INSTALLATION

| INSTALLATION |

Temporarily tighten the two bolts fixing pipe C and D. (bolt A)

| Note | ||

|

Visually check that the hose between tank and pipe D is free from bending or twisting. |

| • |

Saab

9-2X 2.5i Linear

|

|||||||

| • |

Saab 9-2X 2.0T Aero

|

|||||||

Connect the pipe D to oil tank.

Using a new gasket, connect the pipe C to oil pump.

Tightening torque:

39 Nm (4.0 kgf-m, 28.9 ft-lb)

Tighten the two bolts fixing pipe C and D. (bolt A)

Tightening torque:

13 Nm (1.3 kgf-m, 9.4 ft-lb)

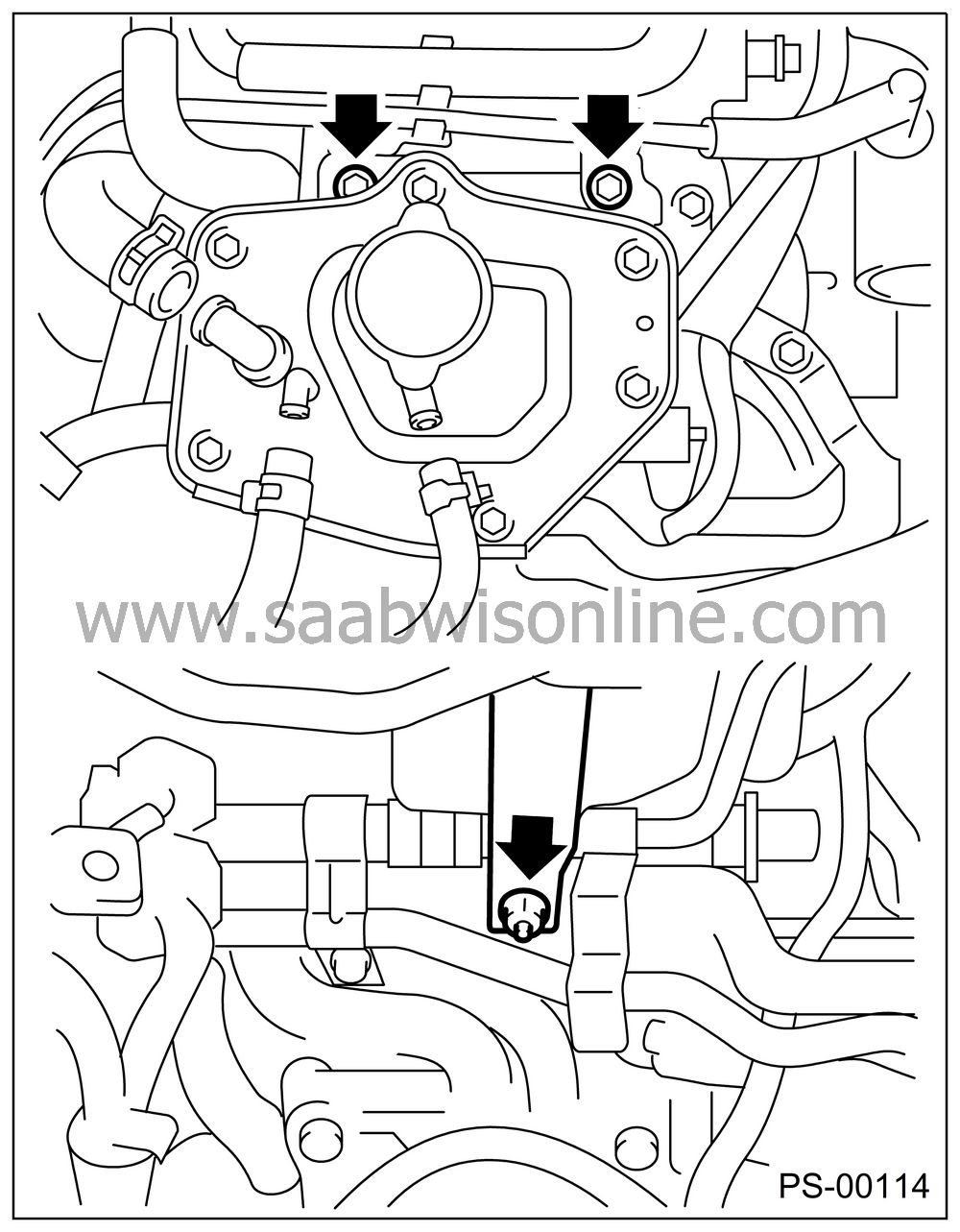

Install the coolant filler tank. (Saab 9-2X 2.0T Aero)

