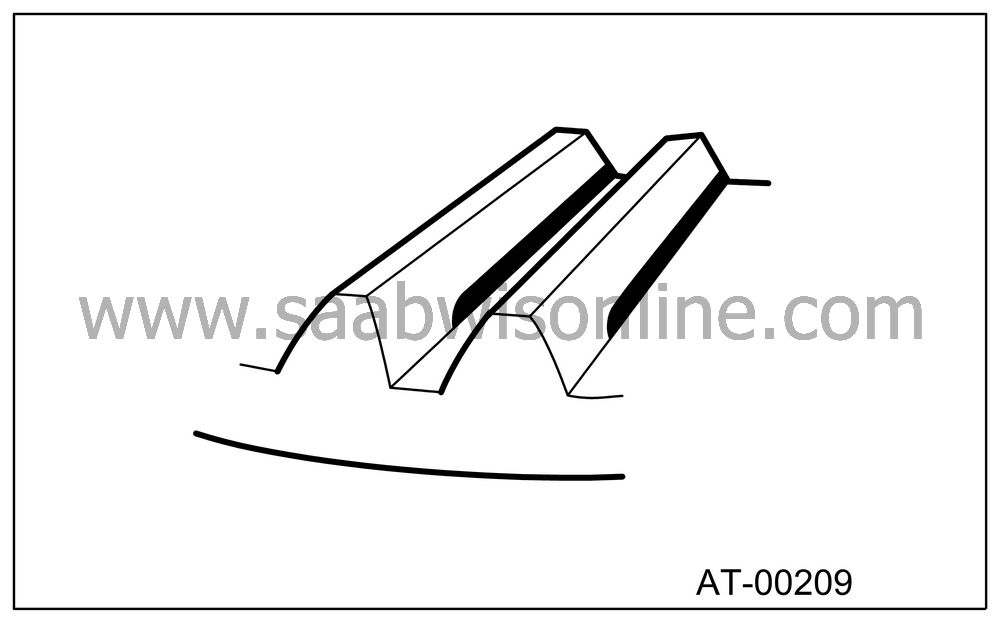

Adjusting side bearing retainer shimsThe driven gear backlash and side bearing preload can be determined by the side bearing retainer shim thickness.

Install the differential case assembly into differential carrier in the reverse order of disassembly.

Install the side retainer shims to the right and left retainers from which they were removed.

| Note | ||

|

Replace the broken or corroded side retainer shim with a new one of same thickness. |

|

Side bearing retainer shim

|

|

|

Part

No.

|

Thickness

mm (in)

|

|

32007015

|

0.20

(0.0079)

|

|

32007016

|

0.25

(0.0098)

|

|

32007017

|

0.30

(0.0118)

|

|

32007018

|

0.40

(0.0157)

|

|

32007019

|

0.50

(0.0197)

