To assemble the engine

| To assemble the engine |

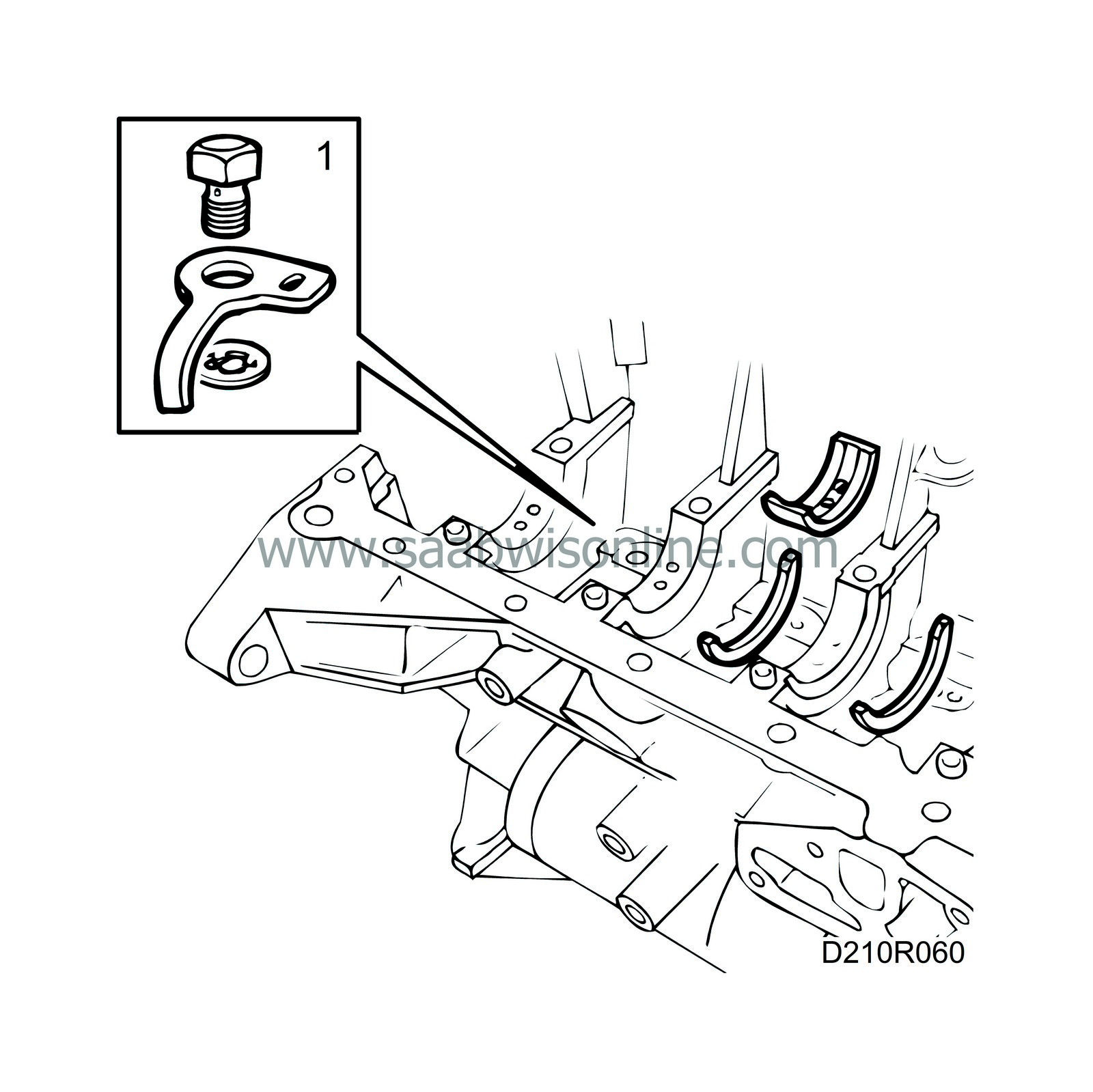

| 1. |

Fit the piston cooling nozzles. Place all main bearings in their correct positions and coat them with oil.

Tightening torques: Piston cooling nozzle: 18 Nm (13.3 lbf ft) |

|

| 3. |

Lubricate and fit all main bearing caps in their correct places, making sure that they are the right way round.

Tightening torques: 20 Nm + 70° (14.8 lbf ft + 70°) |

|

| 4. |

Turn the compression rings so that the gaps are staggered 180° and centred with the ends of the gudgeon pin. Also make sure that the gaps in the top and bottom rings of the three-part scraper ring are not in line with each other.

