INSPECTION

| INSPECTION |

Check all disassembled parts for wear, damage or other abnormalities. Repair or replace faulty parts as required.

| Part name | Inspection | Remedy | ||||||||||||||||||

|

Pipe

|

|

Replace

with a new one.

|

||||||||||||||||||

|

Clamp

|

|

Replace

with a new one.

|

||||||||||||||||||

|

Hose

|

|

Replace

with a new one.

|

||||||||||||||||||

| Important | ||

|

Although the surface layer materials of rubber hoses have excellent weathering resistance, heat resistance and resistance for low temperature brittleness, they are likely to be damaged chemically by brake fluid, battery electrolyte, engine oil and automatic transmission fluid and their service lives are to be very shortened. It is very important to keep the hoses free from before mentioned fluids and to wipe out immediately when the hoses are adhered with the fluids. |

||

|

Since the resistances for heat or low temperature brittleness are gradually declining according to time accumulation of hot or cold conditions for the hoses and their service lives are shortening accordingly, it is necessary to perform the careful inspection frequently when the vehicle is used in hot weather areas, cold weather area and a driving condition in which many steering operations are required in short time. |

||

|

Particularly, continuous work of relief valve over 5 seconds causes to reduce service lives of the hoses, the oil pump, the fluid, etc. due to over heat. |

||

| Trouble | Possible cause | Corrective action |

|

Pressure hose burst

|

Excessive

holding time of relief status

|

Instruct

the customers.

|

|

Malfunction

of relief valve

|

Replace

the oil pump.

|

|

|

Poor

cold characteristic of fluid

|

Replace

the fluid.

|

|

|

Forced out return hose

|

Poor

connection

|

Correct.

|

|

Poor

holding of clip

|

Retighten.

|

|

|

Poor

cold characteristic of fluid

|

Replace

the fluid.

|

|

|

Fluid bleeding out of hose slightly

|

Wrong

layout, tensioned

|

Replace

the hose.

|

|

Excessive

play of engine due to deterioration of engine mounting rubber

|

Replace

the defective parts.

|

|

|

Improper

stop position of pitching stopper

|

Replace

the defective parts.

|

|

|

Crack on hose

|

Excessive

holding time of relief status

|

Replace.

Instruct customer. |

|

Excessive

tightening torque for return hose clip

|

Replace.

|

|

|

Power

steering fluid, brake fluid, engine oil, electrolyte adhere on the

hose surface

|

Replace.

Pay attention on service work. |

|

|

Too

many times use in extremely cold weather

|

Replace.

Instruct the customers. |

| Note | ||

|

It is likely that although one judges fluid leakage, there is actually no leakage. This is because the fluid spilt during the last maintenance was not completely wiped off. Be sure to wipe off spilt fluid thoroughly after maintenance. |

| Fluid leaking area | Possible cause | Corrective action |

|

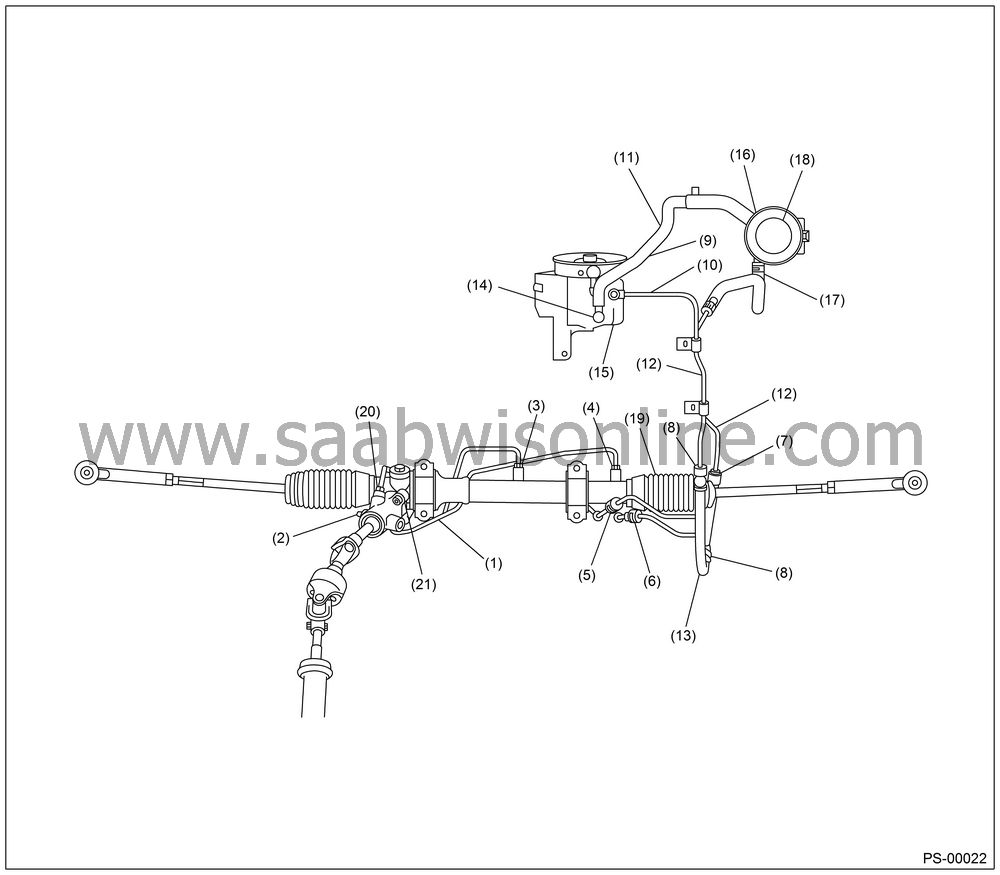

Leakage from connecting portions of pipes and hoses, numbered

with (1) through (10) in figure

|

Insufficient

tightening of flare nut, catching dirt or the like, damage to flare

or flare nut or eye bolt

|

Loosen

and retighten, if ineffective, replace.

|

|

Poor

insertion of hose, poor clamping

|

Retighten

or replace the clamp.

|

|

|

Damaged

O-ring or gasket

|

Replace

the O-ring or gasket pipe or hose with new one, if ineffective,

replace gearbox also.

|

|

|

Leakage from hose (11), (12) and (13) in figure

|

Crack

or damage in hose

|

Replace

with a new one.

|

|

Crack

or damage in hose hardware

|

Replace

with a new one.

|

|

|

Leakage from surrounding of cast iron portion of oil pump

(14) and (15) in figure

|

Damaged

O-ring

|

Replace

the oil pump.

|

|

Damaged

gasket

|

Replace

the oil pump.

|

|

|

Leakage

from oil tank (16) and (17) in figure

|

Crack

in oil tank

|

Replace

the oil tank.

|

|

Leakage from filler neck (18)

|

Damaged

cap packing

|

Replace

the cap.

|

|

Crack

in root of filler neck

|

Replace

the oil tank.

|

|

|

High

fluid level

|

Adjust

the fluid level.

|

|

|

Leakage

from surrounding of power cylinder of gearbox (19) in figure

|

Damaged

oil seal

|

Replace

the oil seal.

|

|

Leakage from control valve of gearbox (20) and (21) in figure

|

Damaged

packing or oil seal

|

Replace

the problem parts.

|

|

Damage

in control valve

|

Replace

the control valve.

|