ASSEMBLY

| ASSEMBLY |

| Note | ||

|

Use specified grease. |

EBJ side:

NTG2218-M (Part No. 32005039)

PTJ side:

NSG301 (Part No. 32009556)

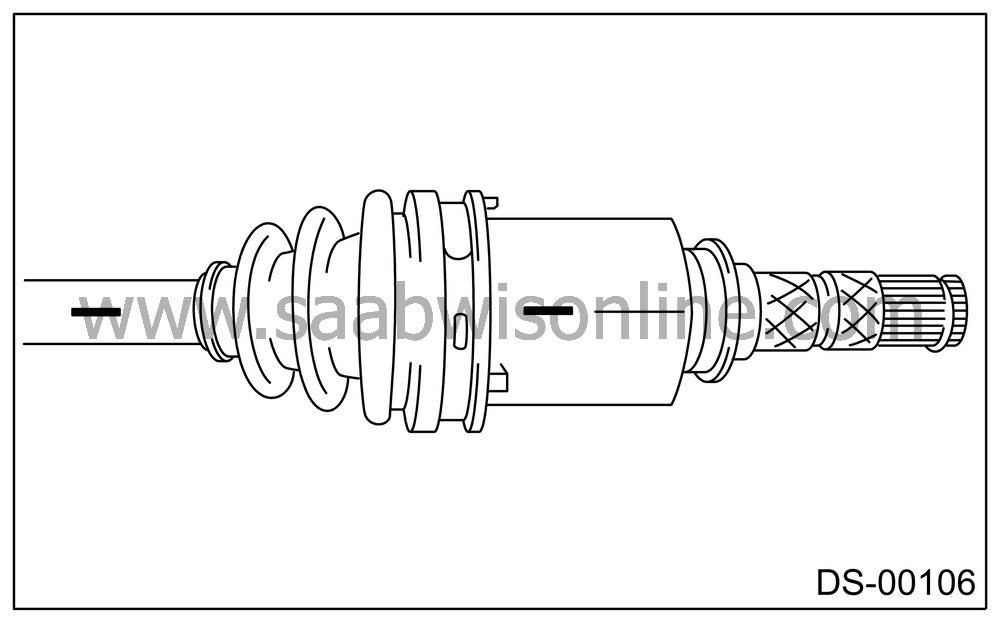

Place the EBJ boot and small boot band on EBJ side of shaft.

| Important | ||

|

Be sure to wrap the shaft splines with vinyl tape to prevent the boot from scratches. |

||

Place the drive shaft in a vise.

| Important | ||

|

Do not place the drive shaft directly in a vise; use wooden blocks. |

||

Apply a coat of specified grease [60 to 70 g (2.12 to 2.47 oz)] to EBJ.

Apply an even coat of specified grease [20 to 30 g (0.71 to 1.06 oz)] to entire inner surface of boot. Also apply grease to shaft.

| Note | ||

|

EBJ installation surface of EBJ boot shall be cleaned so as to be free from grease and other substances. |

