Intermediate shaft (Petrol)

|

|

Intermediate shaft (Petrol)

|

|

1.

|

Disconnect the battery's negative lead.

|

|

2.

|

Place wing protectors over the wings and remove the upper engine cover.

|

|

3.

|

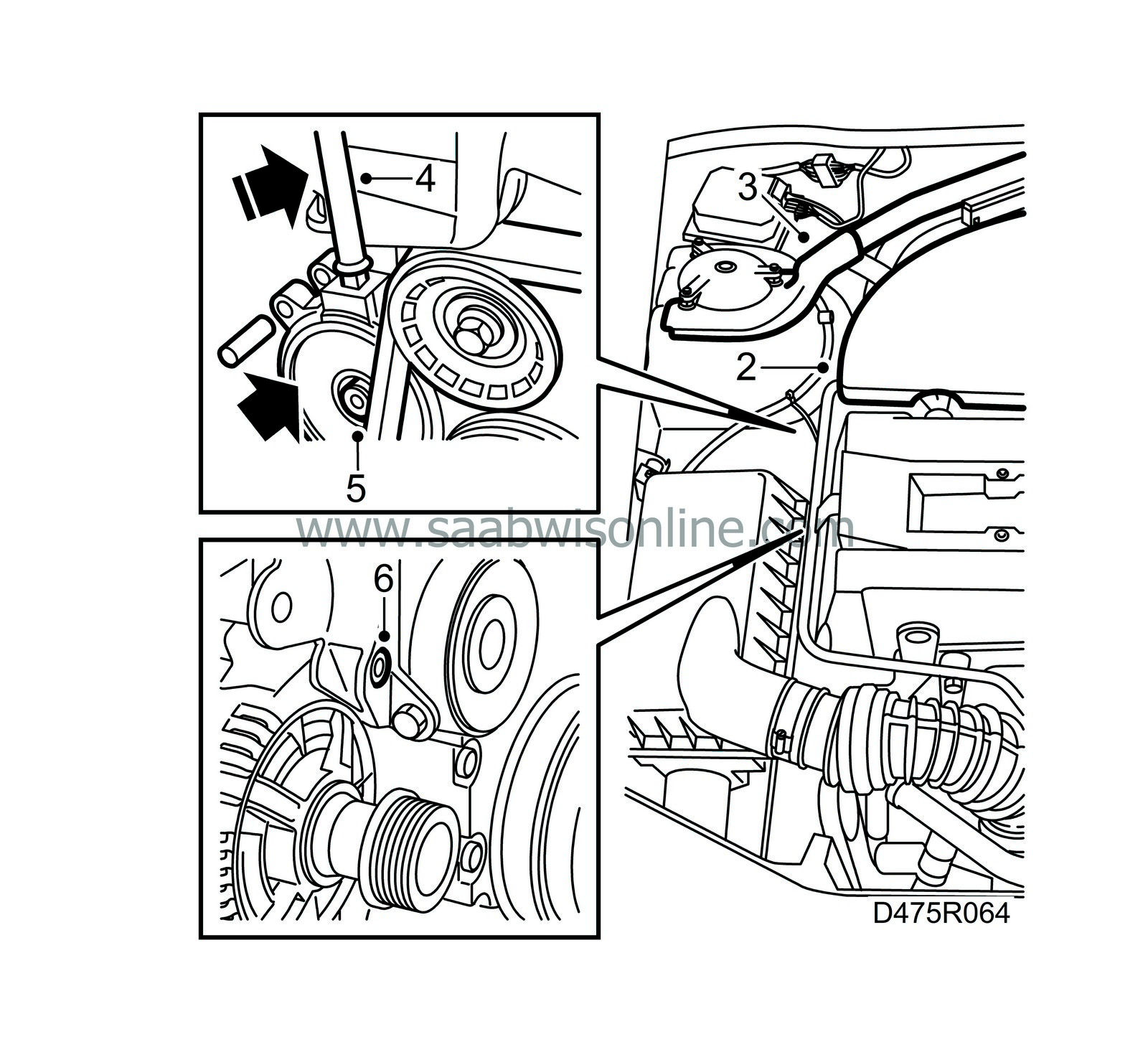

