REPAIR

| REPAIR |

| COATING METHOD FOR PP BUMPER |

| REPAIR INSTRUCTIONS FOR COLORED PP BUMPER |

| Note | ||

|

All PP bumpers are provided with a grained surface, and if the surface is damaged, it cannot normally be restored to its former condition. Damage limited to shallow scratches that cause only a change in the lustre of the base material or coating, can be almost fully restored. Before repairing a damaged area, explain this point to the customer and get an understanding about the matter. Repair methods are outlined below, based on a classification of the extent of damage. |

Minor damage causing only a change in the lustre of the bumper due to a light touch

Almost restorable.

| Process No. | Process name | Job contents | |

|

1

|

Cleaning

|

Clean the area to be repaired using water.

|

|

|

2

|

Sanding

|

Grind the repairing area with #500 sand paper in

a “feathering” motion.

|

|

|

3

|

Finish

|

Resin

section

|

Coated

section

|

|

Repeatedly

apply wax to the affected area using a soft cloth (such as flannel).

Recommended wax: NITTO KASEI Soft 99 TIRE WAX BLACK, or equivalent.

|

Perform either the same operation as for the resin section

or process No. 18 and subsequent operations in the “3)” section,

depending on the degree and nature of damage.

|

||

|

Polish

the waxed area with a clean cloth after 5 to 10 minutes.

|

|||

Deep damage caused by scratching fences, etc.

A dent cannot be repaired but a whitened or swelled part can be removed.

| Process No. | Process name | Job contents | |

|

1

|

Cleaning

|

Clean the damaged area with water.

|

|

|

2

|

Removal

of damaged area

|

Cut off protruding area, if any, due to collision, using a

putty knife.

|

|

|

3

|

Sanding

|

Grind the affected area with #100 to #500

sand paper.

|

|

|

4

|

Finish

|

Resin

section

|

Coated

section

|

|

Same

as Process No. 3 in the “1)” section.

|

Perform

Process No. 12 and subsequent operations in the “3)” section.

|

||

Deep damage such as a break or hole that requires filling

Much of the peripheral grained surface must be sacrificed for repair, and the degree of restoration is not really worth the expense. (The surface, however, will become almost flush with adjacent areas.)

Recommended repair kit: PP Part Repair Kit (NRM)

| Process No. | Process name | Job contents | |||||||||||||||||||||||||||||

|

1

|

Bumper

removal

|

Remove the bumper as required.

|

|||||||||||||||||||||||||||||

|

2

|

Part

removal

|

Remove the parts built into bumper as required.

|

|||||||||||||||||||||||||||||

|

3

|

Bumper

placement

|

Place

the bumper on a paint worktable as required.

It is recommended that contour of worktable accommodate internal shape of bumper. |

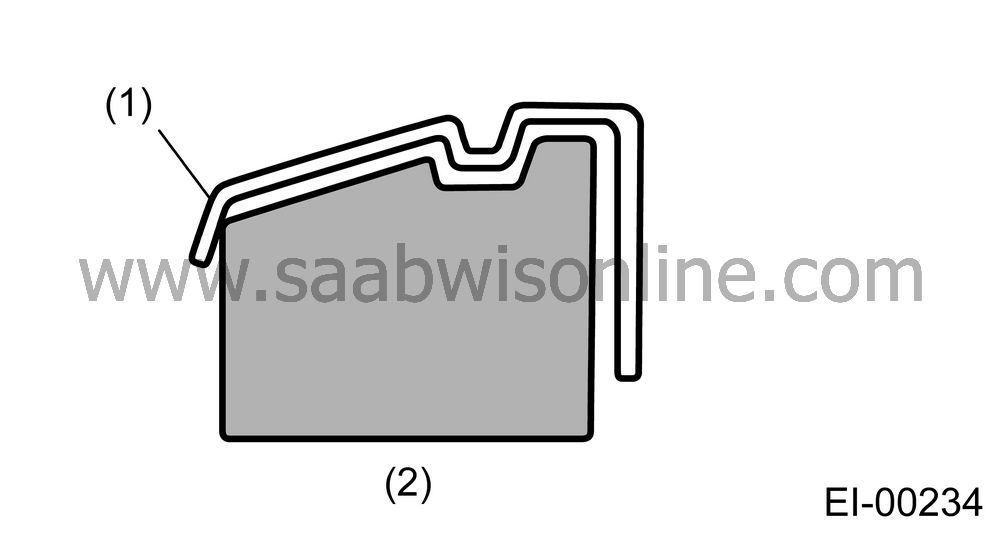

(1) Bumper (2) Set bumper section |

||||||||||||||||||||||||||||

|

4

|

Surface

preparation

|

Remove dust, oil, etc. from areas to be repaired and surrounding

areas, using a suitable solvent (NRM No. 900 Precleno, white gasoline,

or alcohol).