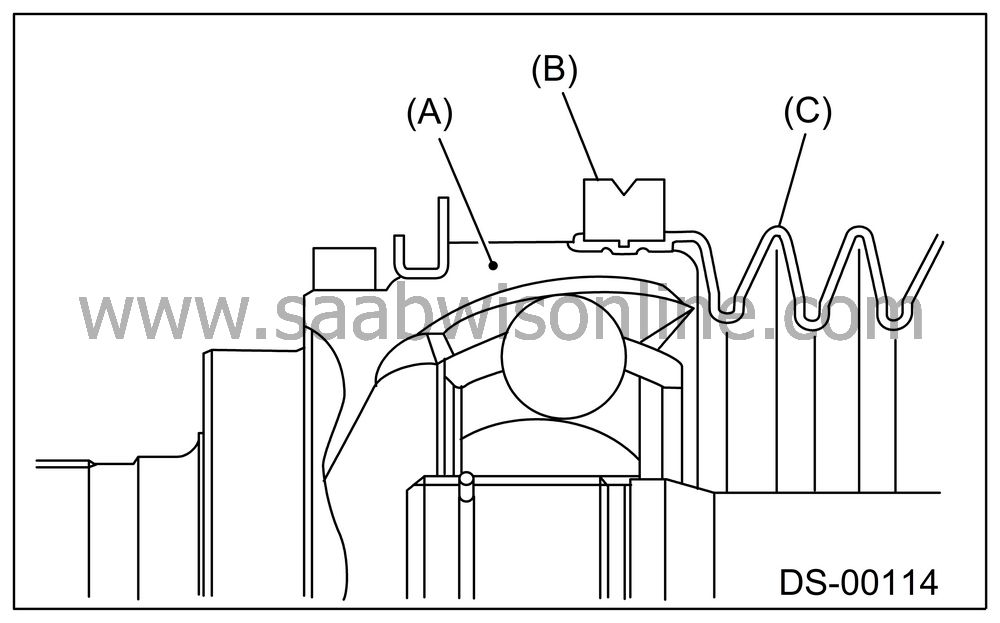

Install the boot projecting portion to EBJ groove.

|

(A)

|

EBJ

|

|

(B)

|

Large boot

band

|

|

(C)

|

Boot

|

Set the large boot band in place.

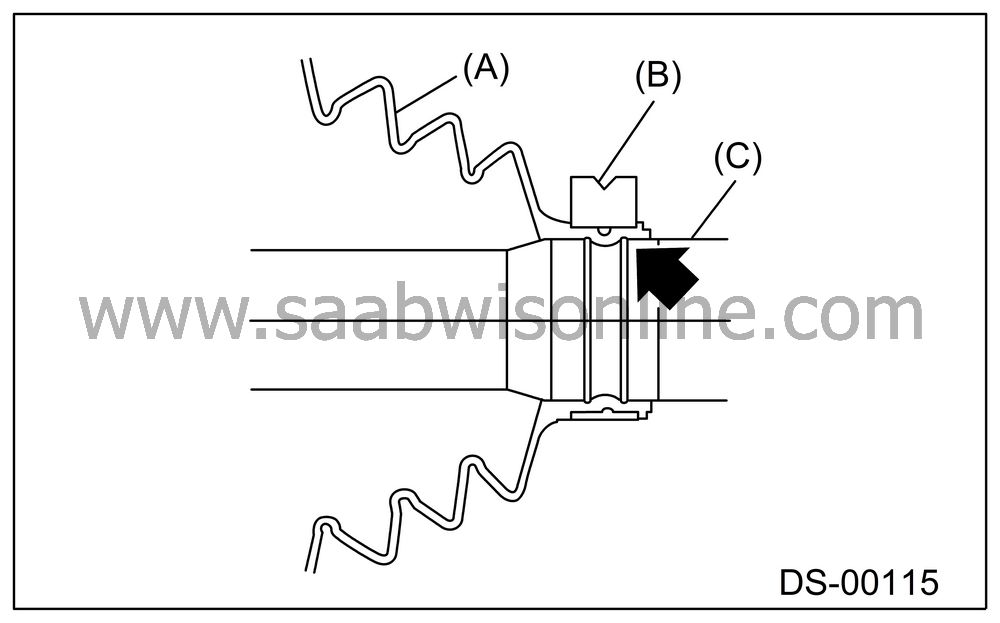

Install the boot projecting portion to shaft groove.

|

(A)

|

Boot

|

|

(B)

|

Small boot

band

|

|

(C)

