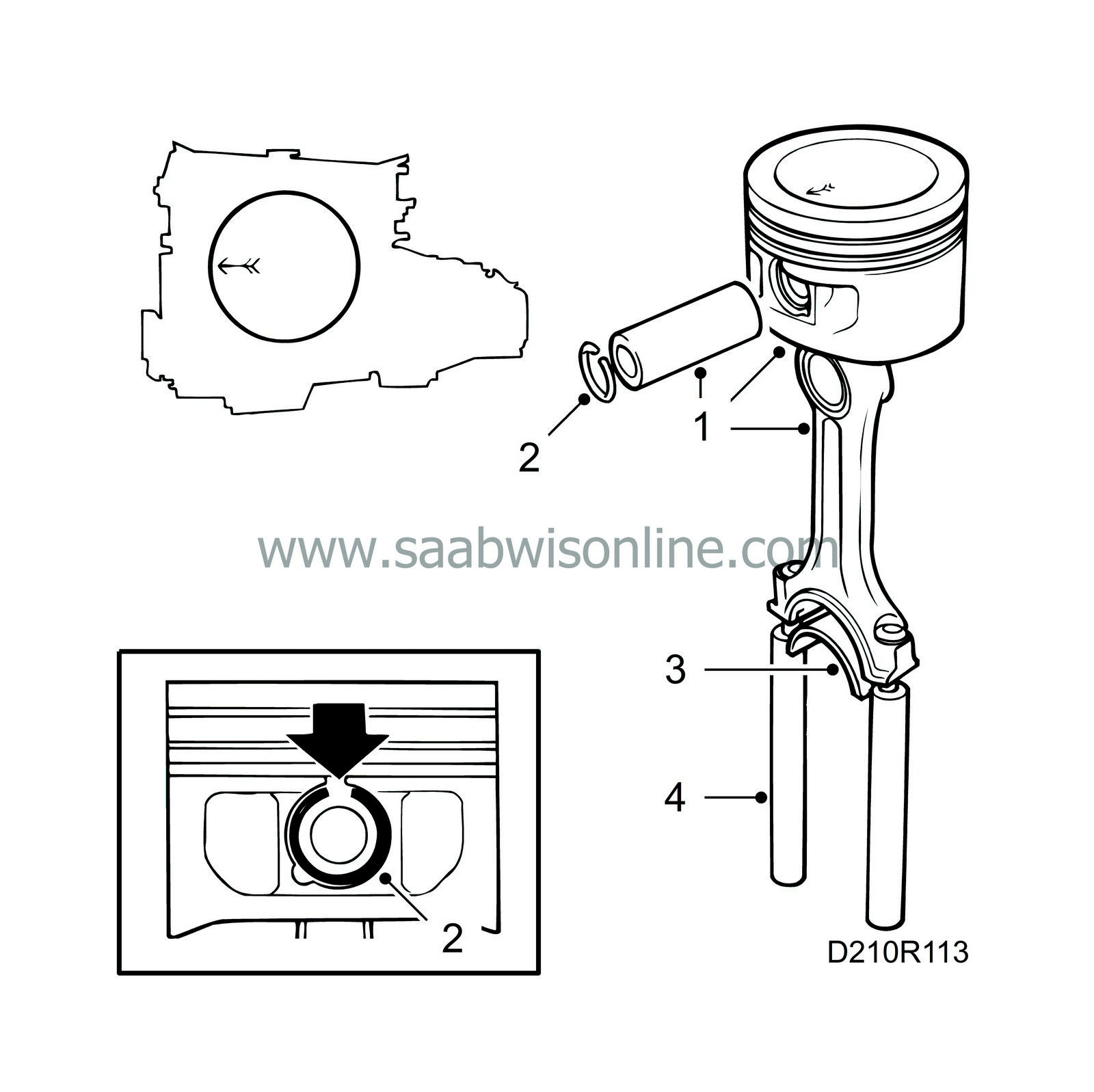

Fitting pistons (in situ)

| Fitting pistons (in situ) |

| Important | ||

|

Pistons of different makes must not be used in the same engine. The name of the manufacturer is cast inside the piston. |

||

| 1. |

Assemble piston and connecting rod by driving in the gudgeon pin, using a plastic mallet and drift. Make sure that the mark on the piston crown faces the timing cover and that the numbers on the connecting rods face the exhaust side.