|

|||||||||||||||||||||||||||||

|

5

|

Cutting

|

If nature

of damage are cracks or holes, cut a guide slit of 20 to 30 mm (0.79

to 1.18 in) in length along the crack or hole up to the bumper’s

base surface. Then, bevel or “vee-out” the affected

area using a knife or grinder.

|

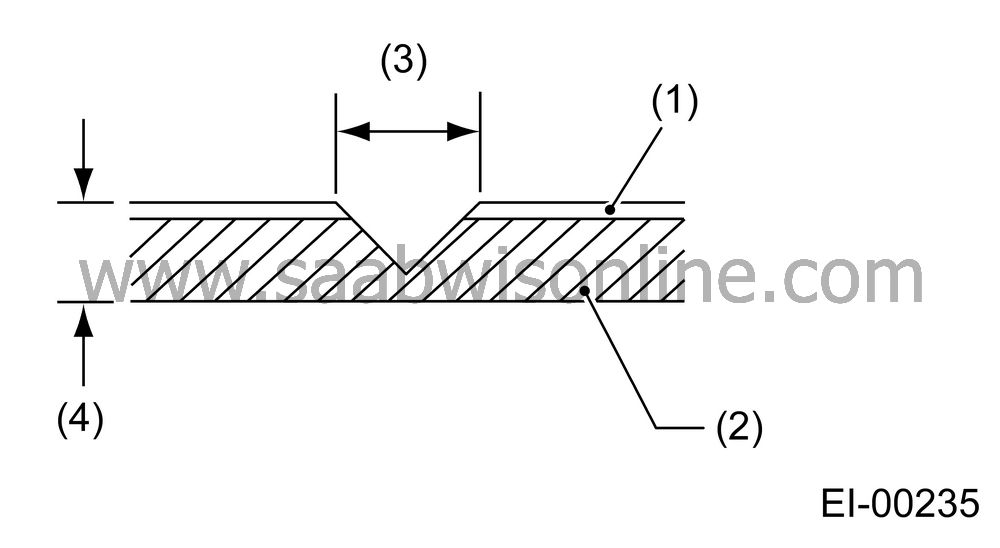

(1) Paint surface (2) PP base surface (3) 20 — 30 mm (0.79 — 1.18 in) (4) 3 mm (0.12 in) |

||||||||||||||||||||||||||||

|

6

|

Sanding

(I)

|

Grind beveled surface with sand paper (#40 to #60)

to smooth finish.

|

|||||||||||||||||||||||||||||

|

7

|

Cleaning

|

Clean the sanded surface with the same solvent as used in

Process No. 4.

|

|||||||||||||||||||||||||||||

|

8

|

Temporary welding

|

Grind the side just opposite the beveled area with sand paper

(#40 to #60) and clean using a solvent.

Temporarily spot-weld the side, using a PP welding rod and heater gun. |

|||||||||||||||||||||||||||||

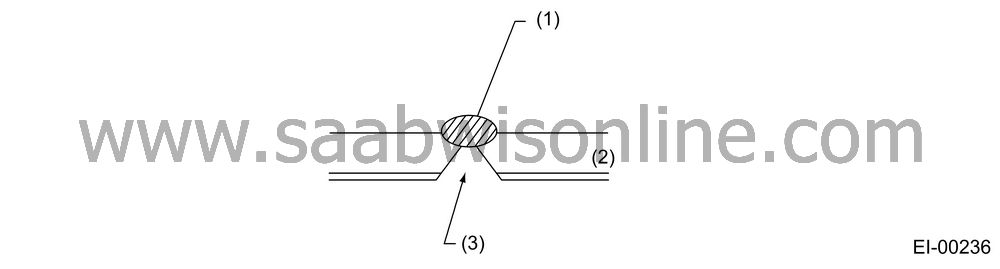

(1) Welded spot (Use heater gun and PP welding rod) (2) PP base surface (3) Beveled section

|

|||||||||||||||||||||||||||||||

|

9

|

Welding

|

Using a heater gun and PP welding rod, weld the beveled spot

while melting the rod and damaged area.