|

|

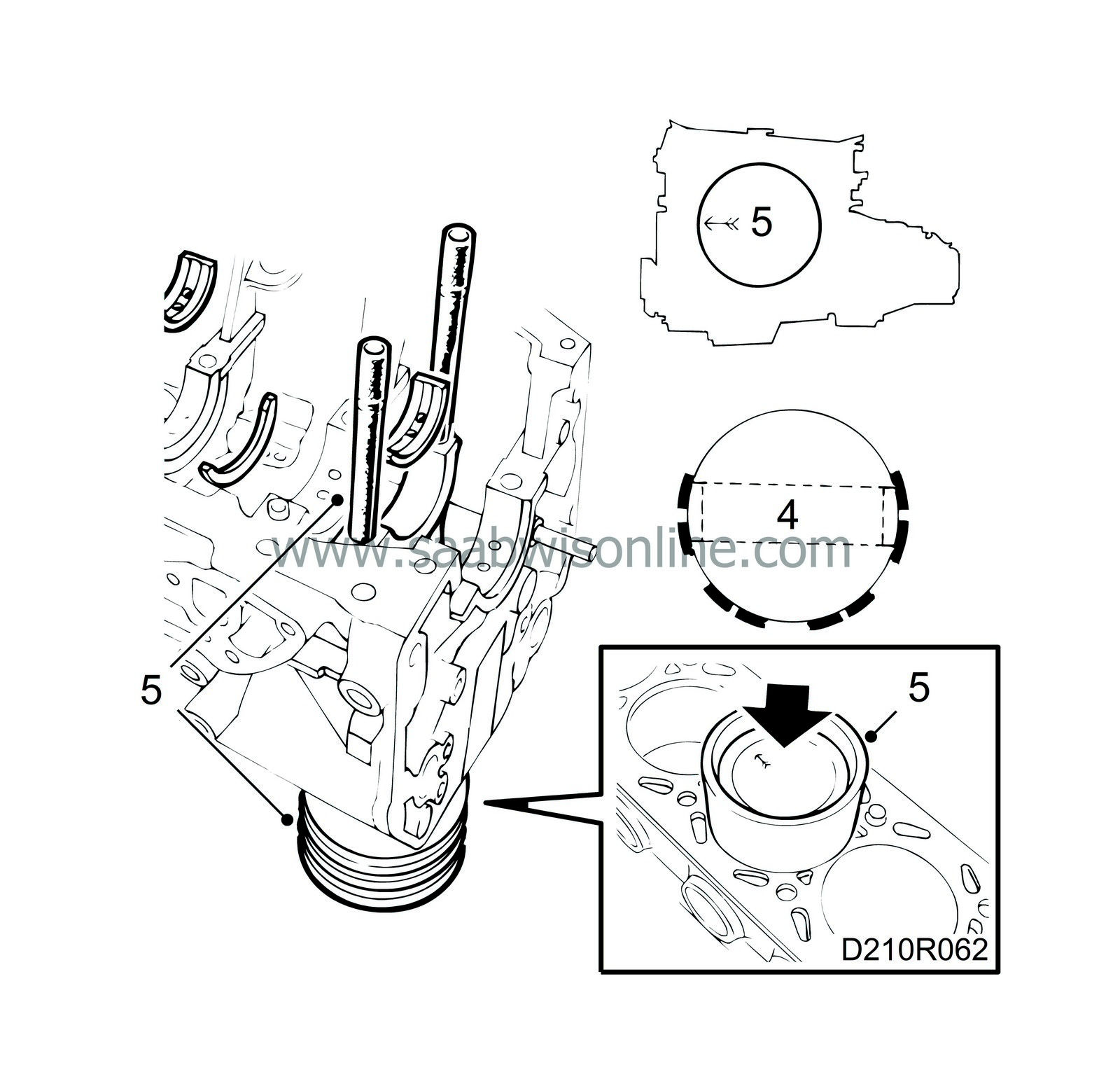

| 5. |

Fit protective sleeves, part no. 75 19 531, onto the connecting rod studs, lubricate the pistons and rings and fit the pistons into their respective cylinders. Make sure the arrow on the piston crown faces the timing end of the engine. Use the fitting tool, part no. 78 62 287, and gently tap the pistons into their bores.

|

|

| 6. |

Lubricate and fit all big-end bearing caps in their original positions, making sure that they are the right way round (number to number, groove in shell to groove in shell).

Tightening torques: 20 Nm + 70° (14.8 lbf ft + 70°) |

|

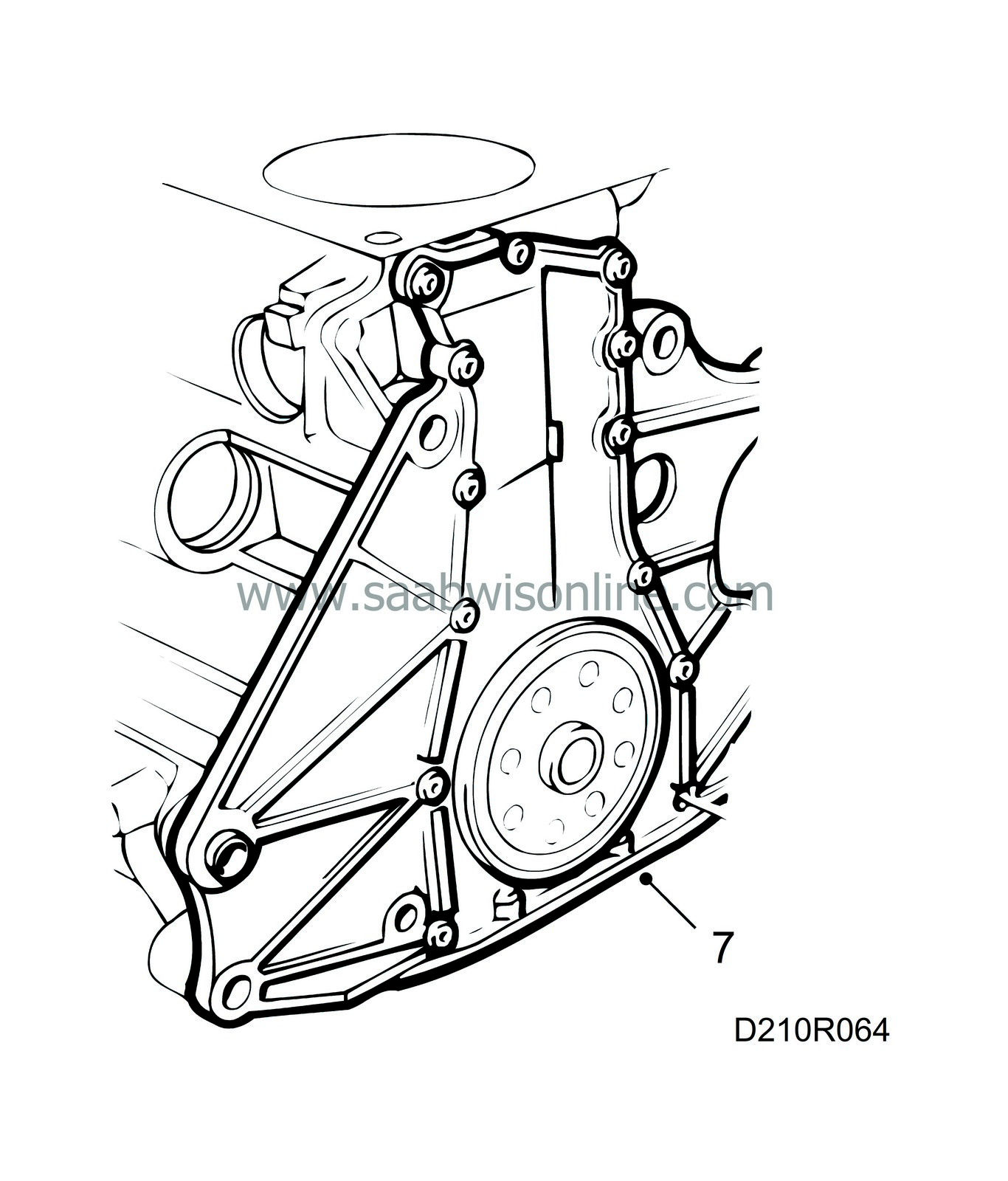

| 7. |

Apply Loctite 518 in a bead approx. 1 mm wide on the mating face of the end plate and fit the end plate. Mind the seal.

Tightening torque: 10 Nm (7.4 lbf ft) |

|

| 8. |

Fit the flywheel or, alternatively, the drive plate loosely. Use Loctite 270D on the bolts. Fit the flywheel locking segment, part no. 83 94 868, and tighten the bolts.

Tightening torque: 20 Nm + 50° (15 lbf ft + 50°) |

|

| 9. |

Align the 0-marking on the flywheel or, alternatively, the drive plate with the marking on the end plate.

