INSPECTION

| INSPECTION |

Repair or replace the differential gear in the following cases:

| • |

The hypoid

drive gear and drive pinion shaft tooth surface are damaged, excessively

worn, or seized.

|

|

| • |

The roller bearing on the drive pinion shaft has a worn

or damaged roller path.

|

|

| • |

There is damage, wear, or seizure of the differential

bevel pinion, differential bevel gear, washer, pinion shaft, and

straight pin.

|

|

| • |

The differential case has worn or damaged sliding surfaces.

|

|

|

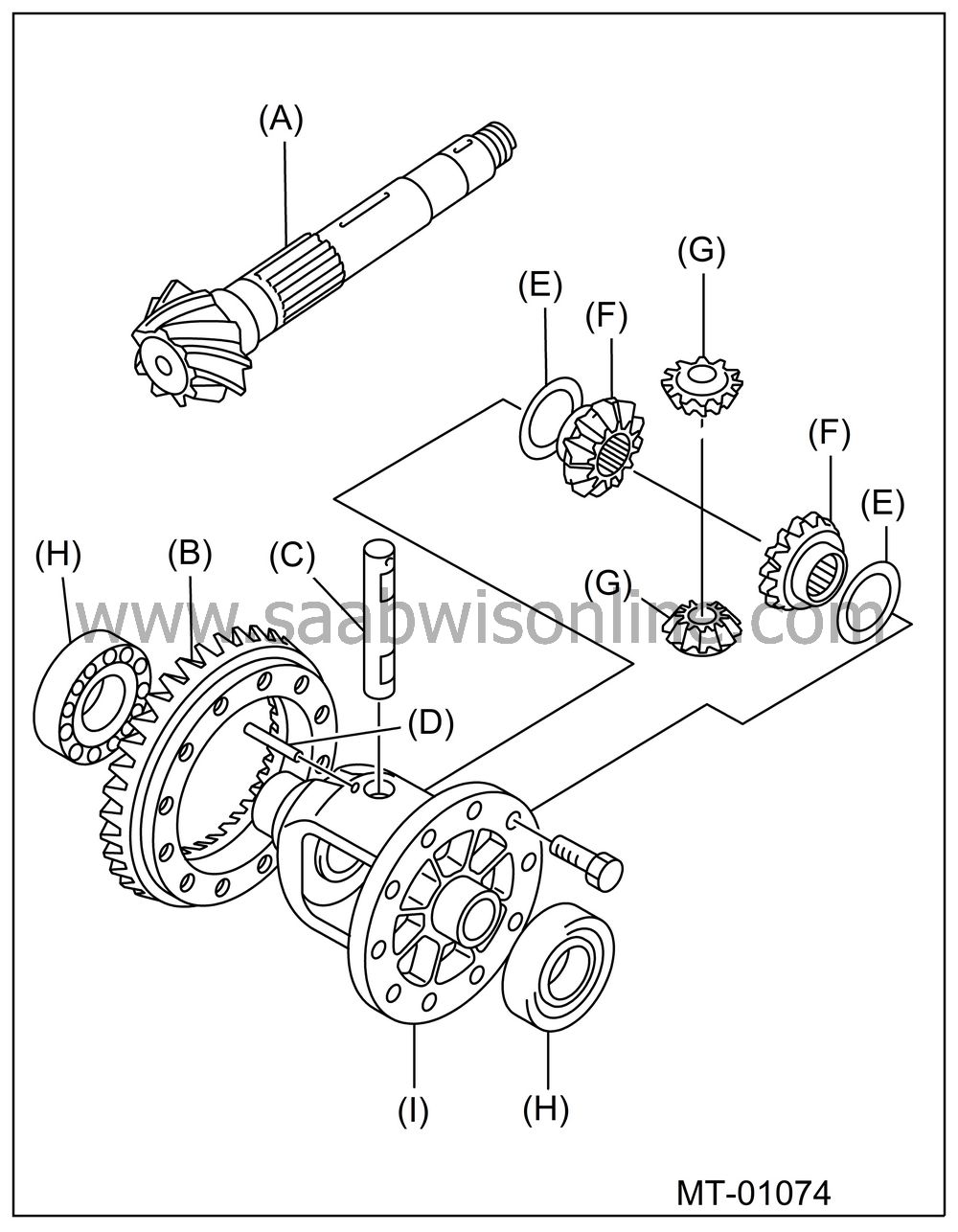

(A)

