Manifold absolute pressure sensor

|

|

Manifold absolute pressure sensor

|

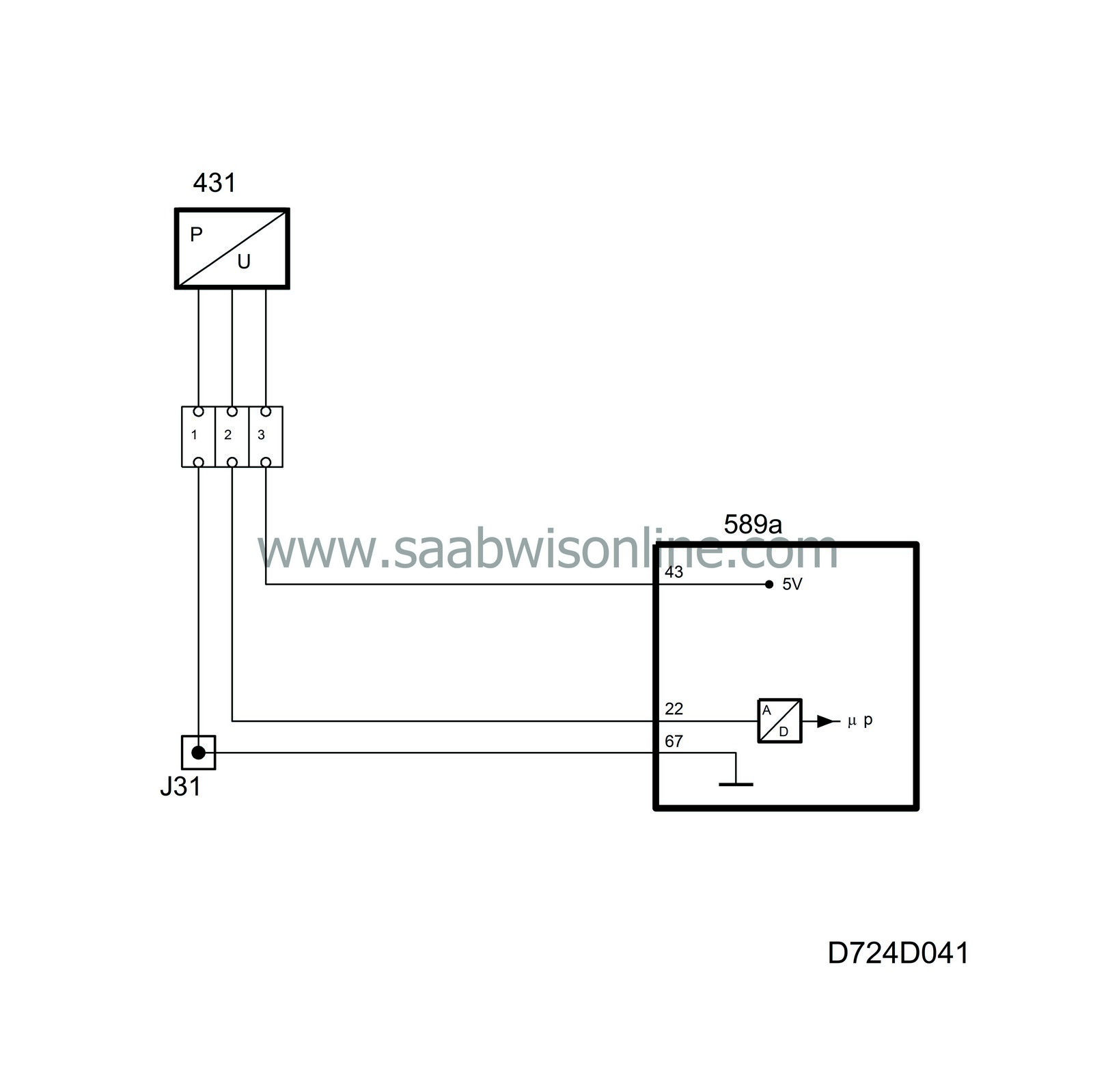

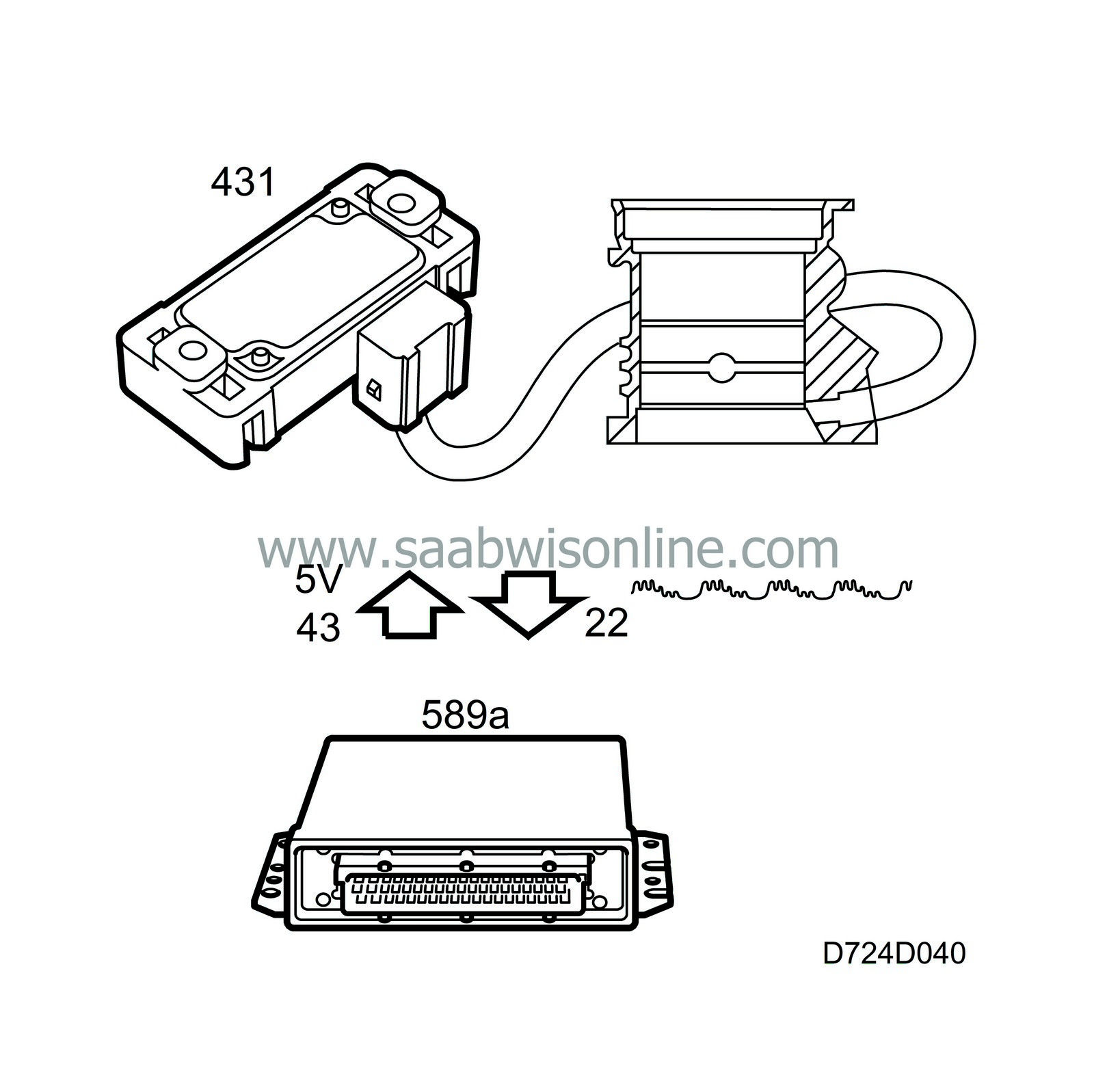

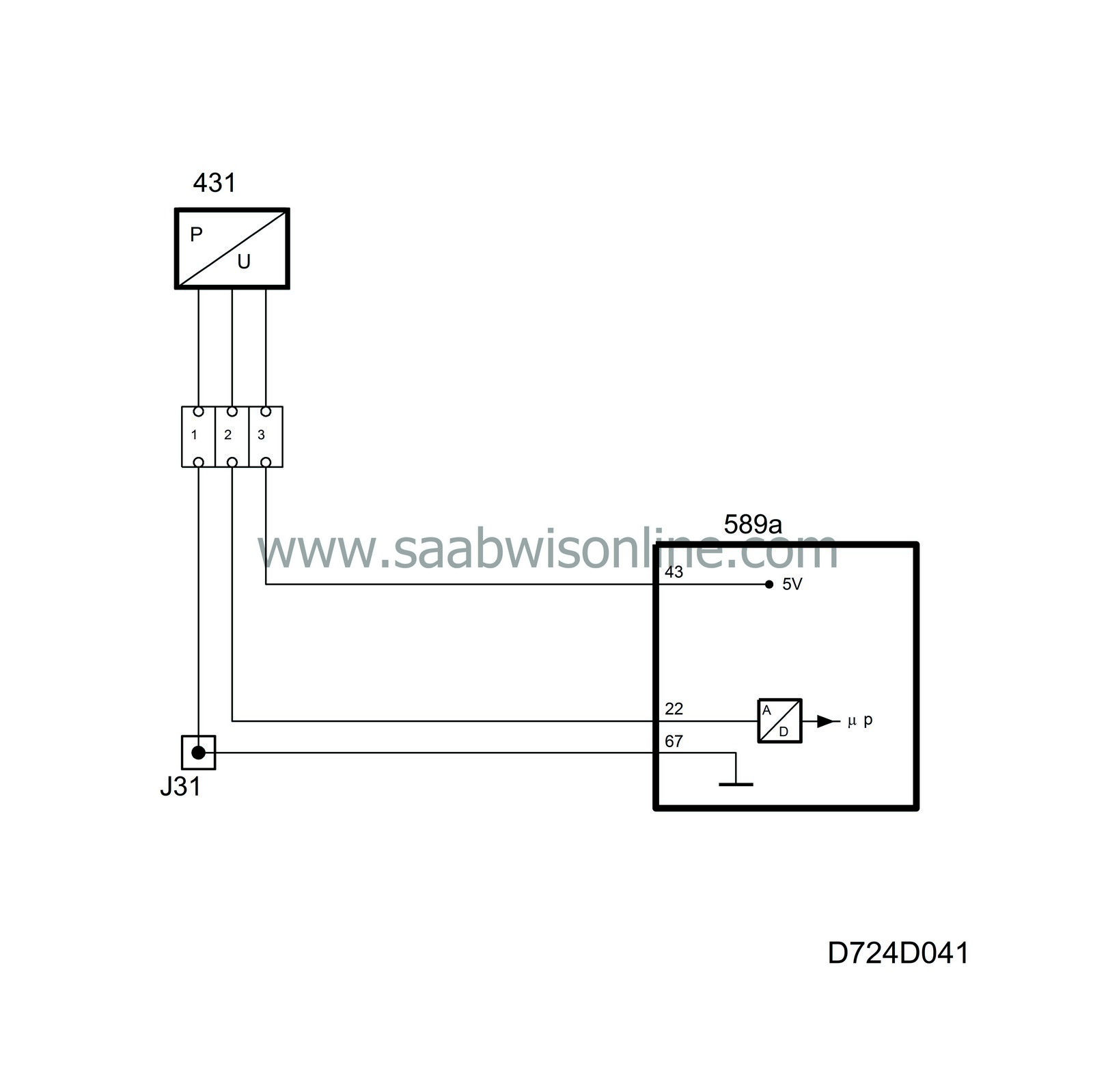

The pressure sensor contains a pressure-sensitive ceramic element, an amplifier and a temperature compensation circuit. It is connected through a special hose to the intake manifold after the throttle and is powered with 5 V from control module pin 43 and grounded from control module pin 67.

The pressure sensor contains a pressure-sensitive ceramic element, an amplifier and a temperature compensation circuit. It is connected through a special hose to the intake manifold after the throttle and is powered with 5 V from control module pin 43 and grounded from control module pin 67.

The pressure sensor delivers a voltage to control module pin 22 proportional to the pressure in the intake manifold.

