Diesel pump

| Diesel pump |

|

|||||||

| • |

Make provision for good ventilation! If approved ventilation for extracting fuel fumes is available then it must be used.

|

|

| • |

Use protective gloves! Prolonged contact with fuel may irritate the skin.

|

|

| • |

Keep a class BE fire extinguisher close at hand! Watch out for sparks, e.g. in connection with breaking electric circuits, short-circuits, etc.

|

|

| • |

Smoking is absolutely forbidden.

|

|

| To remove |

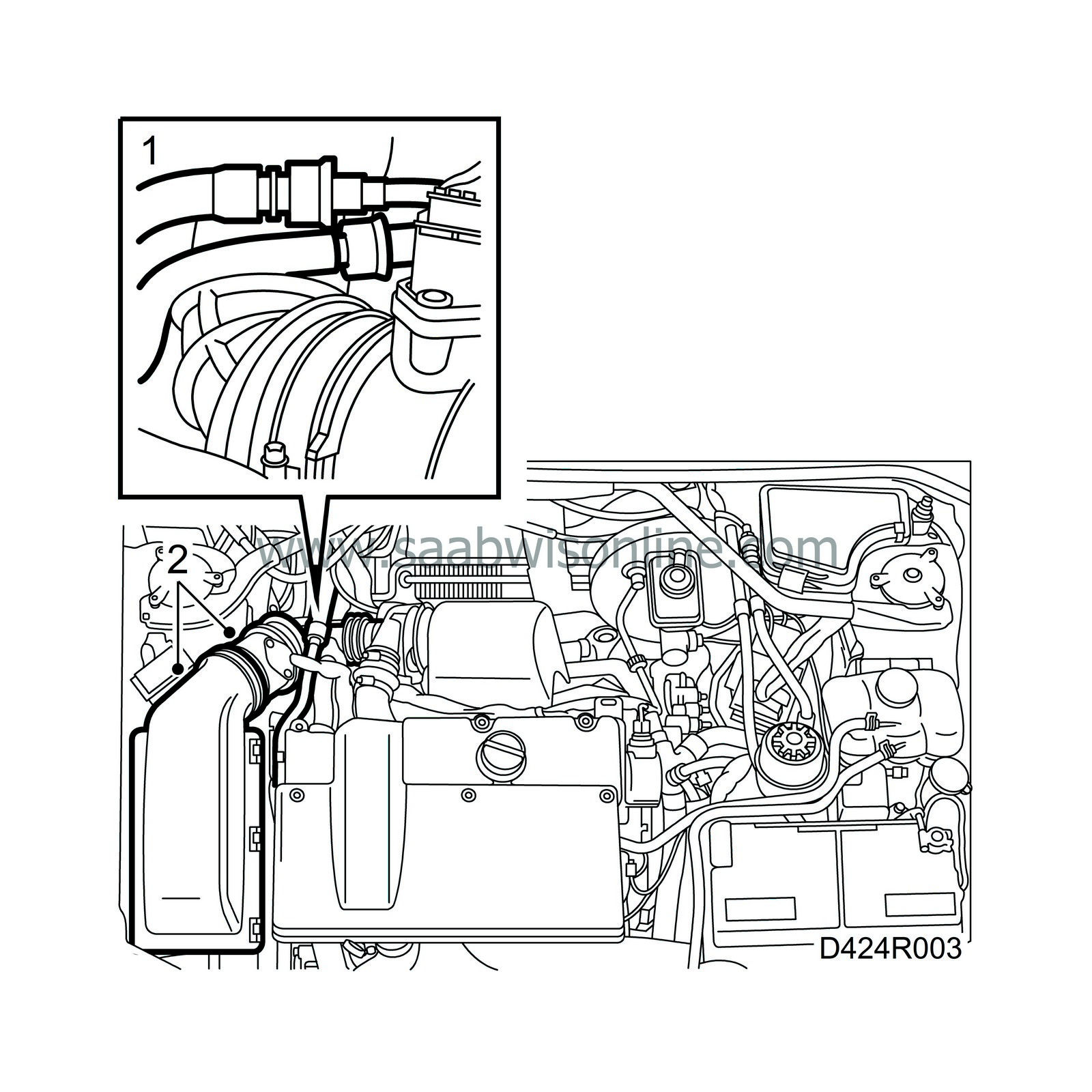

| 1. |

Separate the fuel hoses with tool 83 95 261 and seal them.

|

|

| 2. |

Remove the air cleaner with mass air flow sensor and hoses.

|

|

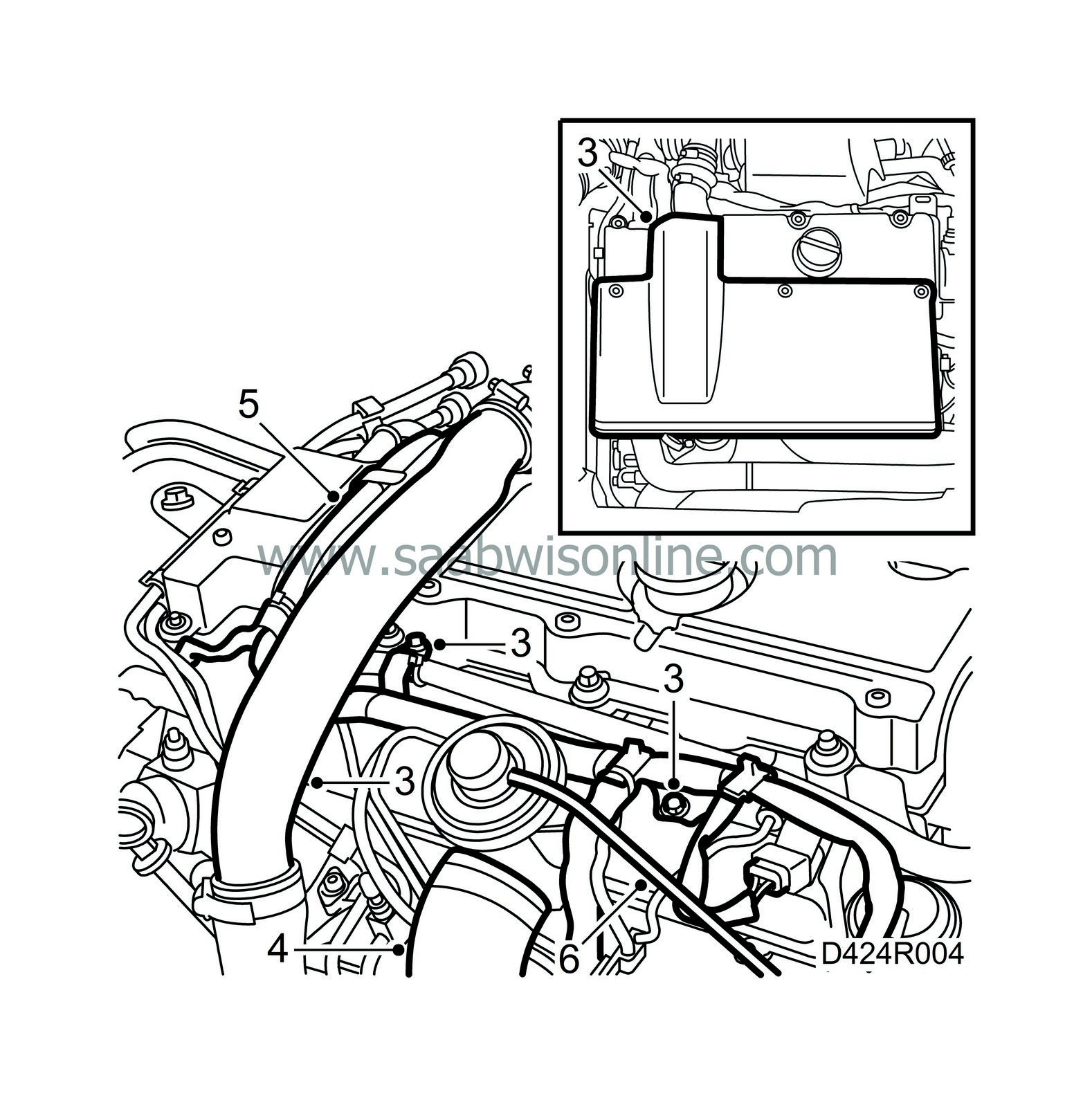

| 3. |

Dismantle the engine cover and remove the turbocharger delivery pipe with connecting hose and connecting piece via the V-clamp. Plug the hoses.

|

|

| 4. |

Detach the air hose from the intake manifold, bend it to one side and plug it.

