INSPECTION

| INSPECTION |

| BASIC INSPECTION |

Clean all disassembled parts, and check for wear, damage, or any other faults, then repair or replace as necessary.

When disassembling, check the inside of gearbox for water. If any water is found, carefully check the boot for damage, input shaft dust seal, adjusting screw and boot clips for poor sealing. If faulty, replace with new parts.

| No. | Parts | Inspection | Corrective action |

|

1

|

Input

shaft

|

|

If the

bend or damage is excessive, replace the entire gearbox.

|

|

2

|

Dust

seal

|

|

If the

outer wall slips, the lip is worn out or damage is found, replace

it with a new one.

|

|

3

|

Rack

and pinion

|

Poor

mating of rack with pinion

|

Even if abnormality is found in either (1) or (2), replace the entire gearbox. |

|

4

|

Gearbox unit

|

|

Replace

the gearbox with a new one.

|

|

|

If the

free play of rack shaft in radial direction is out of the specified

range, replace the gearbox with a new one. (Refer to “Service

limit”.)

|

||

|

|

If the

free plays of input shaft in radial and axial directions are out

of the specified ranges, replace the gearbox with a new one. (Refer

to “Service limit”.)

|

||

|

5

|

Boot

|

Crack,

damage or deterioration

|

Replace.

|

|

6

|

Tie-rod

|

|

Replace.

|

|

7

|

Tie-rod

end

|

Damage

or deterioration on dust seal

|

Replace.

|

|

8

|

Adjusting

screw spring

|

Deterioration

|

Replace.

|

|

9

|

Boot

clip

|

Deterioration

|

Replace.

|

|

10

|

Sleeve

|

Damage

|

Replace.

|

|

11

|

Pipes

|

|

Replace.

|

| SERVICE LIMIT |

Make a measurement as follows. If it exceeds the specified service limit, adjust or replace.

| Note | ||

|

When making a measurement, vise the gearbox by using ST. Never vise the gearbox by inserting aluminum plates, etc. between vise and gearbox. |

