INSPECTION

| INSPECTION |

| Note | ||

|

Do not disassemble the propeller shaft. Check the following and replace if necessary. |

Tube surfaces for dents or cracks

Splines for deformation or abnormal wear

Joints for non-smooth operation or abnormal noise

Center bearing for free play, noise or non-smooth operation

Oil seals for abnormal wear or damage

Center bearing for breakage

Check the following points with propeller shaft installed in vehicle.

| JOINTS AND CONNECTIONS |

Remove the center exhaust pipes.

Remove the heat shield cover.

Check for any looseness of the yoke flange mounting bolts which connect to rear differential and center bearing bracket mounting bolts.

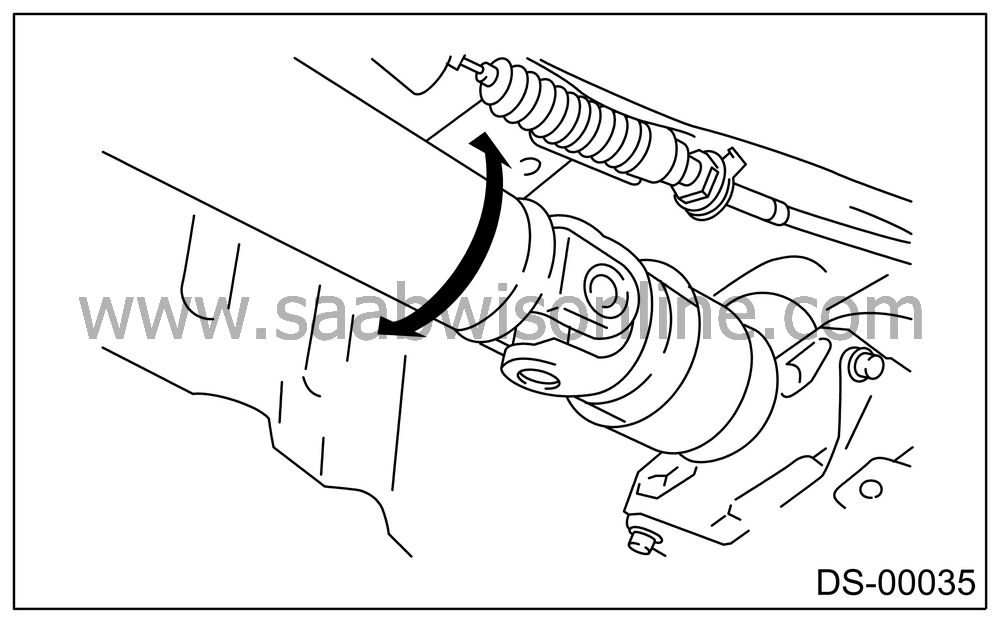

| SPLINES AND BEARING LOCATIONS |

Remove the center exhaust pipes.

Remove the rear exhaust pipe and muffler.

Remove the heat shield cover.

Turn the propeller shaft by hand to see if abnormal free play exists at splines. Also move the yokes to see if abnormal free play exists at spiders and bearings.

