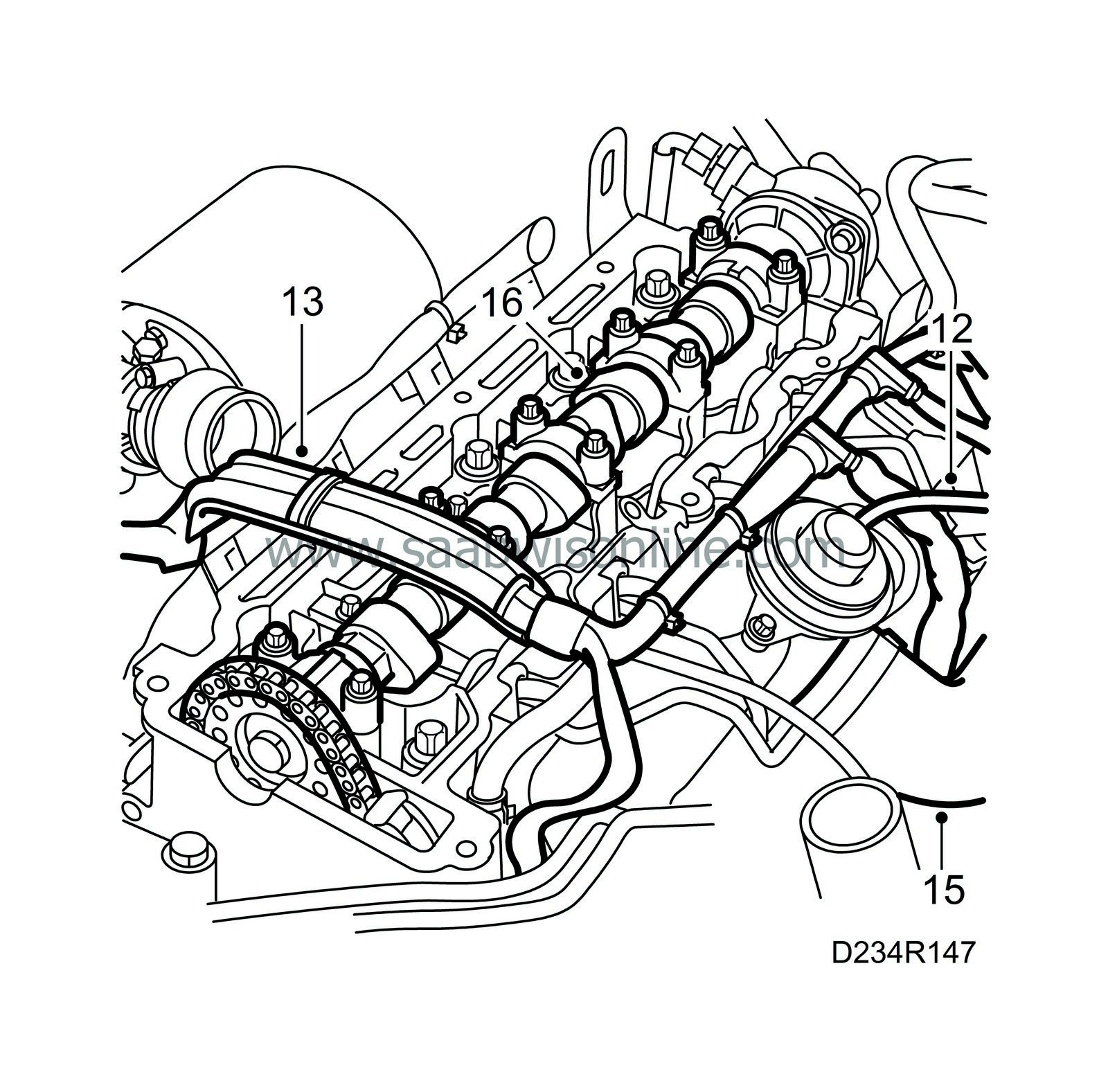

Fuel bridge

| Fuel bridge |

| To remove |

|

|||||||

| • |

Make provision for good ventilation! If approved ventilation for extracting fuel fumes is available then it must be used.

