INSPECTION

| INSPECTION |

Disassembled parts should be washed clean first and then inspected carefully.

Bearings

Replace the bearings in the following cases:

| • |

Bearings

whose balls, outer races and inner races are broken or rusty.

|

|

| • |

Worn bearings

|

|

| • |

Bearings that fail to turn smoothly or make noise when

turned after gear oil lubrication.

|

|

| • |

Bearings having other defects

|

|

Bushing (each gear)

Replace the bushing in the following cases:

| • |

When the

sliding surface is damaged or abnormally worn.

|

|

| • |

When the inner wall is abnormally worn.

|

|

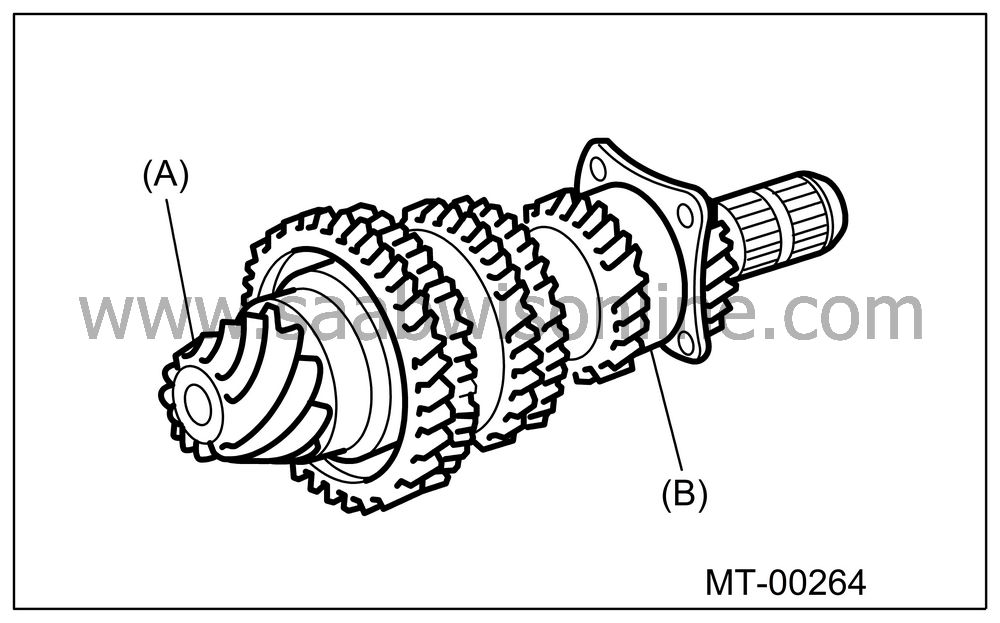

Gears

| • |

Replace

the gears with new ones if their tooth surfaces are broken, damaged,

or excessively worn.

|

|

| • |

Correct or replace if the cone that contacts the baulk

ring is rough or damaged.

|

|

| • |

Correct or replace if the inner surface or end face is

damaged.