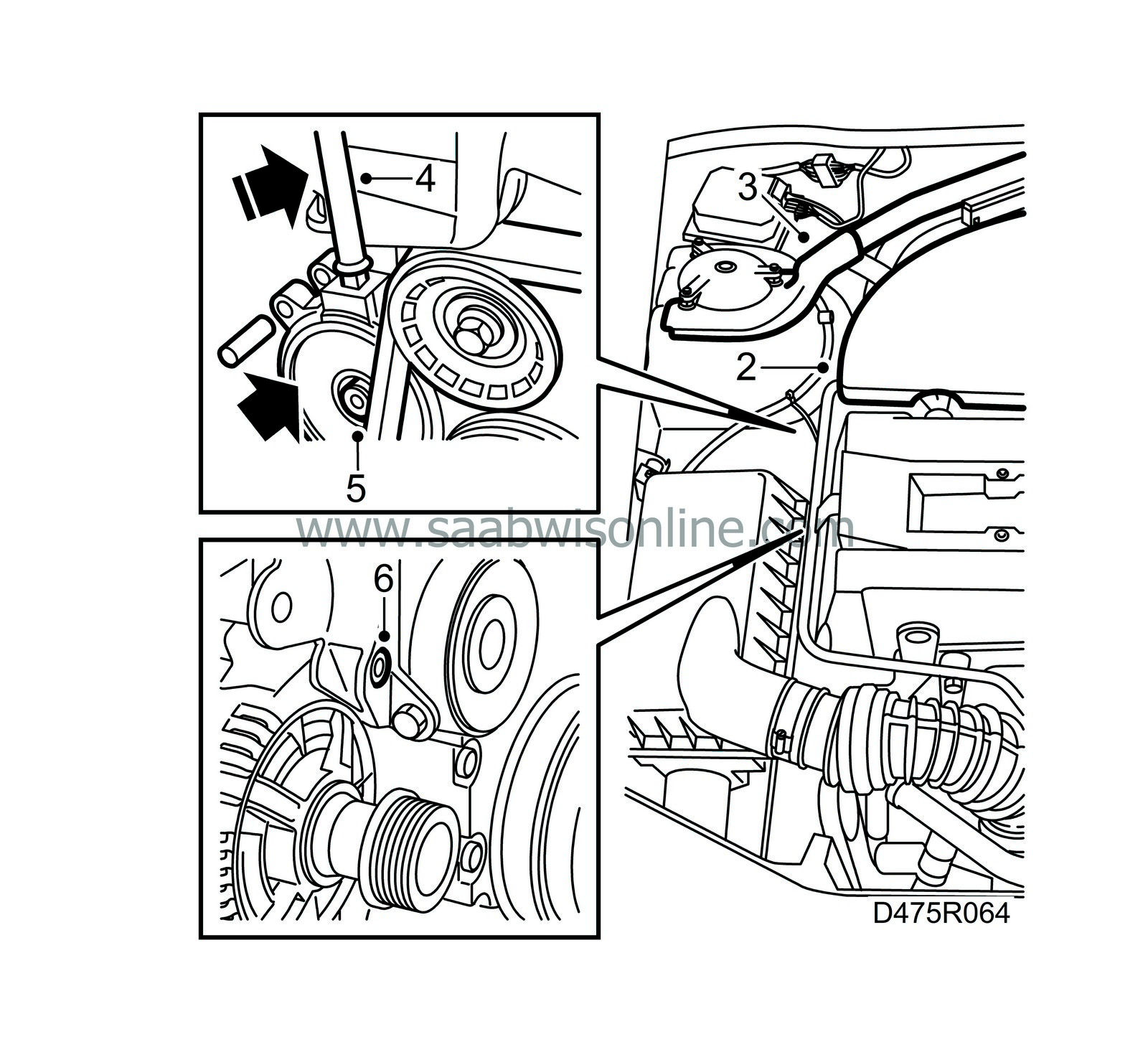

Remove the stay between the suspension strut towers

(RHD only)

.

|

|

4.

|

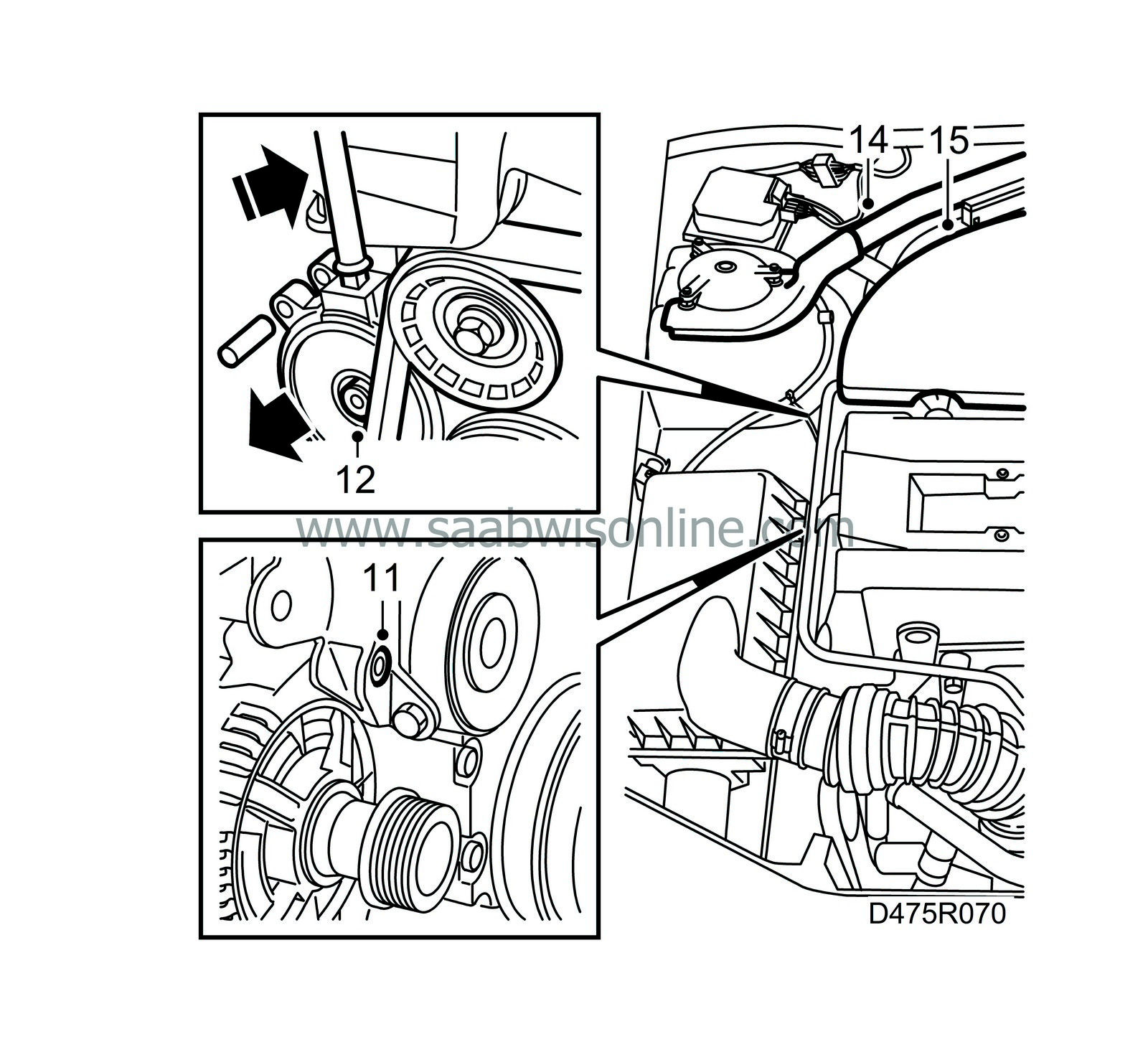

Use a ½" flexible handle to relieve the belt tensioner of tension.