|

|

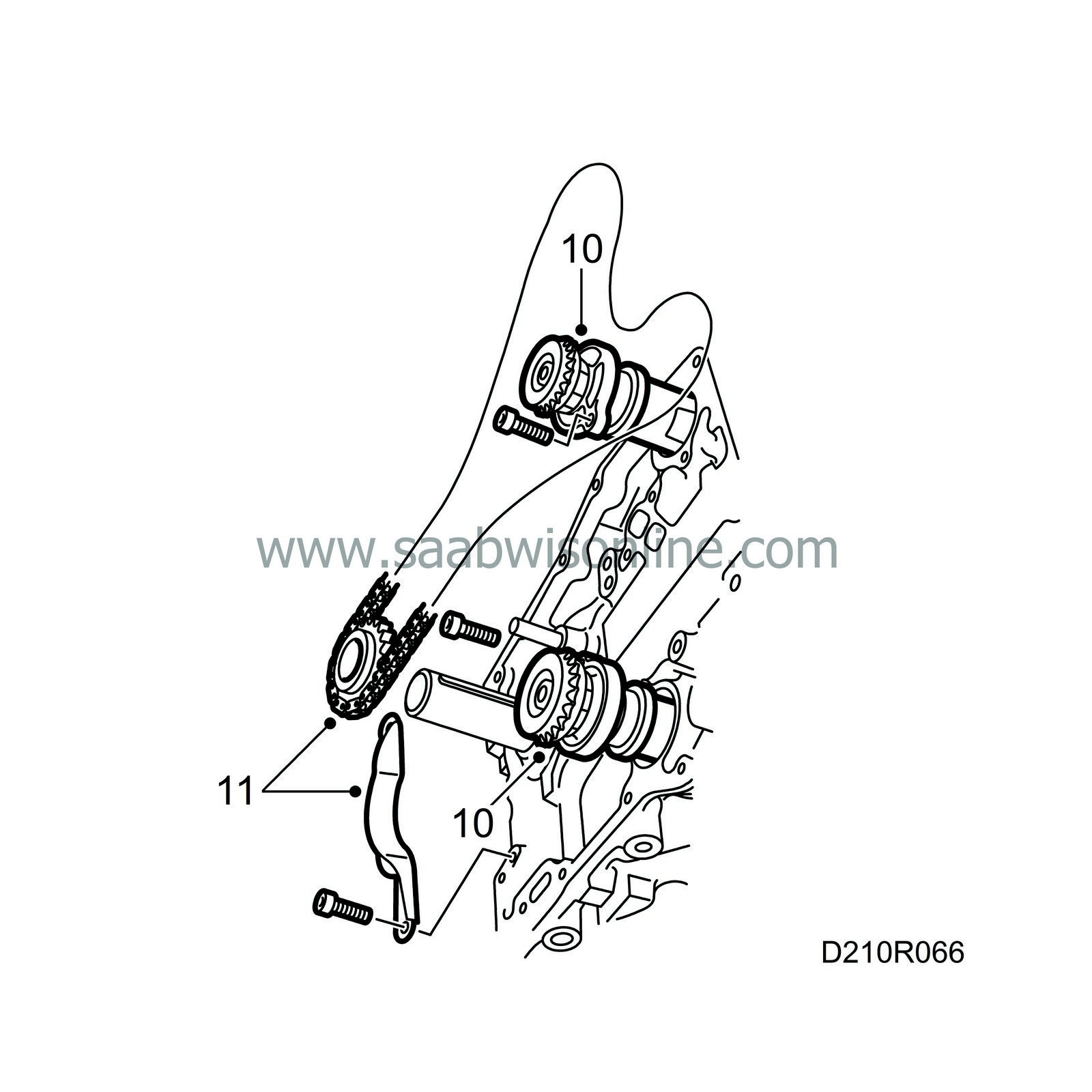

| 10. |

Lubricate the bearing surfaces on the balancer shafts and in the bearing housings and insert the balancer shafts into their respective tunnels, taking the utmost care to avoid damaging the bearing shells inside.

Tightening torques: Bearing housing, balancer shafts to block 10 Nm (7.4 lbf ft)

|

||||||||||

| 11. |

Check the timing chain and fit the chain guard and chain onto the crankshaft end. Screw on the safety plate.

|

|

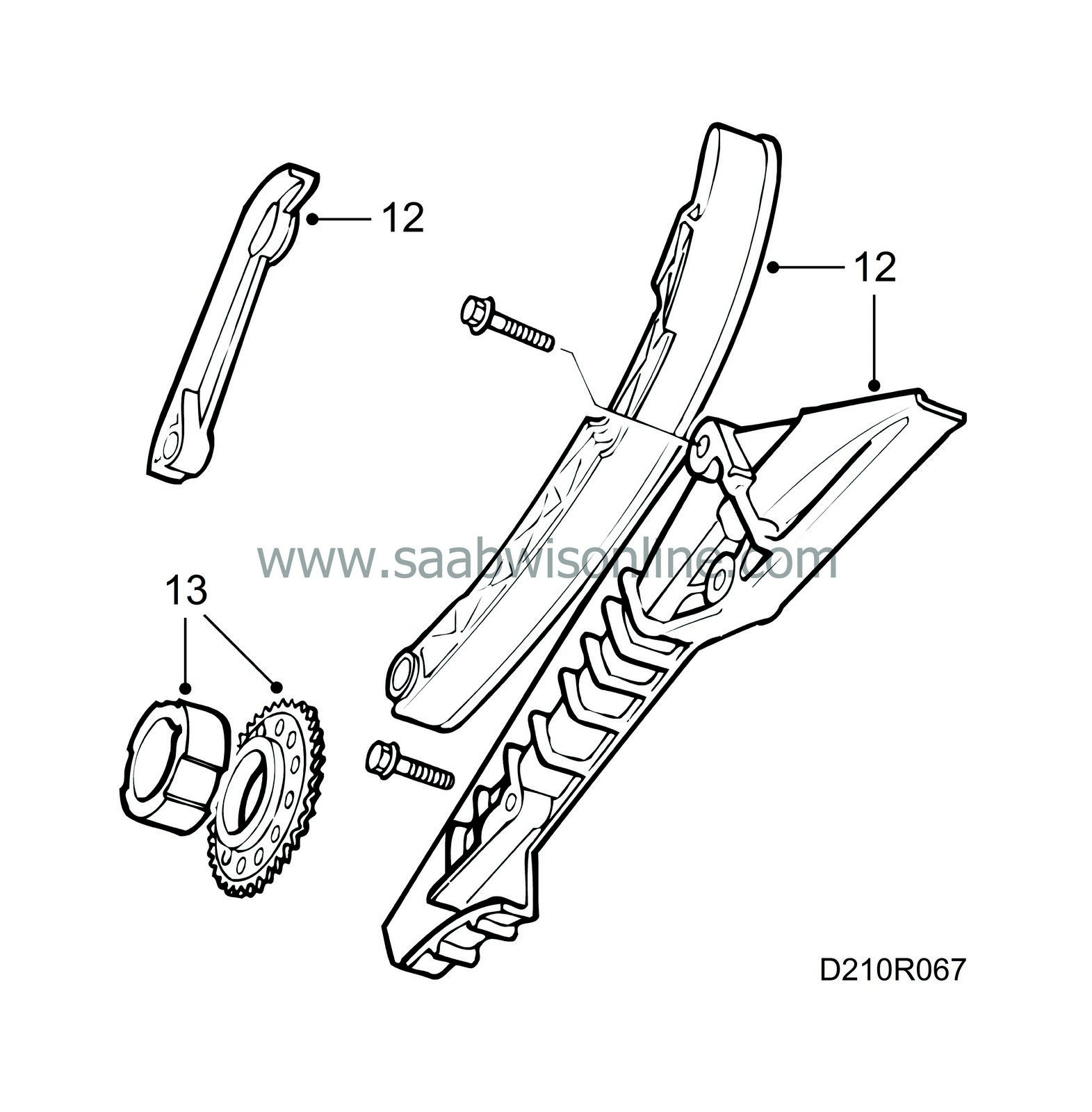

| 12. |

Fit the fixed chain guard first, which is common to the timing chain and the balancer-shaft chain, and then the pivoted chain guides for the timing chain and balancer-shaft chains.

Tightening torque: 10 Nm (7.4 lbf ft) |

|

| 13. |

Fit the balancer-shaft sprocket and the oil-pump driver onto the crankshaft end.

|

|

| 14. |

Cock the chain tensioner and insert a paper clip or similar object through the hole in the cylinder to prevent triggering of the tensioner. Before this, check that the plunger is turned to the position where it really is pressed out by the spring.

|

|

| 15. |

Fit the chain tensioner.

Tightening torque: 10 Nm (7.4 lbf ft)

|

|||||||||

| 16. |

Inspect the balancer-shaft chain and fit it and the idler sprocket so that the upper setting markings behind the balancer-shaft sprocket and bearing housing are aligned with each other. Tauten the chain between the crankshaft and balancer shafts. Fit the idler sprocket last of all. Hold the bolt in place with your thumb, mesh the teeth of the sprocket with the chain and "roll" it into position along the chain.