|

|

| 2. |

Fit the gudgeon pin lock ring.

|

|||||||||

| 3. |

Place the bearing shells in place in the connecting rods.

|

|

| 4. |

Fit protective sleeves, part no. 75 19 531, on the connecting rod studs and oil the piston rings, bearings and cylinder.

|

|

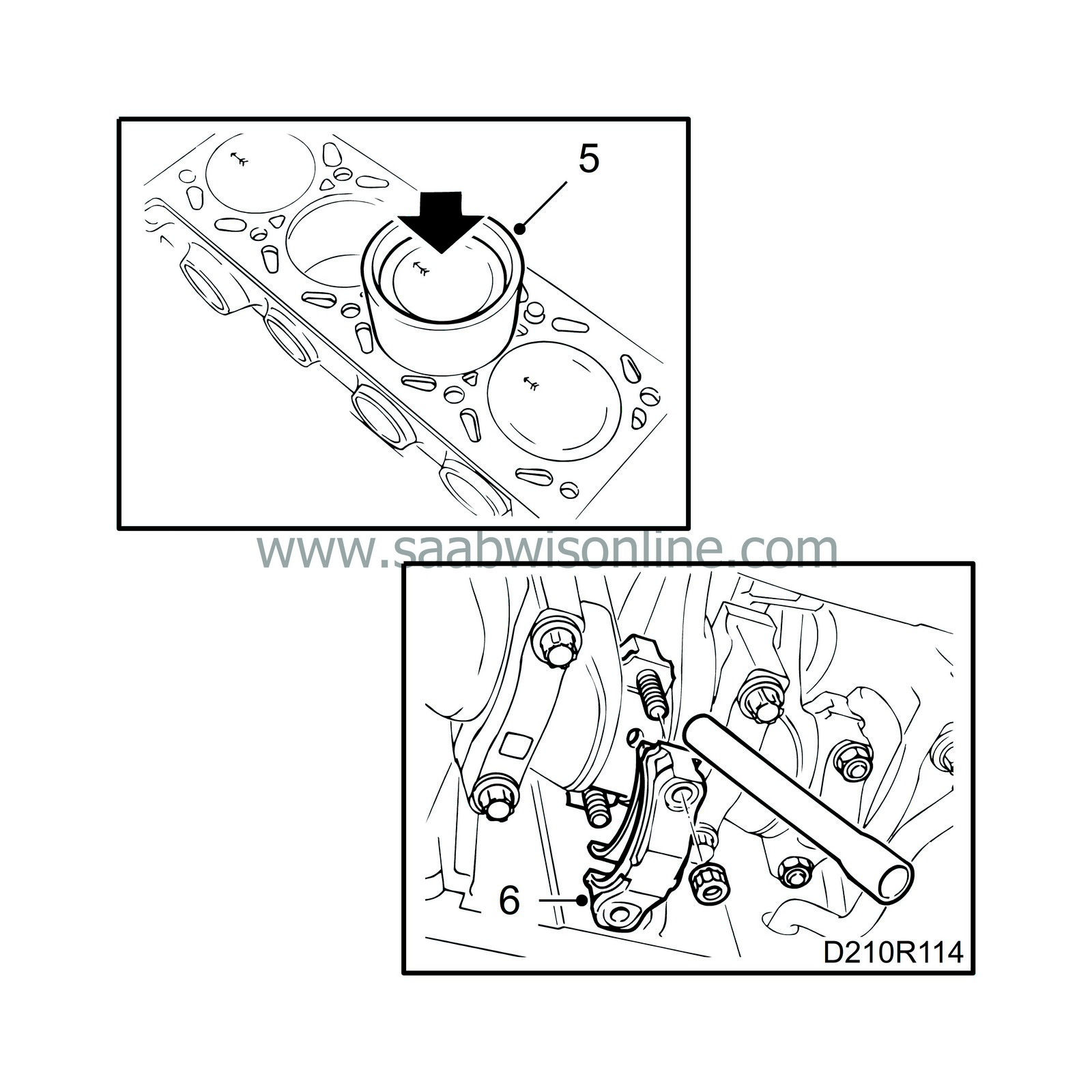

| 5. |

Fit the piston using the fitting tool, part no. 78 62 287.

|

|

| 6. |

Fit the big-end bearing caps with bearing shells (connecting rod numbers facing in the same direction).