|

|

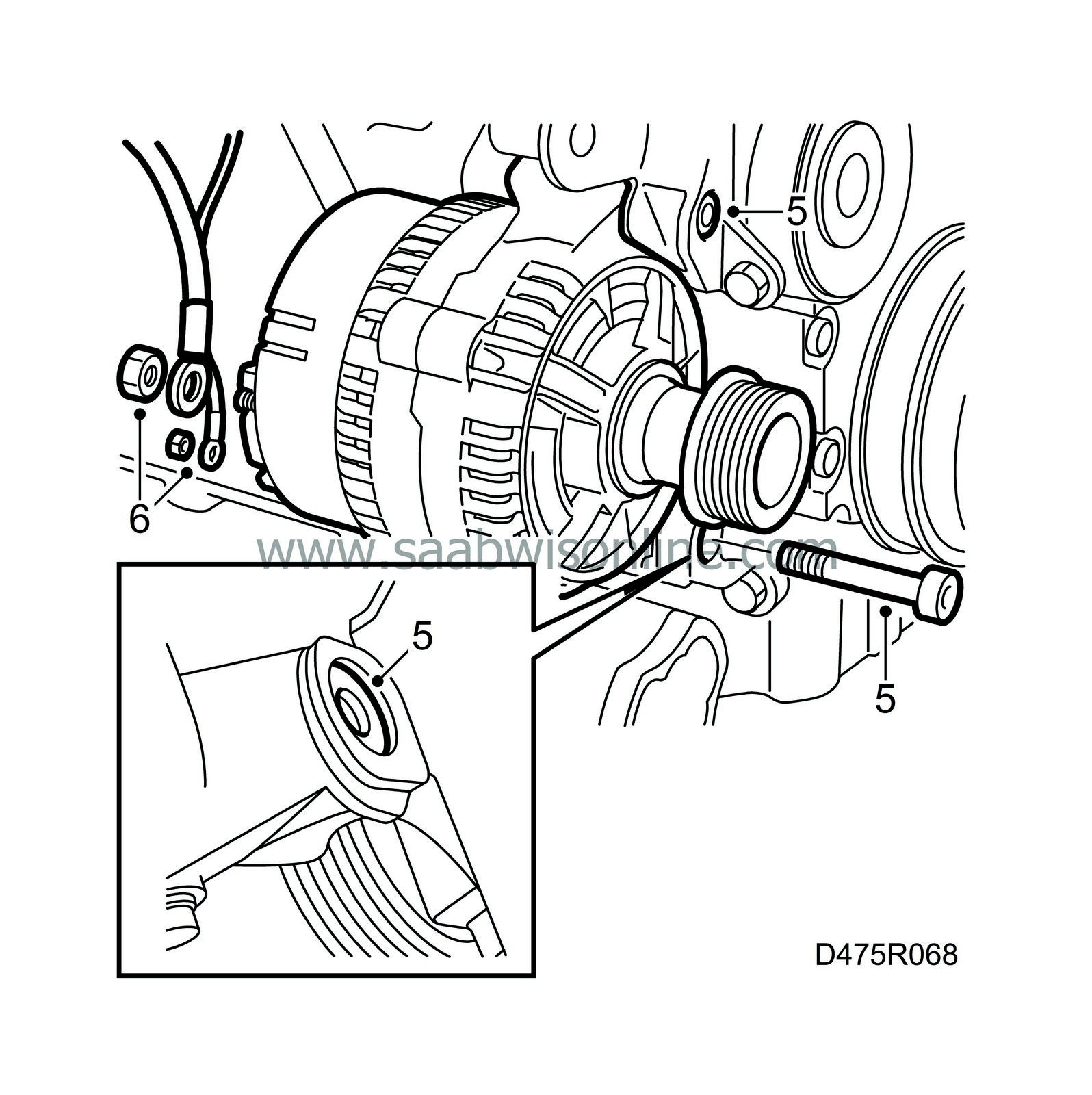

5.

|

Remove the belt tensioner, using an 8 mm Allen key.