|

Shaft

|

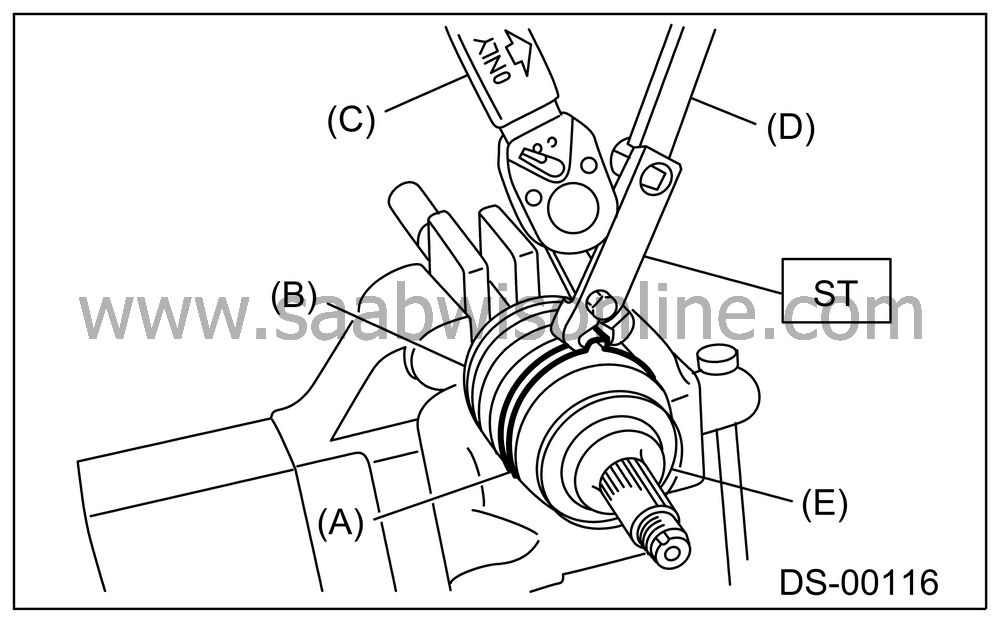

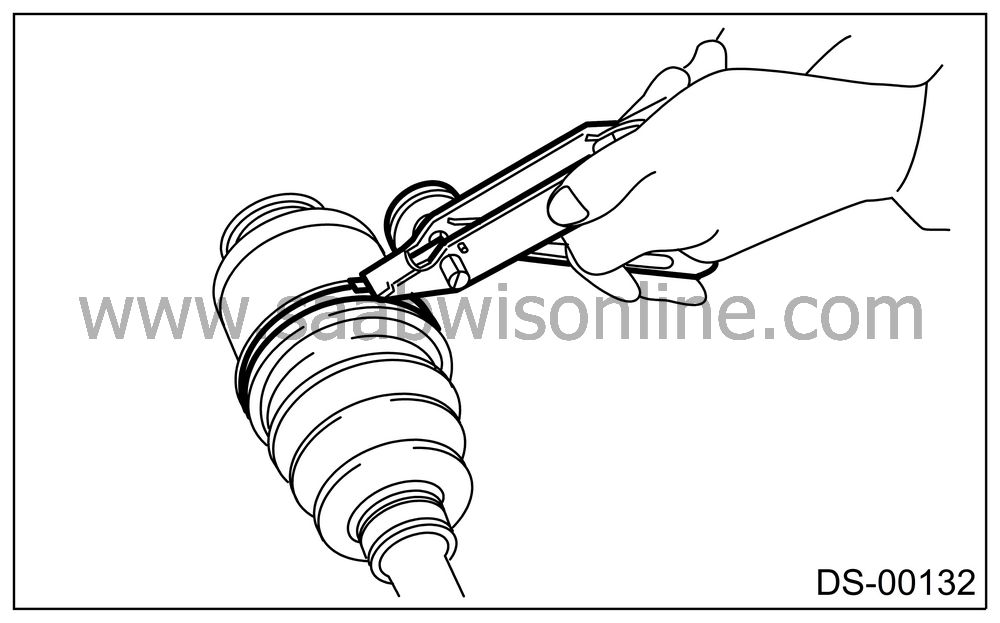

Tighten the boot bands using the ST, torque wrench and socket flex handle.

ST 32005036 BOOT BAND PLIER

|

(A)

|

Large boot

band

|

|

(B)

|

Boot

|

|

(C)

|

Torque

wrench

|

|

(D)

|

Socket

flex handle

|

|

(E)

|

EBJ

|

Tightening torque:

Large boot band

157 Nm (16.0 kgf-m, 116 ft-lb) or moreSmall boot band

133 Nm (13.6 kgf-m, 98 ft-lb) or morePlace the PTJ boot at the center of shaft.

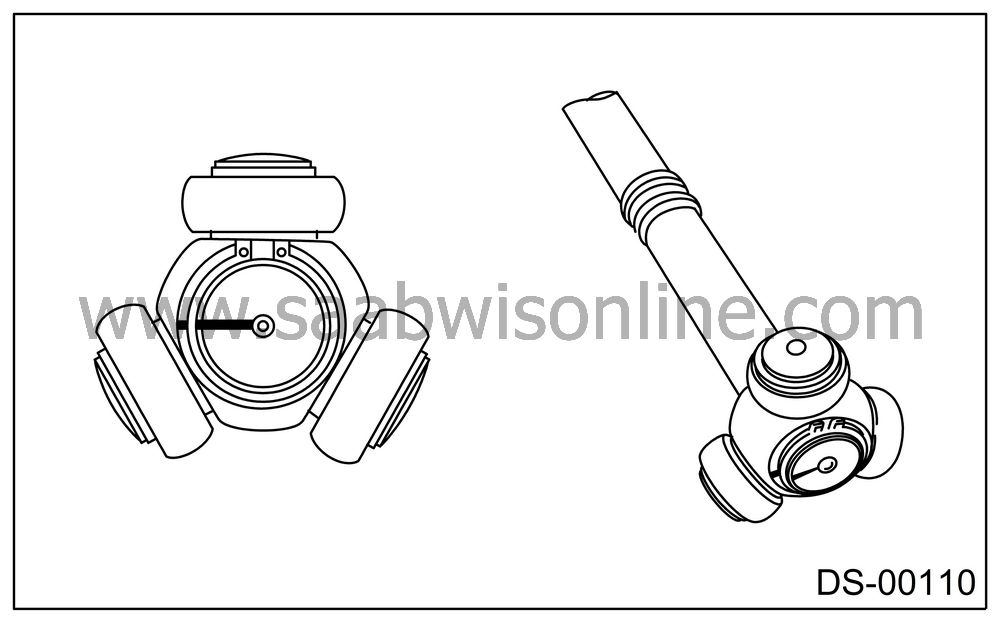

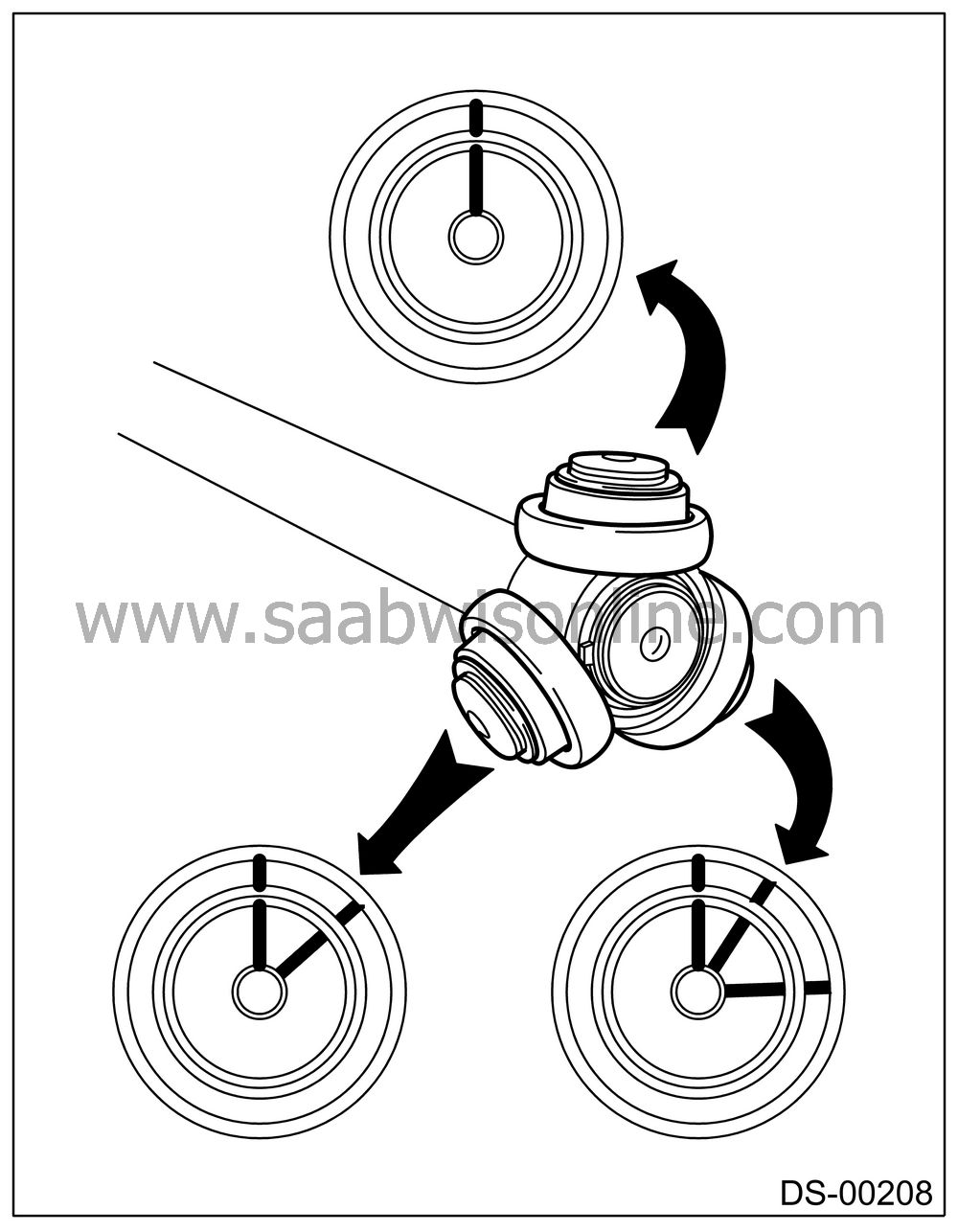

Align the alignment marks, and then install the trunnion on shaft.