Tightening torques: 20 Nm + 70° (14.8 lbf ft + 70°) |

|

| 7. |

Check that there are no impurities or other foreign matter in the sump and clean the sealing surfaces with benzine.

|

|

| 8. |

Apply an even bead of Loctite 518 on the sealing surface of the oil sump and fit the oil sump.

Tightening torque: 22 Nm (16.2 lbf ft). |

|

| 9. |

Fit the protective plate.

|

|

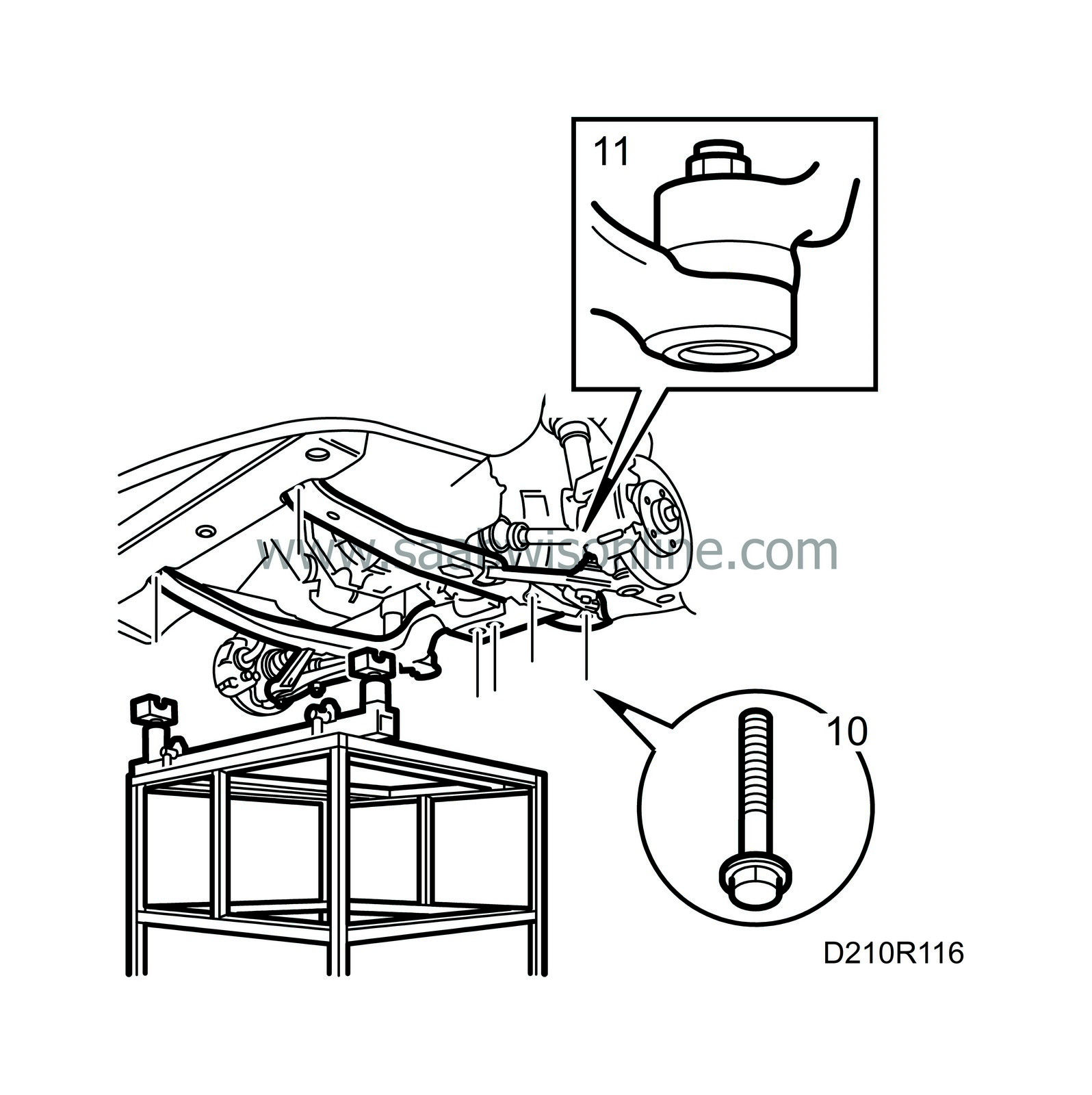

| 10. |

Lift up the subframe and bolt it in place.