|

|

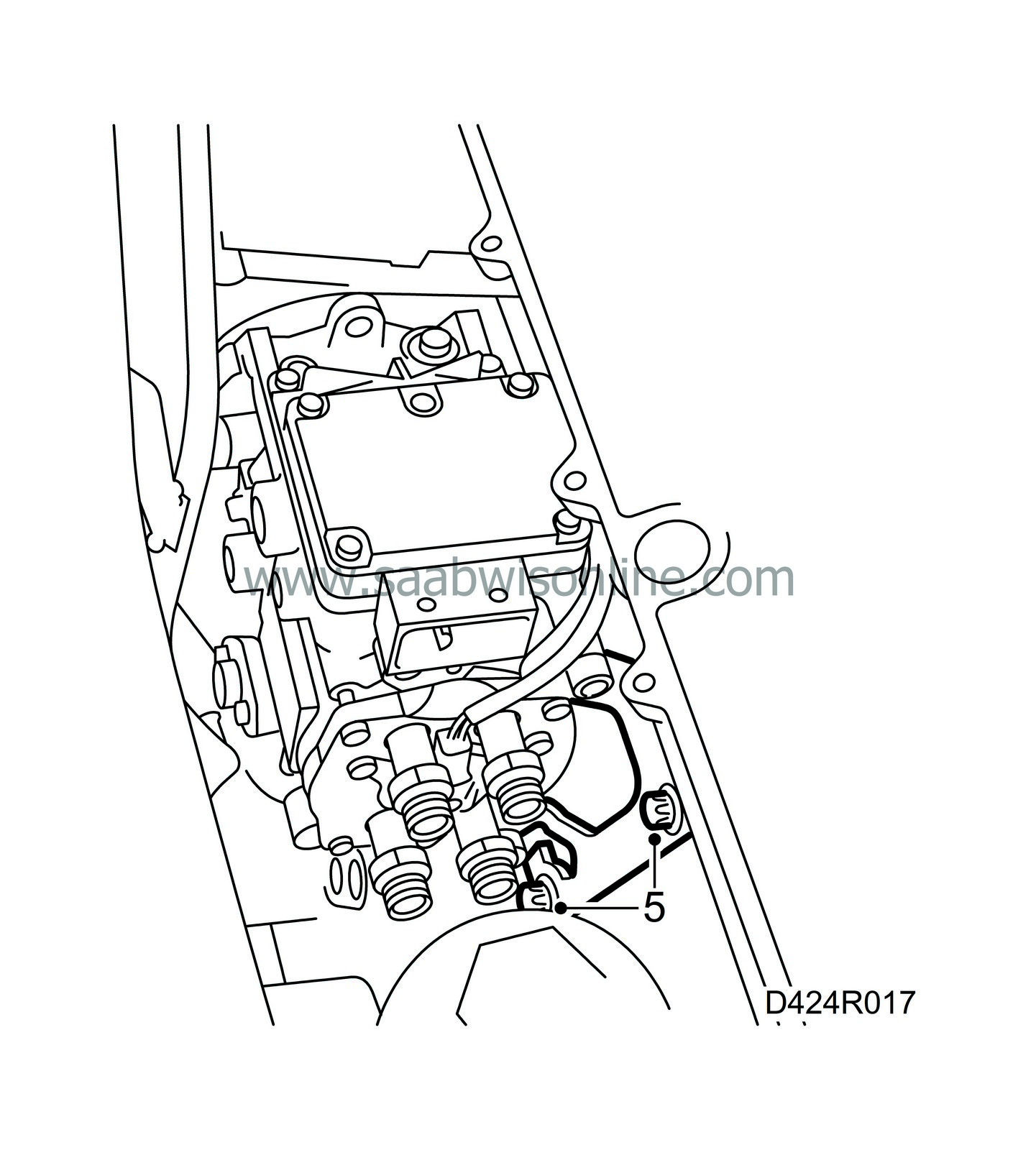

| 5. |

Disconnect all the cables connected to the wiring harness channel and cut the securing points. Remove the channel from the cylinder head and lay it on the engine.

|

|

| 6. |

Pull the vacuum hose off the EGR valve.

|

|

| 7. |

Note the position of the fuel rails and their clips. Mark the rails.

|

|

| 8. |

Remove the fuel return hoses from the cylinder head.

|

|

| 9. |

Remove the fuel rails (remove the clips if necessary).

|

|

| 10. |

Detach the fuel lines from the fuel distributor pump and remove them.

|

|

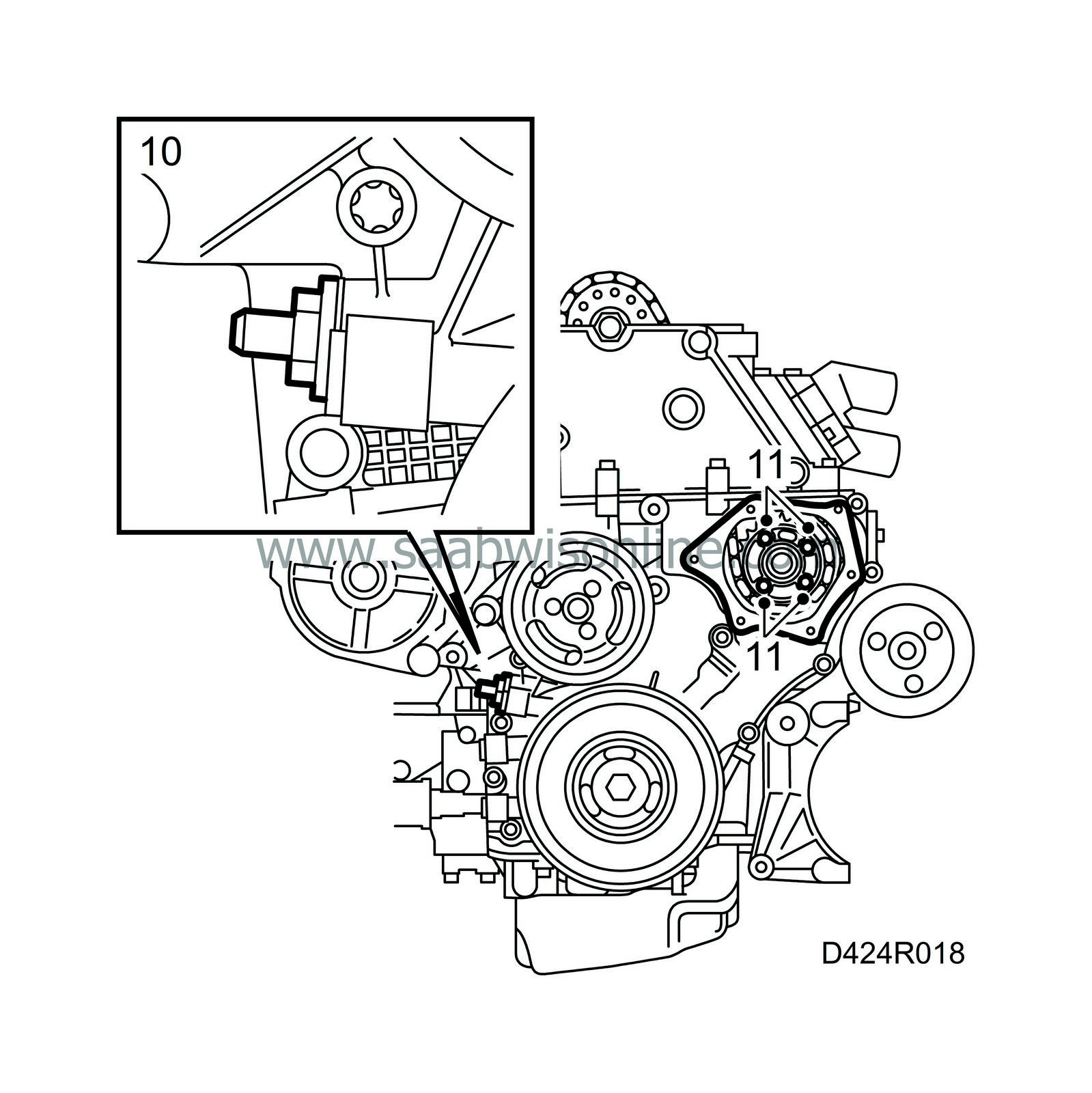

| 11. |

Unscrew the rear nut on the front exhaust pipe connection on the turbocharger.

|

|

| 12. |

Raise the car, remove the front right wheel, lower engine cover and the cover in the right-hand wheel housing.

|

|

| 13. |

Remove the crankshaft position sensor and O-ring.

