Lubricating system

| Lubricating system |

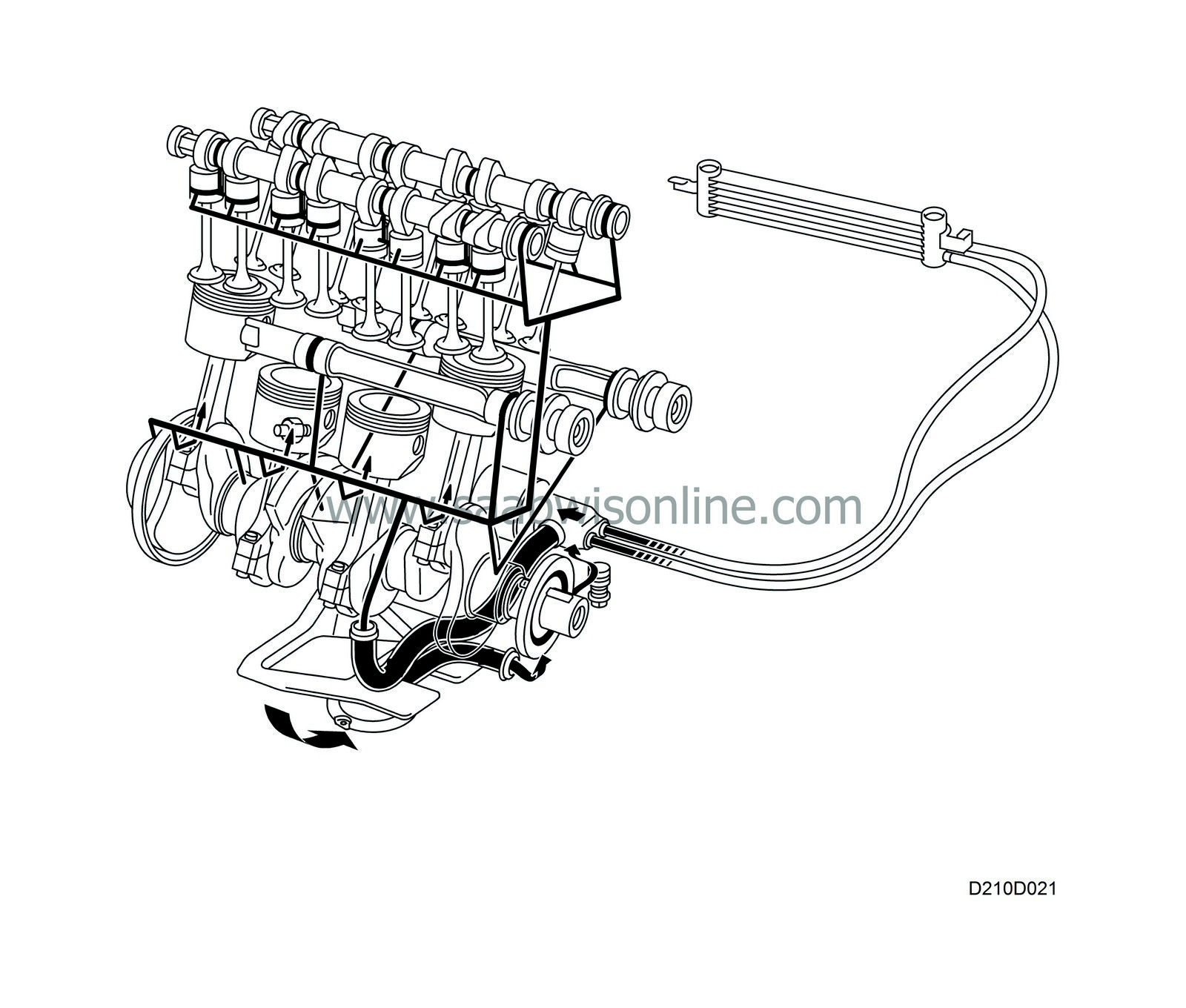

Oil is drawn from the sump to the oil pump via an inlet strainer and pipe. A reducing valve in the timing cover limits the oil pressure and returns surplus oil to the suction side of the pump. The oil then flows to the oil filter via a passage in the cylinder block.

Certain cars are fitted with an engine oil cooler. On these cars, there is a thermostat in the oil filter adapter housing that opens at 105±2°C (221±35.6°F) to allow oil to circulate through the cooler.

After filtering, and cooling if necessary, the oil is carried via a pipe to the main gallery in the cylinder block where the engine oil pressure sensor is located. If the oil pressure is too low, the sensor grounds the circuit for the warning lamp in the main instrument unit.

