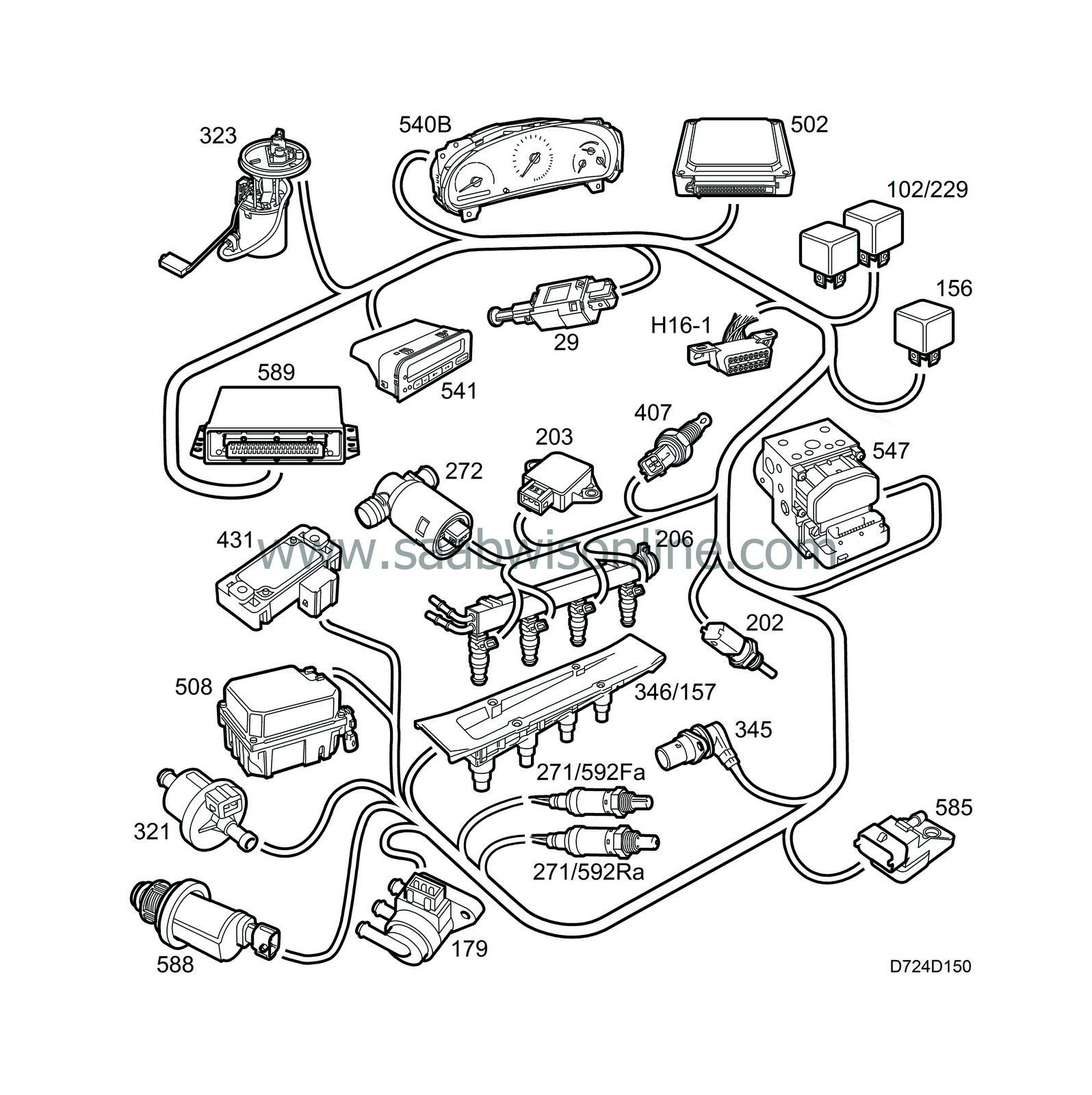

System overview, Saab Trionic

| System overview, Saab Trionic |

Saab Trionic Engine Management System

Saab Trionic is an engine management system that controls ignition, fuel injection and boost pressure. The system was introduced in 1994 on the Saab 900 with B204L engine. Since 1994, a number of modifications have been made.

1995: 4-wire oxygen sensor. Electric heating plates in intake manifold (not US or CA). K-lead connected via VSS to enable immobilizer (certain markets). Brake vacuum pump with some control from T5 on automatic cars.

1996: OBDII diagnostics for US and CA.

1996.5: Leak diagnostics for EVAP system on OBDII variant.

1997: Heating plates removed.

1998.5 (Saab 9-3): K-lead connected via MIU to enable immobilizer from TWICE (not is software for US or CA). Fuel pump relay powered from main relay. A/C request from MIU. Oxygen sensor pre-heating powered from main relay. Requested boost pressure increased slightly on manual cars. SID message when leak in EVAP system on OBDII variants.

1999: Two new engine variants, B204R and B204E. B204R available with manual gearbox only and must be run on high-octane petrol (min. 98 RON) to deliver specified engine torque. B204E available for US and CA without boost pressure control. Cars with B204E engine on Swedish market fitted with OBDII diagnostics and ORVR (On board Refuelling Vapor Recovery system), which disposes of fuel fumes when refuelling.

The Saab Trionic ignition system consists of an ignition discharge module with four ignition coils, one for each spark plug. The ignition system is capacitive. The spark plugs are used as sensors to detect combustion and knocking. This means that neither camshaft position sensor nor knock sensor is required. The function provides an efficient misfire detection, which is a requirement for OBD II.

Fuel injection is sequential and is governed by the pressure in the intake manifold.

Boost pressure control (L and R engines) is achieved with a solenoid valve connected to the turbocharger wastegate.