|

|

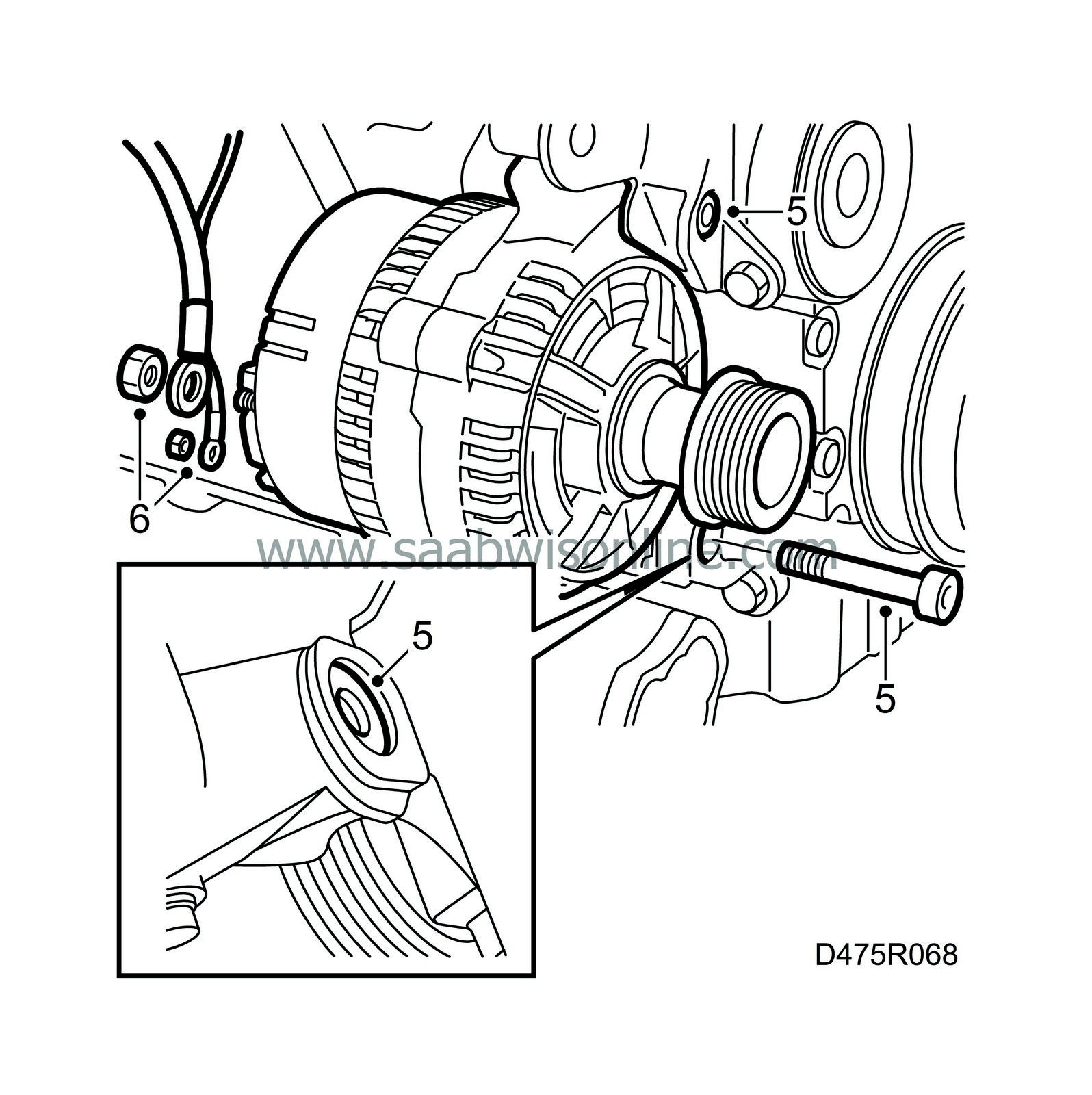

6.

|

Remove the generator's upper screw, using an 8 mm Allen key.