The crankshaft main bearings and big-end bearings are lubricated via oilways in the engine block and crankshaft, while the pistons and cylinder walls are lubricated by oil mist and splash from the crankcase. There is also a piston-cooling nozzle located at each cylinder that sprays the underside of the piston with a fine jet of oil.

The outer bearing on the exhaust side balancer shaft is supplied with oil through a hole in main bearing no. 1. The inner bearing on the exhaust side balancer shaft is supplied with oil through a hole in main bearing no. 3. Both balancer shafts on the intake side are supplied with oil from the main gallery.

From the cylinder block main gallery there is also a rising oilway that goes to the cylinder head to lubricate the camshafts and valve mechanism. Via the hole for one of the cylinder head bolts, oil flows through drilled passages to all the camshaft bearings and valve tappets.

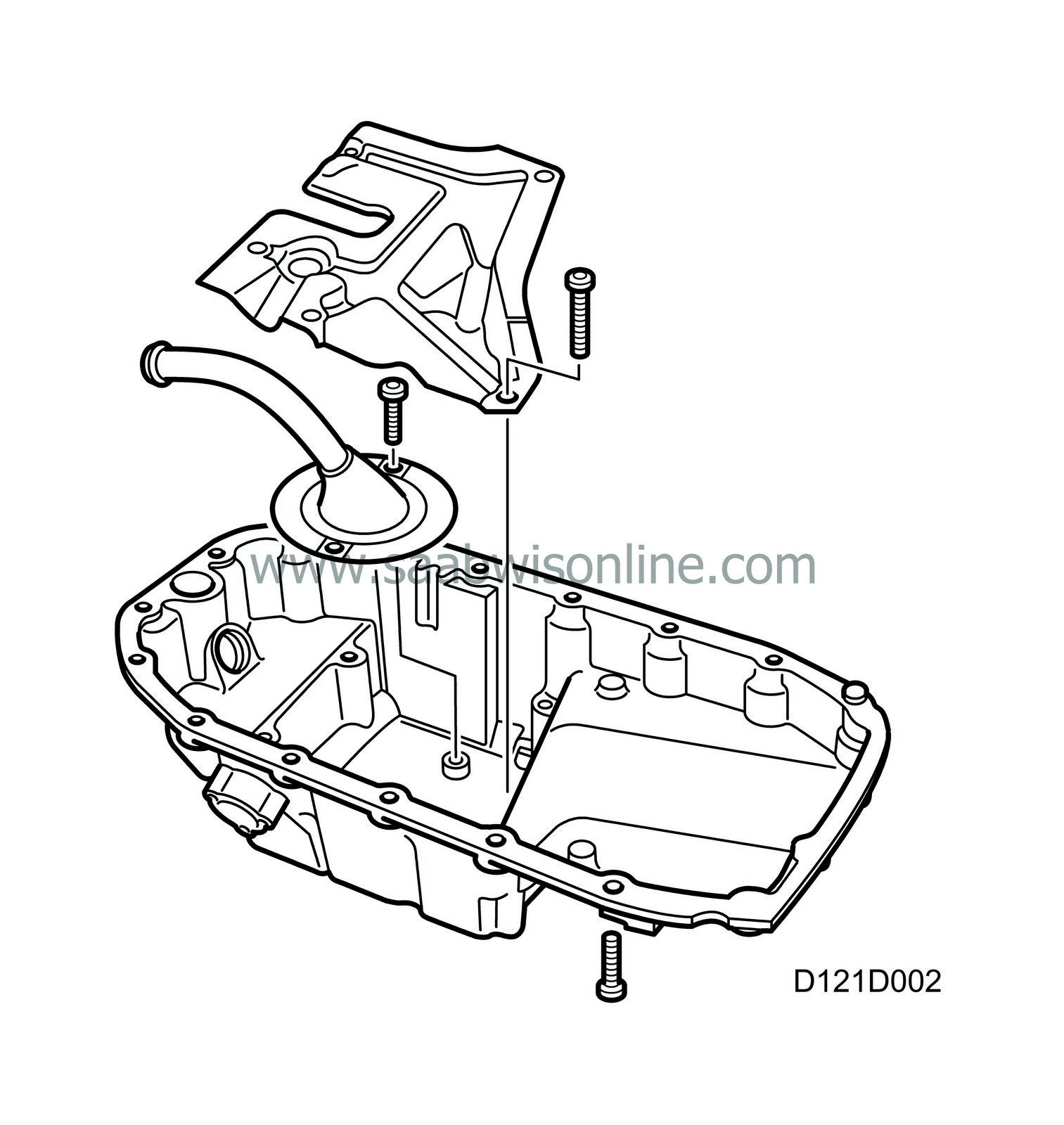

| Oil sump |

The oil sump is adapted to the cylinder block. Sealant (Loctite 518) is applied directly to the flat surface of the flange.