Tightening torques: Idler sprocket, balancer-shaft chain 25 Nm (18.5 lbf ft) |

|

| 17. |

Fit the top chain guide, pull out the chain slightly from the cylinder block and release the tensioner. Make sure there is a certain play by pressing in the tensioner. Rotate the crankshaft one revolution and then check that the setting is correct.

Tightening torque: 10 Nm (7.4 lbf ft) |

|

| 18. |

Make sure the mating face of the timing cover is absolutely clean. Apply Loctite 518 in a bead approx. 1 mm wide on the timing cover. Keep the bead in the centre of the mating surfaces.

|

|

| 19. |

Fit the timing cover.

Tightening torque: 22 Nm (16.2 lbf ft) |

|

| 20. |

Fit the oil pump.

|

|

| 21. |

Fit the oil pump pressure pipe and check that there are no impurities or other foreign matter in the oil sump.

|

|

| 22. |

Make sure the mating face of the oil sump is absolutely clean and apply an even layer of Loctite 518, turn the engine and fit the oil sump.

Tightening torque: 22 Nm (16.2 lbf ft) |

|

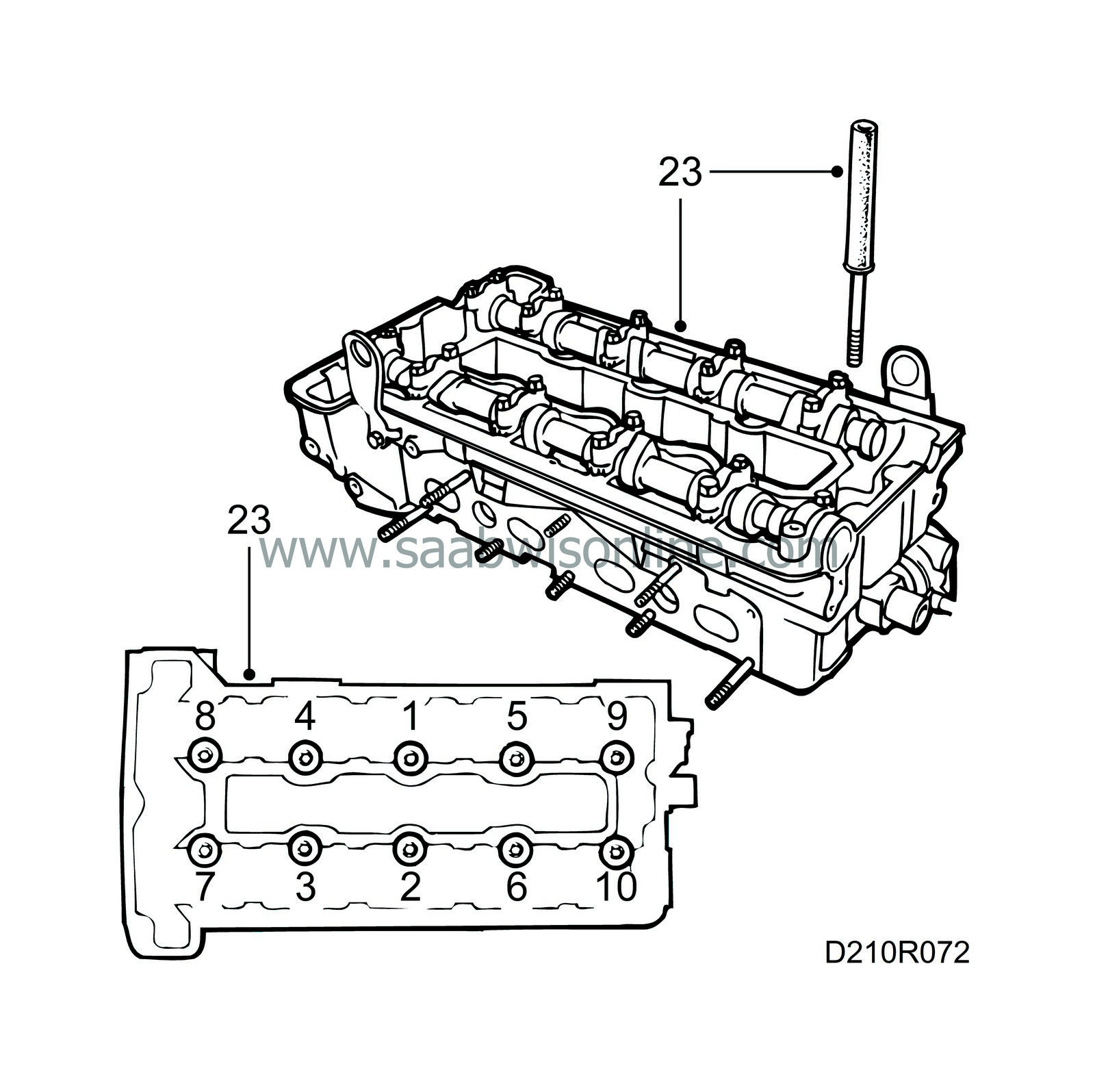

| 23. |

Turn the engine in the stand, rotate the crankshaft 45° and fit the cylinder head with a new gasket. Make sure it is correctly seated on the guide sleeves and that the chain runs freely.

Tighten the bolts in the order shown in the illustration. Tighten in three stages:Step I: 40 Nm (29.5 lbf ft) Step II: 60 Nm (44.3 lbf ft) Step III: Tighten a further 90° |

