ASSEMBLY

| ASSEMBLY |

Before installing the coil spring, strut mount, etc., on strut, check for the presence of air in the damping force generating mechanism of strut since air prevents proper damping force from being produced.

Checking for the presence of air

Place the strut vertically with piston rod facing up.

Move the piston rod to center of its entire stroke.

While holding the piston rod end with fingertips, move the rod up and down.

If the piston rod moves at least 10 mm (0.39 in) in the former step, purge air from the strut.

Air purging procedure

Place the strut vertically with piston rod facing up.

Fully extend the piston rod.

With the piston rod fully extended, place the piston rod side down. The strut must stand vertically.

Fully contract the piston rod.

Repeat three or four times from first step.

| Note | ||

|

After completely purging air from strut, be sure to place the strut with piston rod facing up. If it is laid down, check for entry of air in the strut as outlined under “Checking for the presence of air”. |

Using a coil spring compressor, compress the coil spring.

| Note | ||

|

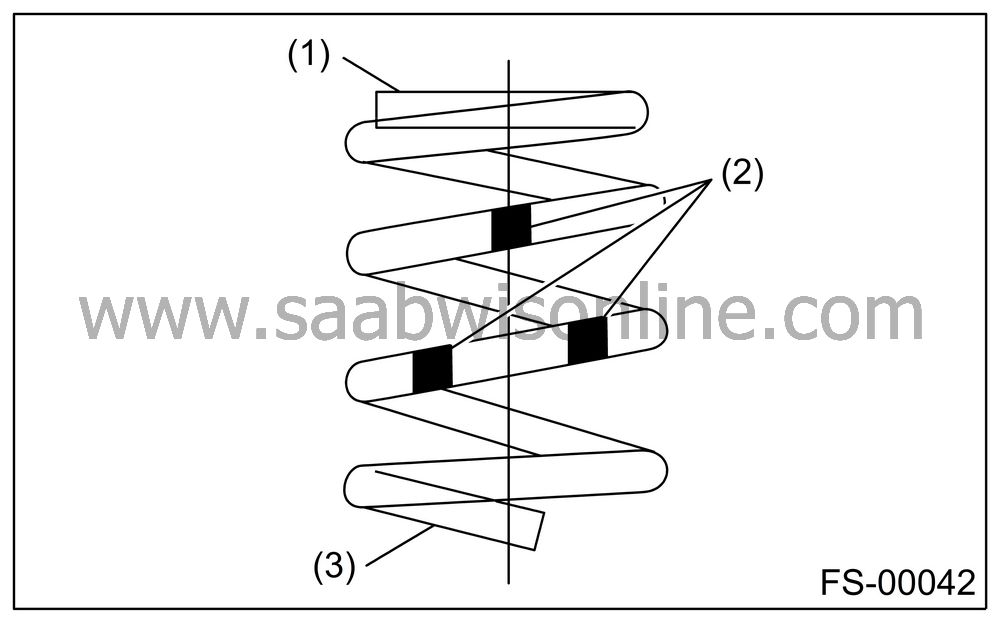

Make sure that the installing direction of coil spring is as shown in the figure. |

|

(1)

|

Flat (top

side)

|

|

(2)

|

Identification

paint

|

|

(3)

|

Inclined

(bottom side)

|

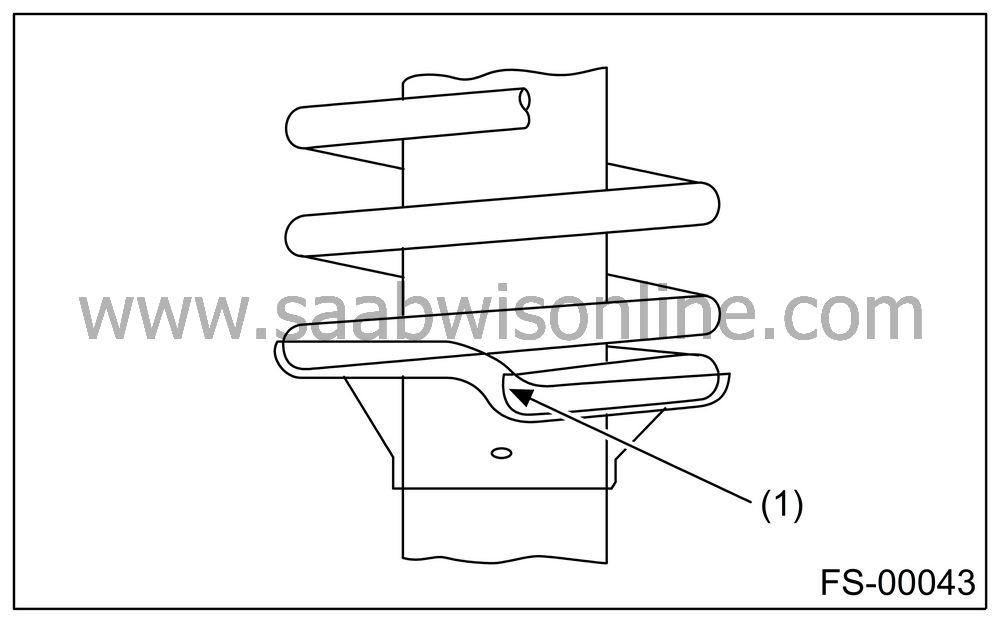

Set the coil spring correctly so that its end face fits well into the spring seat as shown in the figure.

|

(1)

|

Coil spring

end face

|

Install the helper and dust cover to the piston rod.