|

|

| • |

Use protective gloves! Prolonged contact with fuel may irritate the skin.

|

|

| • |

Keep a class BE fire extinguisher close at hand! Watch out for sparks, e.g. in connection with breaking electric circuits, short-circuits, etc.

|

|

| • |

Smoking is absolutely forbidden.

|

|

| 1. |

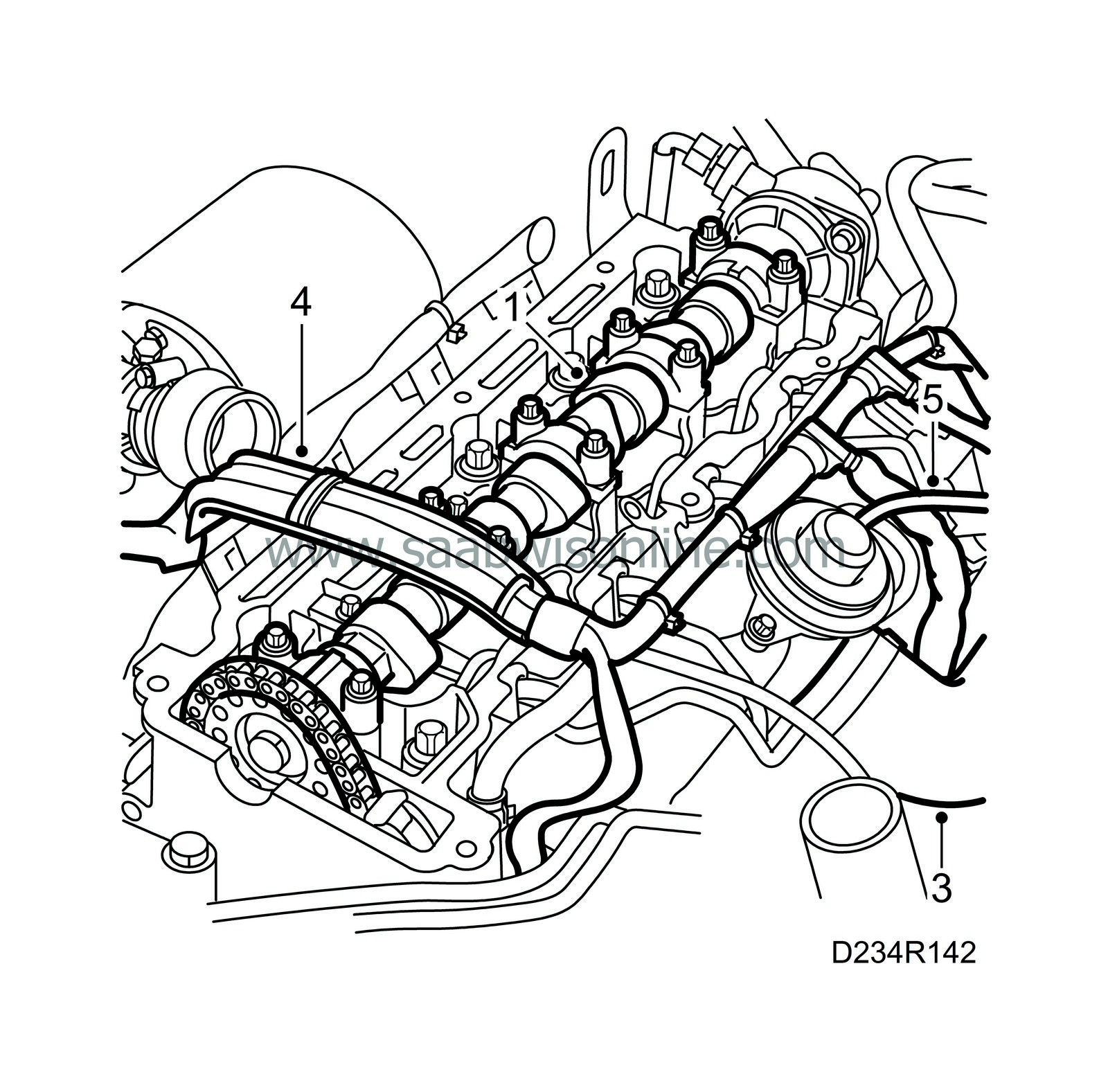

Remove the camshaft, see 2. Basic Engine, Adjustment/replacement, Camshaft

.