|

Drive pinion

shaft

|

|

(B)

|

Hypoid

driven gear

|

|

(C)

|

Pinion

shaft

|

|

(D)

|

Straight

pin

|

|

(E)

|

Washer

|

|

(F)

|

Differential

bevel gear

|

|

(G)

|

Differential

bevel pinion

|

|

(H)

|

Roller

bearing

|

|

(I)

|

Differential

case

|

| BEVEL PINION GEAR BACKLASH |

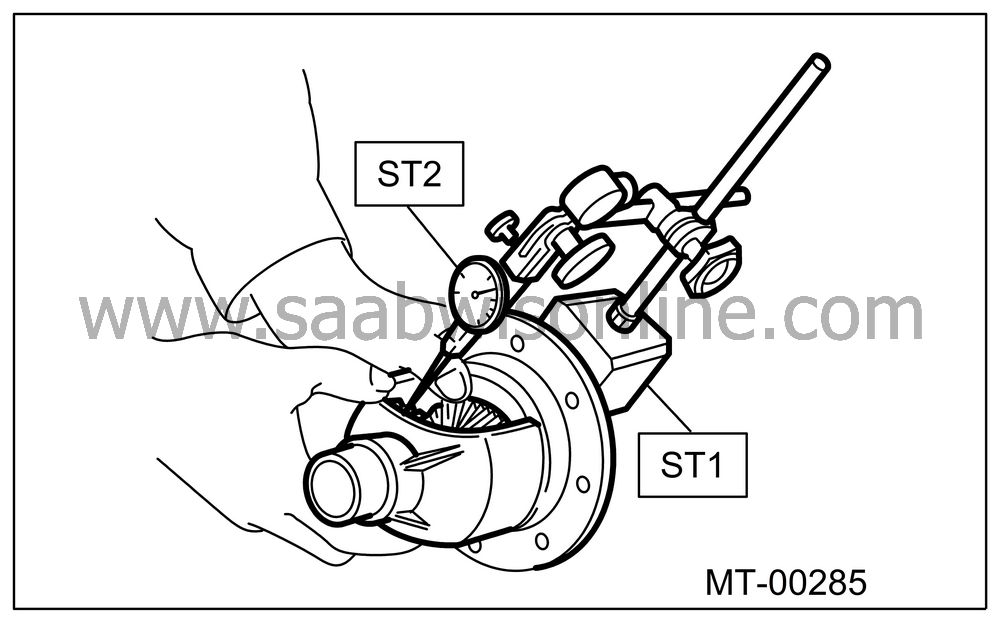

Measure the backlash between bevel gear and pinion. If it is not within specifications, install a suitable washer to adjust it.

| Note | ||

|

Be sure the pinion gear tooth contacts adjacent gear teeth during measurement. |

ST1 32005094 MAGNET BASE

ST2 32005095 DIAL GAUGE

Standard backlash:0.13 — 0.18 mm (0.0051 — 0.0071 in)