ST 32005190 STAND

Sliding resistance of rack shaft:Service limit

400 N (41 kgf, 90 lb) or less

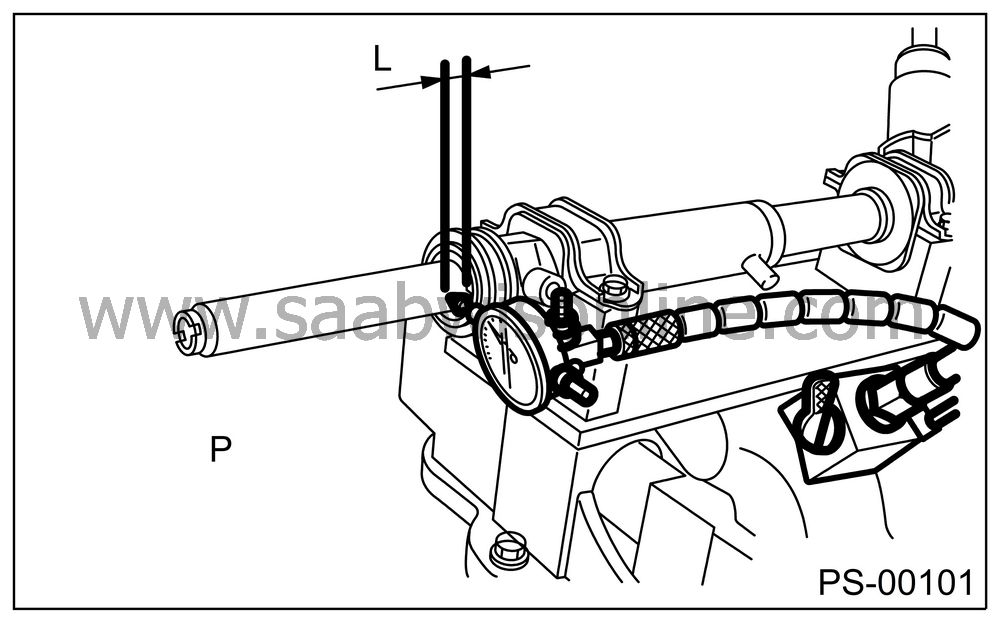

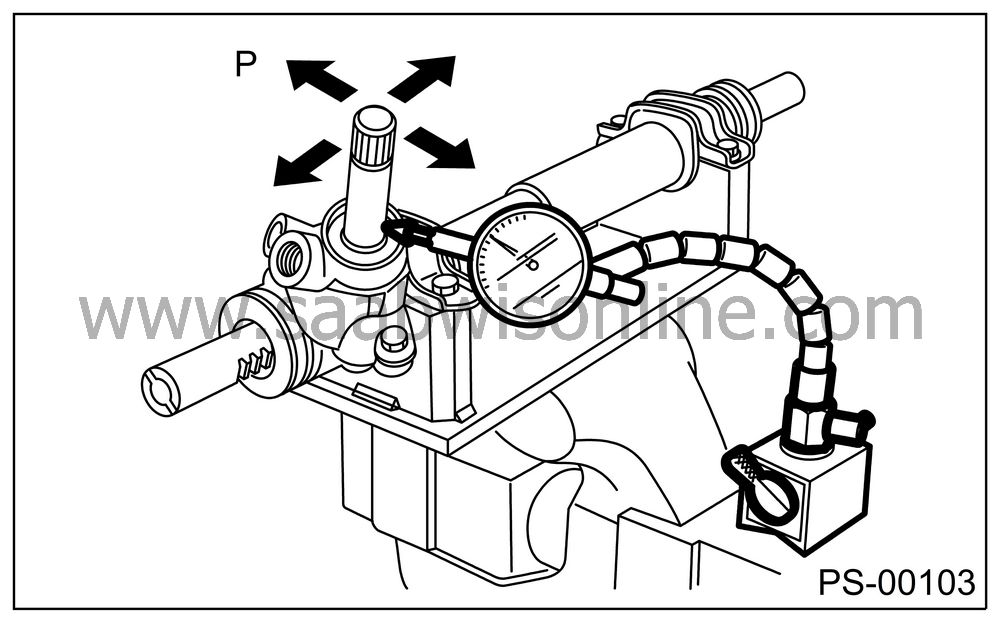

| RACK SHAFT PLAY IN RADIAL DIRECTION |

Right-turn steering:

Service limit

0.19 mm (0.0075 in) or less

On condition

L: 5 mm (0.20 in)

P: 122.6 N (12.5 kgf, 27.6 lb)

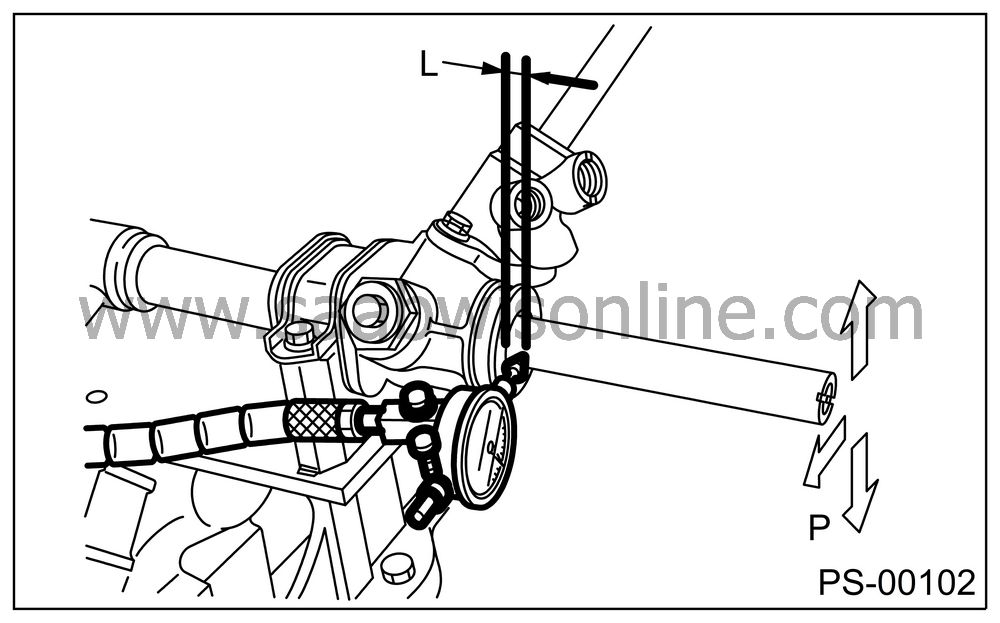

Left-turn steering:

Service limit

Direction

0.3 mm (0.012 in) or lessDirection

0.15 mm (0.0059 in) or lessL: 5 mm (0.20 in)

P: 98 N (10 kgf, 22 lb)

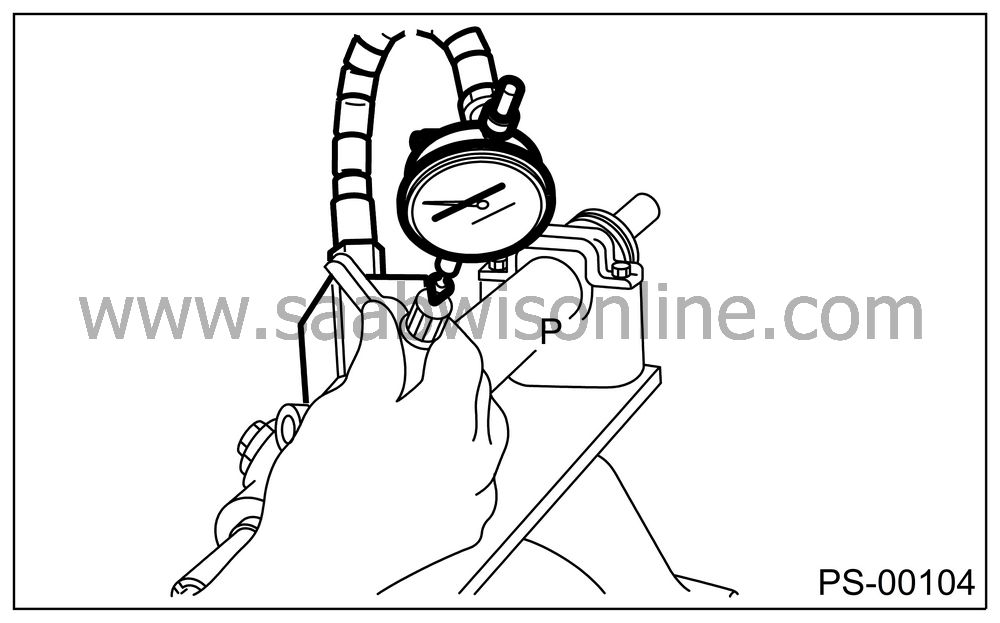

| INPUT SHAFT PLAY |

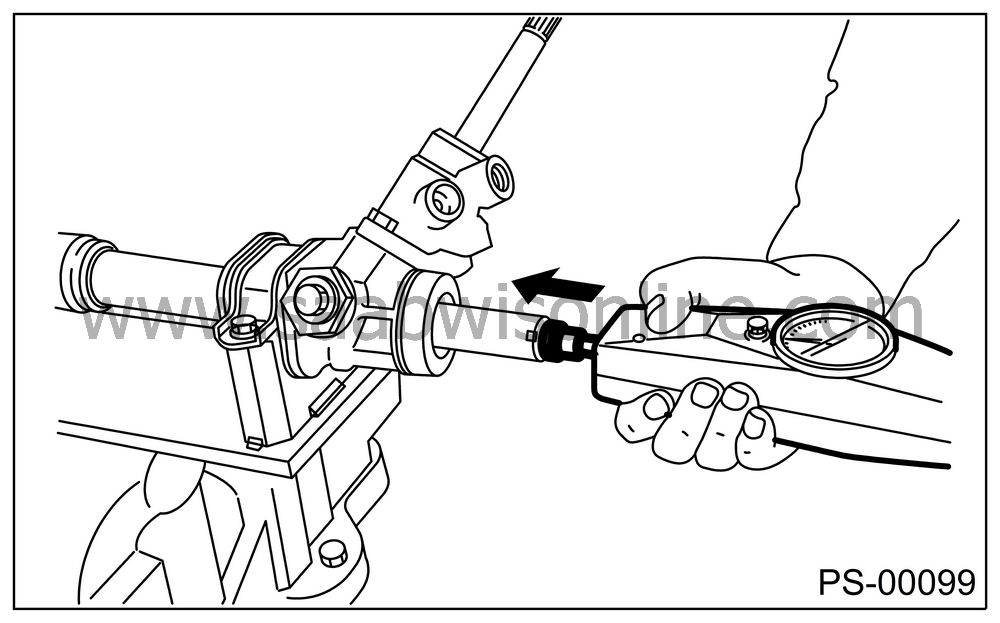

In radial direction:

Service limit

0.18 mm (0.0071 in) or less

On condition

P: 98 N (10 kgf, 22 lb)

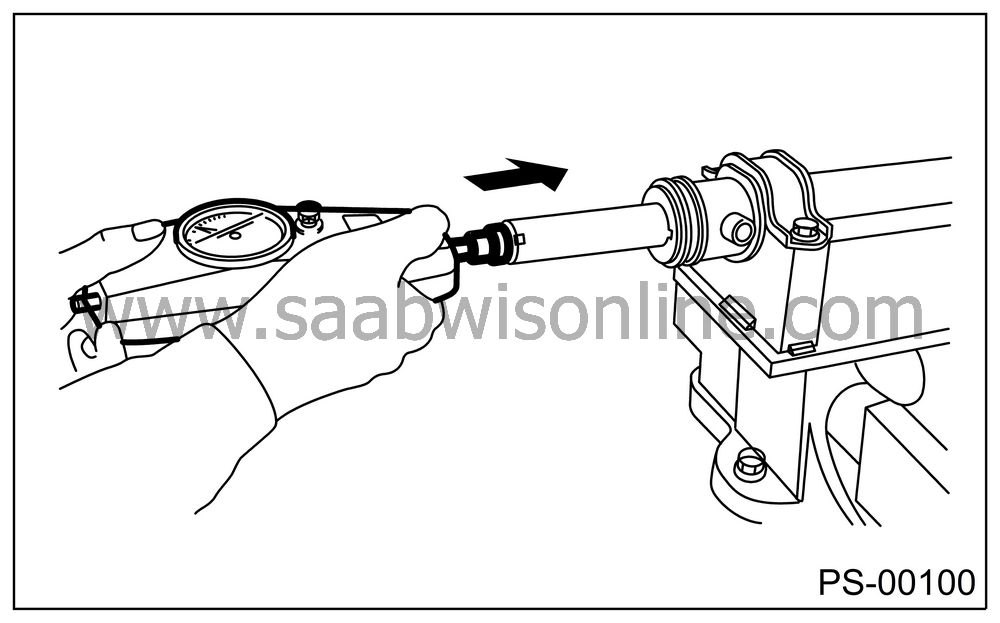

In axial direction:

Service limit

0.5 mm (0.020 in) or less

On condition

P: 20 — 49 N (2 — 5 kgf, 4 — 11 lb)

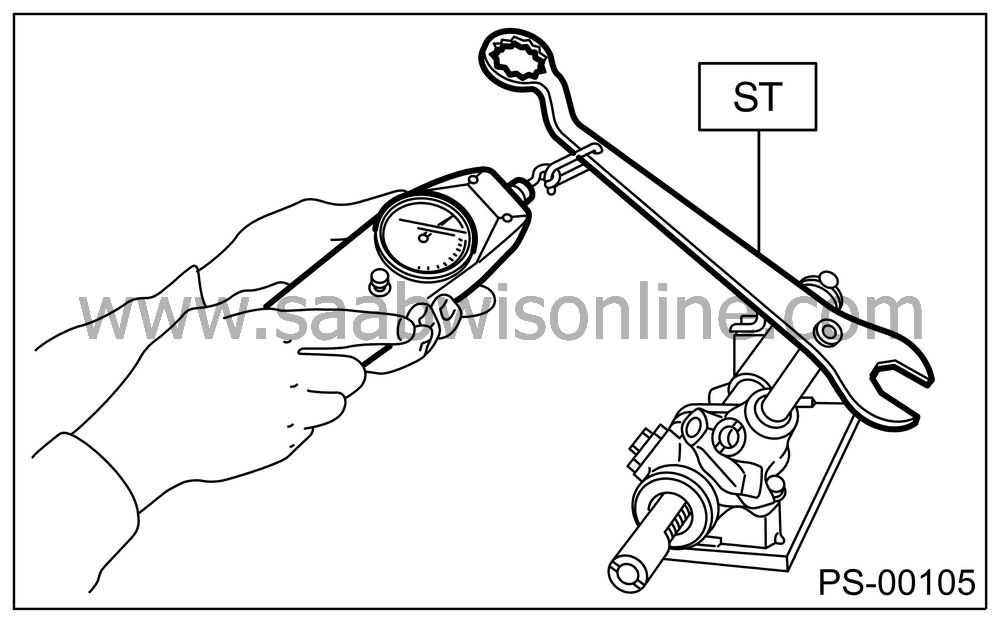

| TURNING RESISTANCE OF GEARBOX |

Using the ST, measure the gearbox turning resistance.

