Crankshaft position sensor

| Crankshaft position sensor |

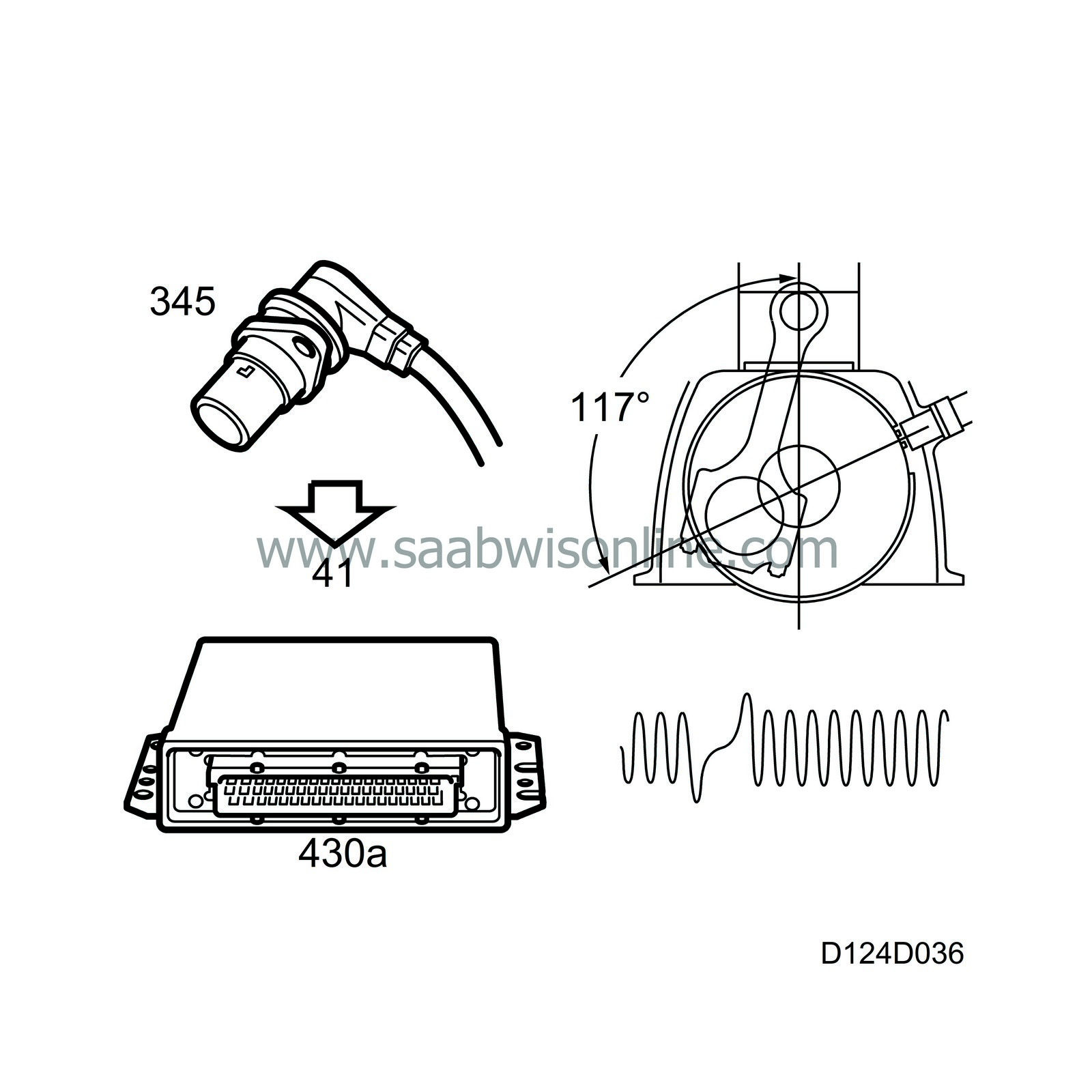

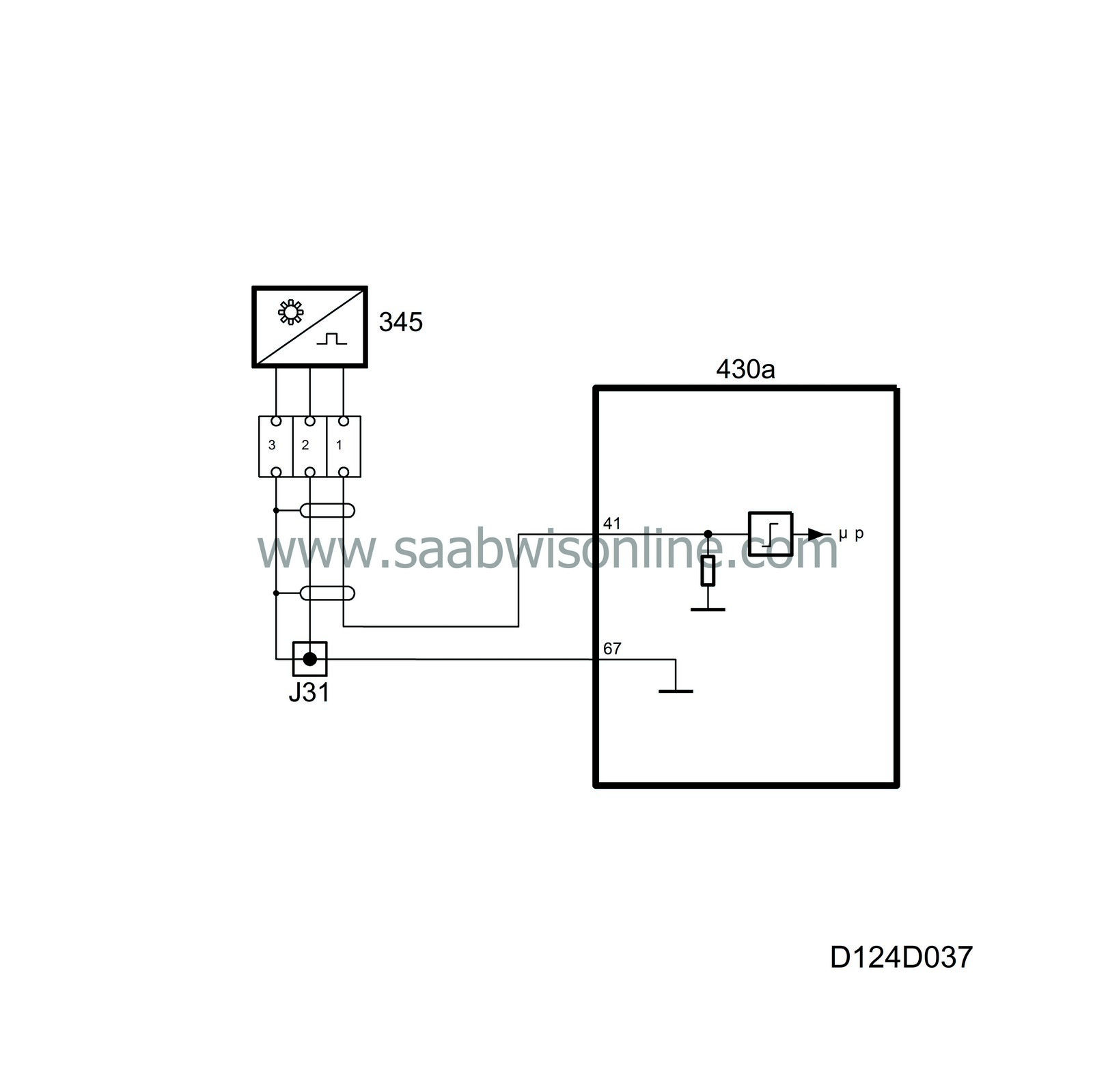

The control module receives information concerning the position and speed of the crankshaft on pin 41 from the crankshaft position sensor.

There is a slotted ring with 58 ribs mounted on the crankshaft. The sensor is inductive and mounted on the wall of the crankcase. The distance between the sensor and the slotted ring is between 0.4-1.3 mm and is not adjustable.

The sensor acts like a generator and delivers a sinusoidal alternating current. By measuring the frequency, the control module will be able to determine the engine speed. There are two ribs missing after the 58th one. When rib 1 subsequently passes the sensor, the control module will know that the crankshaft is 117 before top dead centre (BTDC).

The voltage from the crankshaft position sensor varies with the speed. At idling speed, the voltage will be 7-10 V (AC) and at 2500 rpm approx. 15-20 V (AC). However, it is the frequency and not the voltage that is of interest to the control module.

The control module uses mainly engine speed and crankshaft position to calculate the ignition timing, injection timing, injection duration, boost pressure and idle speed control.

Fuel injection is terminated when the engine speed exceeds 6400 rpm. 6200 rpm applies on cars with automatic transmission.