|

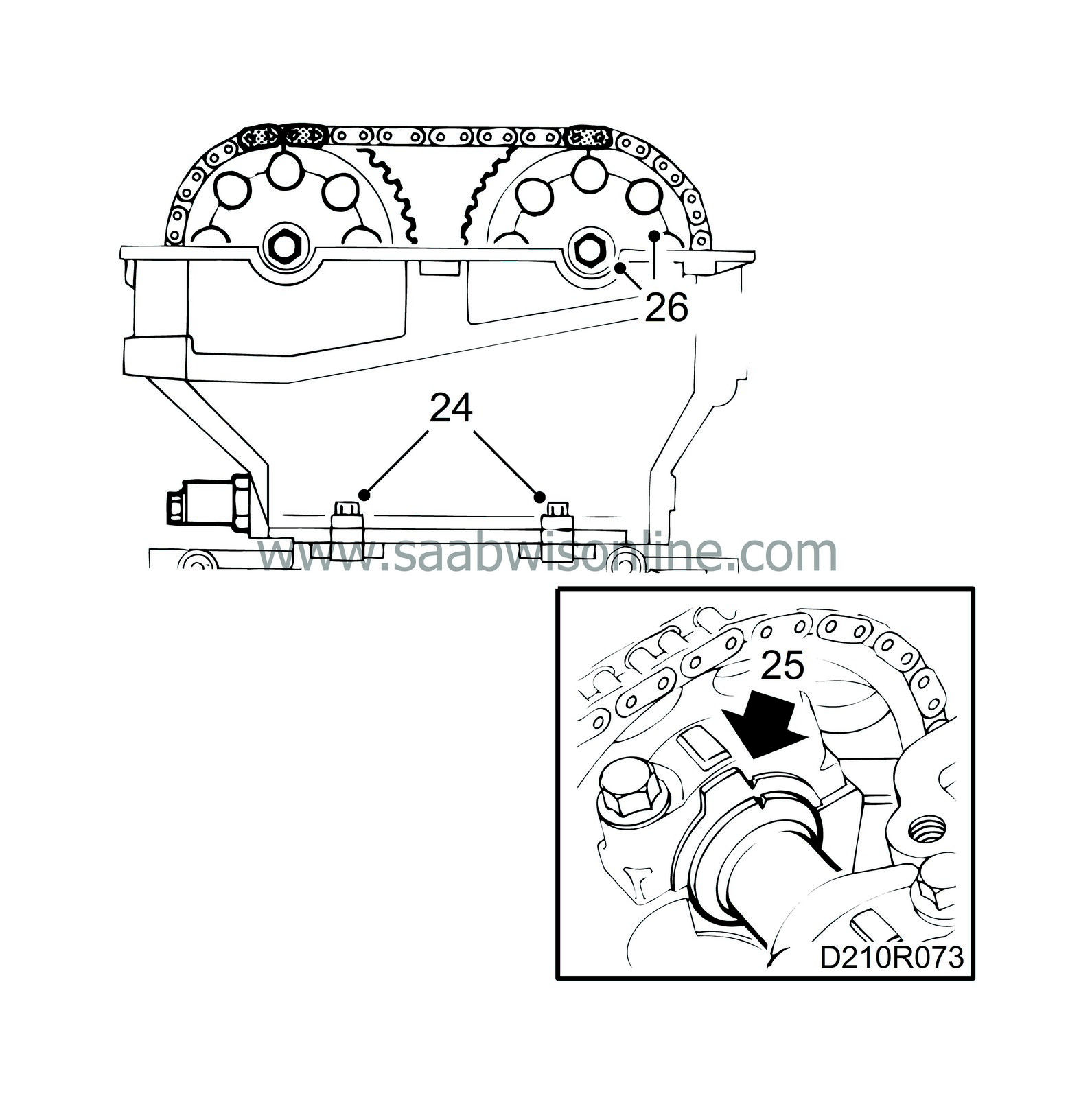

| 24. |

Fit the two bolts between the timing cover and cylinder head.

Tightening torque: 24 Nm (17.7 lbf ft) |

|

| 25. |

Make sure the camshafts are aligned with their setting marks and return the crankshaft to its 0-marking.

|

|

| 26. |

Fit the camshaft sprockets and chain. Start with the intake camshaft.

|

|||||||

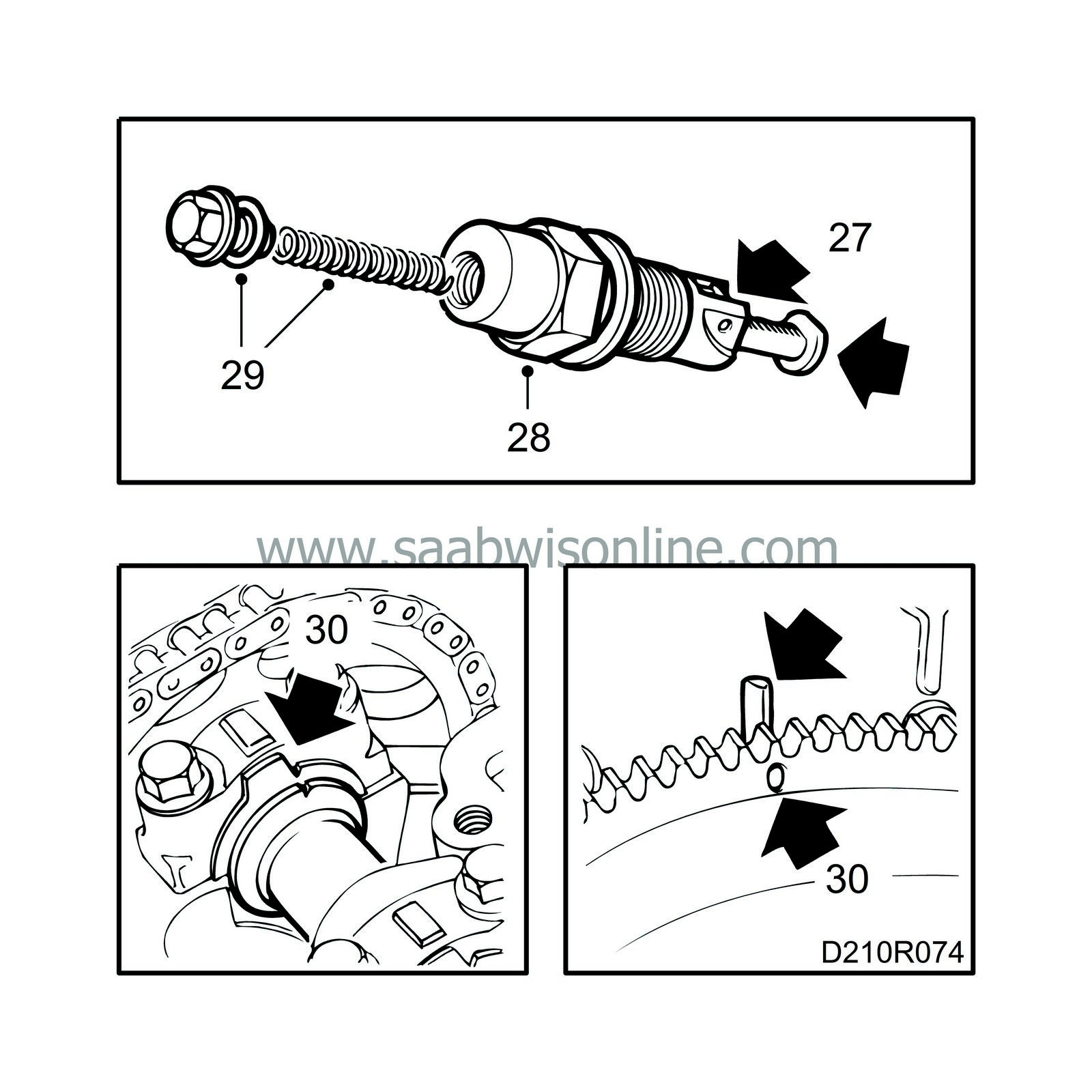

| 27. |

Prepare the chain tensioner for mounting by pressing down the catch and pressing in the chain tensioner.

|

|

| 28. |

Fit the chain tensioner with a 27 mm socket.

Tightening torque: 63 Nm (47 lbf ft) |

|

| 29. |

Fit the chain tensioner plug with push rod and spring.

Tightening torque: 22.5 Nm (16.6 lbf ft) |

|

| 30. |

Make sure the chain is positioned correctly on the chain guards. Rotate the crankshaft two revolutions and check the setting of the flywheel and camshafts.

|

|

| 31. |

Tighten the camshaft sprocket bolts.

Tightening torque: 63 Nm (47 lbf ft) |

|

| 32. |

Clean the sealing surface of the camshaft cover with benzine.

|

|

| 33. |

Apply soap to the opening in the camshaft cover and fit the cover, starting at the opening. Then, tighten the bolt located furthest to the front at the timing chain end. Continue all the way round the outside and inside.

Tightening torque: 15 Nm (11 lbf ft) |

|

| 34. |

Fit the spark plugs.

Tightening torque: 28 Nm (20.7 lbf ft) |

|

| 35. |

Fit the ignition discharge module (turbo), or alternatively the ignition leads and cover.

Tightening torques: Ignition discharge module: 11 Nm (8.1 lbf ft) Cover: 4 Nm (3 lbf ft) |

|

| 36. |

Fit the flywheel locking attachment, part no. 83 94 868, and tighten the crankshaft pulley.