|

|

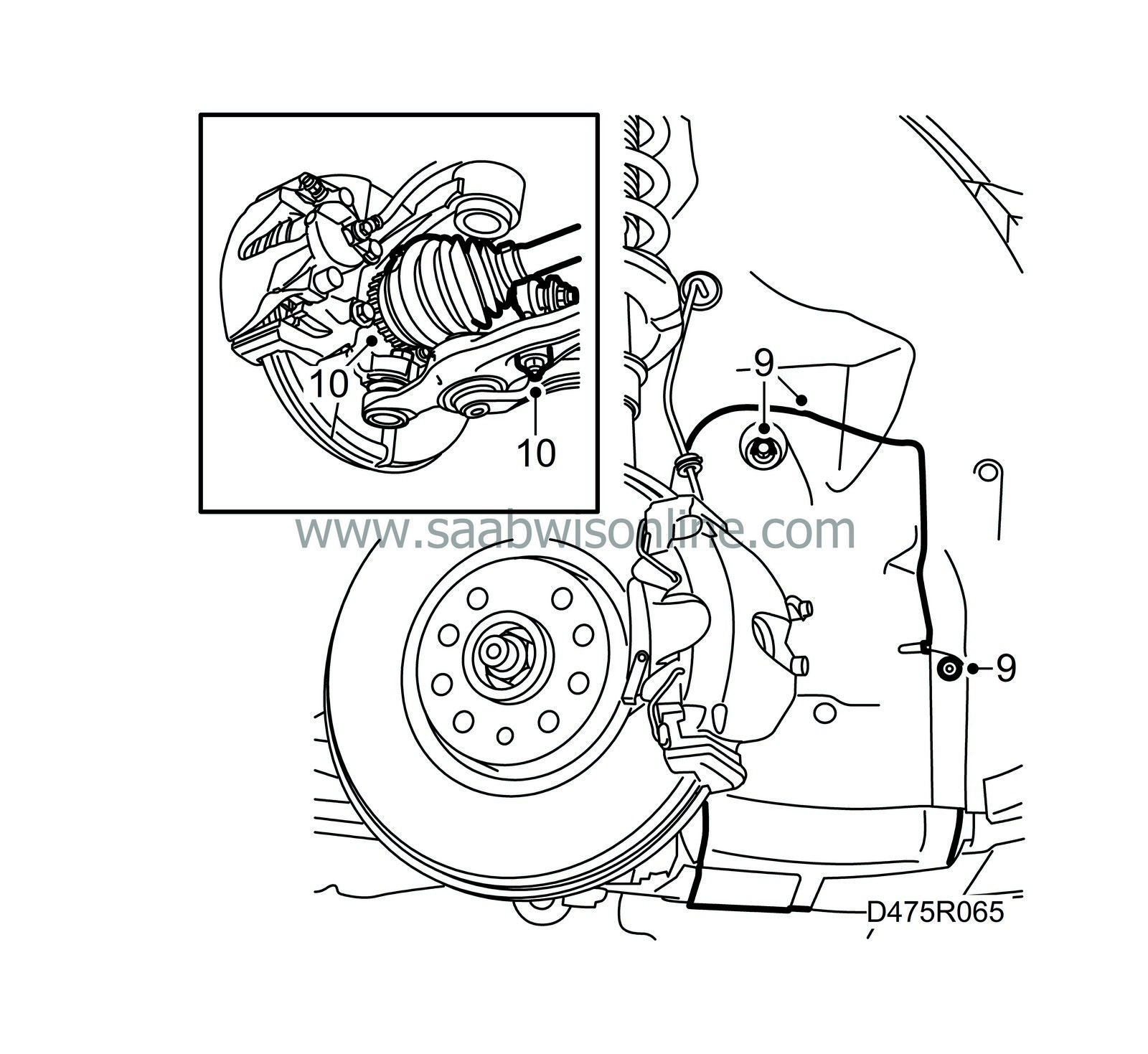

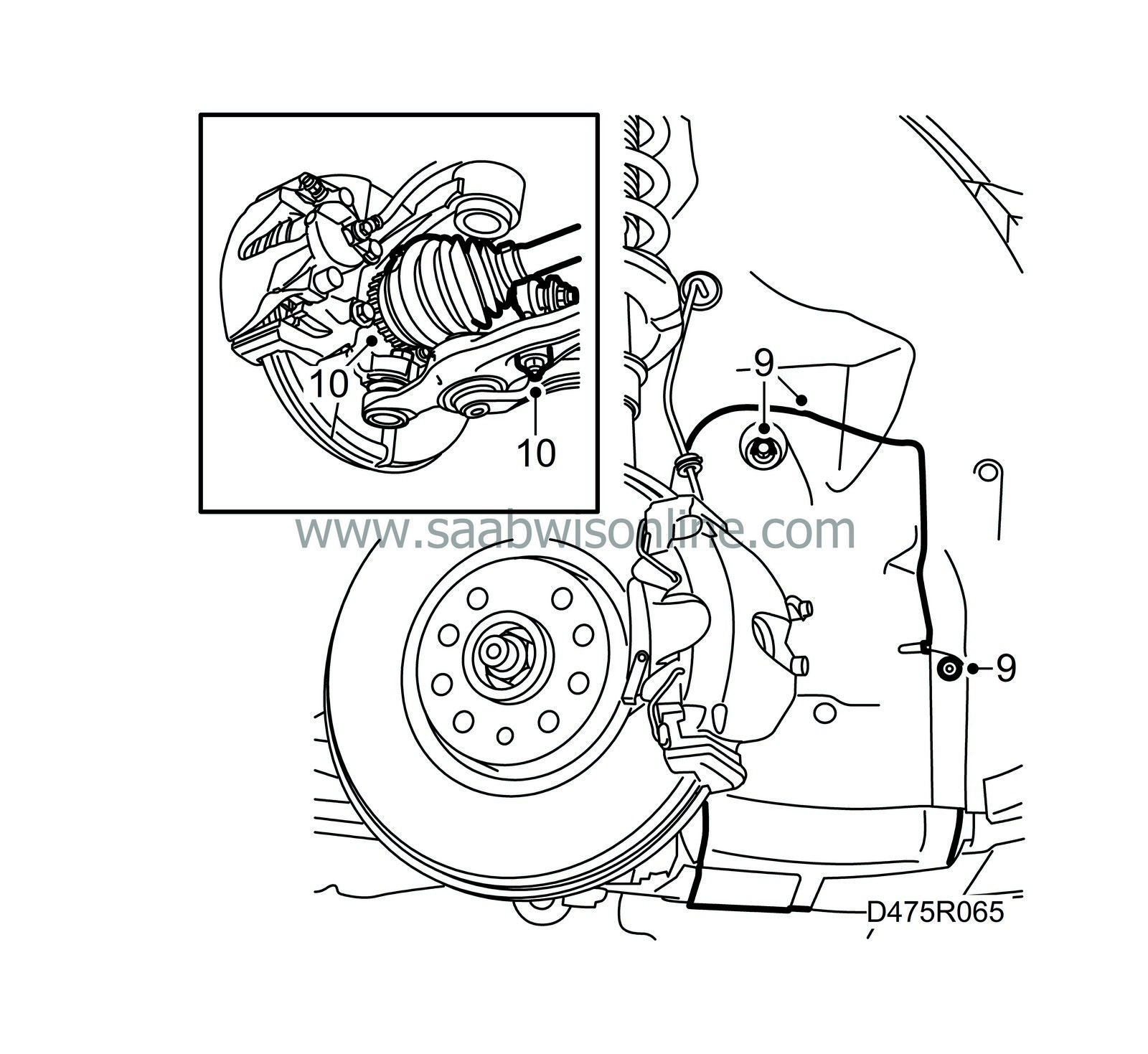

8.

|

Remove the right-hand wheel.