|

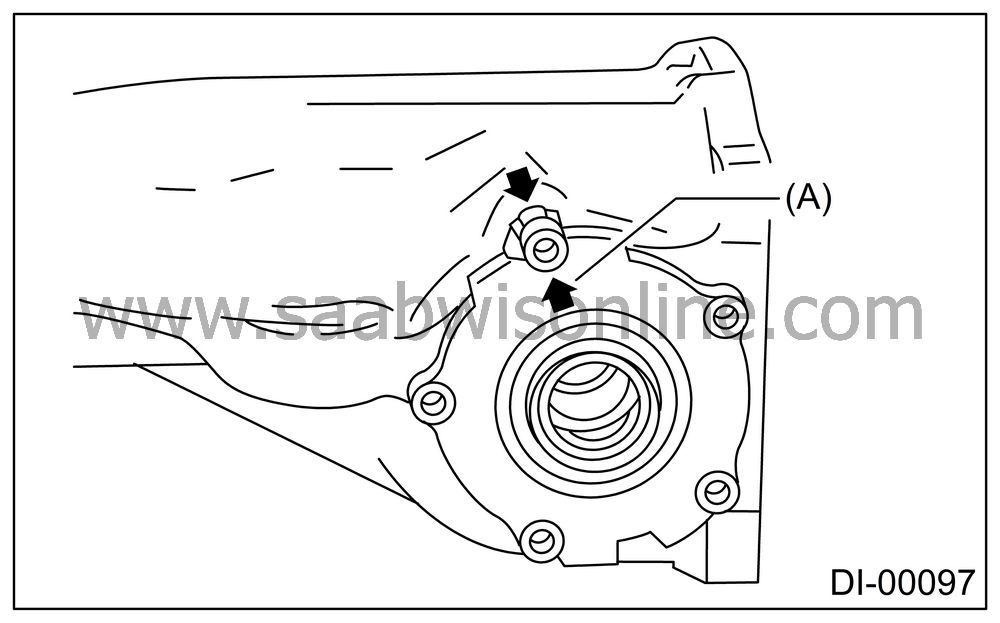

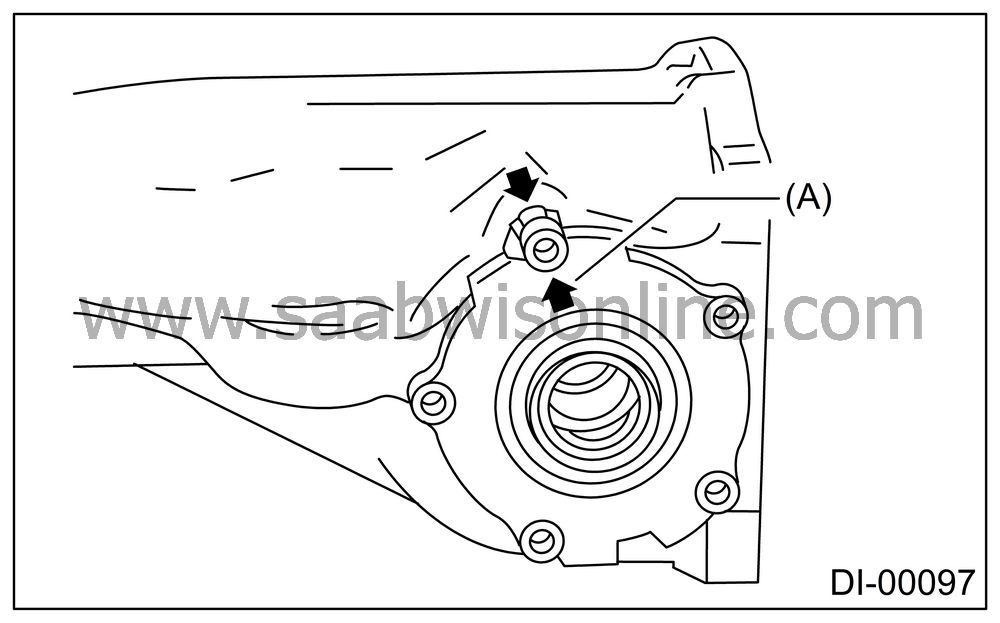

Align the arrow mark on differential carrier with the mark on side retainer during installation.

| Note | ||

|

Be careful that side bearing outer race is not damaged by bearing roller. |

|

(A)

|

Arrow mark

|

Tighten the side bearing retainer bolts.

| Note | ||

|

Before tightening the two side bearing retainer bolts, apply Lock Tite to bolt threads. |

Lock Tite:

THREE BOND 1105 (Part No.32005014) or equivalent

Tightening torque:

