ADJUSTMENT

| ADJUSTMENT |

| THRUST BEARING PRELOAD |

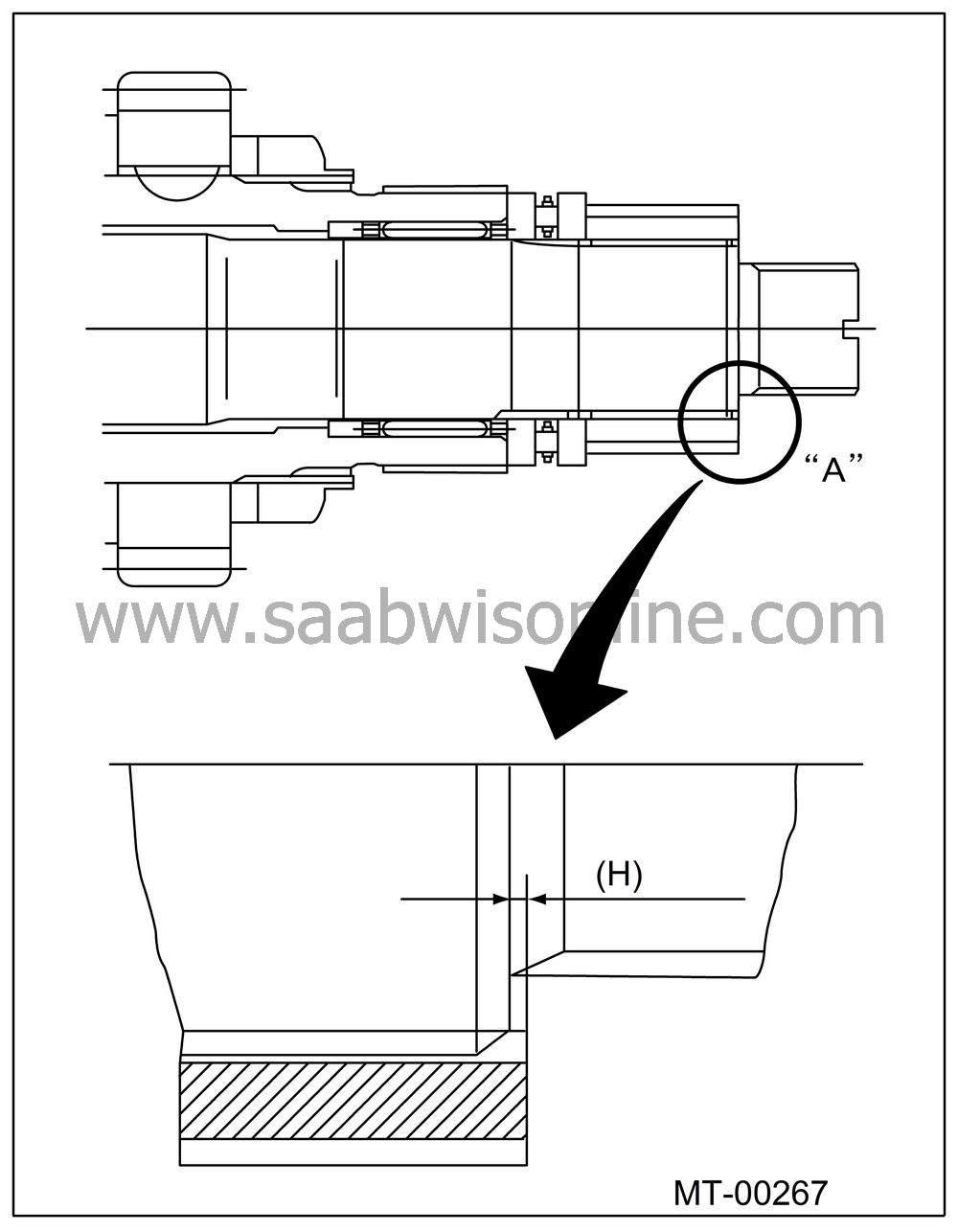

Select the adjusting washer No. 1 so that dimension (H) is zero through visual check. Position the washer (18.3 × 30 × 4) and lock washer (18 × 30 × 2) and install the lock nut (18 × 13.5).