|

|

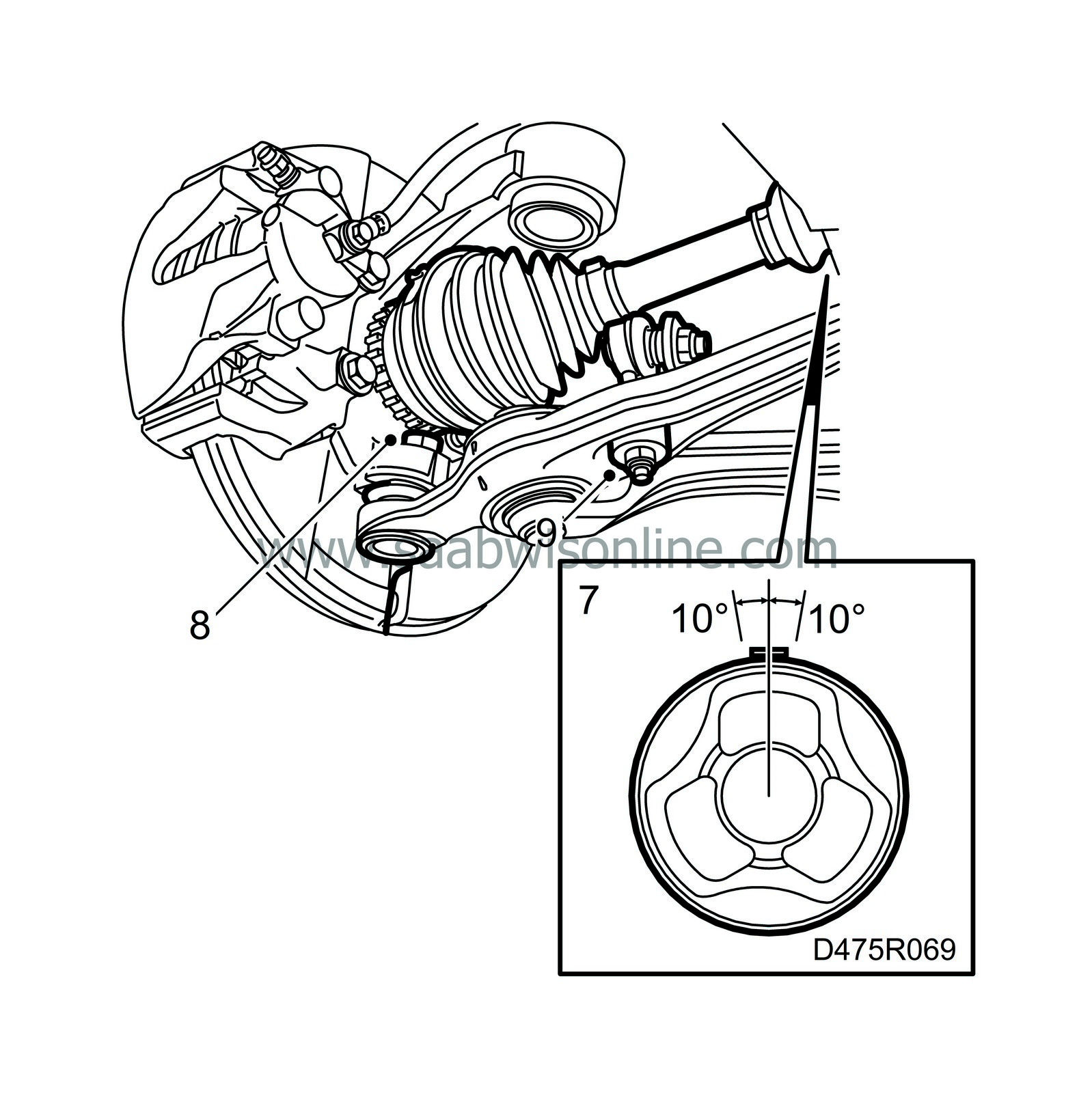

9.

|

Remove the belt circuit cover.

|

|

10.

|

Undo the nuts securing the anti-roll bar and the suspension arm's ball joint. Use

89 96 696 Puller

.

|

|

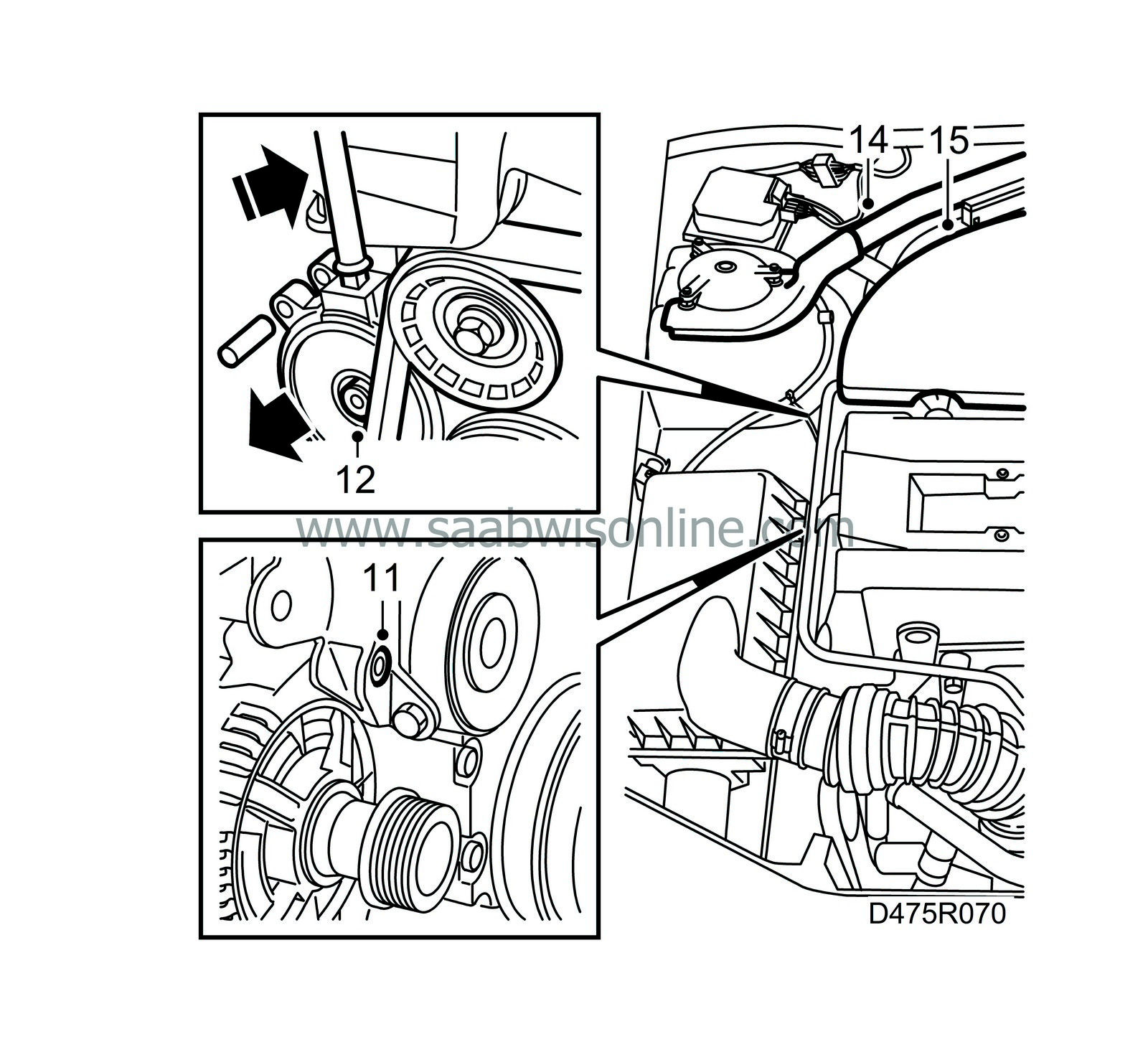

11.

|

Lower the suspension arm and fix it in position with a block of wood inserted between the suspension arm and the anti-roll bar.

|

|

12.

|

Remove the clamp and pull down the gaiter.

|

|

13.

|

Swing the wheel to the left to facilitate removal of the drive shaft.

|

Important

|

|

Make sure that no dirt gets into the universal joint.

|

|

Cover the universal joint and driver with plastic bags or the like.