.

|

|

| 2. |

Suck up the oil on top of the cylinder head.

|

|

| 3. |

Detach the air hose from the intake manifold, bend it to one side and plug it.

|

|

| 4. |

Unplug all the cables connected to the wiring harness channel and cut the securing points. Remove the channel from the cylinder head and lay it over the engine.

|

|

| 5. |

Pull off the vacuum hose from the EGR valve.

|

|

| 6. |

Note the position of the fuel rails and their clips and mark them.

|

|

| 7. |

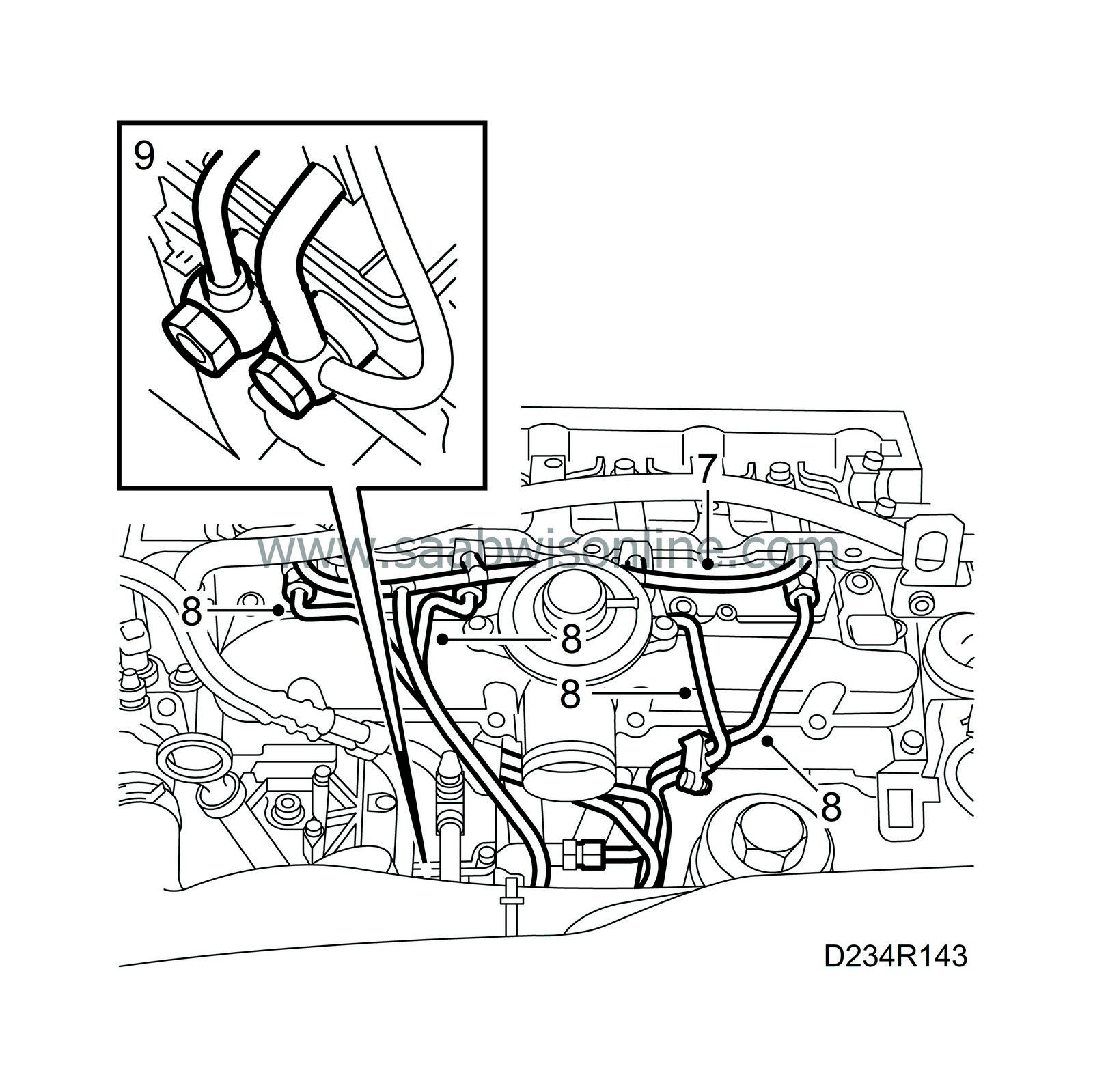

Remove the fuel return hoses from the cylinder head.

|

|

| 8. |

Remove the fuel rails (remove the clips if necessary).

|

|

| 9. |

Slightly loosen the fuel line connections on the fuel pump.

|

|

| 10. |

Remove the upper part of the intake manifold and seal the passageways.