Tightening torques: Front: 115 Nm (85 lbf ft) Centre: 190 Nm (140.6 lbf ft) Rear: 110 Nm + 75° (81.4 lbf ft + 75°) |

|

| 11. |

Fit and tighten the end piece nuts.

Tightening torque: 75 Nm (55.5 lbf ft) |

|

| 12. |

Clean the area for the joint in the exhaust pipe.

|

|

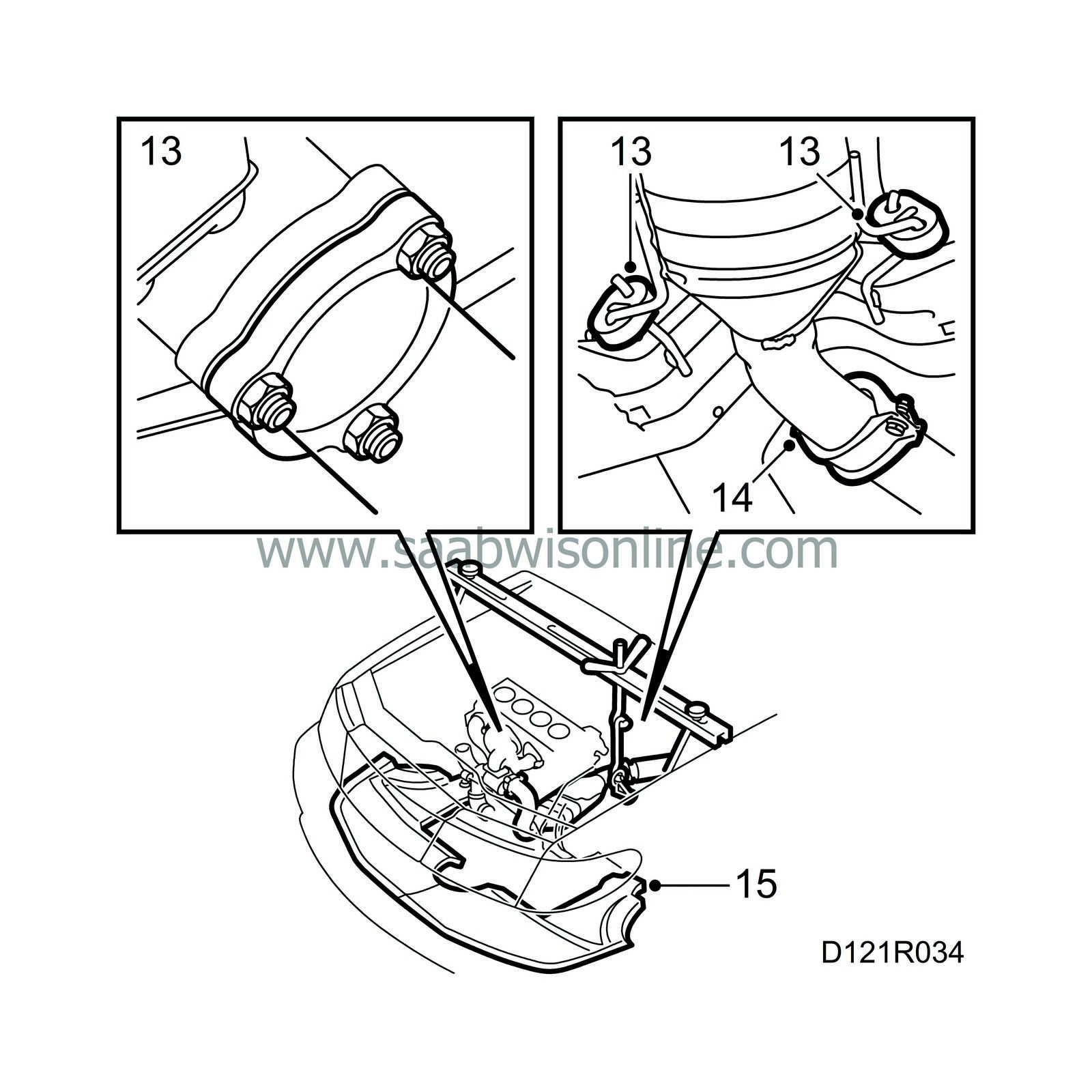

| 13. |

Fit the front exhaust pipe. Lubricate the stud screws on the turbocharger with Molycote 1000 before fitting.

|

|

| 14. |

Screw together the joint between the front and intermediate exhaust pipes.

|

|

| 15. |

Fit the air shields and wheels.