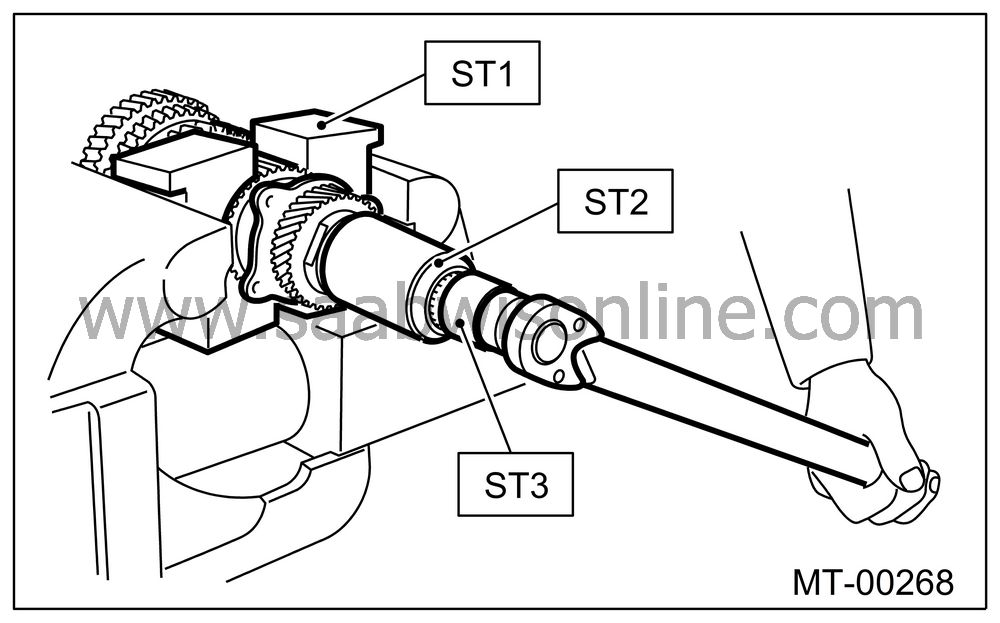

ST1 32005180 HOLDER

ST2 32005100 STOPPER

ST3 32005183 SOCKET WRENCH (27)

Tightening torque:120 Nm (12.2 kgf-m, 88.5 ft-lb)

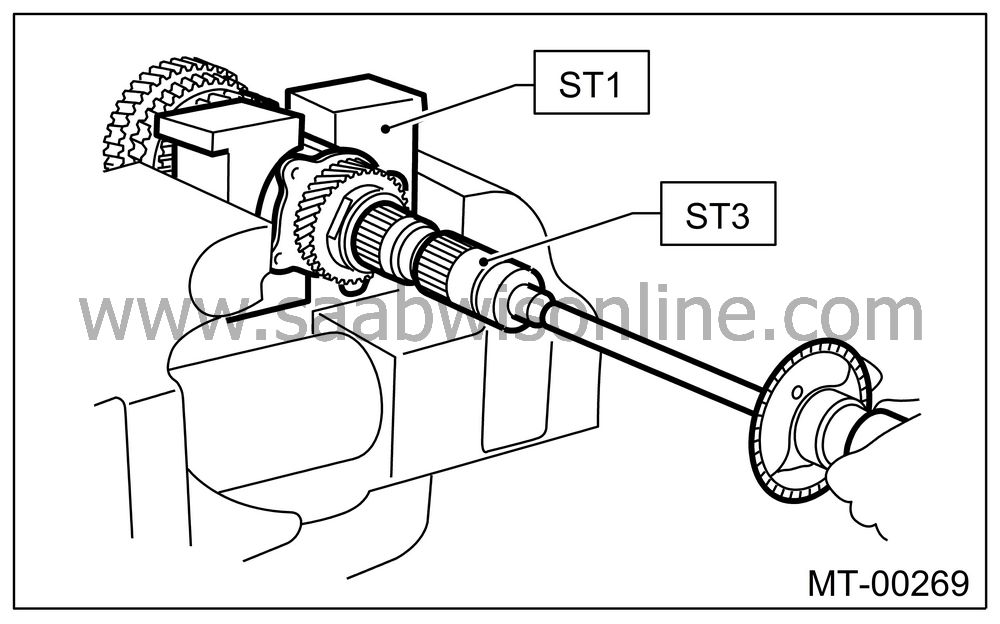

After removing the ST2, measure the starting torque using torque driver.

ST1 32005180 HOLDER

ST3 32005183 SOCKET WRENCH (27)

Starting torque:0.3 — 0.8 Nm (0.03 — 0.08 kgf-m, 0.2 — 0.6 ft-lb)

If the starting torque is not within specified limit, select a new adjusting washer No. 1 and recheck starting torque.