|

|

| 11. |

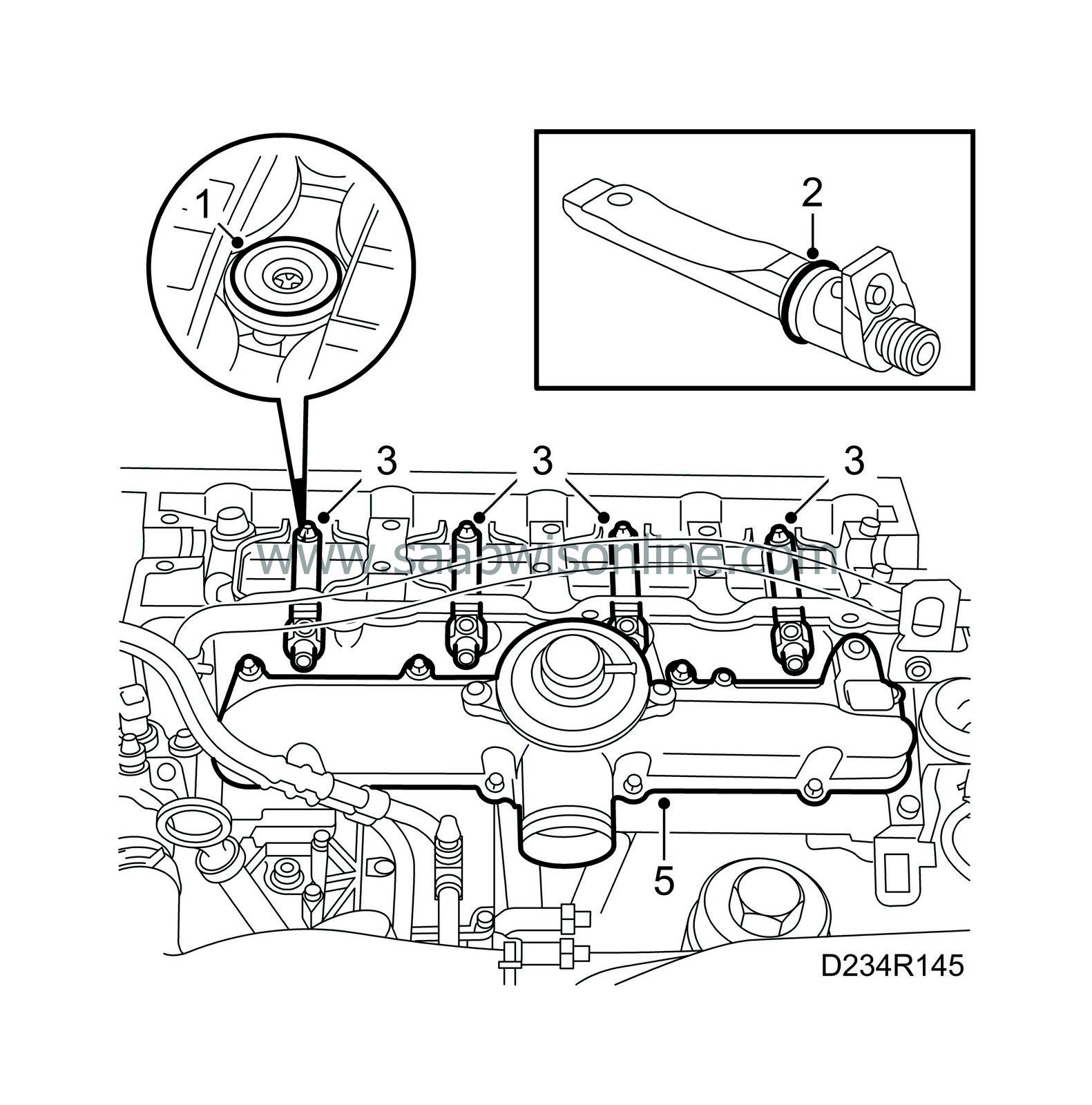

Remove the retaining screws for the fuel bridges, lift the fuel bridges and pull them out of the cylinder head.

|

|

| 12. |

Remove the seals on the injector connections in the cylinder head.

|

|

| To fit |

| 1. |

Blow out the holes for the fuel bridge retaining bolts. Fit new O-rings on the fuel bridges, lubricate the O-rings with non-acidic vaseline and carefully slide the fuel bridges into the cylinder head.

|

|

| 2. |

Fit new O-rings to the fuel bridges, lubricate the O-rings with acid-free vaseline and push the fuel bridges into the cylinder head.

|

|

| 3. |

Tighten the fuel bridge bolts.

Tightening torque 5 Nm + 360° (4 lbf ft + 360°) |

|

| 4. |

Clean the sealing surfaces.

|

|

| 5. |

Fit a new gasket to the lower part of the intake manifold and fit the upper part.

Tightening torque 10 Nm (7 lbf ft). |

|

| 6. |

Fit the pressure sensor and EGR valve if the intake manifold has been changed.