Tightening torque:

T1: 19 Nm (1.9 kgf-m, 13.7 ft-lb)

T2: 21 Nm (2.1 kgf-m, 15.2 ft-lb)

|

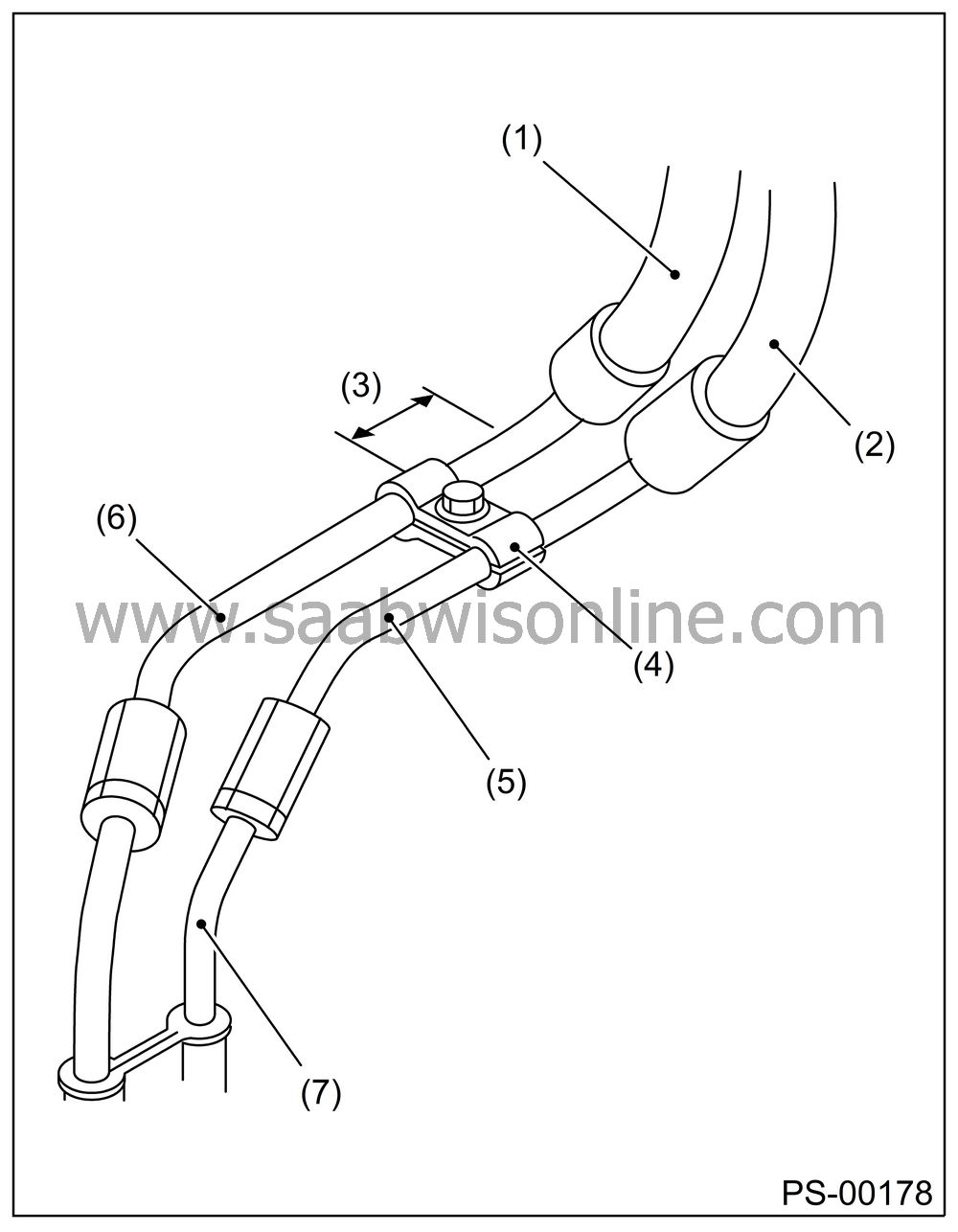

(1)

|

Return

hose

|

|

(2)

|

Pressure

hose

|

|

(3)

|

Approx.