|

|

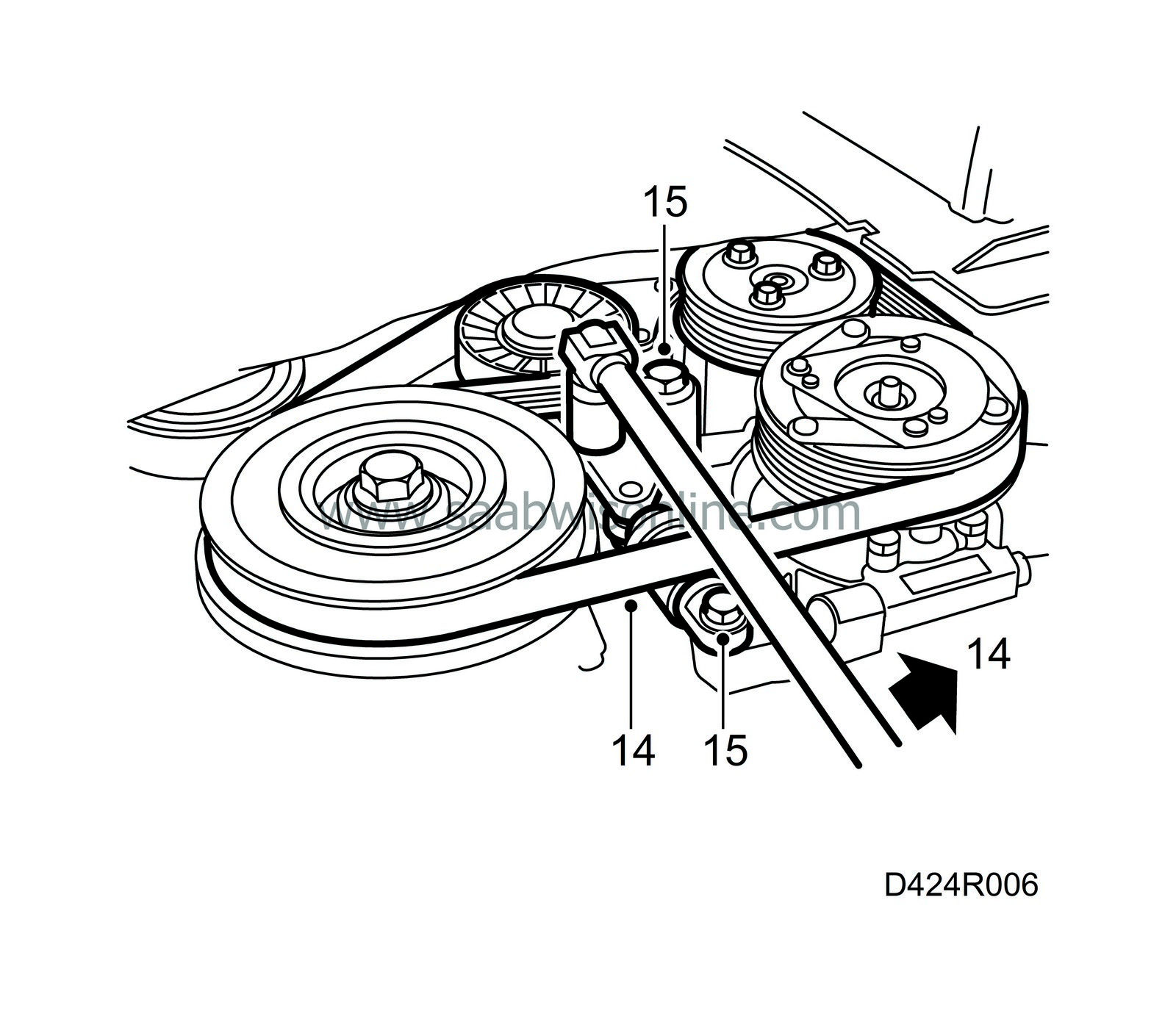

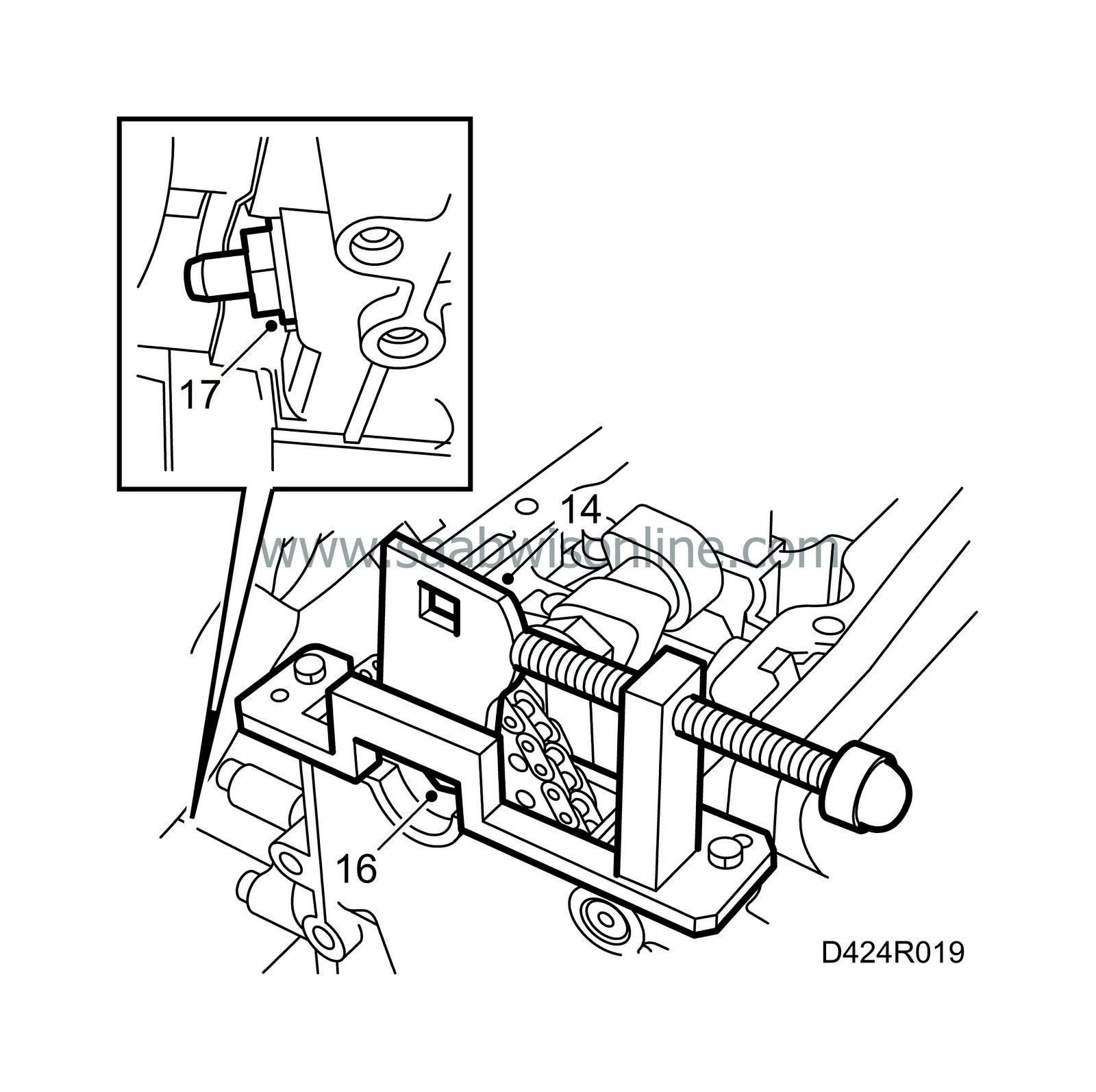

| 14. |

Relieve the belt tensioner by turning it anti-clockwise (to the rear of the car) with a 19 mm spanner and lift off the belt.

|

|

| 15. |

Remove the belt tensioner.

|

|

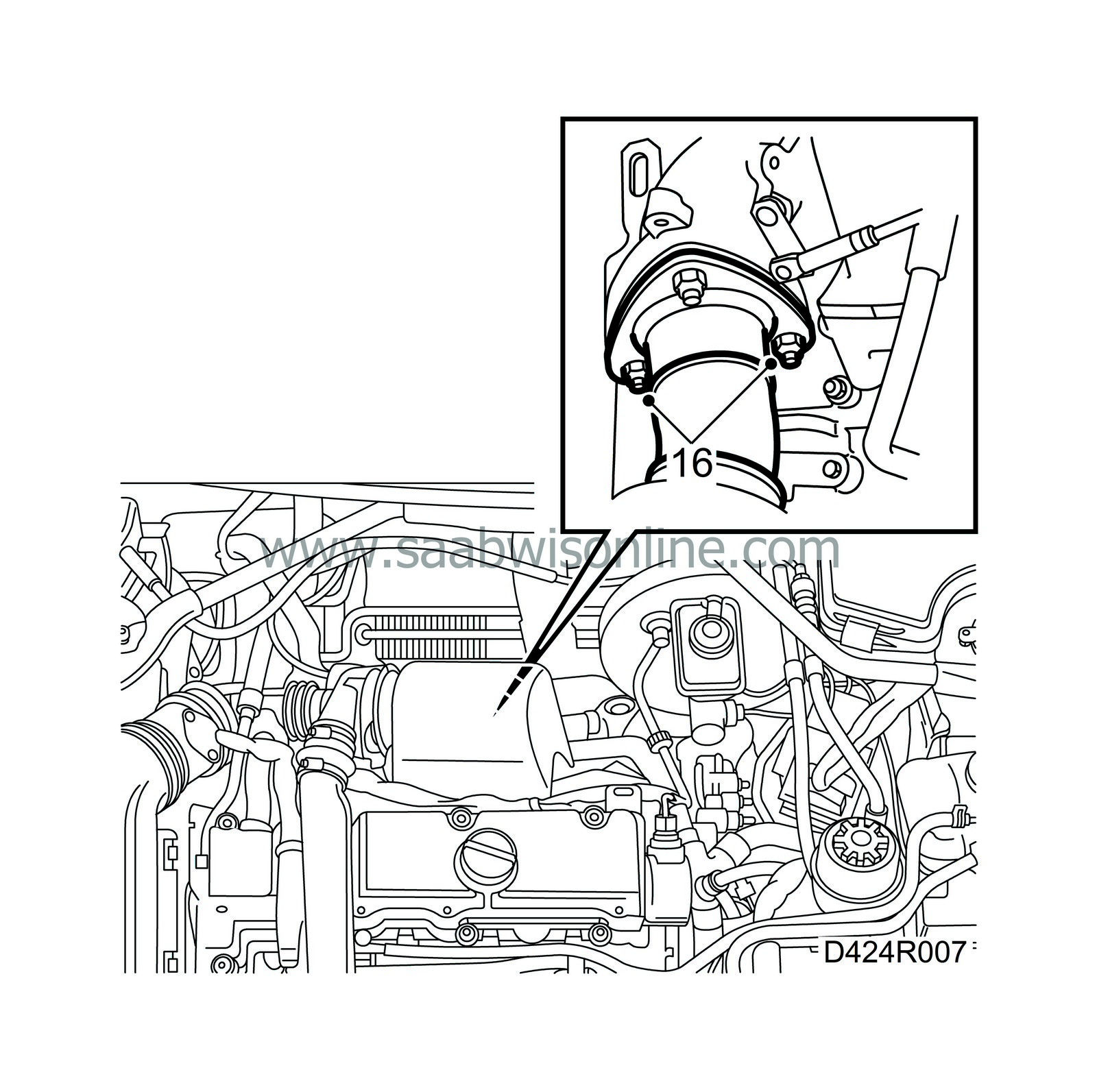

| 16. |

Detach the front part of the exhaust pipe from the turbocharger.

|

|

| 17. |

Lower the car and place a jack with wood block under the oil sump.

|

|

| 18. |

Detach the wiring harness with bracket and bend it to one side.

|

|

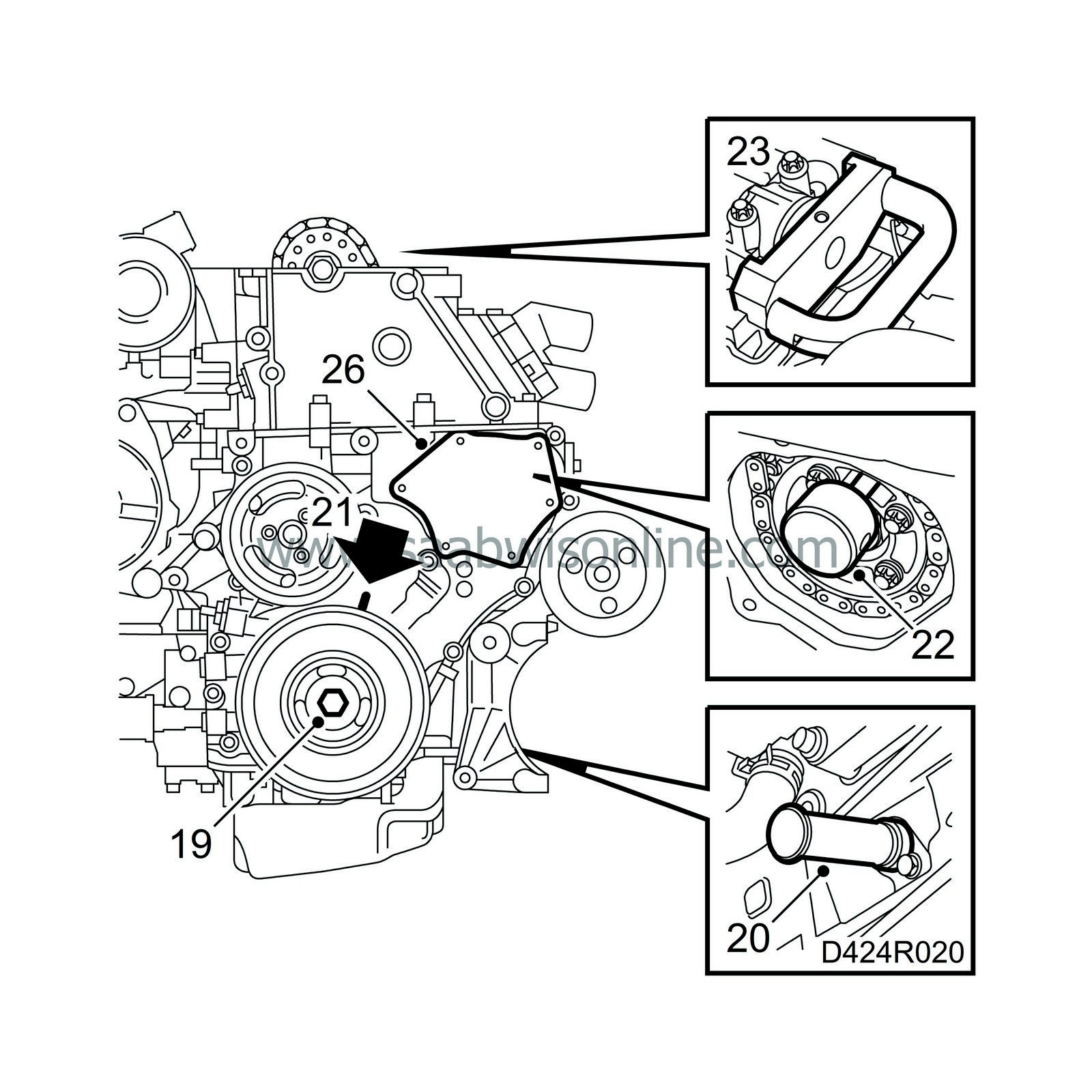

| 19. |

Carefully lift the engine to take the weight off the engine pads.