Tightening torque: 175 Nm (129.5 lbf ft) Remove the flywheel locking attachment. |

|

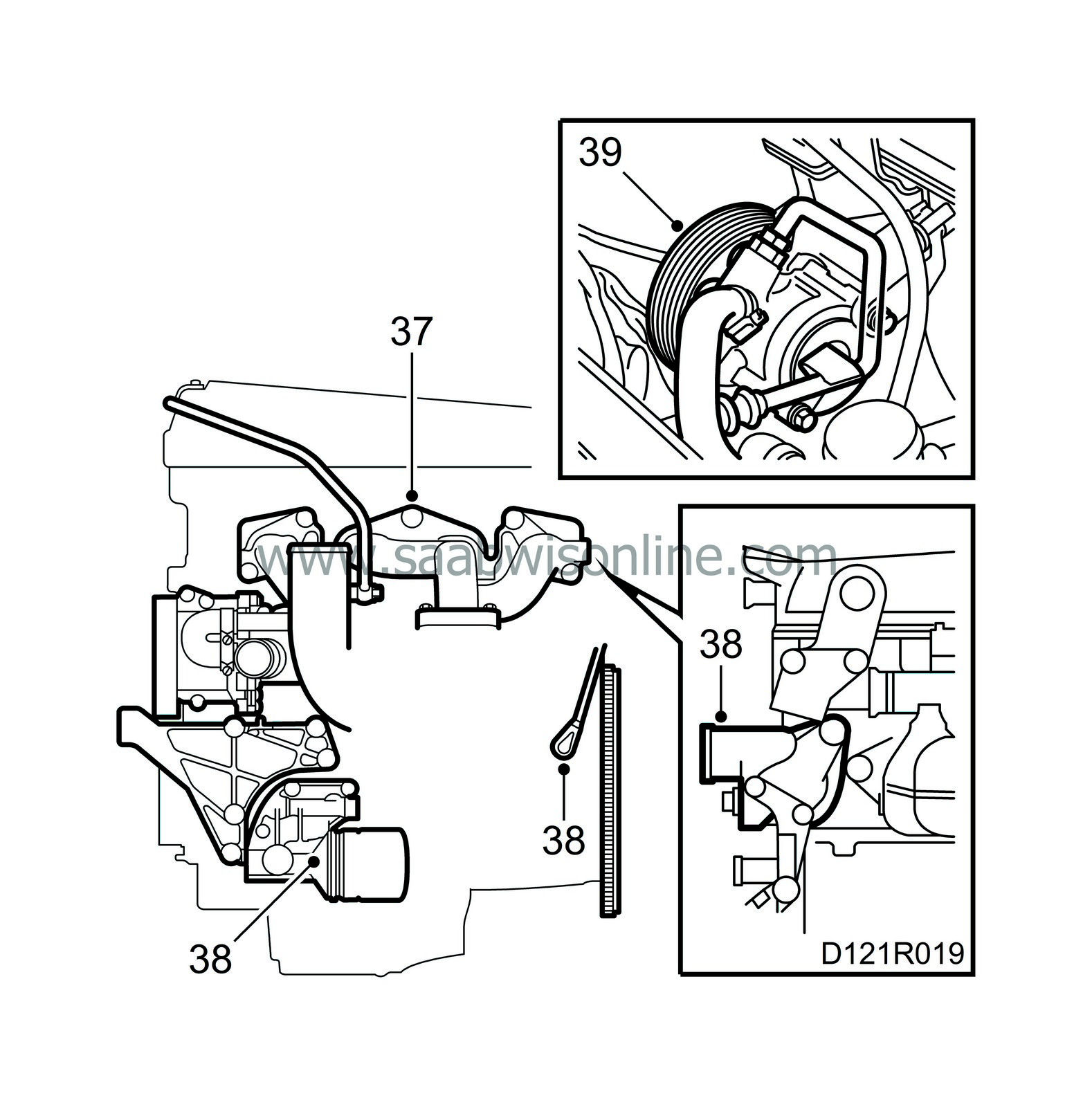

| 37. |

Fit the exhaust manifold with a new gasket. If it is a two-part exhaust manifold, fit the outer part first. Make sure the connecting surfaces to the front pipe are level with each other.

Tightening torques: Lock nuts: 17.5 Nm (12.9 lbf ft) Lock nuts (turbo): 24 Nm (17.7 lbf ft)

|

|||||||

| 38. |

Fit the adapter housing and oil filter. Fit the crankshaft position sensor and thermostat housing cover.

|

|

| 39. |

Fit the power steering pump and bracket.

|

|

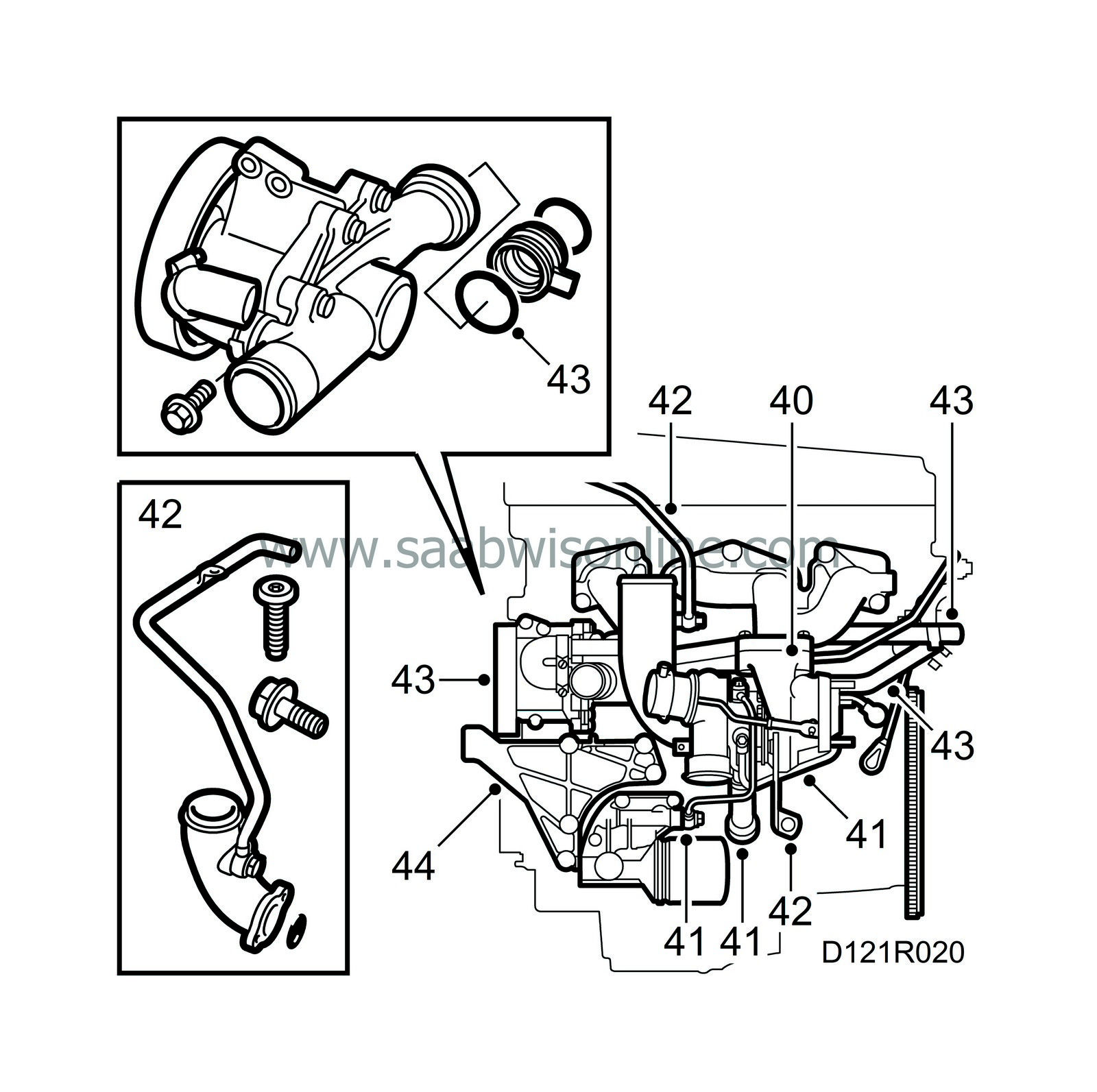

| 40. |

Fit the turbocharger.

