ASSEMBLY

| ASSEMBLY |

| DIFFERENTIAL CASE ASSEMBLY |

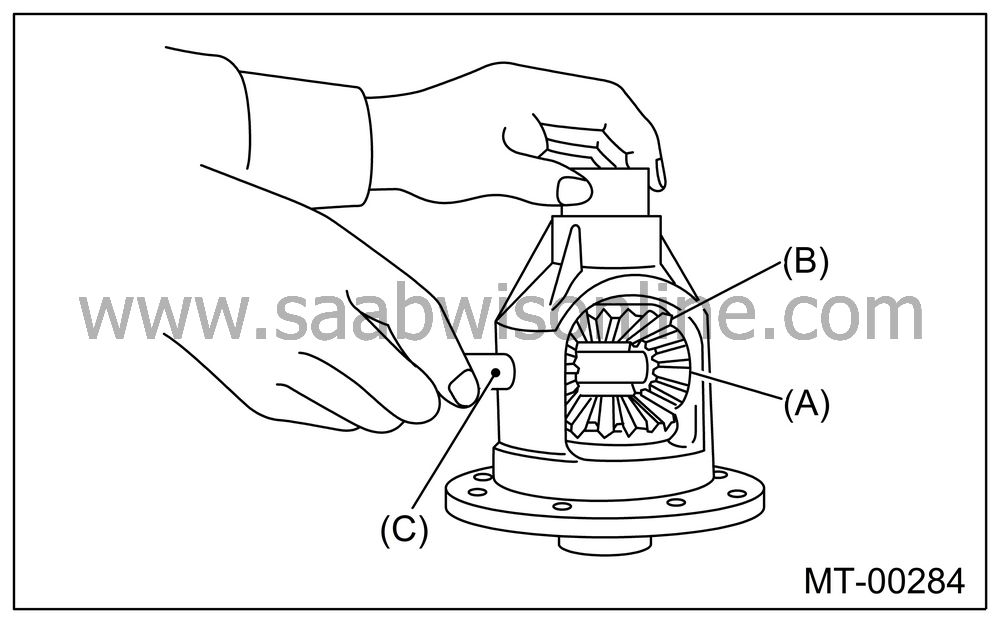

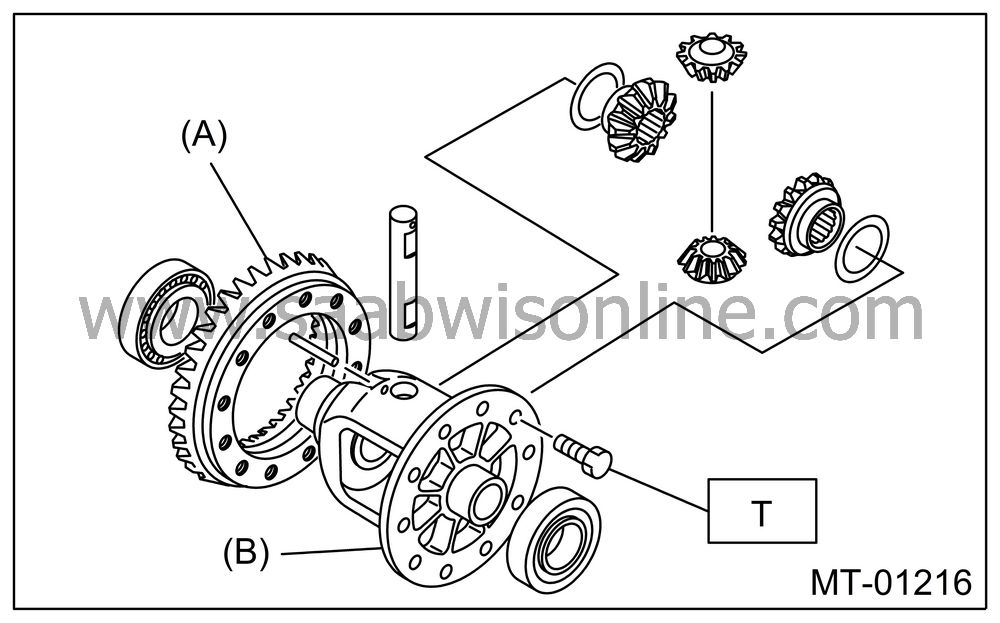

Install the bevel gear and bevel pinion together with washers, and insert pinion shaft.