|

|

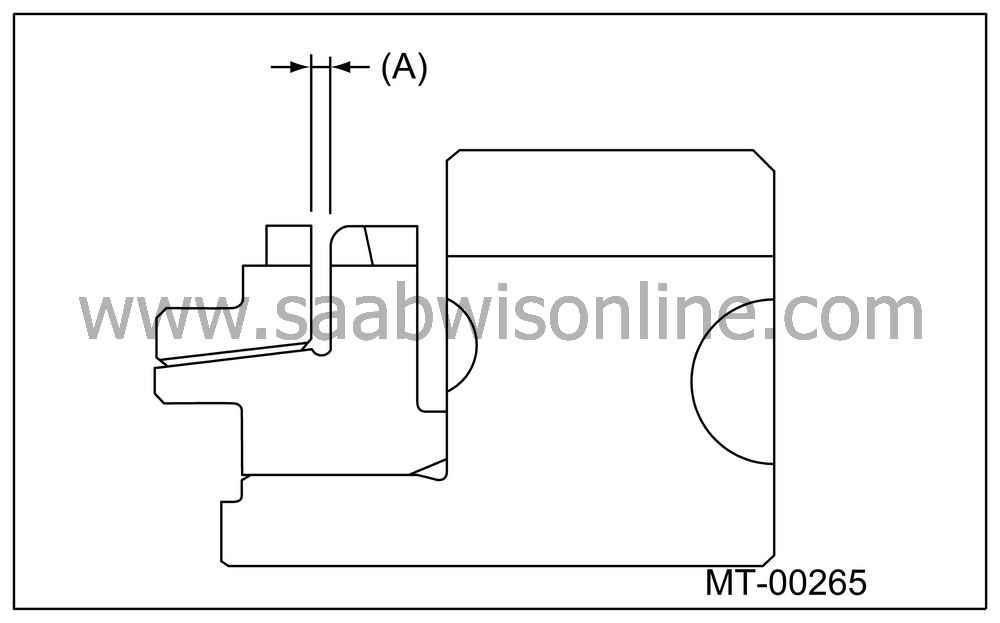

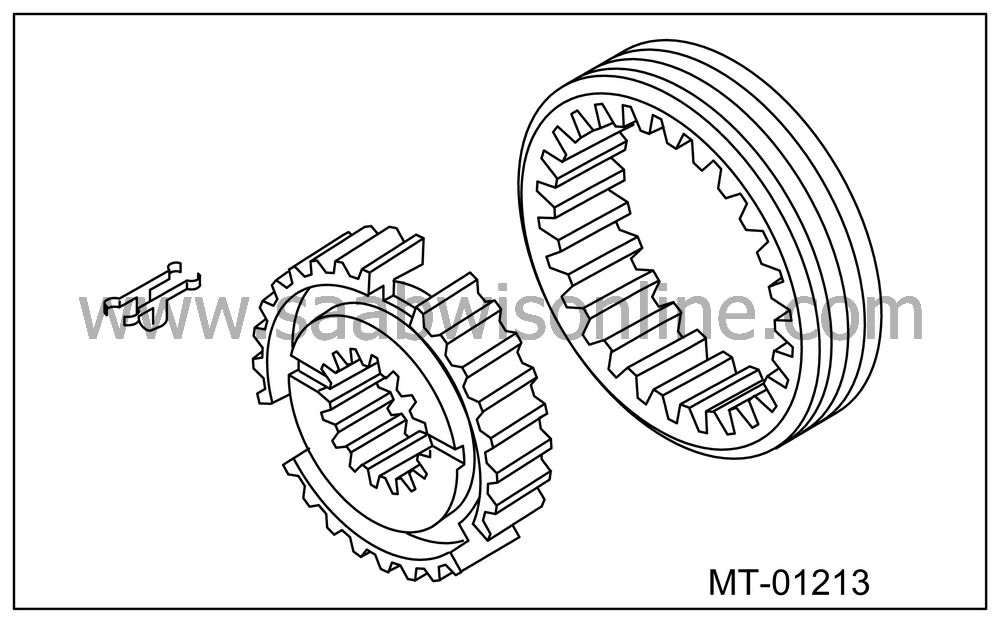

Baulk ring

Replace the ring in the following cases:

| • |

When the

inner surface and end face are damaged.

|

|

| • |

When the ring inner surface is abnormally or partially

worn down.

|

|

| • |

If the gap between the end faces of the ring and the

gear splined part is excessively small when the ring is pressed

against the cone.

Clearance (A): 0.5 — 1.0 mm (0.020 — 0.040 in)

|

|

| • |

When the contact surface of the synchronizer ring insert

is scored or abnormally worn down.

|

|

Shifting insert key

Replace the insert if deformed, excessively worn or defective in any way.

Replace the oil seal if the lip is deformed, hardened, damaged, worn or defective in any way.

O-ring

Replace the O-ring if the sealing face is deformed, hardened, damaged, worn or defective in any way.