As soon as the control module receives impulses from the crankshaft position sensor, it will ground the main relay and fuel pump relay.

If there is a sensor malfunction or a break in the circuit, the engine will not start.

Sensor resistance is 540±55 ohms.

| Diagnosis |

| • |

If the control module loses track of the crankshaft position while the engine is running, diagnostic trouble code P0336 will be generated.

|

|

| • |

If the crankshaft position is absent, the engine will not start

|

|

| System reaction to a fault |

| • |

There is no substitute value for the crankshaft position sensor.

|

|

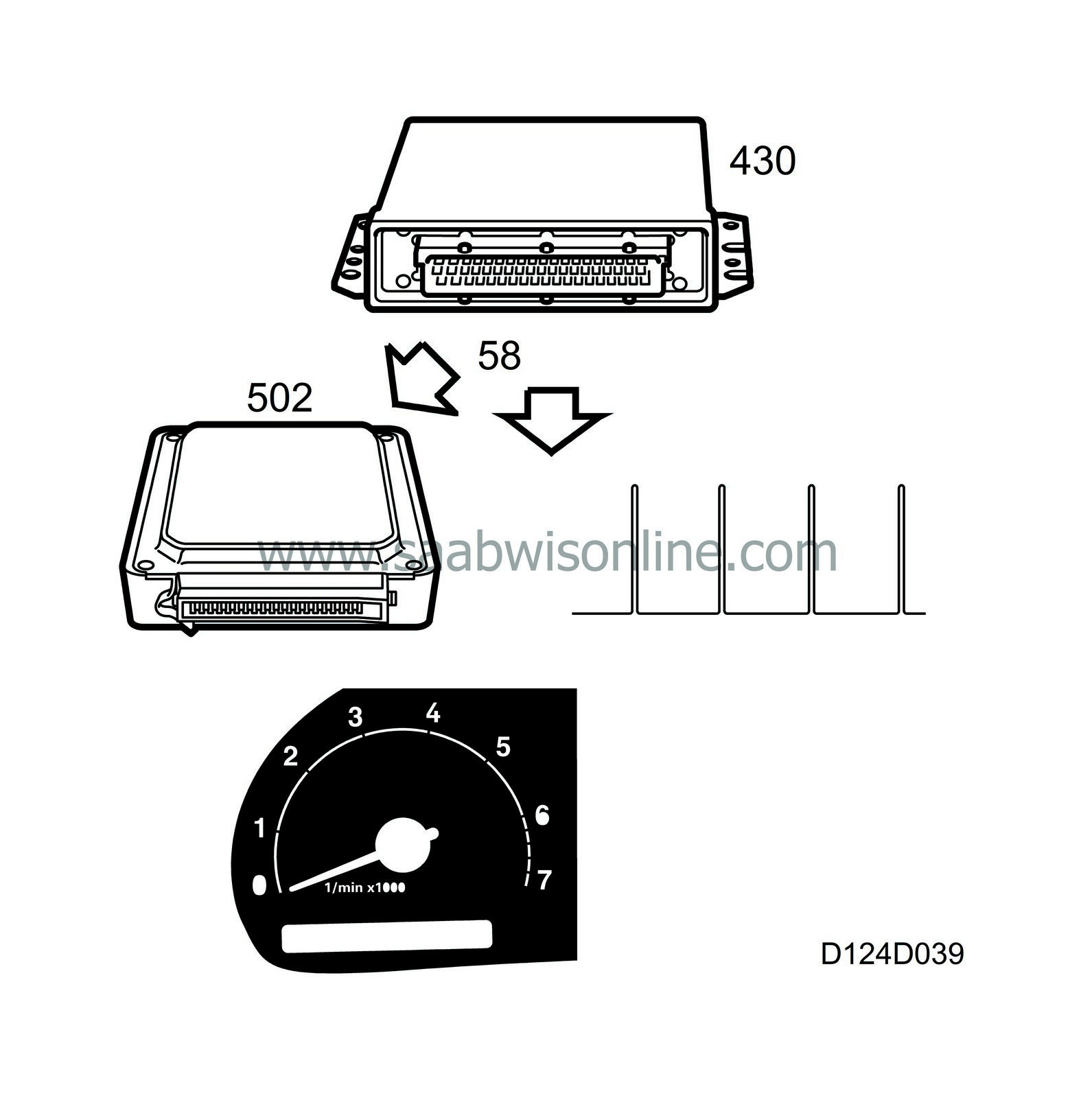

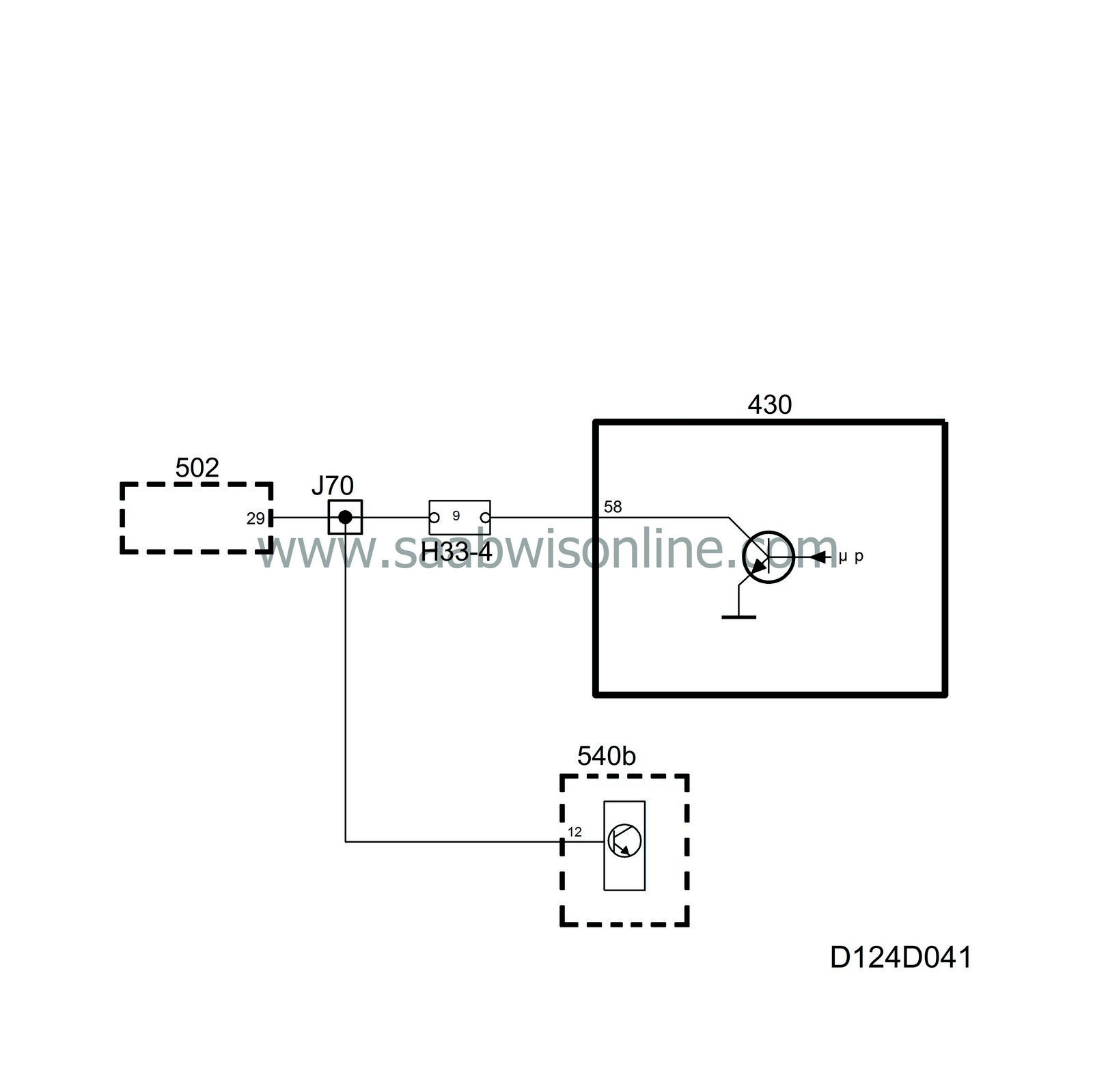

Engine speed signal

The control module transmits the engine speed signal from pin 58.The signal is a pulse train that varies between 0 and B+ and is approx 30 Hz at idling speed and approx. 85 Hz at 2500 rpm. This corresponds to 2 pulses per crankshaft revolution.

The engine speed signal is used by the main instrument unit and the automatic transmission control module.

| Diagnosis |

| • |

If the engine speed signal is shorted to ground, the motor will still start but it will stop shortly afterwards. (This function is used by ETS and Sensonic)

|

|