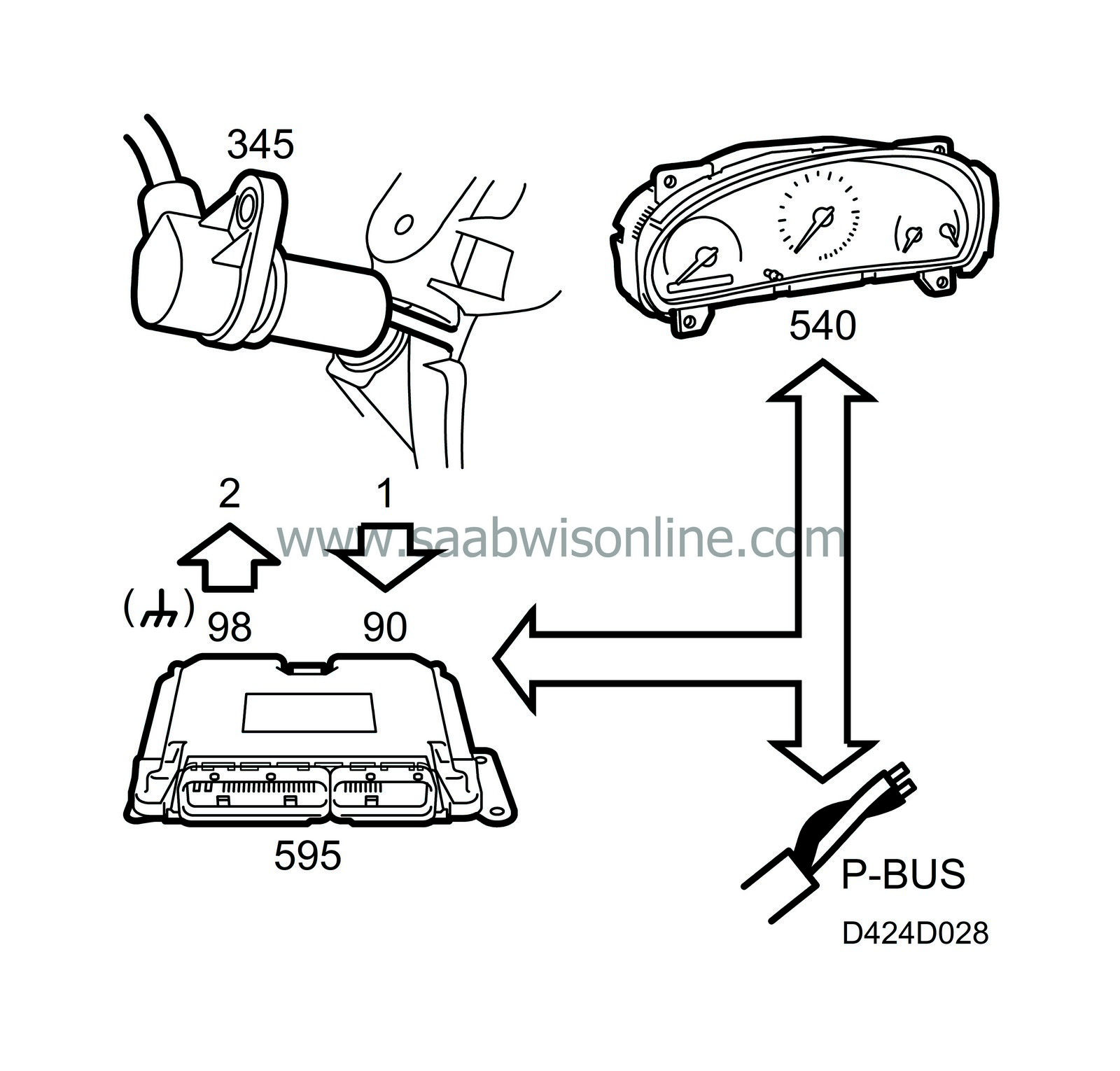

Crankshaft position sensor

| Crankshaft position sensor |

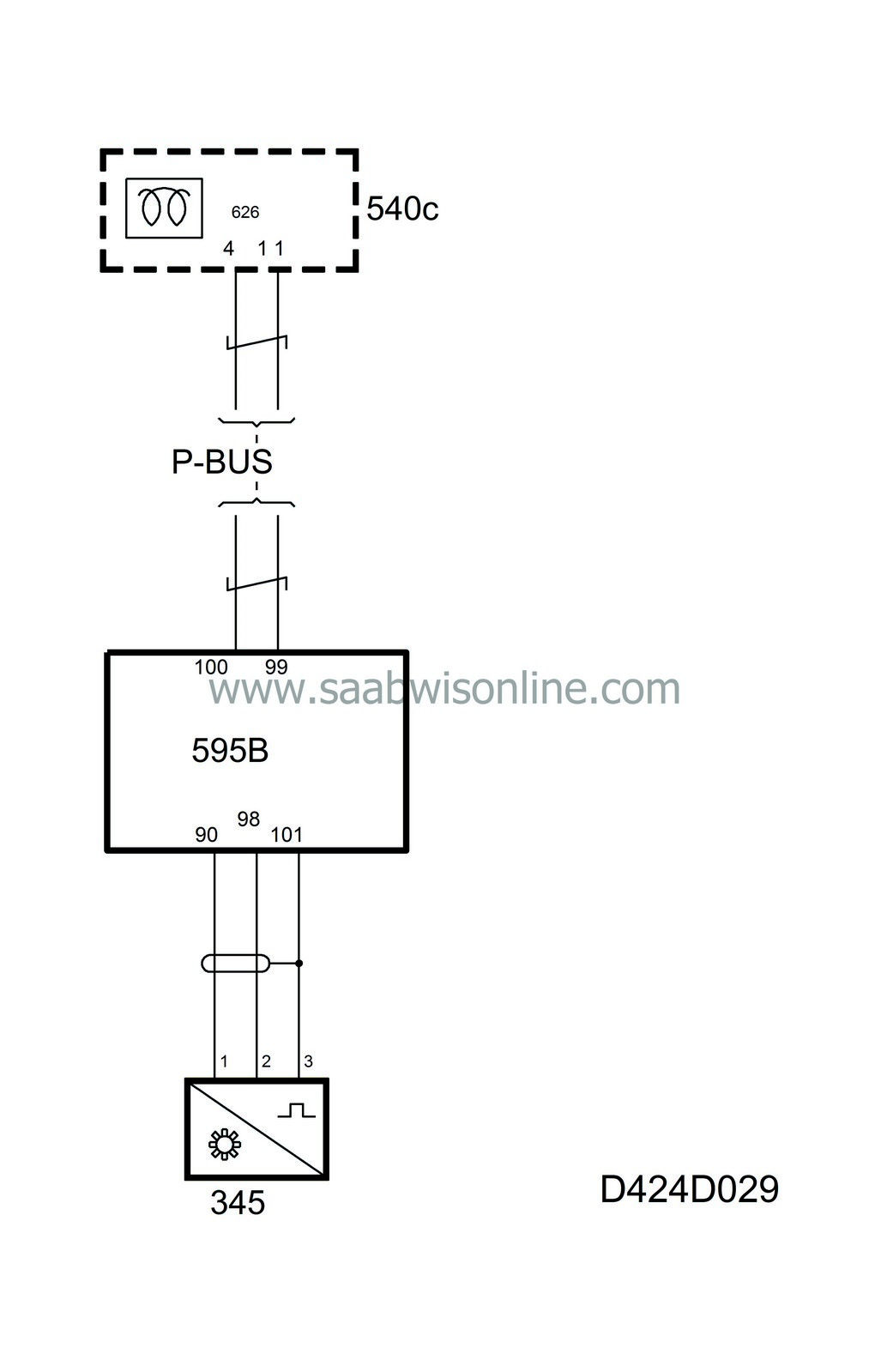

The engine control module receives information on the engine speed and on when the engine is at top dead centre from the crankshaft position sensor. This information is used to calculate the permitted injection quantity and to determine when the fuel pressure build-up should start.

There are four air gaps in one of the crankshaft balance weights that induce an alternating current when they pass the sensor. The frequency of this current is proportional to the engine speed. Two of the air gaps are used by the control module to determine top dead centre. These gaps are displaced 13° in relation to TDC.

Note that the special tool for locking the engine at top dead centre does not fit the crankshaft position sensor air gap. Instead, there is a special recess for the tool that is not displaced in relation to top dead centre.

| Diagnostics |

The following diagnostic trouble codes are generated if a fault should occur in the crankshaft position sensor:

| • |

P0726 Engine Speed Sensor, Electrical Malfunction

|

|

| • |

P0727 Engine Speed Sensor, Mechanical Malfunction

|

|

| • |

P0728 Engine Speed. Has been too high

|

|

The pump camshaft position sensor is used as a substitute value for the crankshaft position sensor.