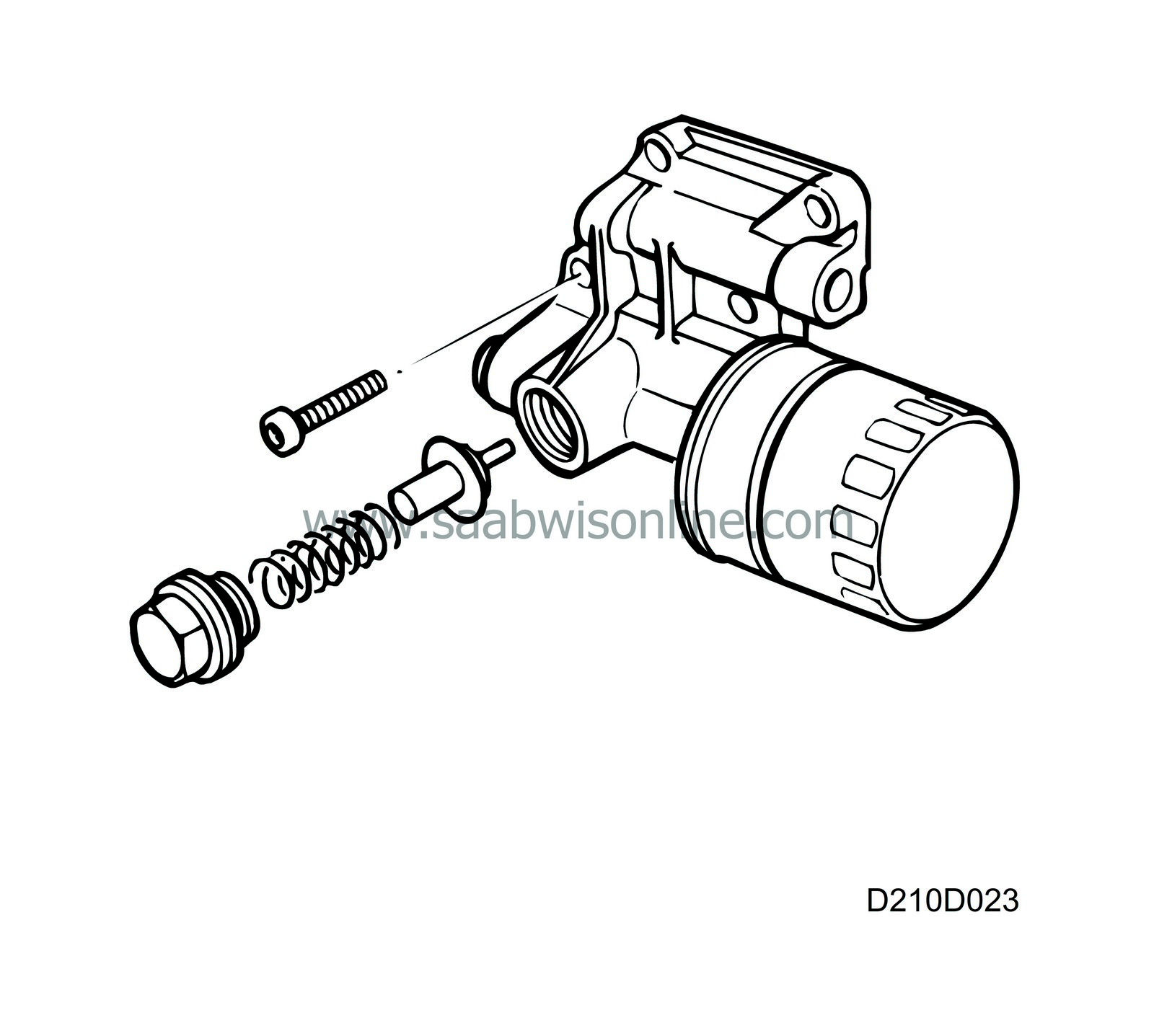

| Oil filter |

The oil filter is mounted easily accessible on the exhaust side of the cylinder block. An adapter housing is fitted between the oil filter and the block.