|

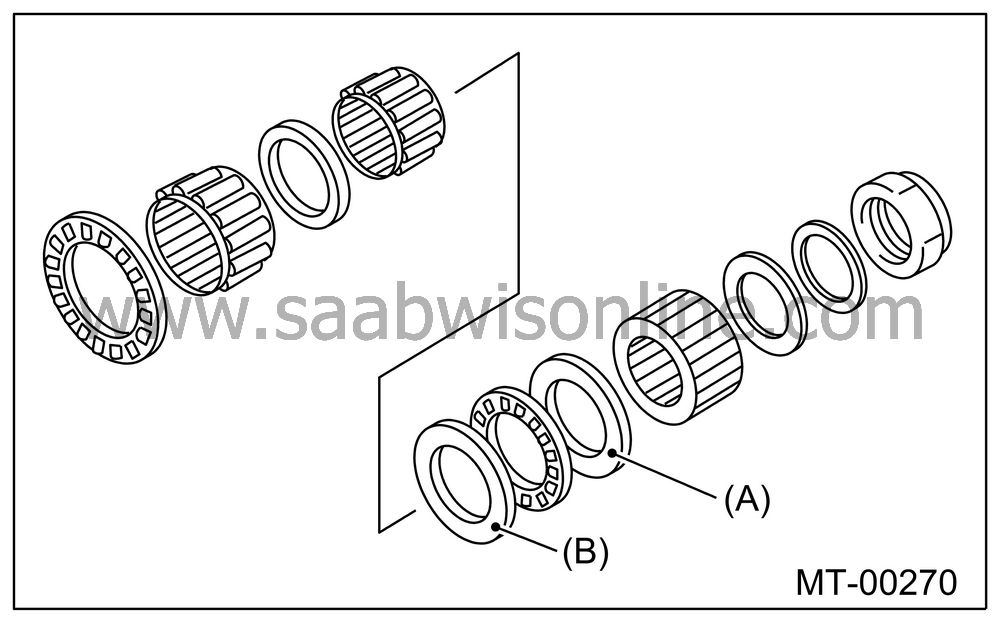

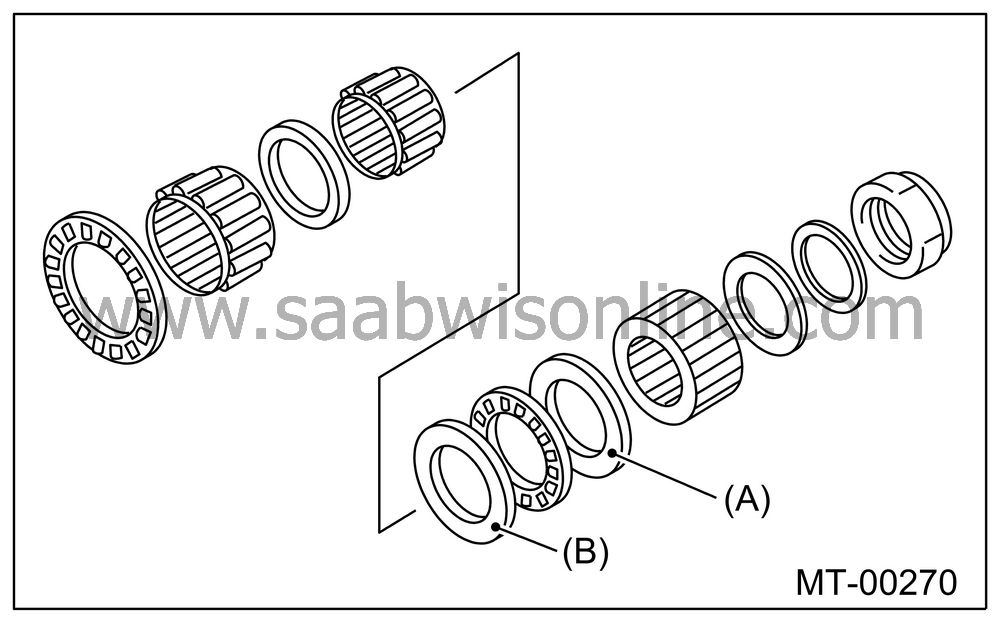

(A)

|

Adjusting

washer No. 1

|

|

(B)

|

Adjusting

washer No. 2

|

| Adjusting washer No. 1 | |

| Part No. | Thickness mm (in) |

|

32008260

|

3.925

(0.1545)

|

|

32008261

|

3.950

(0.1555)

|

|

32008262

|

3.975

(0.1565)

|

|

32008263

|

4.000

(0.1575)

|

|

32008264

|

4.025

(0.1585)

|

|

32008265

|

4.050

(0.1594)

|

|

32008266

|

4.075

(0.1604)

|

If the specified starting torque range cannot be obtained when a No. 1 adjusting washer is used, then select a suitable No. 2 adjusting washer from those listed in the following table. Repeat steps 1) through 4) to adjust starting torque.

|

(A)

|

Adjusting

washer No. 1

|

|

(B)

|

Adjusting

washer No. 2

|

| Starting torque | Dimension H | Washer No. 2 |

|

Low

|

Small

|

Select

thicker one.

|

|

High

|

Large

|

Select

thinner one.

|

| Adjusting washer No. 2 | |

| Part No. | Thickness mm (in) |

|

32008268

|

3.850

(0.1516)

|

|

32008263

|

4.000

(0.1575)

|

|

32008267

|

4.150

(0.1634)

|

Recheck that the starting torque is within specified range, then clinch the lock nut at four positions.