|

|||||||||||||||||||||||||||||

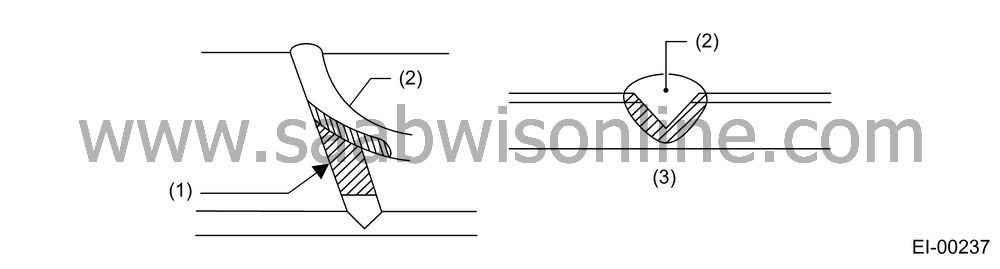

(1) Melt hatched area (2) Welding rod (3) Section

|

|||||||||||||||||||||||||||||||

|

10

|

Sanding (II)

|

Remove excess part of weld with a putty knife. If a drill

or disc wheel is used instead of the knife, operate it at a rate

lower than 1,500 rpm and grind the excess part little by little.

A higher rpm will cause the PP substrate to melt from the heat.

|

|||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||

|

Sand the welded spot smooth with #240 sand paper.

|

|||||||||||||||||||||||||||||||

|

11

|

Masking

|

Mask the black substrate section using masking tape.

Recommended masking tape: Nichiban No. 533 or equivalent |

|||||||||||||||||||||||||||||

|

12

|

Cleaning/

degreasing |

Completely clean the entire coated area, using solvent similar

to that used in Process No. 4.

|

|||||||||||||||||||||||||||||

|

13

|

Primer

coating

|

Apply a coat of primer to the repaired surface and its surrounding

areas. Mask these areas, if necessary.

Recommended primer: Mp/ 364 PP Primer

|

|||||||||||||||||||||||||||||

|

14

|

Leave

unattended.

|

Leave the repaired area unattended at 20°C (68°F)

for 10 to 15 minutes until primer is half-dry.

|

|||||||||||||||||||||||||||||

|

15

|

Primer

surfacer coating

|

Apply a coat of primer surfacer to the repaired area two or

three times at an interval of 3 to 5 minutes.

Recommended surfacer:

|

|||||||||||||||||||||||||||||

|

16

|

Drying

|

Allow the coated surface to dry for 60 minutes at 20°C

(68°F) [or 30 minutes at 60°C (140°F)].

|

|||||||||||||||||||||||||||||

|

17

|

Sanding

(III)

|

Sand the coated surface and its surrounding areas using #400

sand paper and water.

|

|||||||||||||||||||||||||||||

|

18

|

Cleaning/

degreasing |

Same as Process No. 12.

|

|||||||||||||||||||||||||||||

|

19

|

Top coat (I)

|

Solid

color

|

Metallic

color

|

||||||||||||||||||||||||||||

Use

a “block” coating method.

|

Use

a “block” coating method.

|

||||||||||||||||||||||||||||||

|

20

|

Leave

unattended.

|

Not

required.

|

Leave

unattended at 20°C (68°F) for at least 10 minutes

until the topcoated area is half-dry.

|

||||||||||||||||||||||||||||

|

21

|

Top

coat (II)

|

Not

required.

|

Apply

a clear coat three times at an interval of 3 to 5 minutes.

|

||||||||||||||||||||||||||||

|

22

|

Drying

|

Allow the coated surface to dry at 20°C (68°F)

for two hours or 60°C (140°F) for 30 minutes.

|

|||||||||||||||||||||||||||||

|

23

|

Inspection

|

Carefully check the condition of the repaired area.

|

|||||||||||||||||||||||||||||

|

24

|

Masking

removal

|

Remove the masking tape applied in Process No. 11 and 13.

|

|||||||||||||||||||||||||||||

|

25

|

Parts

installation

|

Install the parts on bumper in reverse order of removal.

|

|||||||||||||||||||||||||||||

|

26

|

Bumper

installation

|

Install the bumper.

|

|||||||||||||||||||||||||||||