|

|

| 7. |

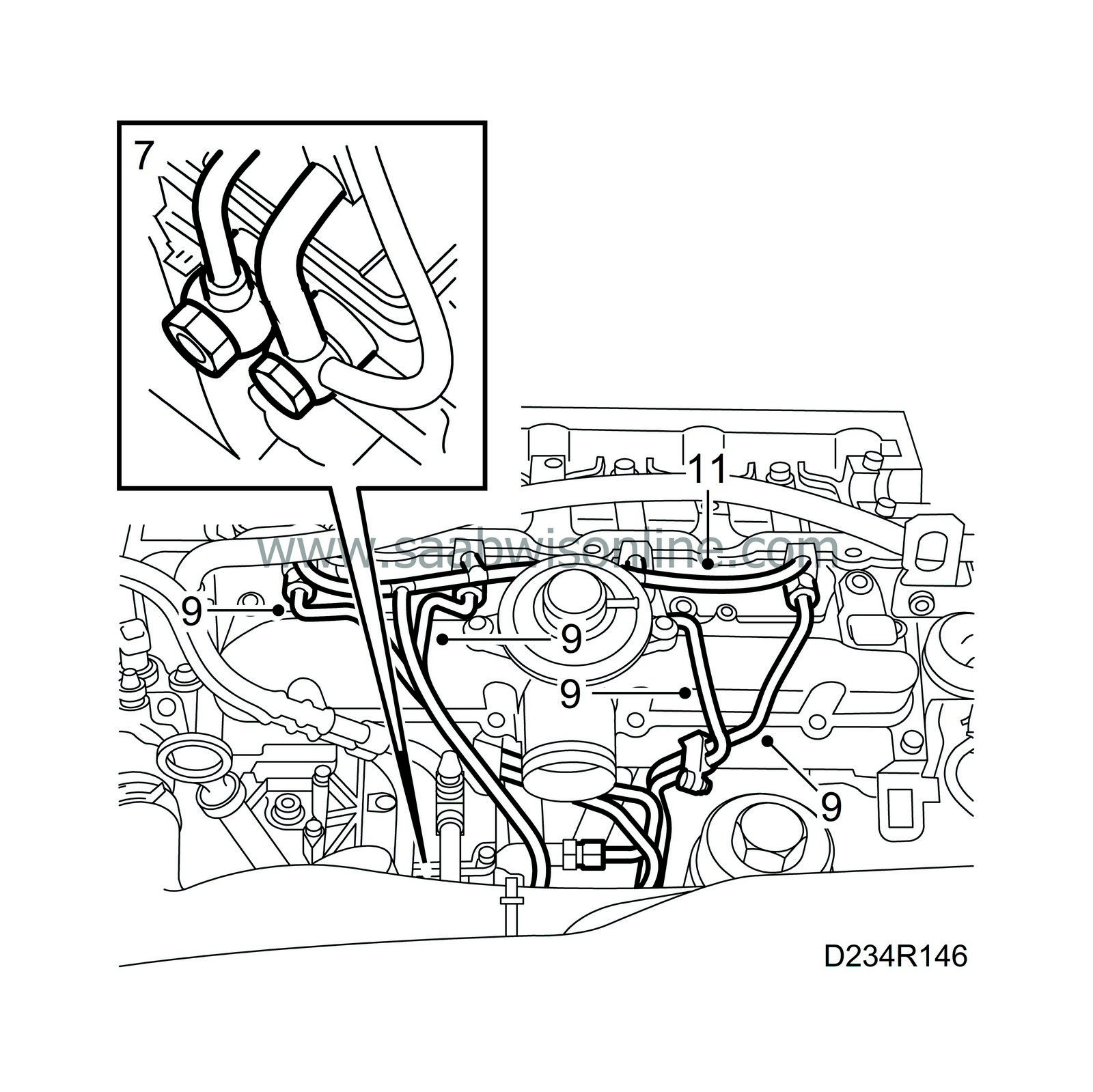

Tighten the fuel lines to the fuel pump.

Tightening torque 25 Nm (18.5 lbf ft). |

|

| 8. |

Check the fuel rail connecting cones and replace them if necessary.

|

|

| 9. |

Connect the fuel rails with clips in their original positions.

Tightening torque 25 Nm (18.5 lbf ft). |

|

| 10. |

Check the condition of the fuel return hoses and joints and replace as necessary.

|

|

| 11. |

Connect the fuel return hoses to the fuel bridges. Detach the fuel return hose from the fuel pump and connect the hose to pressure/vacuum pump 30 14 883. Pump up a vacuum of 750 mbar and wait 1 minute. Check that the pointer on the tool has not moved.

If a leak is found, the fuel bridges must be examined individually. Connect the pressure/vacuum pump to the return fuel connection (not to the return hose) on each fuel bridge. If the fuel bridges are OK, check the return fuel hoses and T-pieces. The hoses should be pliable and exhibit no cracks or other damage. If there are signs of leakage, change all fuel return hoses and T-pieces. If there is leakage in the fuel bridge, remove it, change the seal and refit the bridge. Check for leakage once again. |

|

| 12. |

Connect the vacuum hose to the EGR valve.

|

|

| 13. |

Fit the wiring harness channel to the engine.

|

|

| 14. |

Secure the wiring harness as it was previously.

|

|

| 15. |

Refit the hose to the intake manifold.

|

|

| 16. |

Fit the camshaft. See

Camshaft

.

|

|

Warning

Warning