Matching of pistons

| Matching of pistons |

| Important | ||

|

Pistons of different makes must not be used in the same engine. The name of the manufacturer is cast inside the piston. |

||

Pistons are stocked as a spare part in standard and oversize dimensions. When oversized pistons are used, the cylinder bore must be rebored to obtain the correct piston clearance.

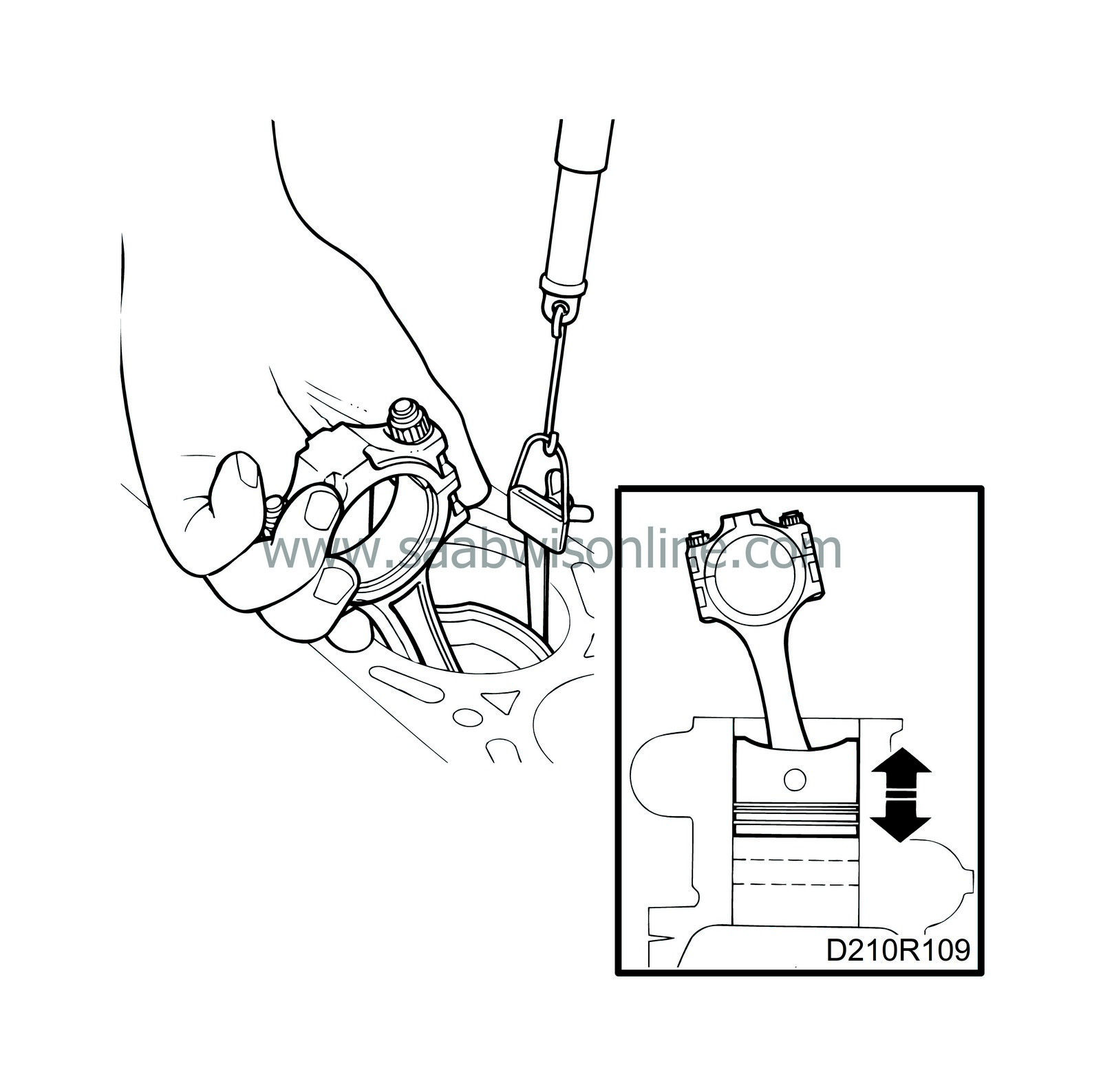

Use a 1/2” feeler gauge when fitting in the pistons to their bores. The cylinder bore must be lightly oiled and the piston, without rings, must be placed in the bore in which it is to be fitted while measuring. Connect the feeler gauge to a spring balance and place it between the piston and the cylinder bore at right angles to the gudgeon pin. When pulling power is 8-12 N (1.8-2.7 lbf), the mean play corresponds with the thickness of the feeler gauge. Test at several levels.

For piston clearances, see

Example: class A cylinder and class A piston

When the pistons are measured in the engine with a 0.05 mm feeler gauge, no measurable force will be recorded on the spring balance in cylinders 2 and 3. This means that the piston clearance in cylinders 2 and 3 is greater than 0.05 mm and these cylinders are judged to have a maximum tolerance, 90.012, and to be slightly bedded-in, which should result in +0.003 mm = 90.015 mm.Assuming a class AB piston, the theoretical piston clearance will be 0.026-0.035 mm.

In cylinders 1 and 4, the pistons cannot be fitted together with a 0.05 mm or 0.04 mm feeler gauge.

With a 0.03 mm feeler gauge, the force necessary to withdraw it will be 20 N (4.6 lbf) and with a 0.02 mm feeler gauge, it will be 6 N (1.4 lbf).

The piston clearance in cylinders 1 and 4 is assumed to be 0.024 mm and the pistons in these cylinders will not need replacing.