| HYPOID GEAR BACKLASH |

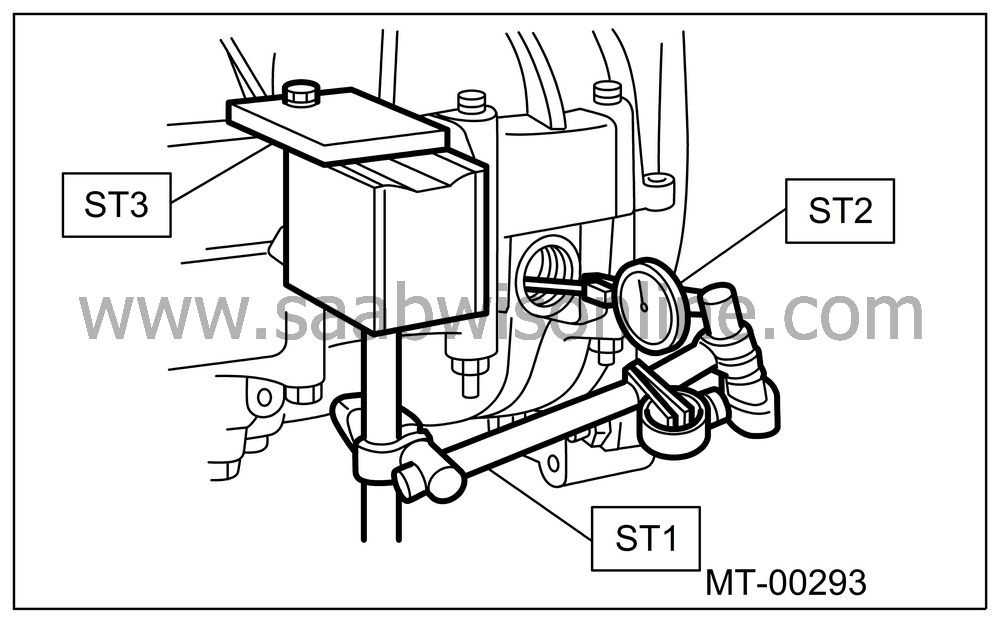

Set the ST1, ST2 and ST3. Insert the needle through transmission oil drain plug hole so that the needle comes in contact with the tooth surface at a right angle and check the backlash.

ST1 32005094 MAGNET BASE

ST2 32005095 DIAL GAUGE

ST3 32005096 PLATE

Backlash:0.13 — 0.18 mm (0.0051 — 0.0071 in)

| Note | ||

|

If the backlash is outside specified range, adjust it by turning the holder in right side case. |

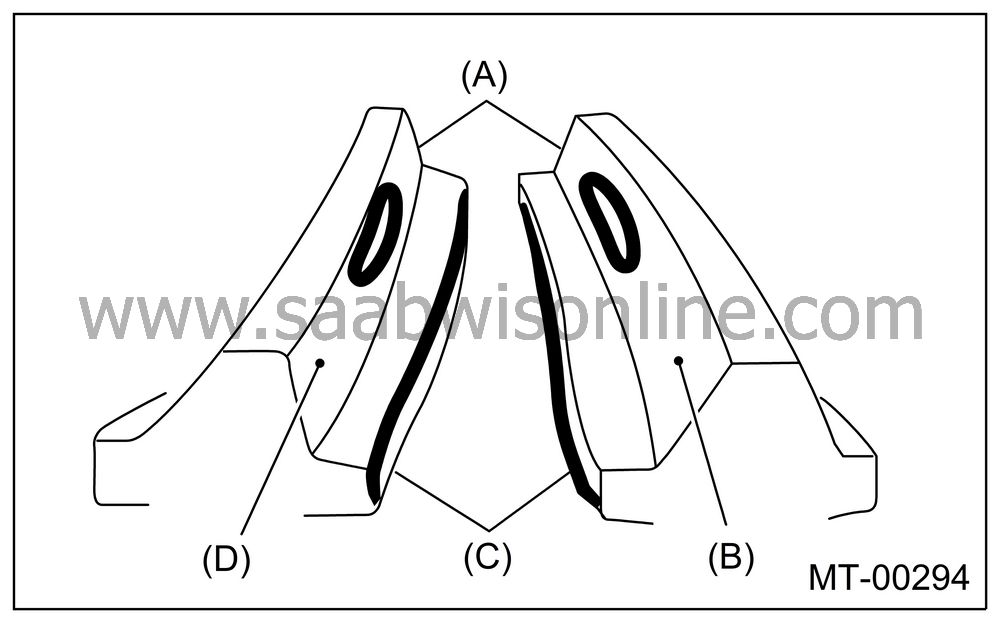

| TOOTH CONTACT OF HYPOID GEAR |

Check the tooth contact of hypoid gear as follows: Apply a uniform thin coat of red lead on both tooth surfaces of 3 or 4 teeth of the hypoid gear. Move the hypoid gear back and forth by turning the transmission main shaft until a definite contact pattern is developed on hypoid gear, and judge whether face contact is correct. If it is inaccurate, make adjustment.

| • |

Tooth contact is correct.

|

|||||||||