Pull the piston rod fully upward, and install the rubber seat and spring seat.

| Note | ||

|

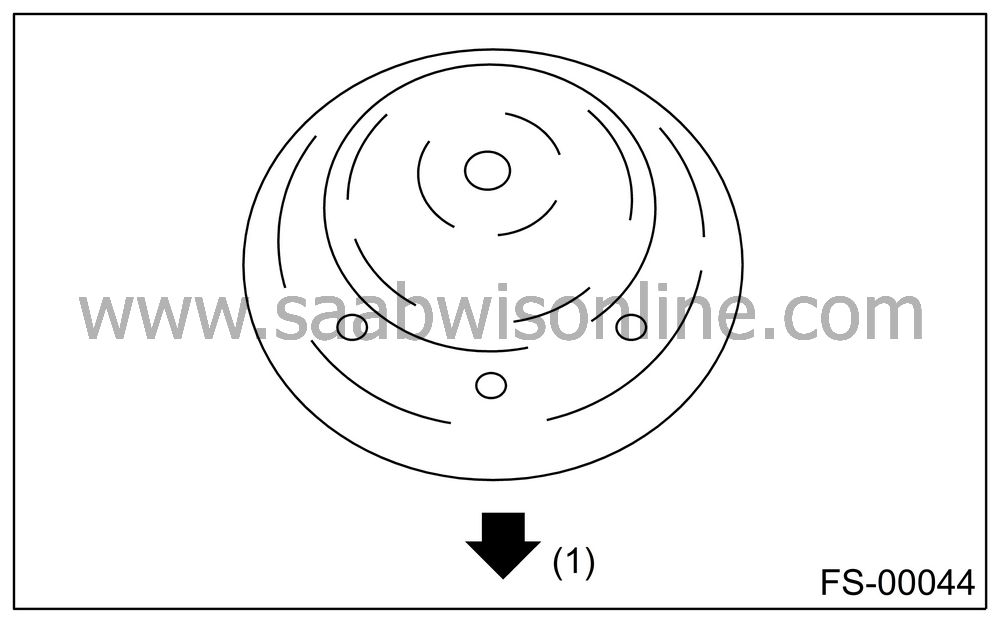

Ensure that the upper spring seat is positioned as shown in the figure. |

|

(1)

|

Outside

of body

|

Install the strut mount to the piston rod, and then tighten a new self-locking nut temporarily.

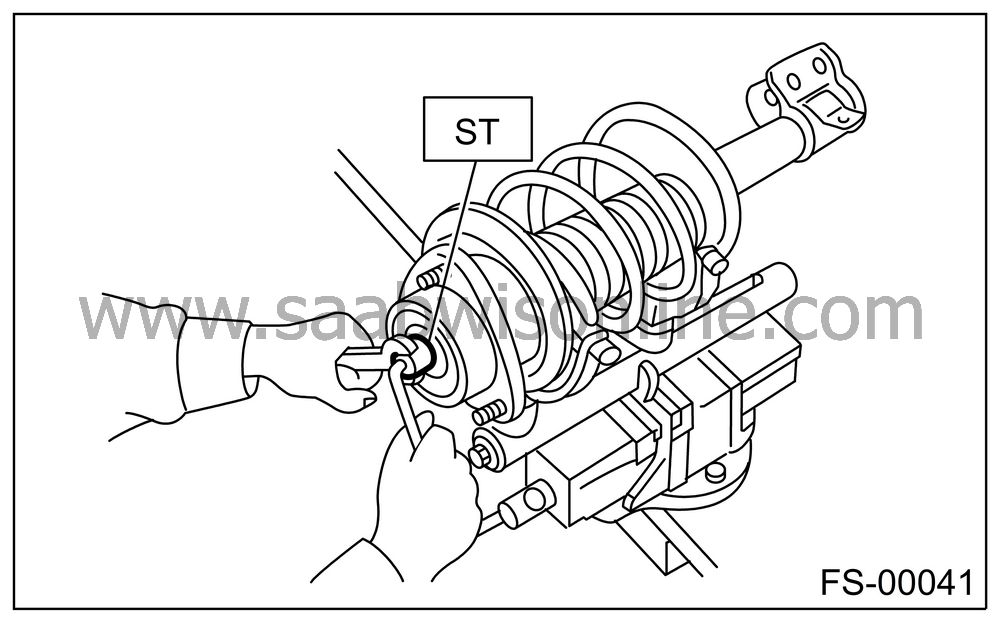

Using a hexagon wrench to prevent strut rod from turning, tighten the self-locking nut with ST.

ST 32005223 STRUT MOUNT SOCKET

Tightening torque:55 Nm (5.6 kgf-m, 41 ft-lb)

Loosen the coil spring carefully.