Tightening torques: Stud screws: 22 Nm (16.2 lbf ft) Lock nuts: 25 Nm (18.5 lbf ft) |

|

| 41. |

Connect the water and oil pipes (turbo).

Tightening torques: Water pipe: 25 Nm (18.5 lbf ft) Oil pipe, in: 25 Nm (18.5 lbf ft) Oil pipe, out: 22 Nm (16.2 lbf ft) |

|

| 42. |

Fit the turbocharger stay and the pipe for the crankcase ventilation together with the intake manifold (turbo). Be careful with the O-ring!

Tightening torques: Turbo, stay to block: 22 Nm (16.2 lbf ft) Turbo/intake manifold: 8 Nm (5.9 lbf ft) Crankcase ventilation pipe: 24 Nm (17.7 lbf ft) Pipe clamp: 9.5 Nm (7 lbf ft) |

|

| 43. |

Lubricate the O-rings with acid-free petroleum jelly and fit the water pump and the water pipes from the expansion tank and heat exchanger. Fit the clips for the crankshaft position sensor at the same time.

|

|

| 44. |

Fit the bracket for the engine mounting.

|

|

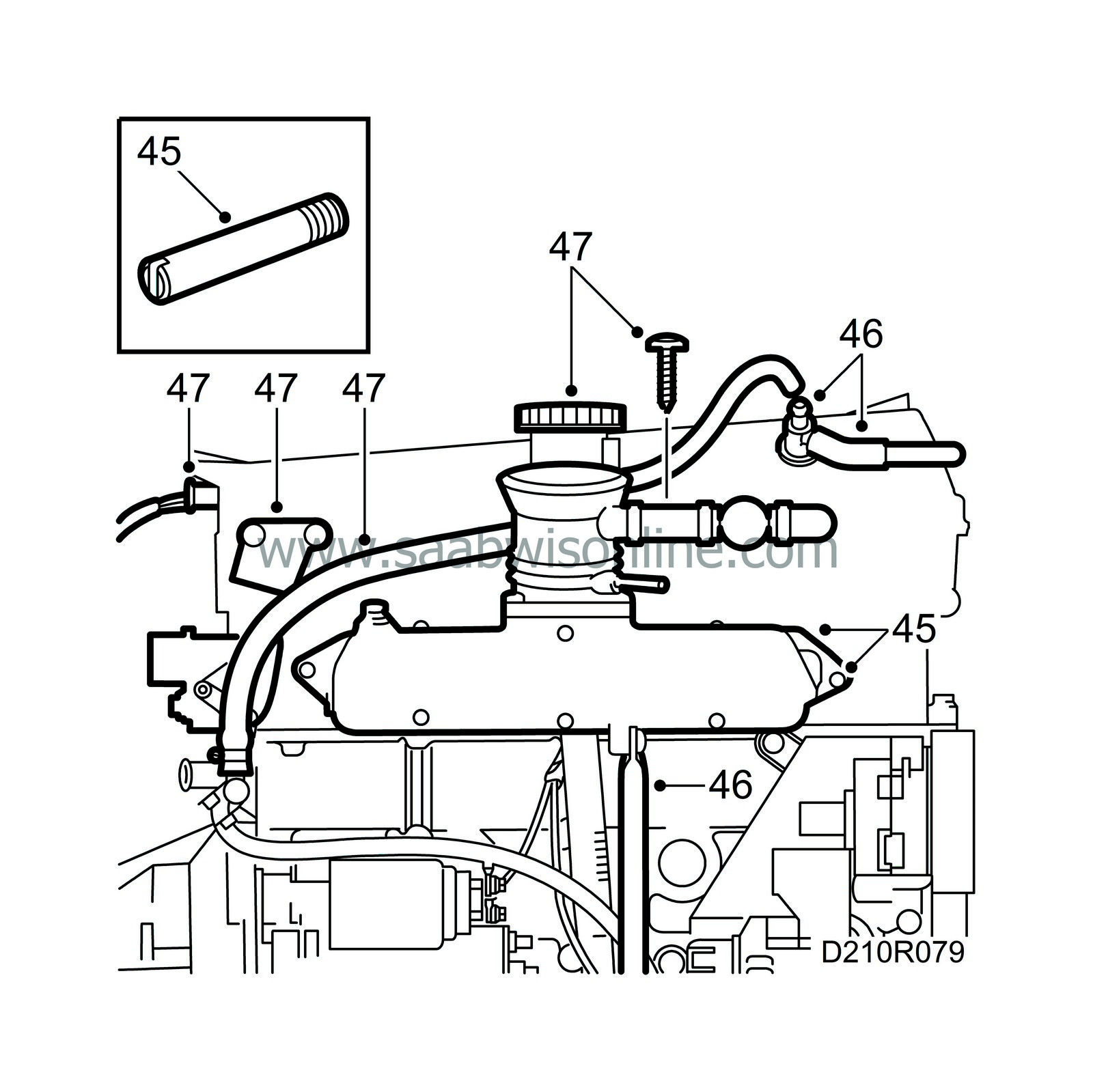

| 45. |

Position the intake manifold gasket using guide pins, part no. 83 94 736, and fit the intake manifold.

Tightening torque: 24 Nm (17.7 lbf ft) |

|

| 46. |

Fit the intake manifold stay and connect the positive crankcase ventilation nipple.

Tightening torque: 24 Nm (17.7 lbf ft) |

|

| 47. |

Connect the cables to the ignition discharge module (turbo), the temperature sensor and the hoses to the throttle body. Fit the oil filler pipe bracket.

Tightening torques: Upper mounting: 10 Nm (7.4 lbf ft) Lower mounting: 22 Nm (16.2 lbf ft) |