30 mm (1.18 in)

|

|

(4)

|

Clamp E

|

|

(5)

|

Pipe C

|

|

(6)

|

Pipe D

|

|

(7)

|

Pipe (Gear

box side)

|

Temporarily install the clamp E on pipes C and D.

| Note | ||

|

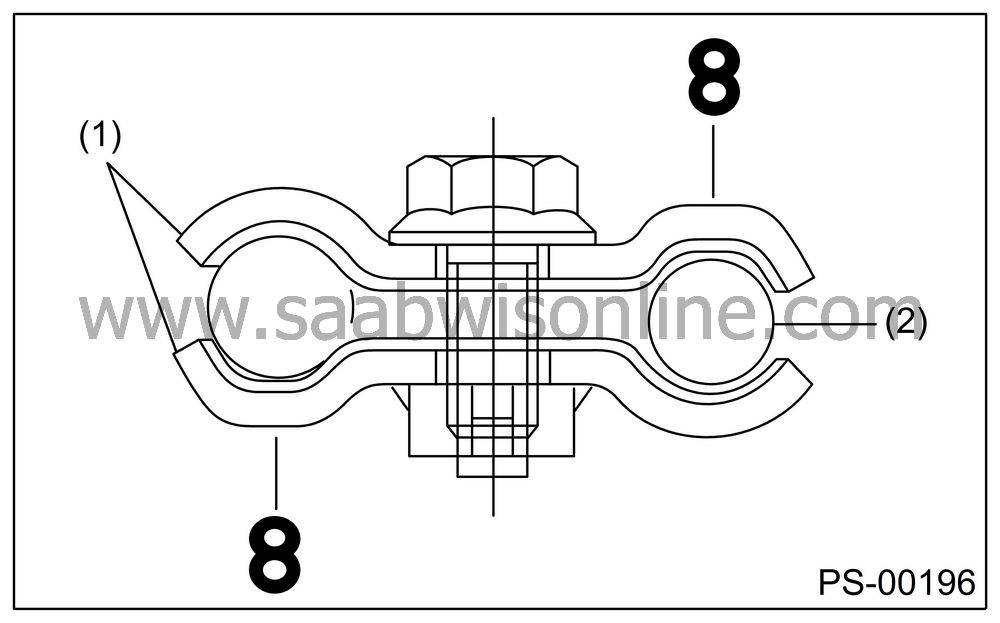

Ensure the letter “8” on each clamp are diagonally opposite each other as shown in the figure. |

|

(1)

|

Clamp E

|

|

(2)

|

Pipe C

|

Tighten the clamp E firmly.

Tightening torque:

7.4 Nm (0.75 kgf-m, 5.4 ft-lb)

Tighten the joint nut.

Tightening torque:

15 Nm (1.5 kgf-m, 10.8 ft-lb)

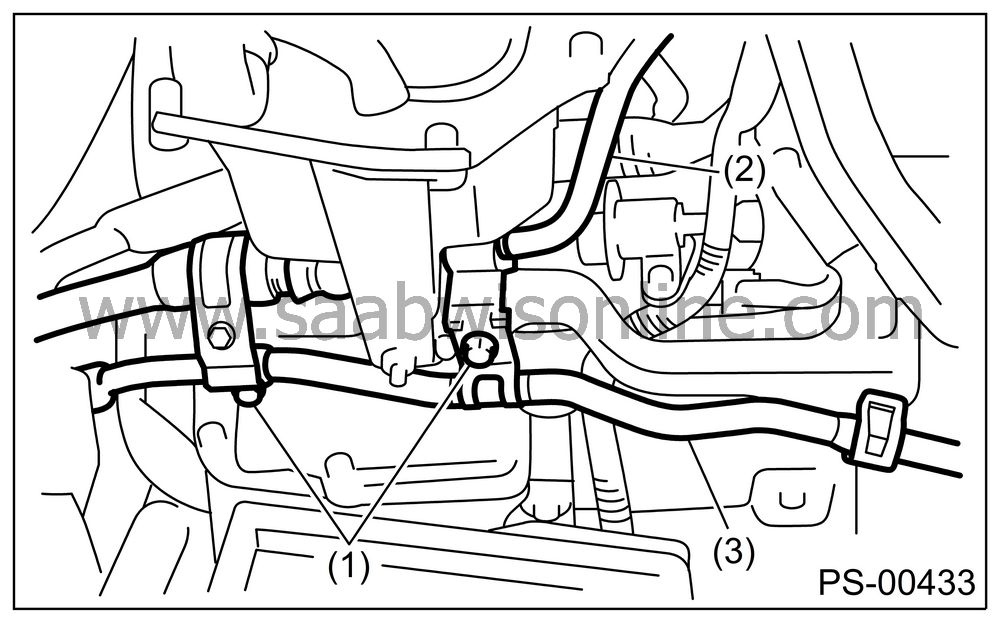

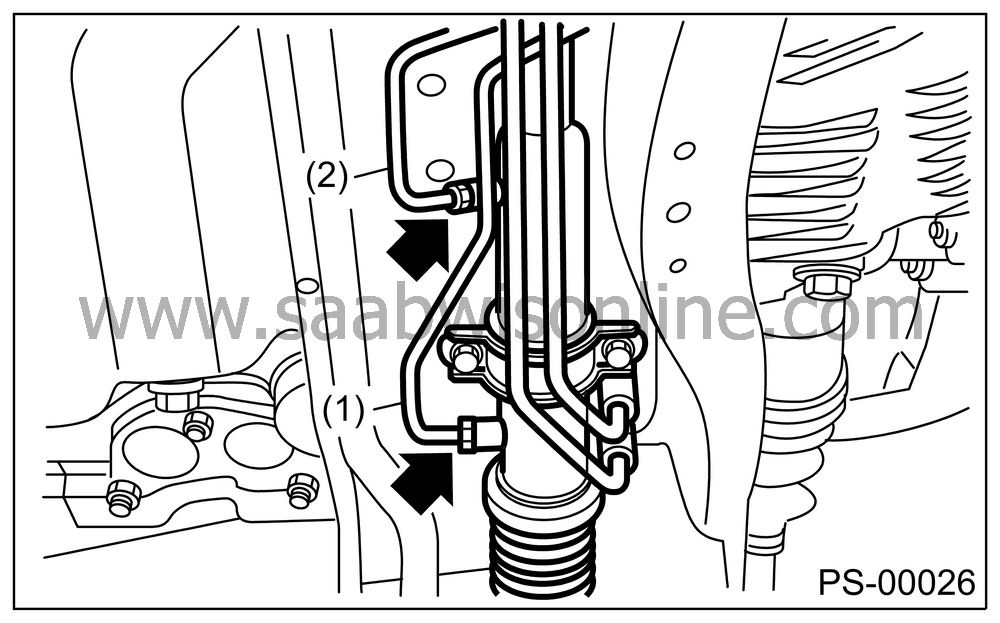

Connect the pipes A and B to four pipe joints of gearbox. Connect the upper pipe B first, and lower pipe A second.

Tightening torque:

Saab 9-2X 2.5i Linear:

13 Nm (1.3 kgf-m, 9.4 ft-lb)

Saab 9-2X 2.0T Aero:

Housing side:

20 Nm (2.0 kgf-m, 14.5 ft-lb)Cylinder side:

24 Nm (2.4 kgf-m, 17.4 ft-lb)

|

(1)

|

Pipe A

|

|

(2)

|

Pipe B

|

Install the jack-up plate.

Install the air intake duct.

Install the air intake duct, air cleaner upper cover and air intake boot.

and

and

Connect the battery ground cable to battery.