|

|

| 20. |

Remove the right-hand engine pad from the engine and the body.

|

|

| 21. |

Remove the engine mounting (the lower bolt does not require removing entirely).

|

|

| 22. |

Undo the nut from the rear engine pad and raise the engine a bit further.

|

||||||||||

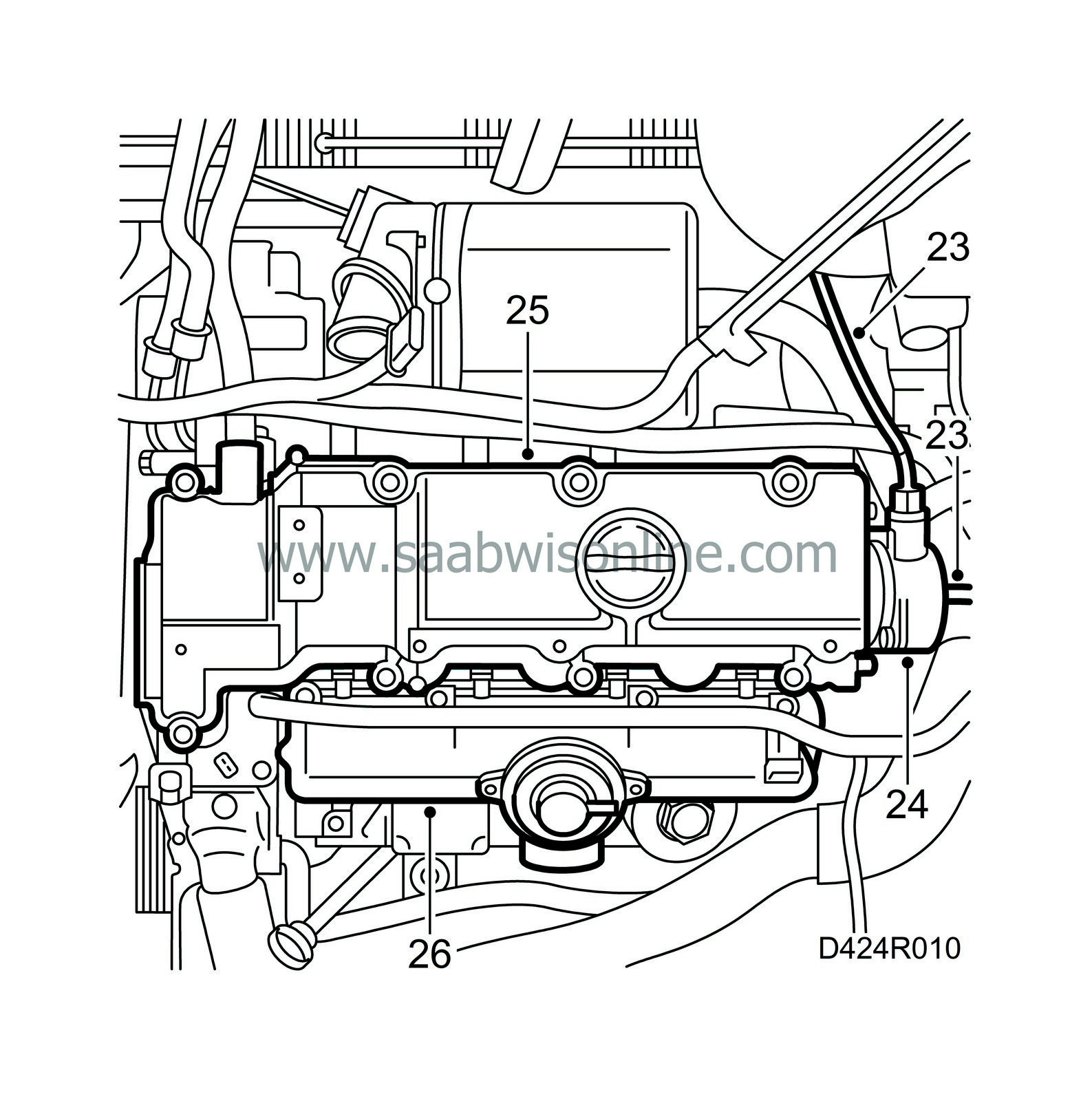

| 23. |

Detach the vacuum hose on the brake servo and the vacuum hose connected to the bottom of the vacuum pump.

|

|

| 24. |

Remove the four vacuum pump retaining bolts and carefully lift away the pump and its adapter.

|

||||||||||

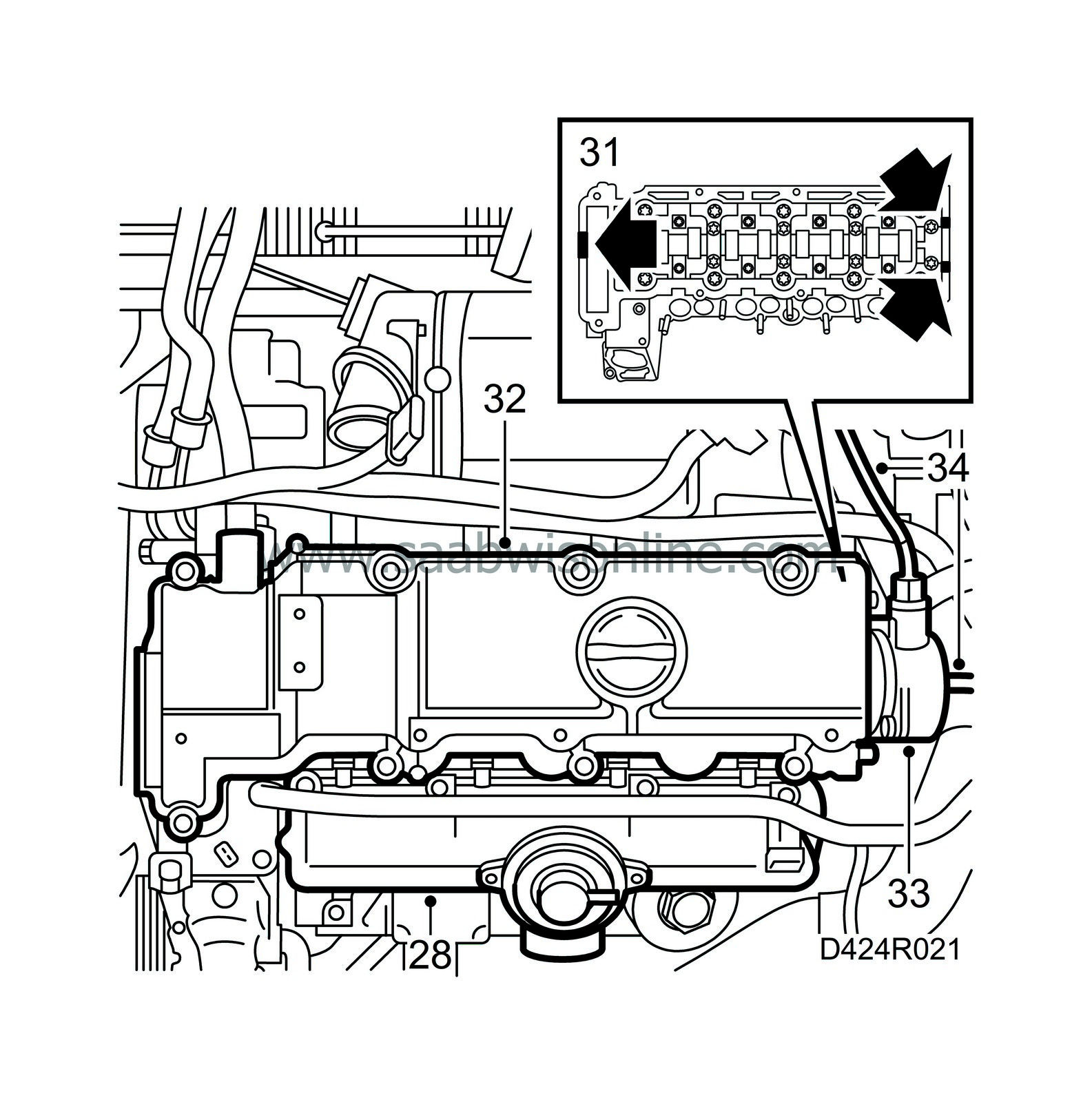

| 25. |

Remove the camshaft cover.

|

|

| 26. |

Remove the upper part of the intake manifold.