|

|

|

|

|

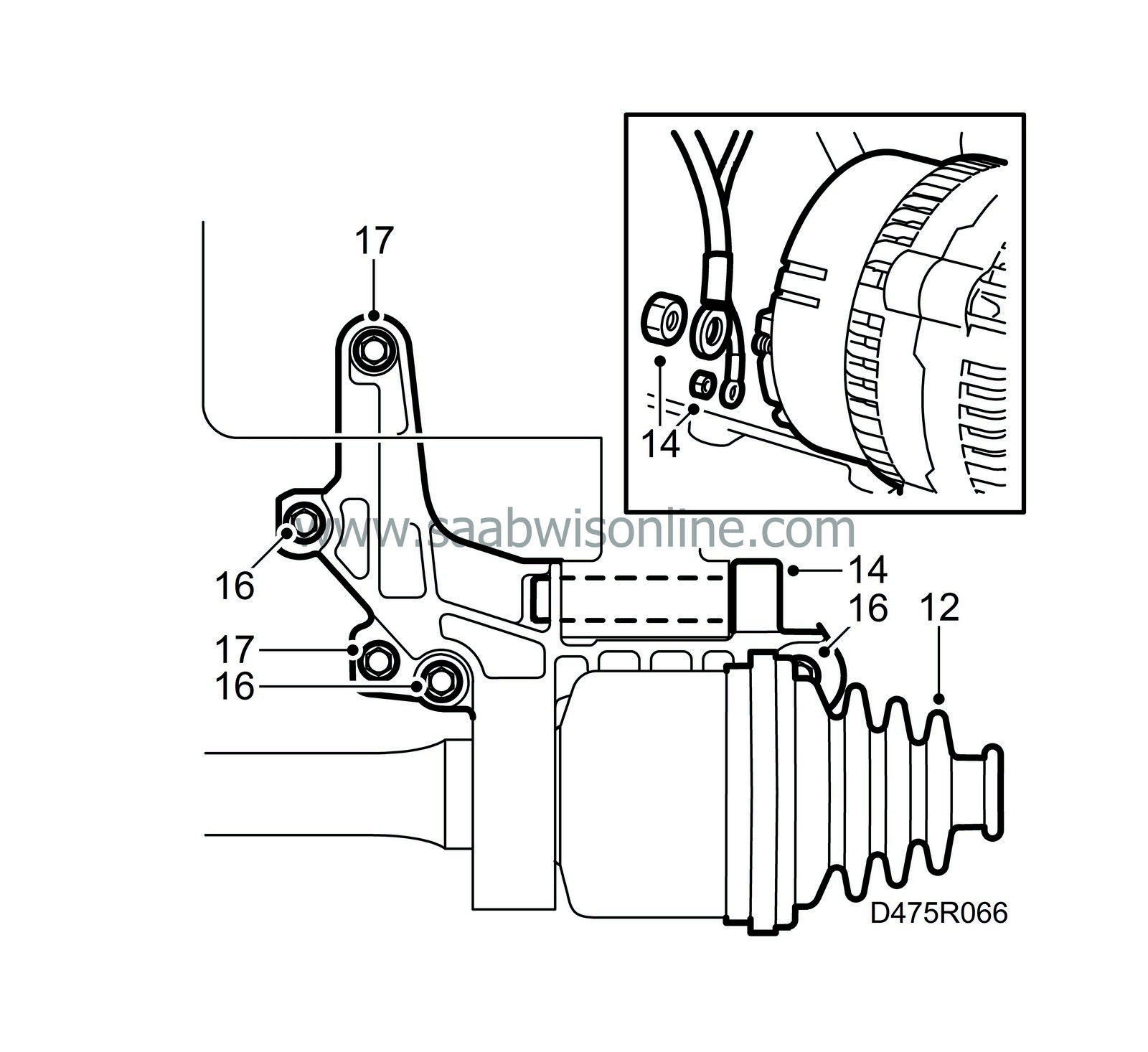

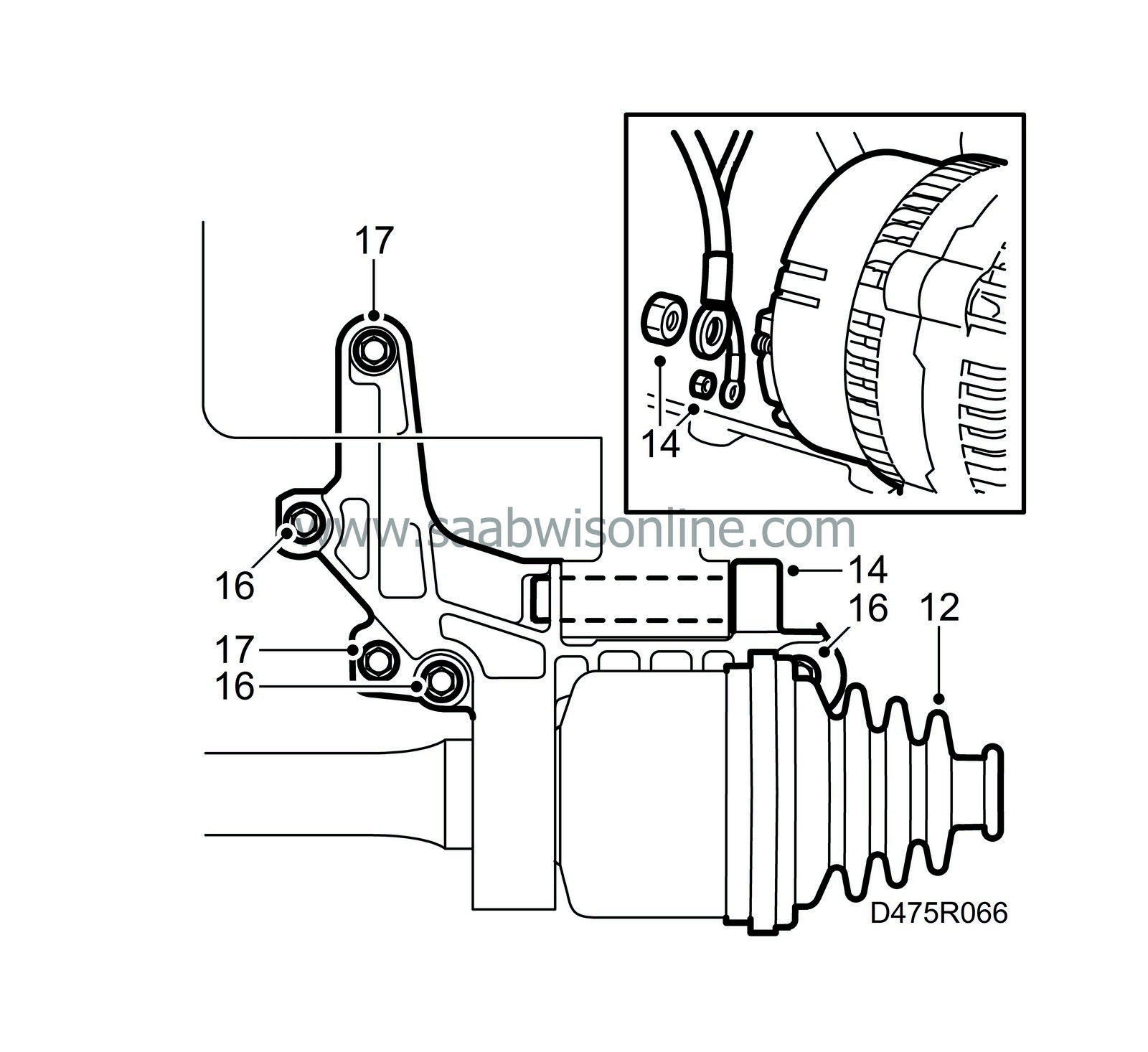

14.

|

Disconnect the generator cables and the generator bracket's lower bolt.

|

|

15.

|

Move the generator aside.

|

|

16.

|

Unscrew the support bearing bracket bolts.

|

Important

|

|

Place a receptacle under the gearbox to avoid spilling oil on floor.

|

|

|

|

|

17.

|

Pull the support bearing bracket away from the guide pins in the engine block and withdraw the intermediate shaft from the gearbox.

|

|

2.

|

Make sure that the intermediate shaft is clean and then fit the shaft in the tool.

|

Important

|

|