| Note | ||

|

Face the chamfered side of washer toward gear. |

|

(A)

|

Bevel pinion

|

|

(B)

|

Bevel gear

|

|

(C)

|

Pinion

shaft

|

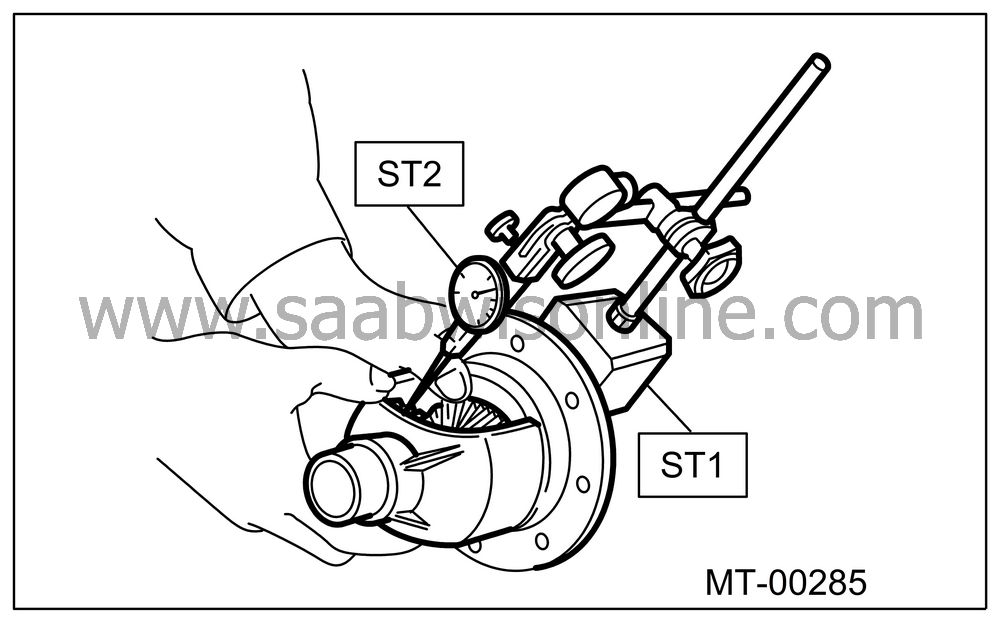

Measure the backlash between bevel gear and pinion. If it is not within specifications, install a suitable washer to adjust it.