|

|

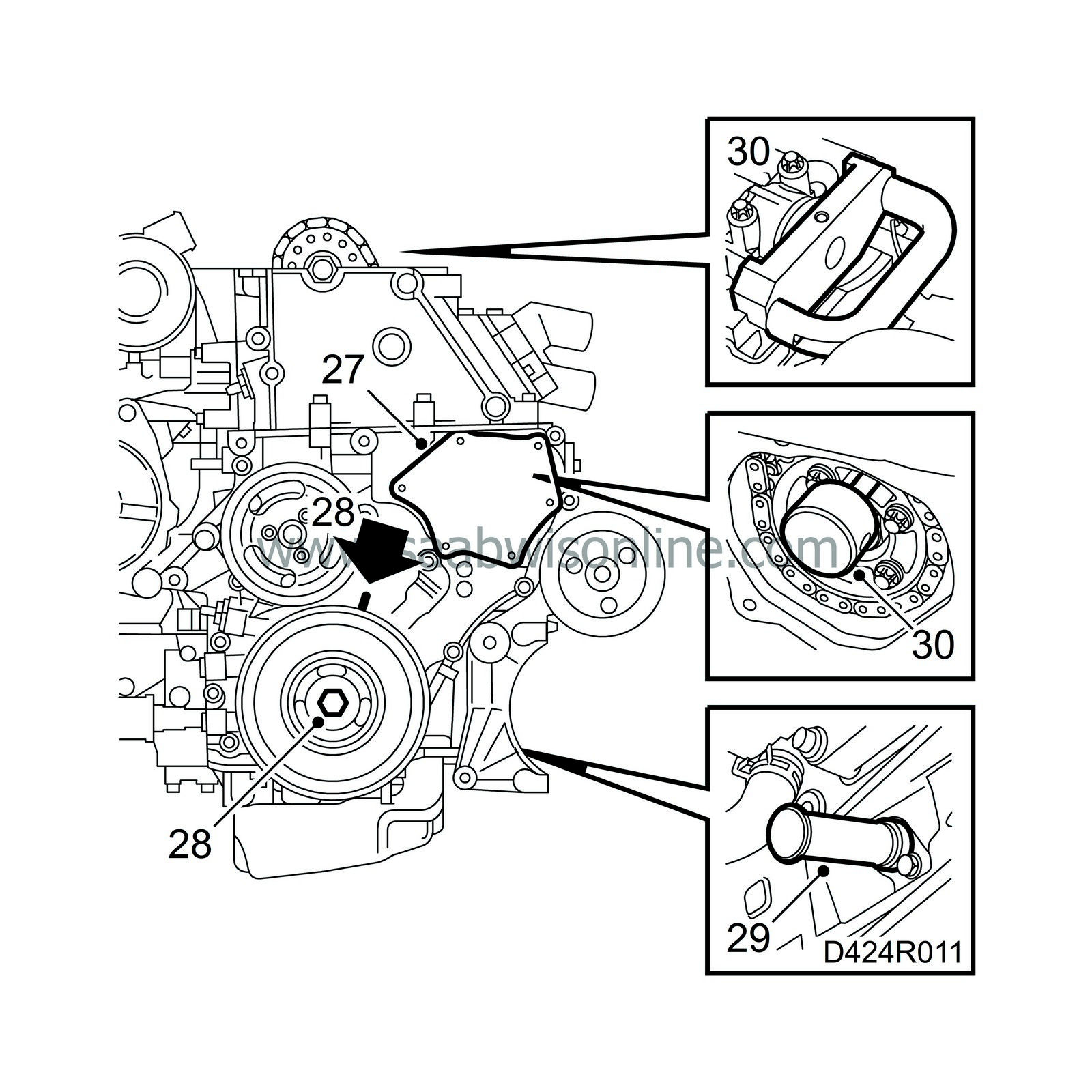

| 28. |

Turn the crankshaft two revolutions with the pulley centre bolt until it comes just in front of the mark for top dead centre in cylinder 1. Make sure both cam ridges for cylinder 1 are pointing up.

|

|

| 29. |

Position the inspection gauge 83 95 352 into the hole for the crankshaft position sensor. Press in the tool at the same time as the crankshaft is turned to the zero marking. The tool will then enter a recess in the crankshaft and lock it.

|

|

| 30. |

Position the inspection gauge 83 95 337 into the recess in the fuel distributor pump and the inspection gauge 83 95 386 to the camshaft and cylinder head.

|

|

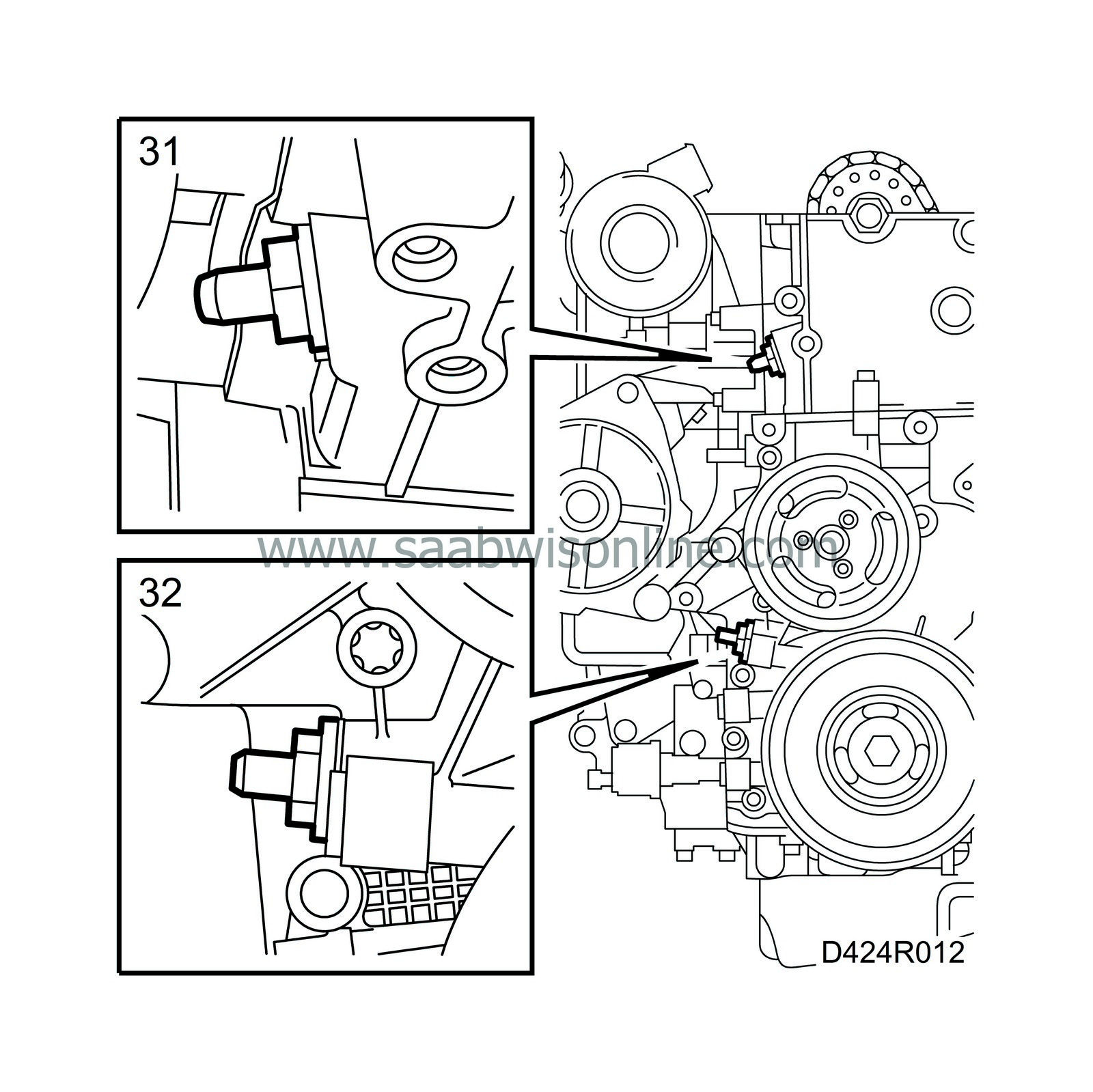

| 31. |

Remove the upper timing chain tensioner.

|

|

| 32. |

Remove the lower timing chain tensioner.

|

|

| 33. |

Remove inspection gauge 83 95 337.

|

|

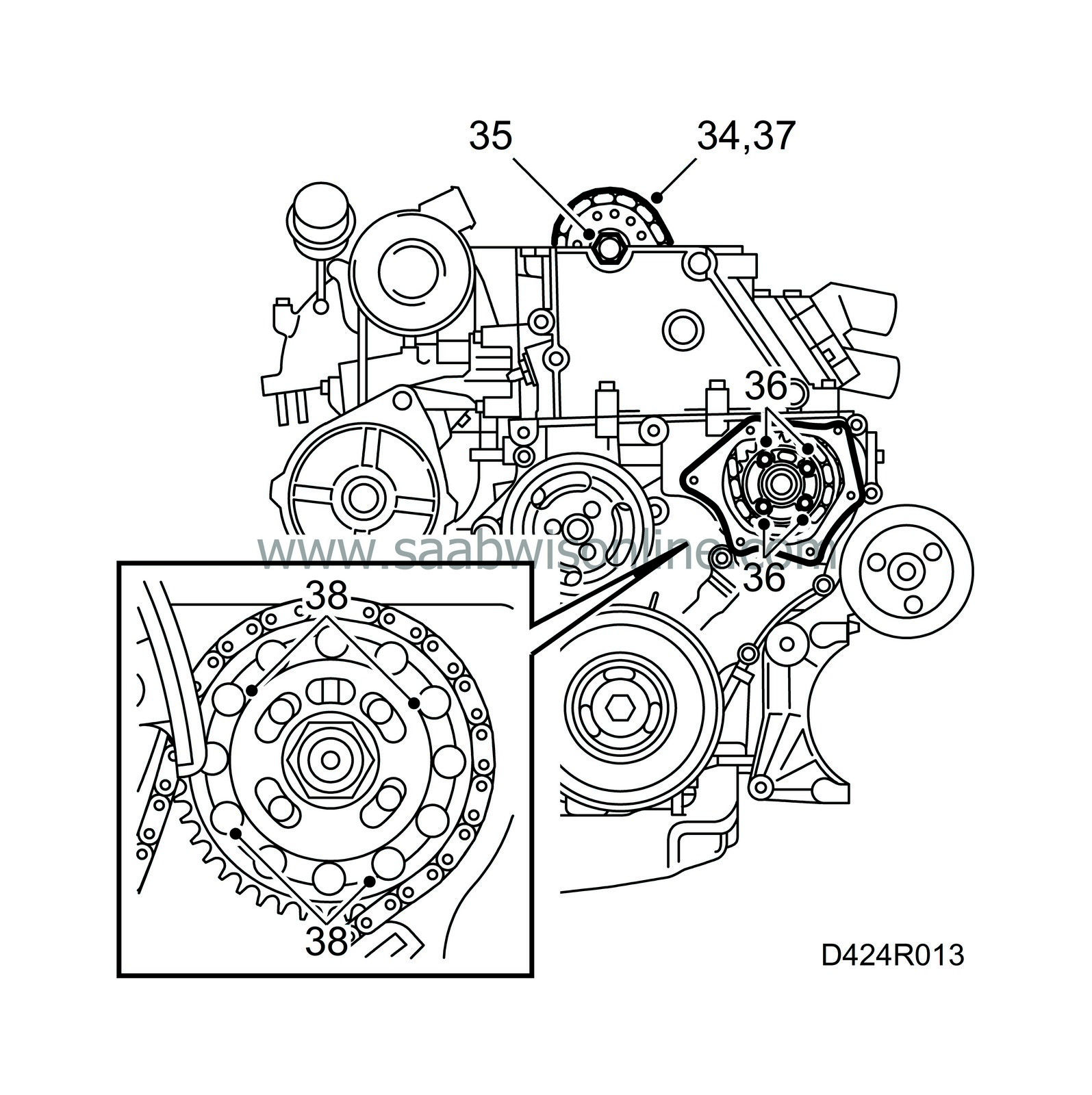

| 34. |

Secure the upper timing chain to the camshaft gear.