10.3 Nm (1.05 kgf-m, 7.6 ft-lb)

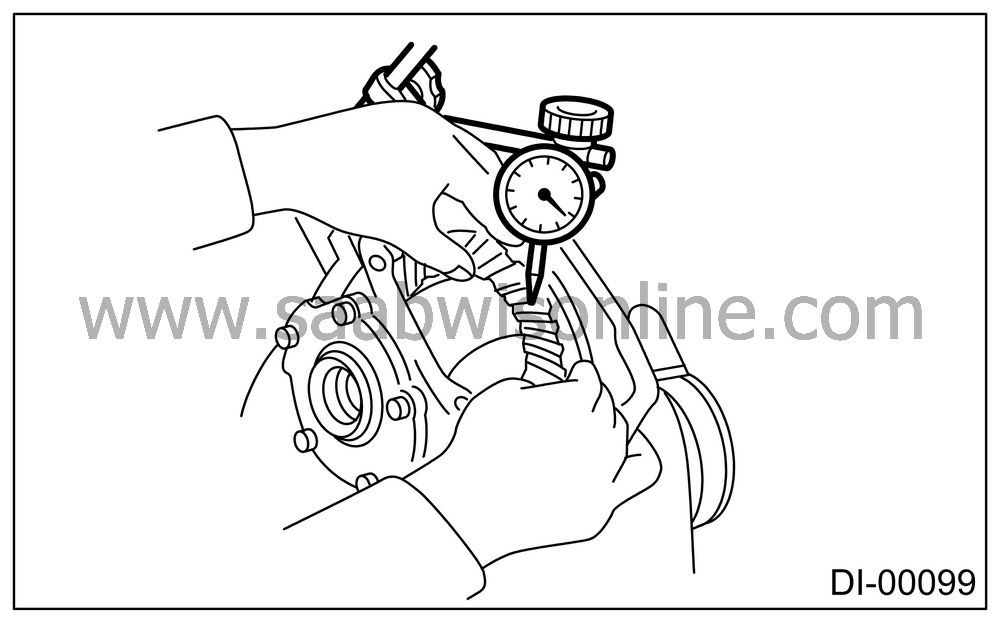

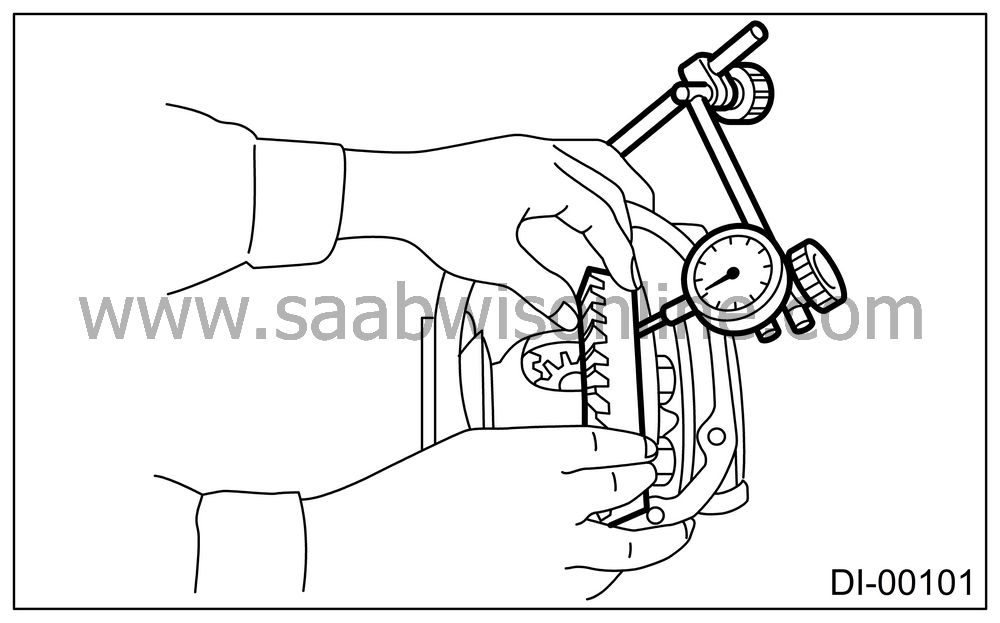

Measure the hypoid driven gear-to-drive pinion backlash. Set the magnet base on differential carrier. Align the contact point of dial gauge with tooth face of hypoid driven gear, and move the hypoid driven gear while holding drive pinion still. Read the value indicated on dial gauge.

Backlash:

0.10 — 0.20 mm (0.0039 — 0.0079 in)

At the same time, measure the total preload of drive pinion. Compared with the resistance when differential case is not installed, if the total preload is not within specification, adjust the thickness of side bearing retainer shims, increasing/reducing by an even amount at a time.