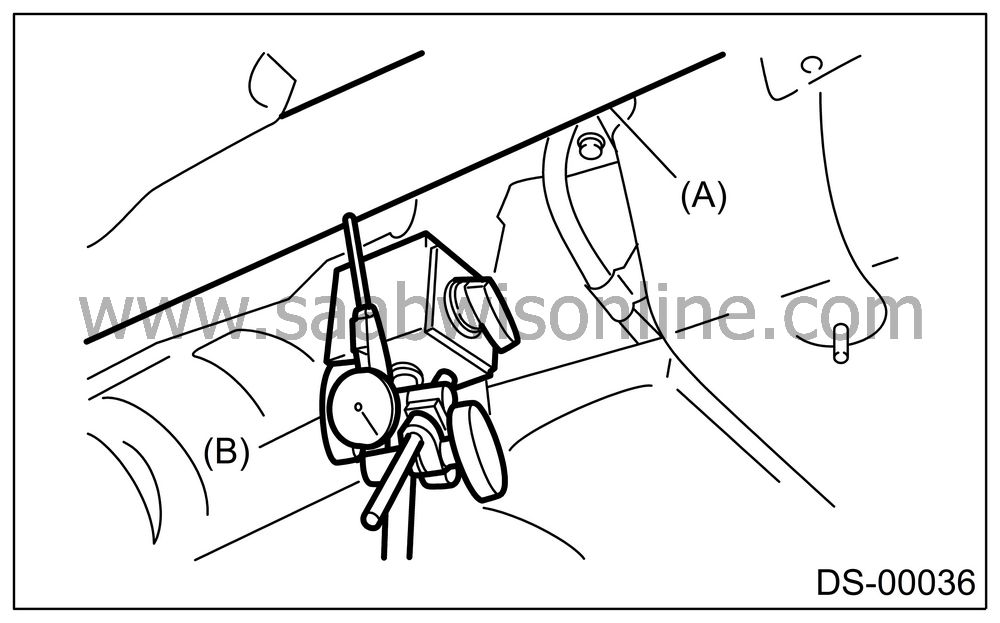

| RUNOUT OF PROPELLER SHAFT |

Remove the center exhaust pipes.

Remove the rear exhaust pipe and muffler.

Remove the heat shield cover.

Set the dial gauge with its indicator stem at center of propeller shaft tube.

Turn the propeller shaft slowly by hands to check for “runout” of propeller shaft.

Runout:

Limit 0.6 mm (0.024 in)

|

(A)

|

Propeller

shaft

|

|

(B)

|

Dial gauge

|

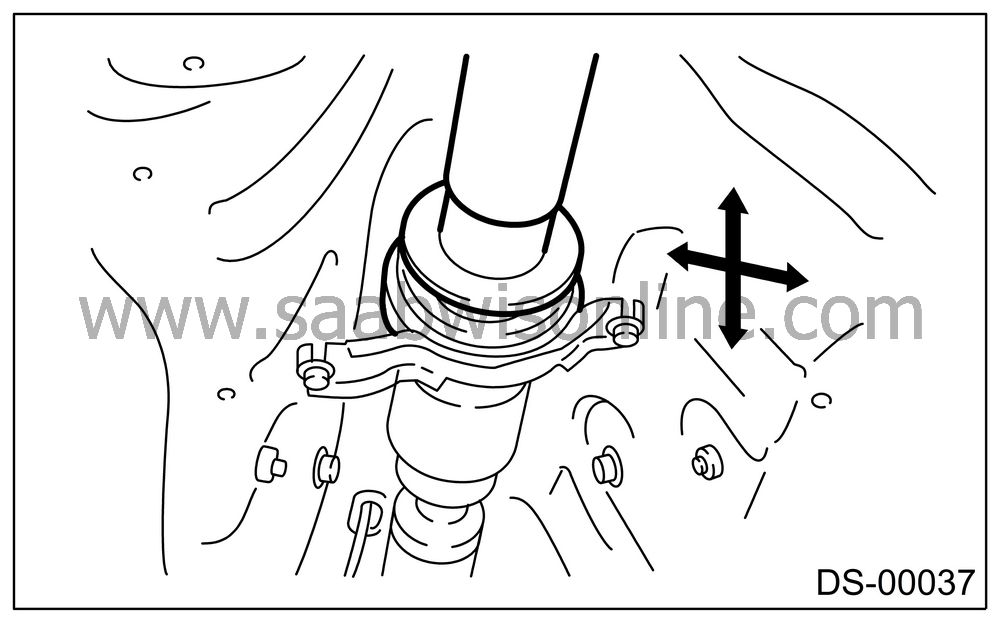

| CENTER BEARING FREE PLAY |

Remove the front and center exhaust pipes.

Remove the rear exhaust pipe and muffler.

Remove the heat shield cover.

Move the propeller shaft near center bearing up and down, and left and right with your hand to check for any abnormal bearing free play.