|

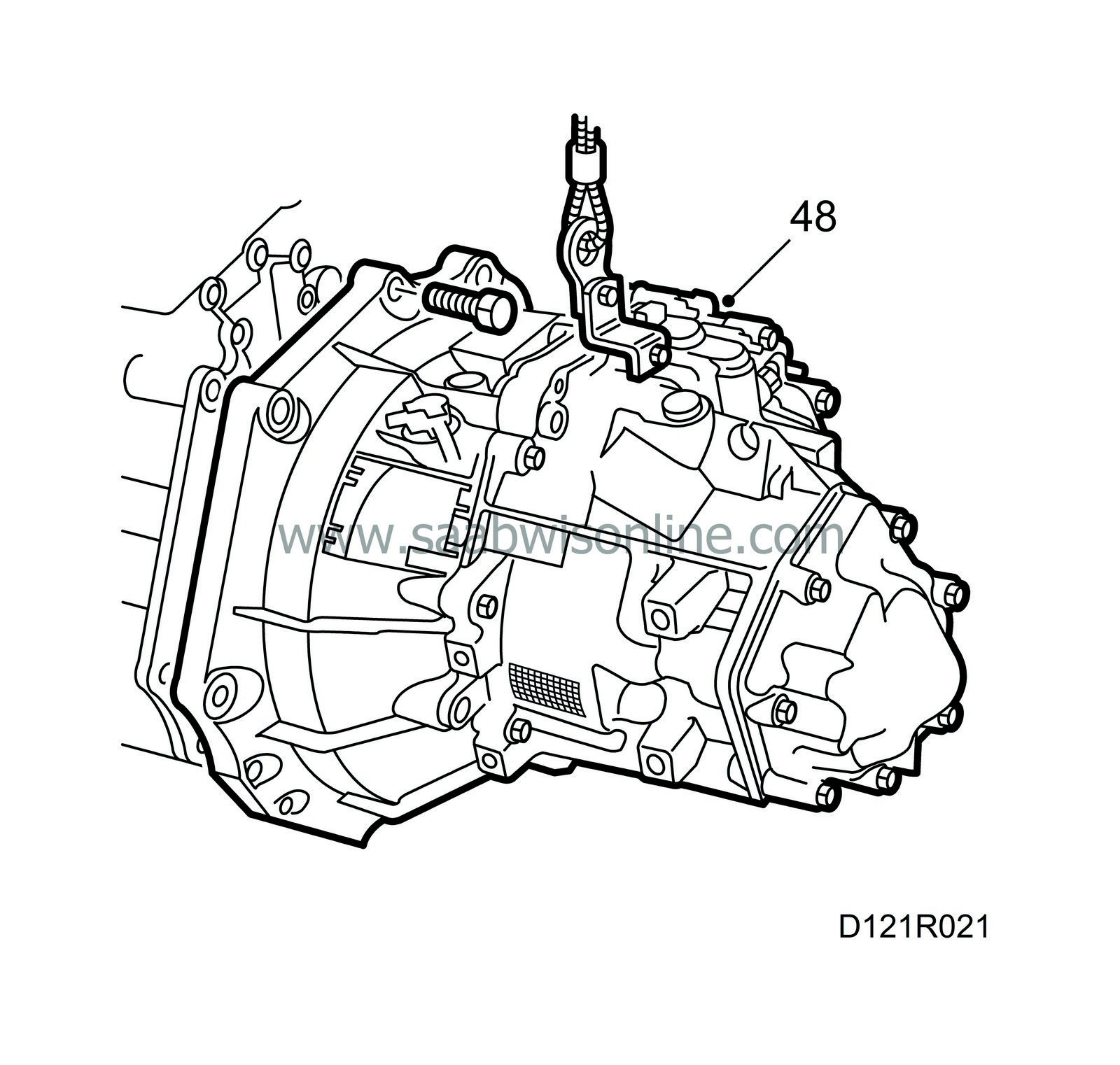

| 48. |

Make sure the torque converter bottoms in the gearbox and that the lock screw is fitted (aut.). Fit the gearbox and tighten the bolts.

|

|

| 49. |

Tighten the torque converter bolts (aut.). Apply Loctite 270D to the bolts.

Tightening torque: 60 Nm (44.4 lbf ft) |

|

| 50. |

Connect a lifting sling and lift the engine away from the stand. Remove the fixture and place the engine on the lifting trolley.

|

|

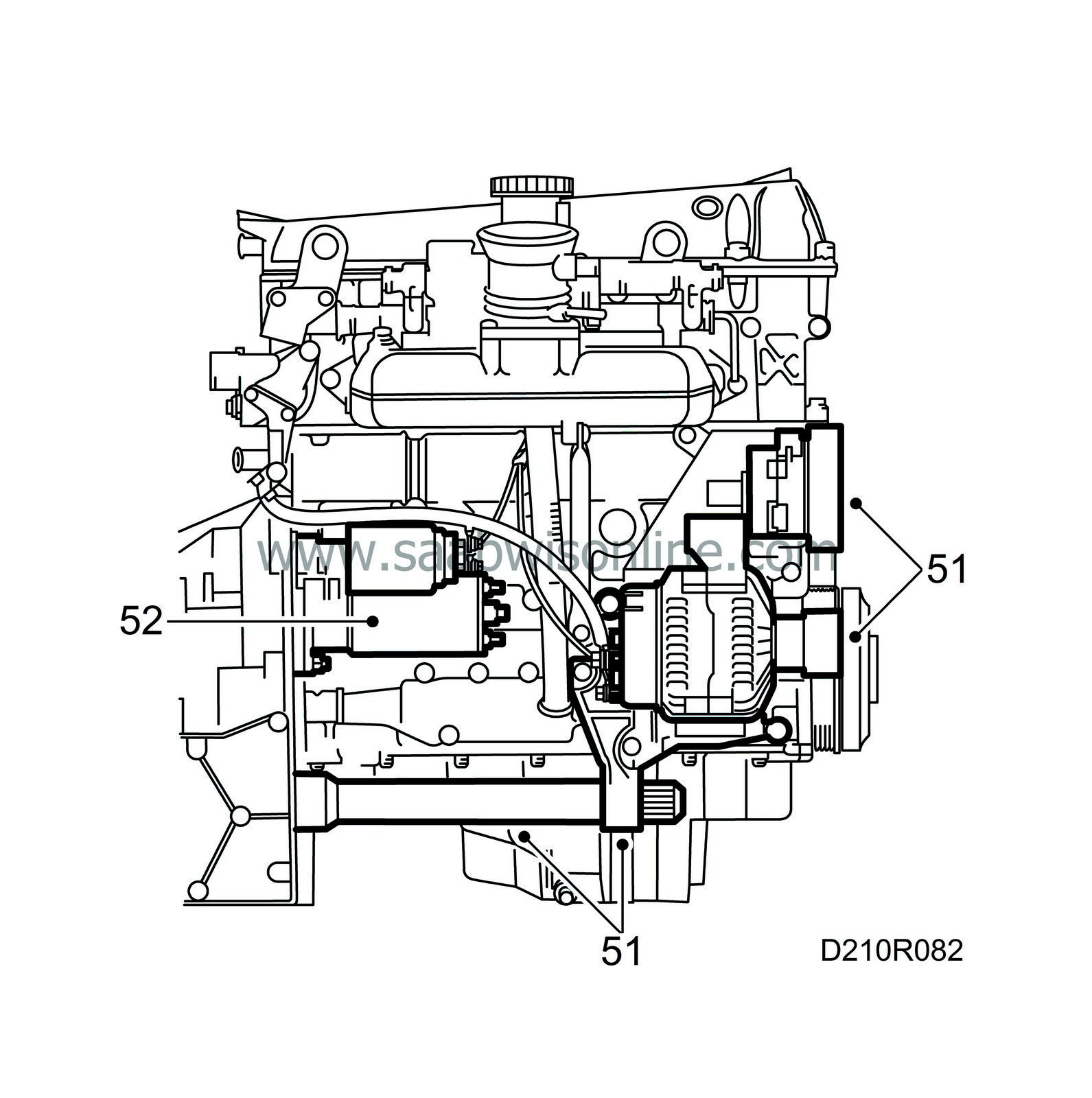

| 51. |

Fit the bearing bracket with pipe and the inboard drive shaft. Fit and connect the generator and fit the belt tensioner.

|

|

| 52. |

Fit the starter motor and connect the cables. Make sure the oil drain plug is tight. The power train is now ready for fitting in the car.

|

|

Warning

Warning