| Note | ||

|

Be sure the pinion gear tooth contacts adjacent gear teeth during measurement. |

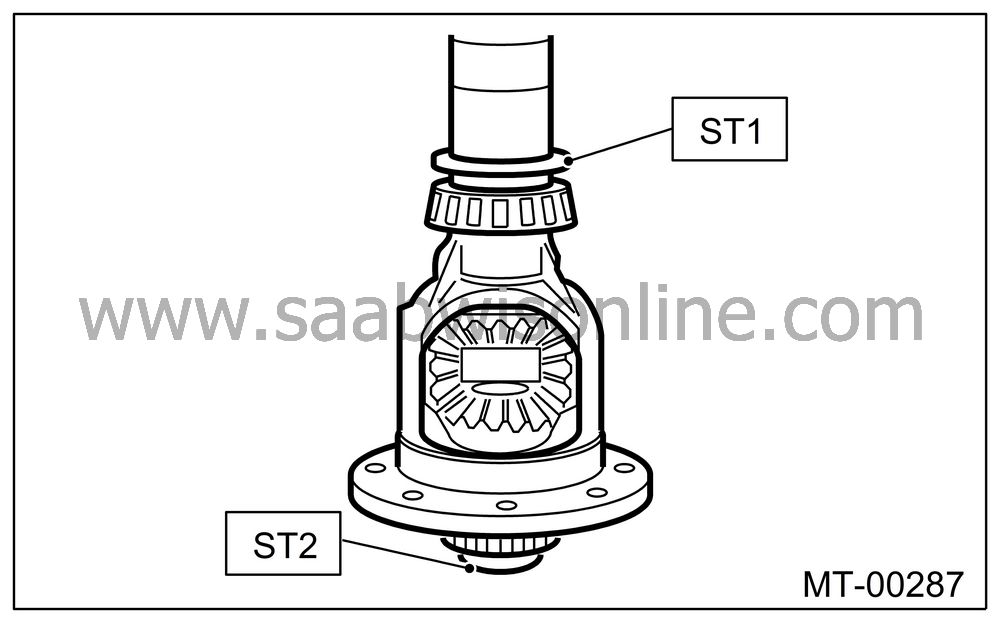

ST1 32005094 MAGNET BASE

ST2 32005095 DIAL GAUGE

Standard backlash:0.13 — 0.18 mm (0.0051 — 0.0071 in)