|

|

| 35. |

Remove the camshaft gear using an open-end spanner as a backstop in the hexagonal recess on the camshaft.

|

|

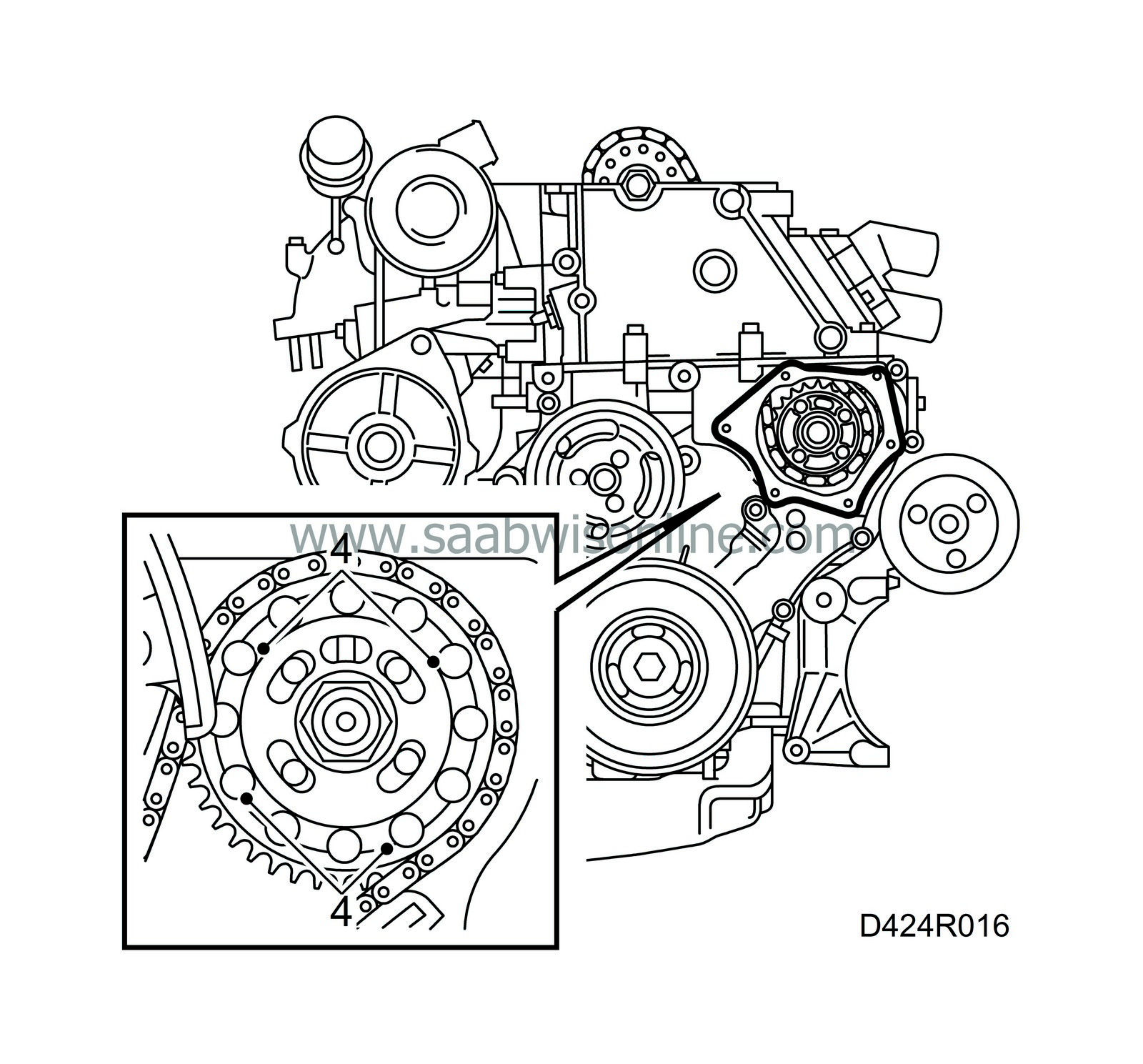

| 36. |

Undo the bolts on the fuel distributor pump chain drive and remove the pinion. Use sleeve 83 95 543.

|

||||||||||

| 37. |

Pull up the chain and remove it.

|

|

| 38. |

Remove the four retaining bolts on the fuel distributor pump that are accessible through the hole in the timing chain cover.

|

|

| 39. |

Remove the bracket from the fuel distributor pump and the cylinder block, and remove the fuel pump.

|

|

| To fit |

| 1. |

Clean the sealing surfaces.

|

|

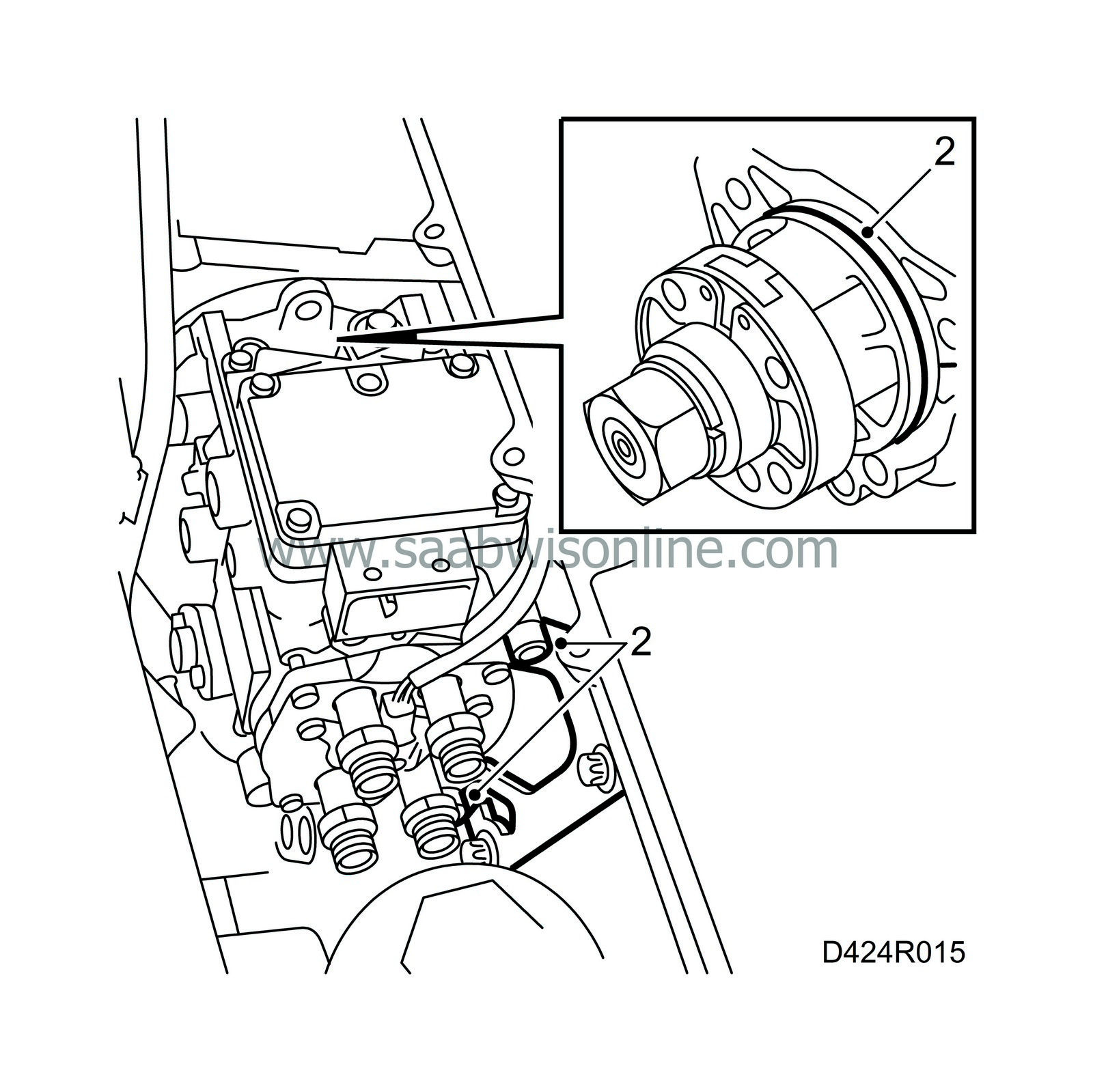

| 2. |

Fit a new O-ring on the fuel distributor pump, lubricate the O-ring with acid-free vaseline, position the pump on the cylinder block and fit the bracket to the pump.

Tightening torque 20 Nm (15 lbf ft). Position the screws to be fitted through the hole in the timing cover but do not tighten them. |

|

| 3. |

Position the inspection gauge 83 95 337 into the recess in the fuel distributor pump.

|

|

| 4. |

Tighten the bolts through the opening in the timing cover. Use sleeve 83 95 543.

Tightening torque 25 Nm (18.5 lbf ft). |

|

| 5. |

Tighten the screws securing the bracket to the cylinder block.

Tightening torque 20 Nm (15 lbf ft). |

|

| 6. |

Remove the inspection gauge from the fuel distributor pump.

|

|

| 7. |

Release the upper timing chain, position the sprocket on the fuel distributor pump, fit the sprocket with one bolt, fit the chain and tighten the bolts on the sprocket by hand.

|

||||||||||

| 8. |

Position the inspection gauge 83 95 337 into the recess in the fuel distributor pump again.

|

|

| 9. |

Position the camshaft gear on the camshaft.

|

|

| 10. |

Fit the chain tensioner for the lower timing chain with a new gasket.

Tightening torque 60 Nm (44 lbf ft). |

|

| 11. |

Remove the inspection gauge from the fuel distributor pump and tighten the bolts on the sprocket.