Total preload:

20.7 — 54.4 N (2.1 — 5.5 kgf, 4.7 — 12.2 lb)

Re-check the hypoid driven gear-to-pinion backlash.

Backlash:

0.10 — 0.20 mm (0.0039 — 0.0079 in)

Check the hypoid driven gear runout on its back surface, and make sure that pinion and hypoid driven gear rotate smoothly.

Limit of runout:

Less than 0.05 mm (0.0020 in)

Checking and adjusting tooth contact of hypoid driven gear

Apply an even coat of red lead on both sides of three or four teeth on the hypoid driven gear. Check the contact pattern after rotating the hypoid driven gear several revolutions back and forth until a definite contact pattern appears on the hypoid driven gear.

When the contact pattern is incorrect, readjust according to the instructions given in “TOOTH CONTACT PATTERN”.

| Note | ||

|

Be sure to wipe off red lead completely after adjustment is completed. |

| • |

Correct

tooth contact

Checking item: Tooth contact pattern is slightly shifted toward to toe side under no-load rotation. (When loaded, contact pattern moves toward heel)

|

|||||

If proper tooth contact is not obtained, once again adjust the drive pinion height by changing RH and LH side bearing retainer shims and the hypoid gear backlash.

Remove the side bearing retainers on right and left side.

Install new O-rings to side bearing retainers on right and left side.

Install the oil seals to side bearing retainers on right and left side.

Align the arrow mark on differential carrier with the mark on side retainer during installation.

|

(A)

|

Arrow mark

|

Tighten the side bearing retainer bolts.

Lock Tite:

THREE BOND 1105 (Part No. 32005014) or equivalent

Tightening torque:

10.3 Nm (1.05 kgf-m, 7.6 ft-lb)

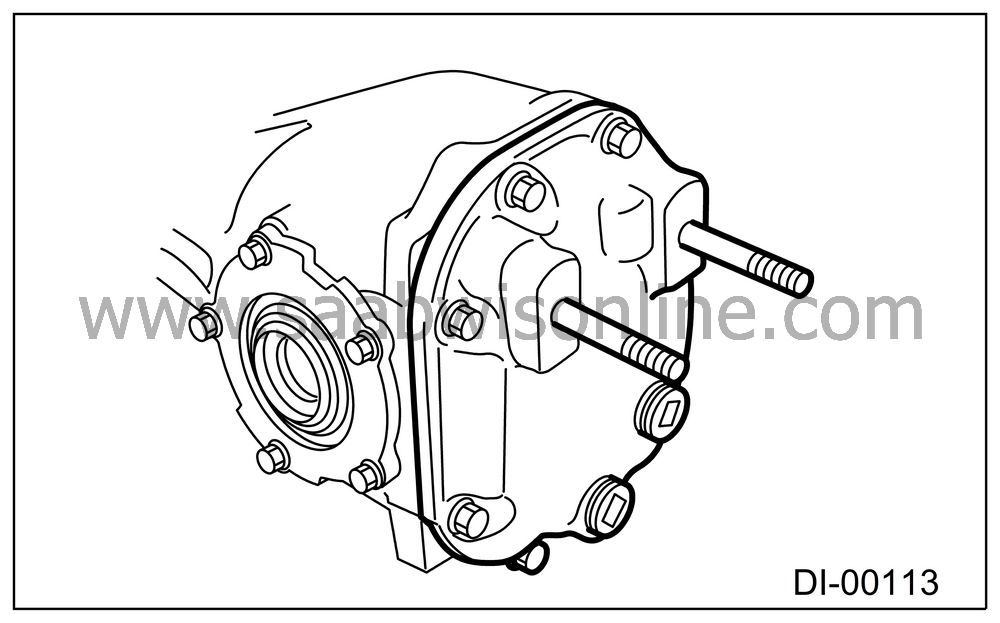

Install the new gasket and rear cover and tighten the bolts to specified torque.

Tightening torque:

29 Nm (3.0 kgf-m, 21.7 ft-lb)

Install the breather cap.

Install the drain plug and filler plug.

Tightening torque:

49 Nm (5.0 kgf-m, 36.2 ft-lb)