Tightening torques: Wheels: 120 Nm (89 lbf ft) |

|

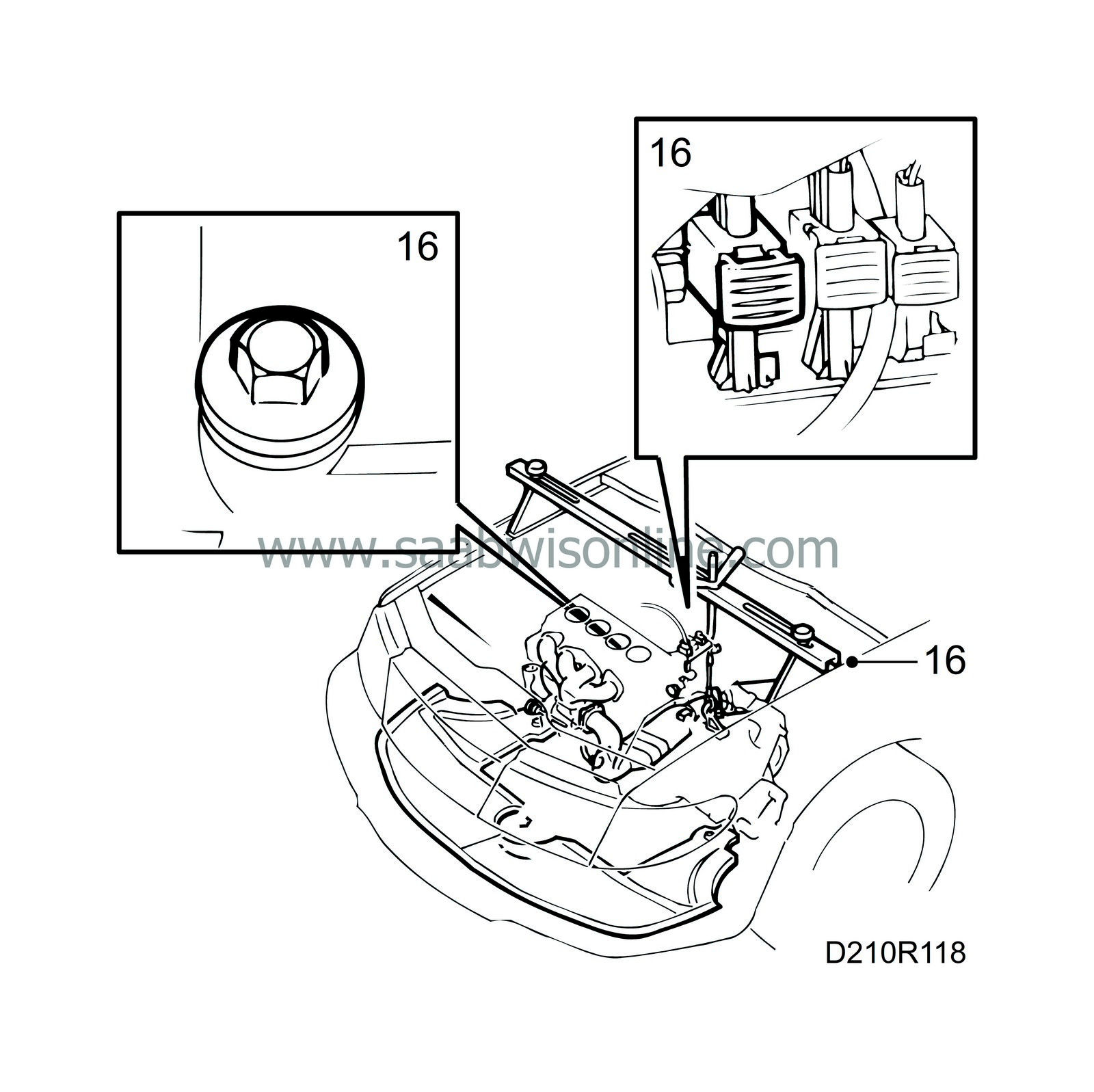

| 16. |

Make sure the oil drain plug is tight, lower the car and fill with engine oil. Replace the dipstick, connect the oxygen sensor cable and remove the lifting beam

|

|

Warning

Warning