Tightening torque 20 Nm (15 lbf ft). |

|

| 12. |

Position the inspection gauge 83 95 337 into the recess in the fuel distributor pump again.

|

|

| 13. |

Make sure the camshaft gear runs freely on the camshaft and fit a new bolt. Tighten it by hand.

|

|

| 14. |

Fit the adapter for timing chain adjuster 83 95 394 onto the camshaft gear and fit the adjuster on the cylinder head.

|

|

| 15. |

Secure the position of the adapter on the camshaft gear by turning it slightly anti-clockwise with a ratchet handle. Tighten the adjuster screw on the tool.

|

||||||||||

| 16. |

Tighten the bolt on the camshaft gear.

Tightening torque 90 Nm (66.5 lbf ft) + 60°. |

|

| 17. |

Fit the chain tensioner for the upper timing chain with a new gasket.

Tightening torque 60 Nm (44 lbf ft). |

|

| 18. |

Remove all the tools and gauges.

|

|

| 19. |

Turn the crankshaft two revolutions with the pulley centre bolt until it comes just in front of the mark for top dead centre in cylinder 1. Make sure both cam ridges for cylinder 1 are pointing up.

|

|

| 20. |

Position the inspection gauge 83 95 352 into the hole for the crankshaft position sensor. Press in the tool at the same time as the crankshaft is turned to the zero marking. The tool will then enter a recess in the crankshaft and lock it.

|

|

| 21. |

Make sure the markings on the crankshaft pulley and the timing cover are aligned. The arrow on the single timing chain sprocket on the fuel distributor pump must also be aligned with the recess in the pump.

|

|

| 22. |

Position the inspection gauge 83 95 337 into the recess in the fuel distributor pump.

|

|

| 23. |

Position the inspection gauge 83 95 386 to the camshaft and cylinder head.

|

|

| 24. |

Remove all the inspection gauges.

|

|

| 25. |

Cover the opening in the timing cover with a lint-free cloth and clean the sealing surfaces from any remains of the old gasket. Also, clean the sealing surface on the cap.

|

|

| 26. |

Apply a string of sealing compound 87 81 841 approx. 2 mm wide to the cap, remove the cloth from the timing cover and fit the cap.

Tightening torque 6 Nm (4.5 lbf ft). |

|

| 27. |

Clean the sealing surfaces on the upper part of the intake manifold.

|

|

| 28. |

Fit a new gasket onto the lower part of the intake manifold and fit the upper part.

Tightening torque 10 Nm (7 lbf ft). |

|

| 29. |

Clean the sealing surfaces on the cylinder head from remains of the old gasket.

|

|

| 30. |

Position a new gasket on the camshaft cover. The bolts have sleeves on which the gasket fits.

|

|

| 31. |

Apply sealing compound 87 81 841 to the sealing surface, see illustration.

|

|

| 32. |

Position the camshaft cover on the cylinder head and tighten the bolts.

Tightening torque 8 Nm (6 lbf ft). |

|

| 33. |

Fit a new seal on the vacuum pump and fit the pump together with the adapter.

Tightening torque 8 Nm (6 lbf ft). |

||||||||||

| 34. |

Connect the vacuum hose for the brake servo to the vacuum pump.

Tightening torque 18 Nm (13 lbf ft). Connect the vacuum hose to the bottom of the vacuum pump. |

|

| 35. |

Tighten the fuel lines with new seals to the fuel pump.

Tightening torque 25 Nm (18.5 lbf ft). |

|

| 36. |

Check the fuel rail connection cones and replace as necessary.

|

|

| 37. |

Fit the fuel rails in their original positions with the clips.

Tightening torque 25 Nm (18.5 lbf ft). |

|

| 38. |

Check the condition of the fuel return hoses and joints, replace them if necessary.

|

|

| 39. |

Connect the fuel return hoses.

|

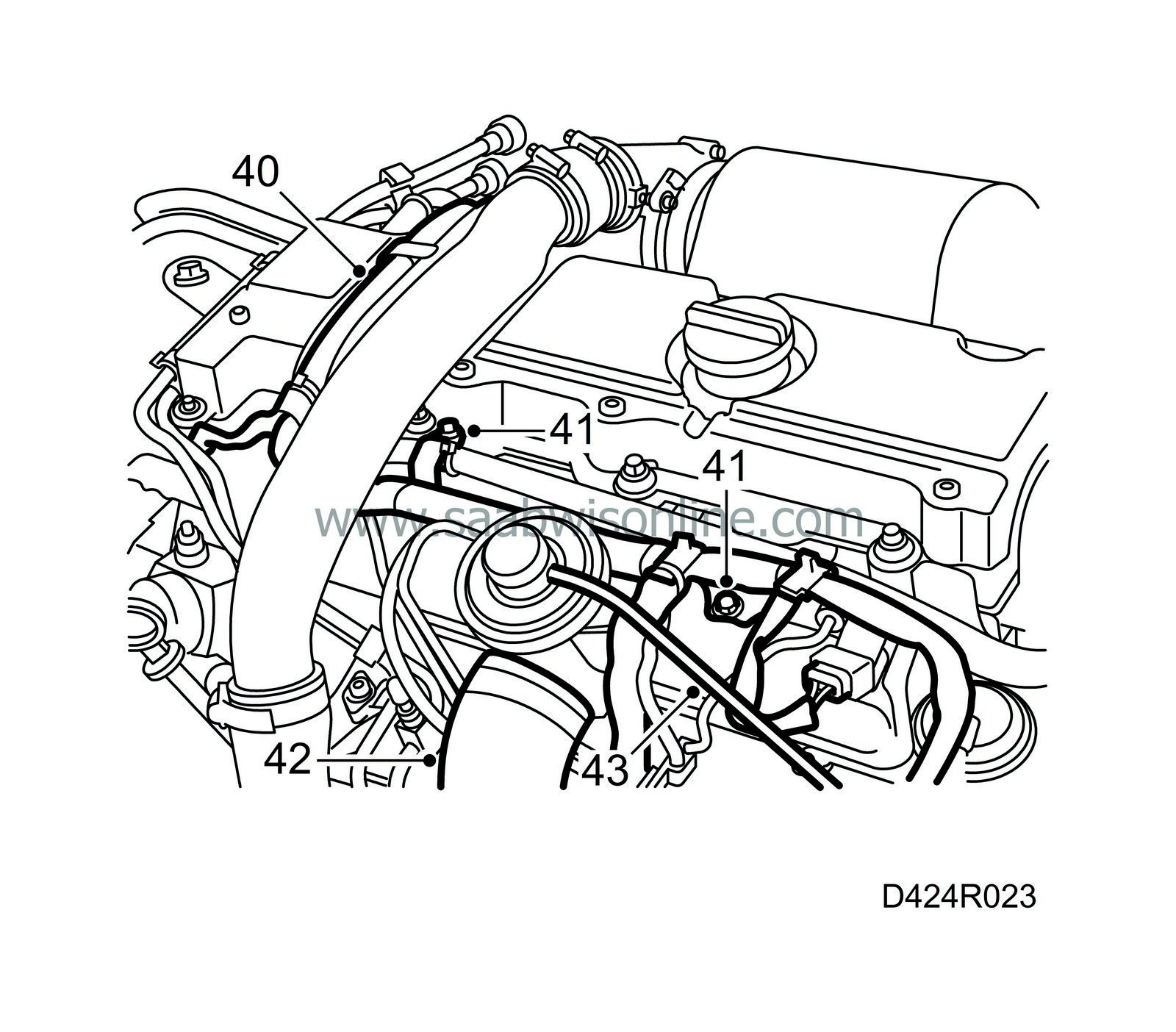

|

| 40. |

Fit the wiring harness channel to the cylinder head and attach the cables.

|

|

| 41. |

Secure the wiring harness as it was previously.

|

|

| 42. |

Put back the hose onto the intake manifold.

|

|

| 43. |

Connect the vacuum hose to the EGR valve.

|

|

| 44. |

Fit the right-hand engine pad bracket onto the timing cover.

Tightening torque 47 Nm (35 lbf ft). |

|

| 45. |

Position the right-hand engine pad, lower the engine and tighten the right-hand engine pad bolts.

Tightening torque 47 Nm (35 lbf ft). |

|

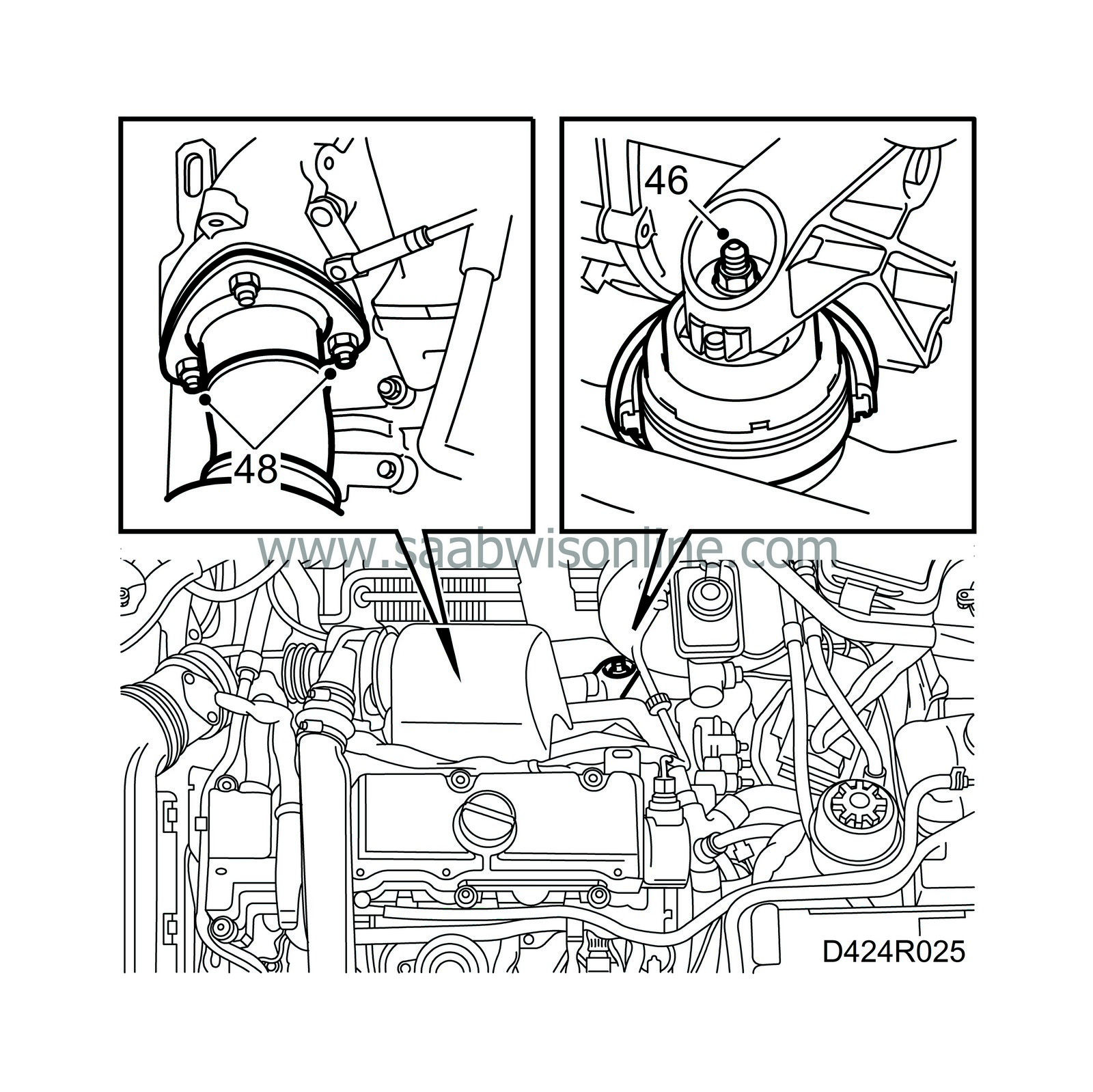

| 46. |

Tighten the nut on the rear engine pad.