Install the snap ring to shaft.

| Important | ||

|

Confirm that the snap ring is completely fitted in shaft groove. |

||

Fill 100 to 110 g (3.53 to 3.88 oz) of specified grease into the interior of PTJ outer race.

Apply a coat of specified grease to free ring and trunnion.

Align the alignment marks on free ring and trunnion, and then install the free ring.

| Important | ||

|

Be careful with the free ring position. |

||

Align the alignment marks on shaft and outer race, and then install the outer race.

Install the circlip in the groove on PTJ outer race.

| Important | ||

|

Pull the shaft lightly and assure the circlip is completely fitted in groove. |

||

Apply an even coat of the specified grease 30 to 40 g (1.06 to 1.41 oz) to the entire inner surface of boot.

Install the PTJ boot taking care not to twist it.

| Important | ||

| • |

PTJ installation surface of

PTJ boot shall be cleaned so as to be free from grease and other substances.

|

|

| • |

When installing the PTJ boot, position the outer race

of PTJ at center of its travel.

|

|

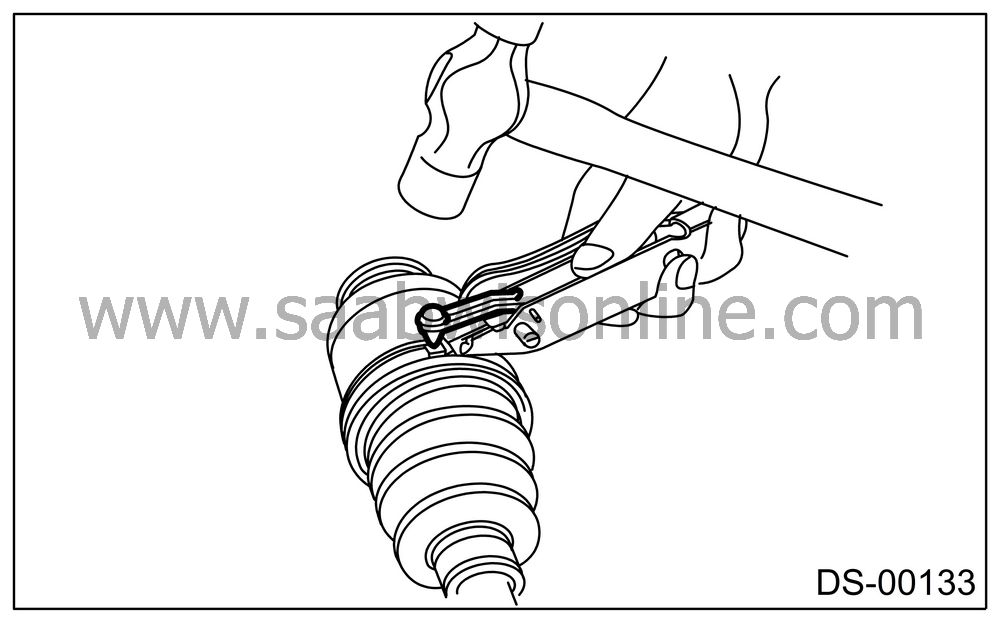

Put a new band through the clip and wind twice in alignment with band groove of boot.

Tighten the band by using the ST.

ST 32005185 BAND TIGHTENING TOOL

| Note | ||

|

Tighten the band until it cannot be moved by hand. |

Tap on the clip with punch provided at the end of ST.

ST 32005185 BAND TIGHTENING TOOL

| Important | ||

|

Tap to an extent that the boot underneath is not damaged. |

||

Cut off the band with an allowance of about 10 mm (0.39 in) left from clip, and bend this allowance over clip.

| Important | ||

|

Be careful so that the end of band is in close contact with clip. |

||

Extend and retract the PTJ to provide equal grease coating.