Feed the specified fluid.

| Important | ||

|

Never start the engine before feeding the fluid; otherwise vane pump might be seized up. |

||

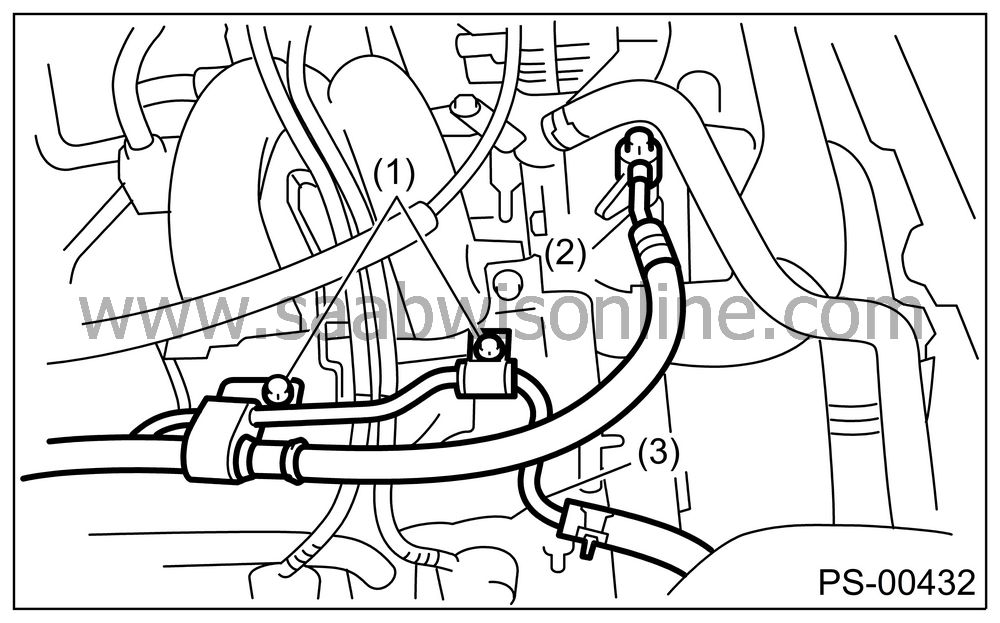

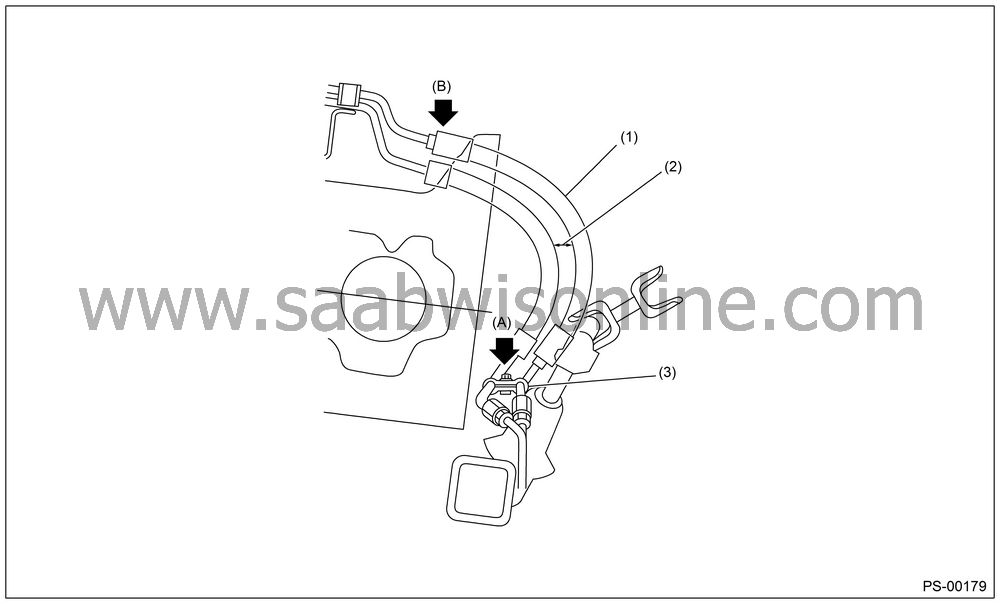

Finally check clearance between pipes and/or hoses, as shown above.

If cruise control actuator-to-power steering hose clearance is less than 10 mm (0.39 in), move the portion (A) secured by clamp to other portion, or bend portion (B) to adjust.

|

(1)

|

High pressure

hose

|

(2)

|

No interference is allowed between hoses.

|

(3)

|

Clearance between crossmember and pipe: 3 — 8 mm

(0.12 — 0.31 in)

|