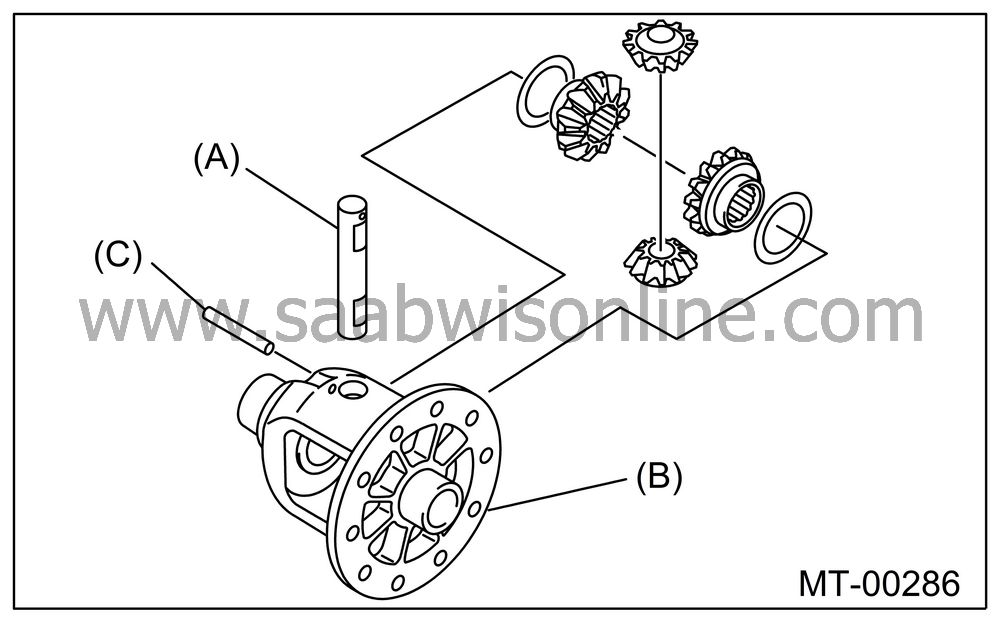

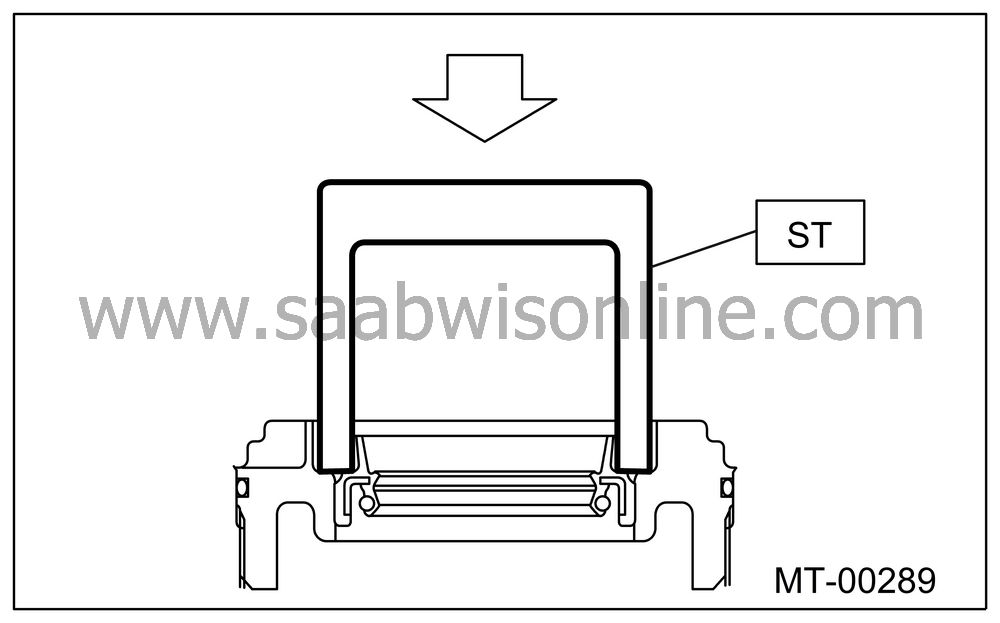

Align the pinion shaft and differential case at their holes, and drive the straight pin into holes from the hypoid driven gear side, using ST.

| Note | ||

|

Lock the straight pin after installing. |

ST 32005181 REMOVER

|

(A)

|

Pinion

shaft

|

|

(B)

|

Differential

case

|

|

(C)

|

Straight

pin

|

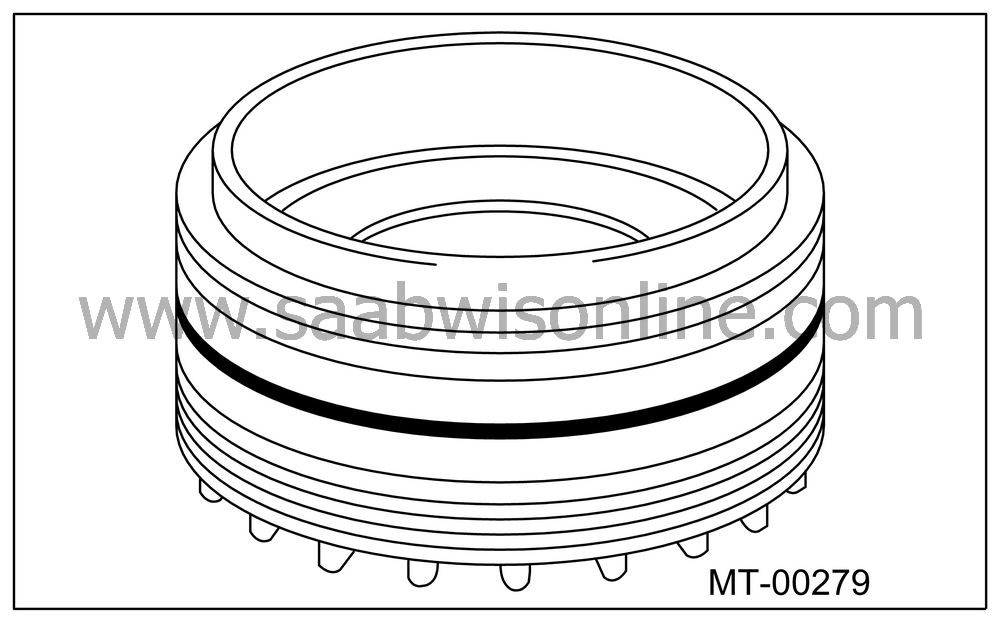

Install the roller bearing to differential case.

| Note | ||

| • |

Do not apply pressure in excess of 10 kN (1 ton, 1.1

US ton, 1.0 Imp ton).

|

|

| • |

Be careful because the roller bearing outer races are

used as a set.

|

|

ST1 32005130 BUSH 1-2 INSTALLER

ST2 32005065 ADAPTER

Install the hypoid driven gear to differential case using twelve bolts.

Tightening torque:

T: 62 Nm (6.3 kgf-m, 45.6 ft-lb)

|

(A)

|

Hypoid

driven gear

|

|

(B)

|

Differential

case

|

| SIDE RETAINER |

Install a new oil seal.

ST 32005024 DIFFERENTIAL SIDE OIL SEAL INSTALLER

Install a new O-ring.

| Note | ||

|

Do not stretch or damage the O-ring. |