Tightening torque 47 Nm (35 lbf ft). |

|

| 47. |

Raise the car, apply Molycote 1000 to the studs on the turbocharger, position the front part of the exhaust pipe together with a new gasket and fit new nuts.

|

|

| 48. |

Tighten the front exhaust pipe on the turbocharger.

Tightening torque 20 Nm (15 lbf ft). |

|

| 49. |

Fit the crankshaft position sensor with a new O-ring.

Tightening torque 8 Nm (6 lbf ft). |

|

| 50. |

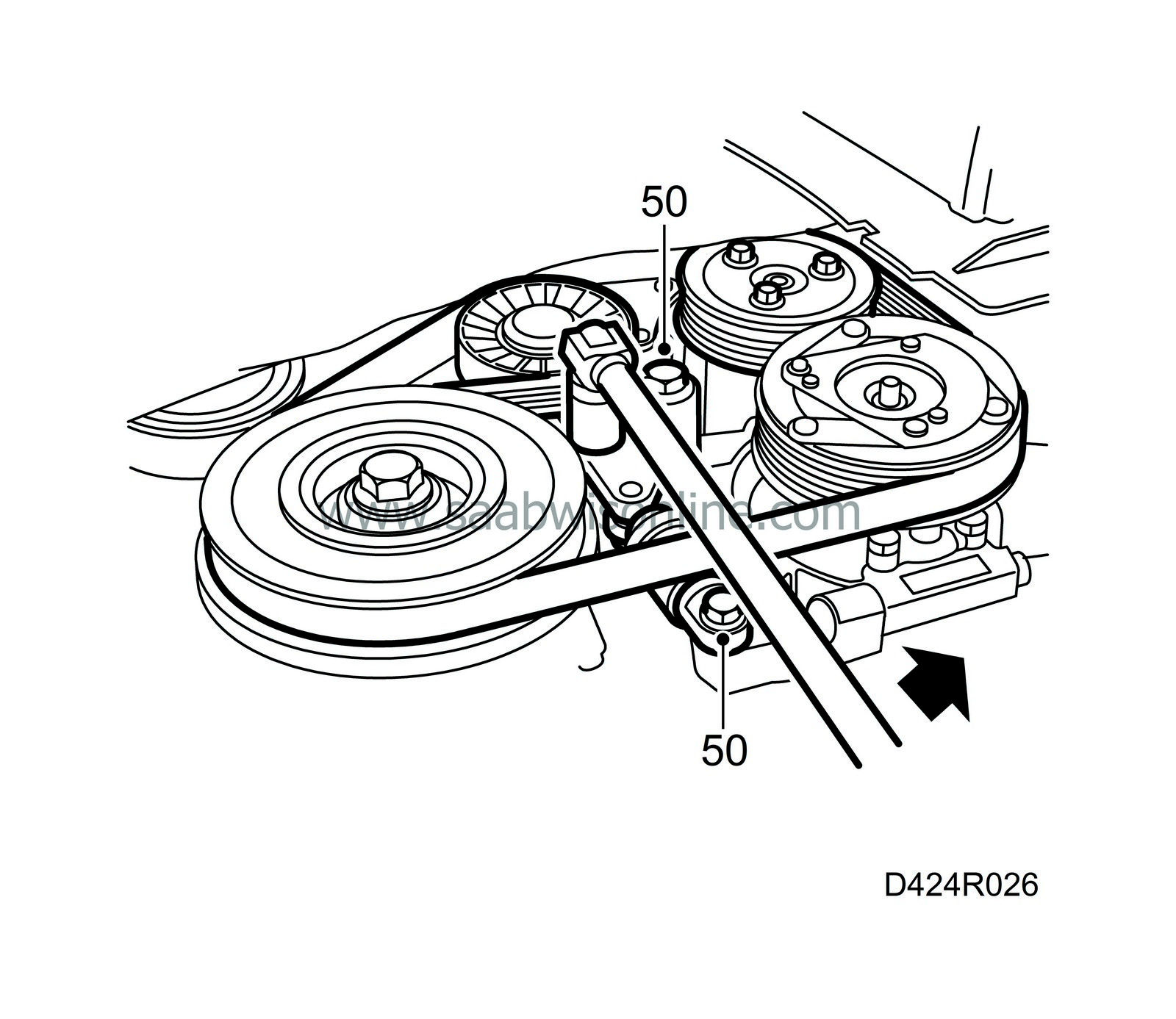

Fit the belt tensioner and tighten the top bolt first.

Tightening torque 42 Nm (31 lbf ft). Tighten the bottom bolt. Tightening torque 23 Nm (17 lbf ft). |

|

| 51. |

Fit the multigroove V-belt on all the pulleys. Relieve the tension on the belt tensioner by turning it anti-clockwise (towards the rear of the car) with a 19 mm spanner and fit the belt onto the belt tensioner pulley. Check the position of the belt on all the pulleys.

|

|

| 52. |

Put back the cover in the right-hand wheel housing, the lower engine cover and the wheel.

Tightening torque 110 Nm (81 lbf ft). Lower the car. |

|

| 53. |

Fit the wiring harness with bracket and press in the fuel lines.

|

|

| 54. |

Tighten the remaining nut for the front exhaust pipe on the turbocharger.

Tightening torque 20 Nm (15 lbf ft). |

|

| 55. |

Replace the turbocharger delivery pipe with connecting pipe and connecting piece. Lubricate the O-ring with acid-free vaseline.

|

|

| 56. |

Fit the engine cover.

|

|

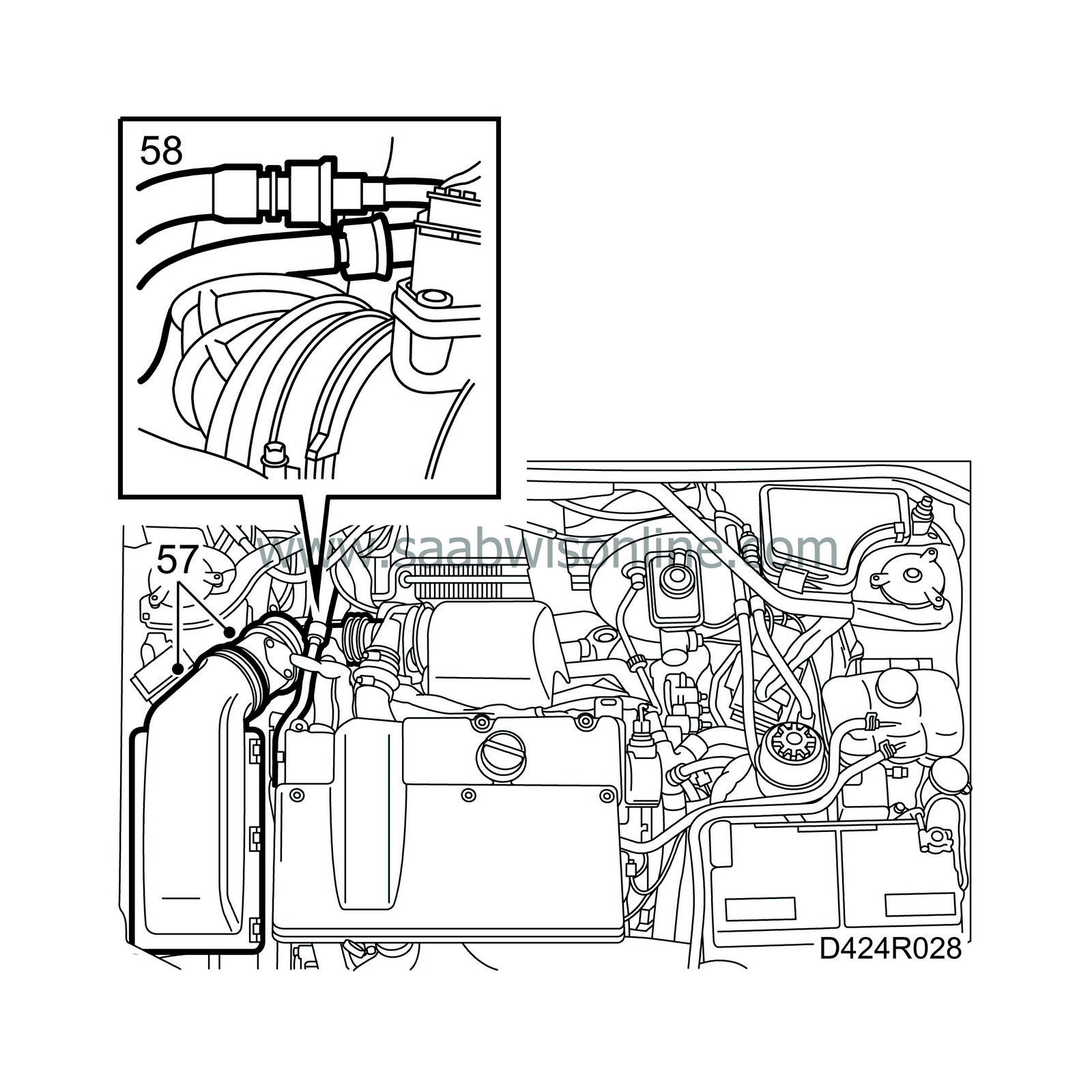

| 57. |

Put back the air cleaner with mass air flow sensor and hoses.

|

|

| 58. |

Connect the fuel lines.

|

|

Warning

Warning