ST 32005049 SPANNER

Service limitMaximum allowable resistance

10.5 N (1.1 kgf, 2.4 lb) or lessDifference between right and left turning resistance: Less than 20%

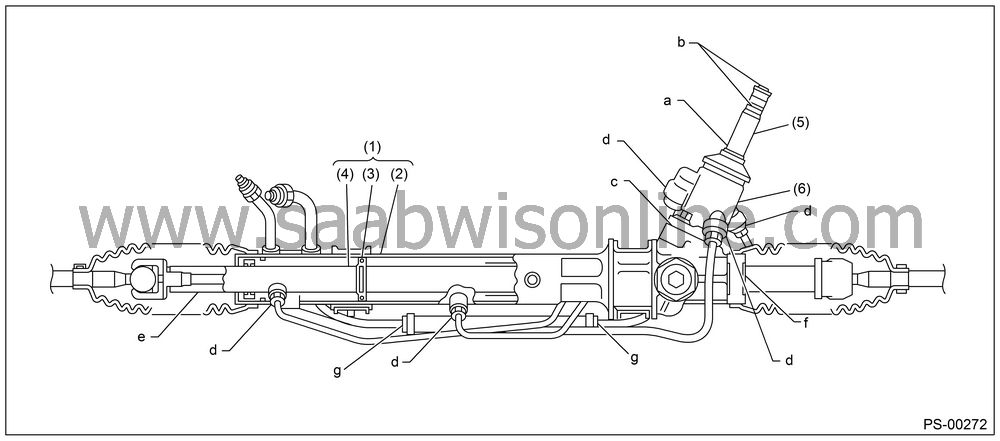

| OIL LEAKING |

|

(1)

|

Power cylinder

|

(3)

|

Rack piston

|

(5)

|

Input shaft

|

|

(2)

|

Cylinder

|

(4)

|

Rack axle

|

(6)

|

Valve housing

|

Lift up the vehicle.

Even if the location of the leak can be easily found by observing the leaking condition, it is necessary to thoroughly remove the fluid from the suspected portion and turn the steering wheel from lock to lock about thirty to forty times with engine running, then make comparison of the suspected portion between immediately after and several hours after this operation.

Inspect leakage from “a”.

The oil seal is damaged. Replace the valve assembly with a new one.

Inspect leakage from “b”.

The torsion bar O-ring is damaged. Replace the valve assembly with a new one.

Inspect leakage from “c”.

The oil seal is damaged. Replace the valve assembly or oil seal with a new one.

Inspect leakage from “d”.

The pipe is damaged. Replace the faulty pipe or O-ring.

Inspect leakage from “g”.

The hose is damaged. Replace the hose with a new one.

If leak is other than a, b, c, d, or g, and if oil is leaking from the gearbox, move the right and left boots toward tie-rod end side, respectively, with the gearbox mounted to the vehicle, and remove fluid from the surrounding portions. Then, turn the steering wheel from lock to lock thirty to forty times with the engine running, then make comparison of the leaked portion immediately after and several hours after this operation.

Leakage from “e”

The cylinder seal is damaged. Replace the rack bush with a new one.

Leakage from “f”

There are two possible causes. Take the following step first. Remove the pipe assembly B from the valve housing, and close the circuit with ST.

ST 32005196 PLUG

Turn the steering wheel from lock to lock thirty to forty times with the engine running, then make comparison of the leaked portion between immediately after and several hours after this operation.| • |

If leakage

from “f” is noted again:

The oil seal of pinion and valve assembly is damaged. Replace the pinion and valve assembly with a new one. Or replace the oil seal and parts that are damaged during disassembly with new ones. |

|

| • |

If oil stops leaking from “f”:

The oil seal of rack housing is damaged. Replace the oil seal and the parts that are damaged during disassembly with new ones. |

|