The control module uses the pressure and temperature in the intake manifold to calculate the engine load, i.e. the air mass each cylinder draws in. The injection duration is proportional to the air mass drawn in. At atmospheric pressure (100 kPa), the voltage from the pressure sensor will be approx. 1.9 V. Information from the pressure sensor is also used to calculate the ignition timing and for the boost pressure control.

In case of a disconnected hose, sensor malfunction or a break in the circuit, the control module will use the throttle position as a substitute value.

|

•

|

If the sensor voltage is too low, diagnostic trouble code P0107 will be generated.

|

|

•

|

If the sensor voltage is too high, diagnostic trouble code P0108 will be generated.

|

|

•

|

If the pressure reading is implausible (e.g. if the hose has come loose), diagnostic trouble code P0106 will be generated.

|

System reaction to a fault

|

•

|

Throttle position is used as a substitute value.

|

|

•

|

Basic charging pressure

|

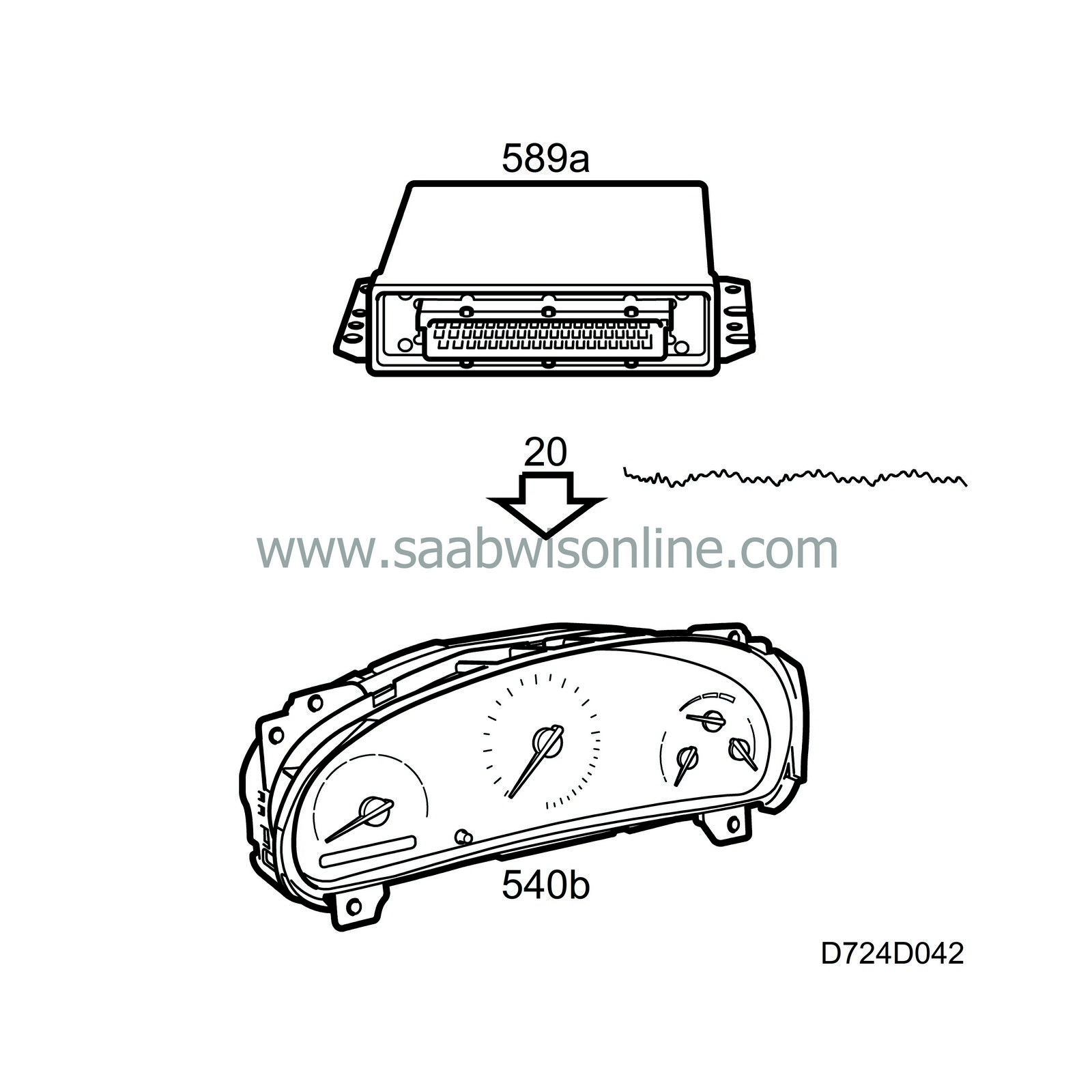

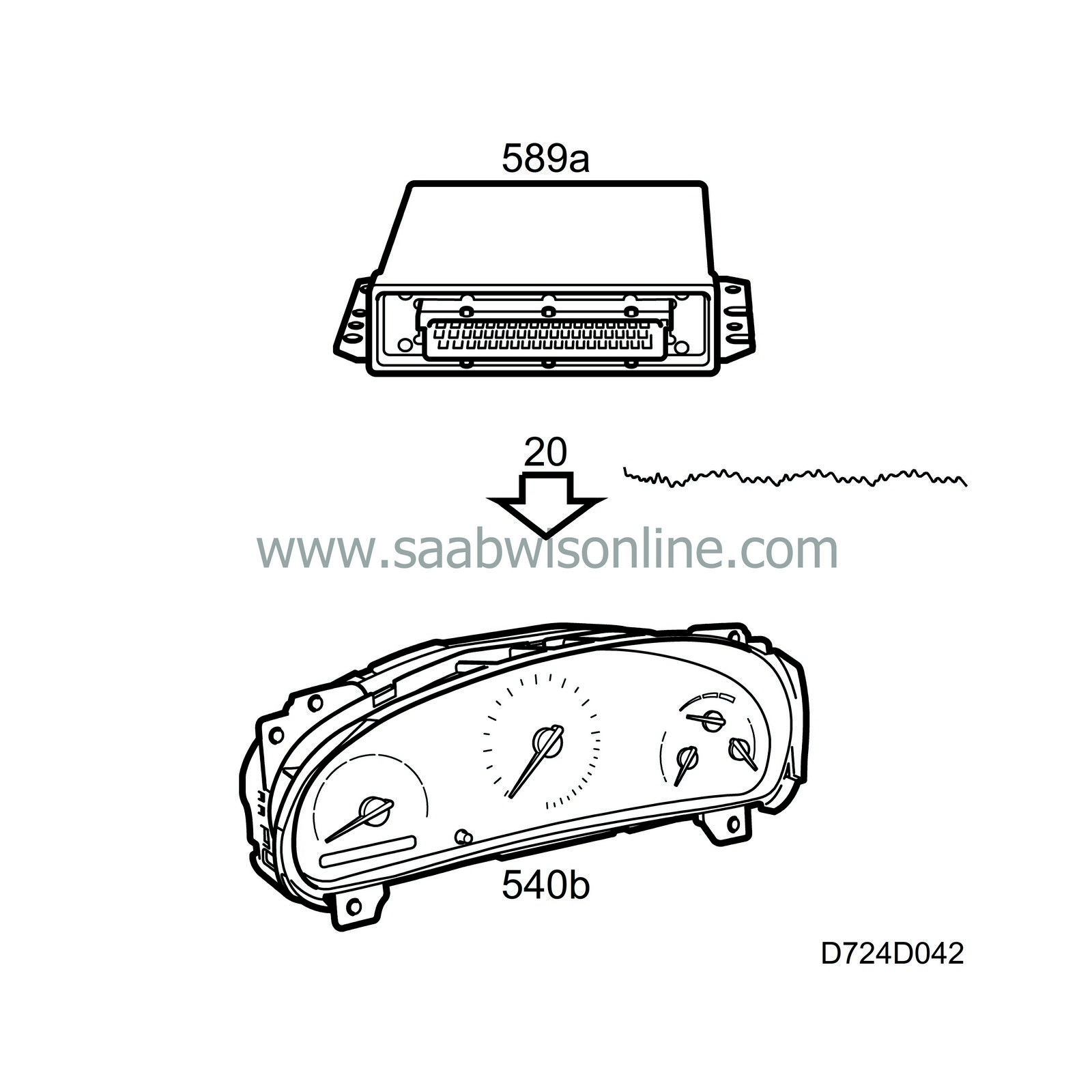

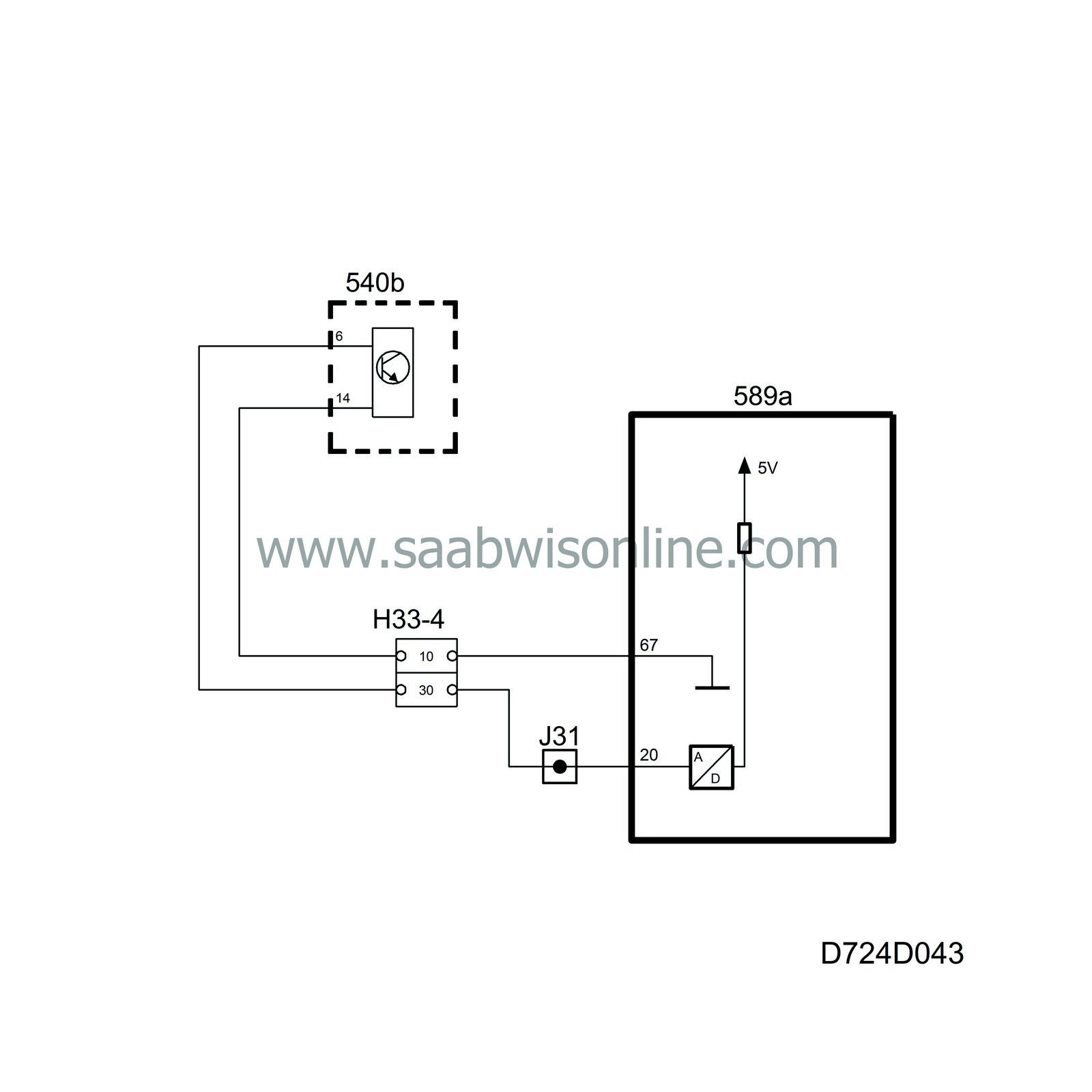

Pressure signal

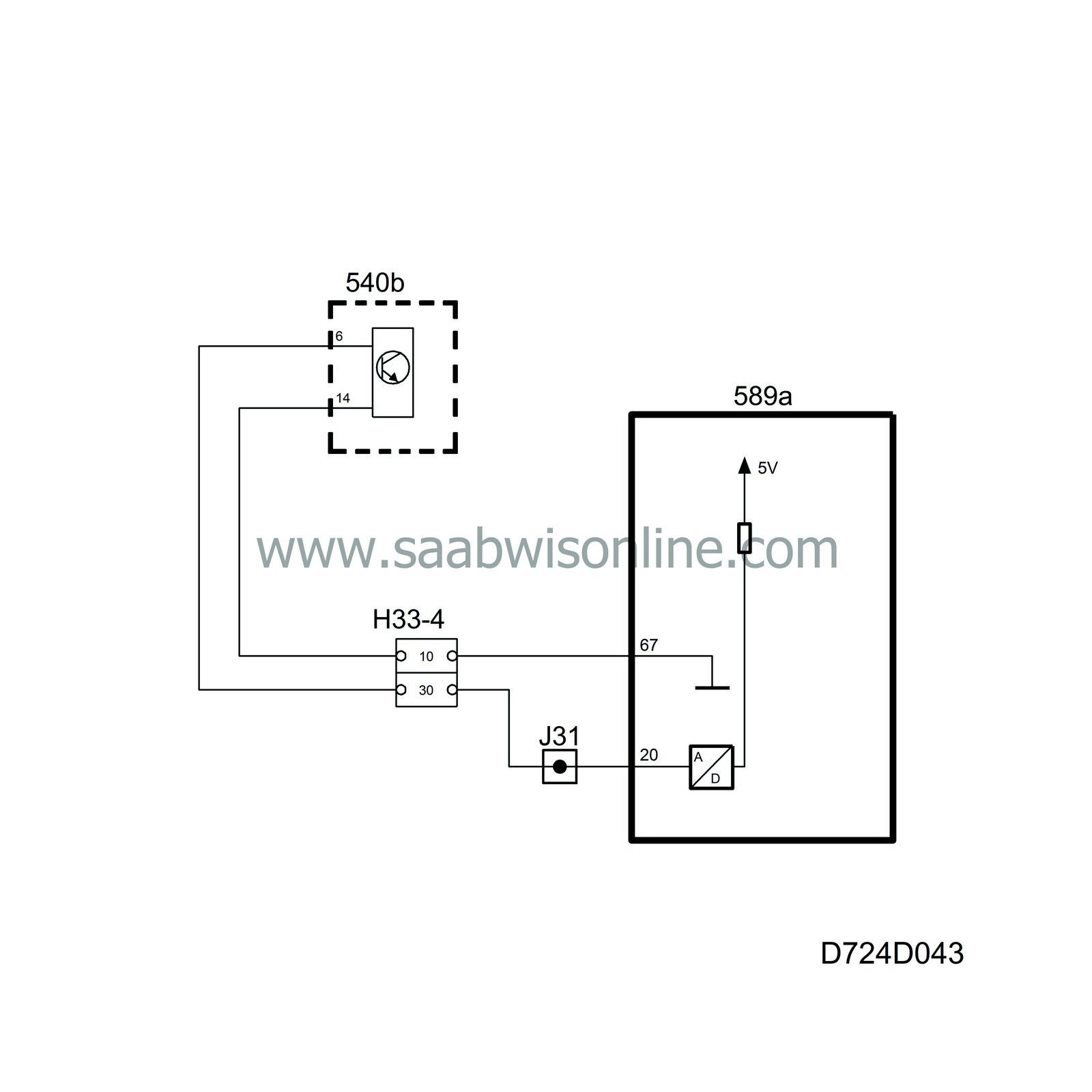

The control module transmits a pressure signal from pin 20 in the form of a voltage depending on the pressure in the intake manifold. At 100 kPa (atmospheric pressure), the voltage will be approx. 1.0 V.

The pressure signal is used by the main instrument unit, which also uses the sensor ground from pin 67 as a reference ground for accurate pressure readings.

|

•

|

No diagnosis. In case of a break or short circuit to ground on any of the two leads, the turbo gauge will show minimum value.

|