Insert the intermediate shaft in the gearbox until about 20 mm of it remains and withdraw the tool before the shaft's sealing surface reaches the shaft seal.

|

|

|

|

|

3.

|

Insert the remainder of the shaft.

|

|

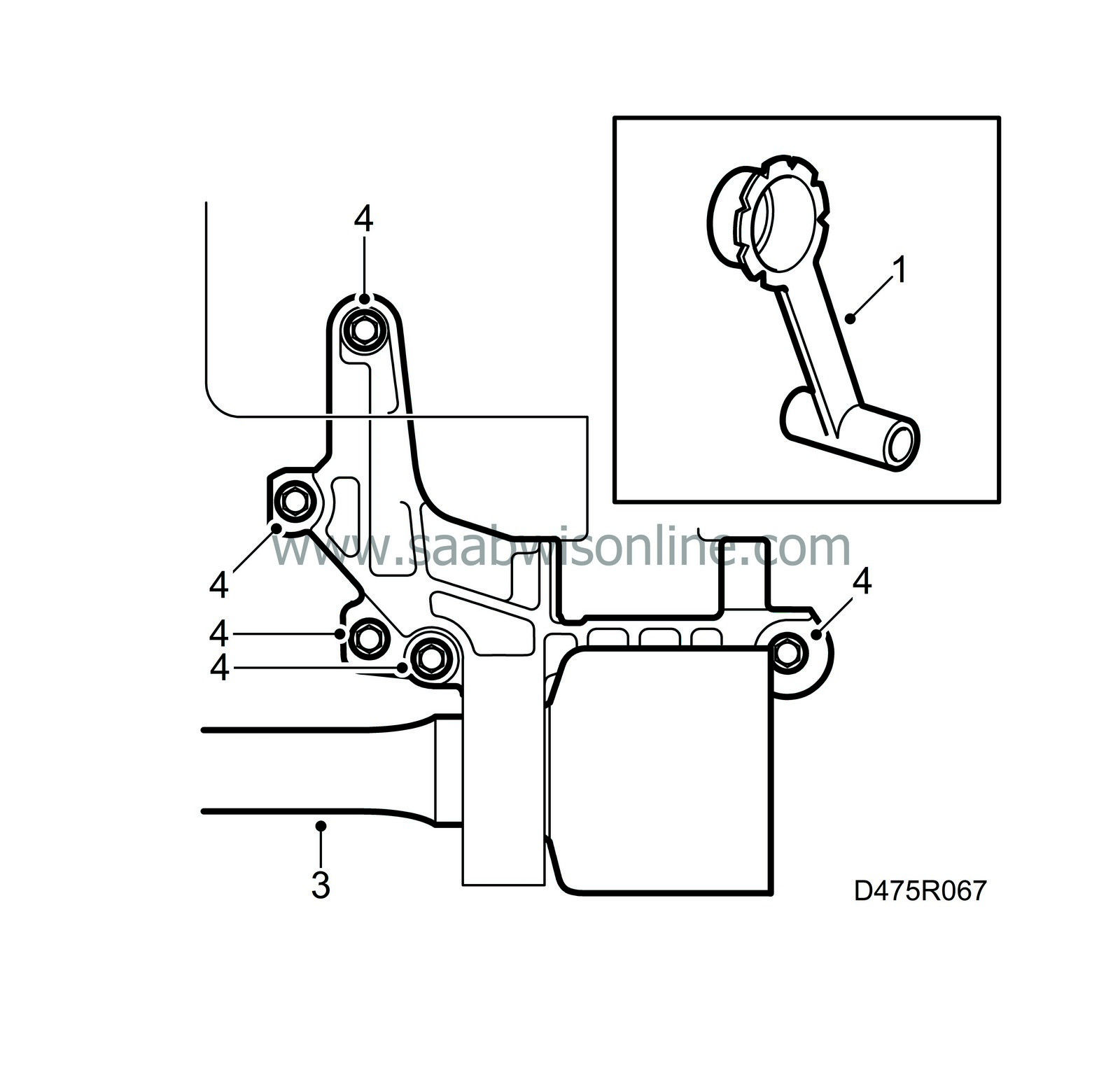

4.

|

First guide the support bearing bracket to the upper guide pin and then tighten the bearing bracket.

Tightening torque 24 Nm (18 lbf ft)

|

|

5.

|

Make sure that the adjusting sleeves are tapped out about 1 mm to facilitate fitting the generator on the mountings. Then fit the two generator retaining bolts and tighten the lower one.

Tightening torque 47 Nm (35 lbf ft).

|

|

6.

|

Connect the generator cables.

|

|

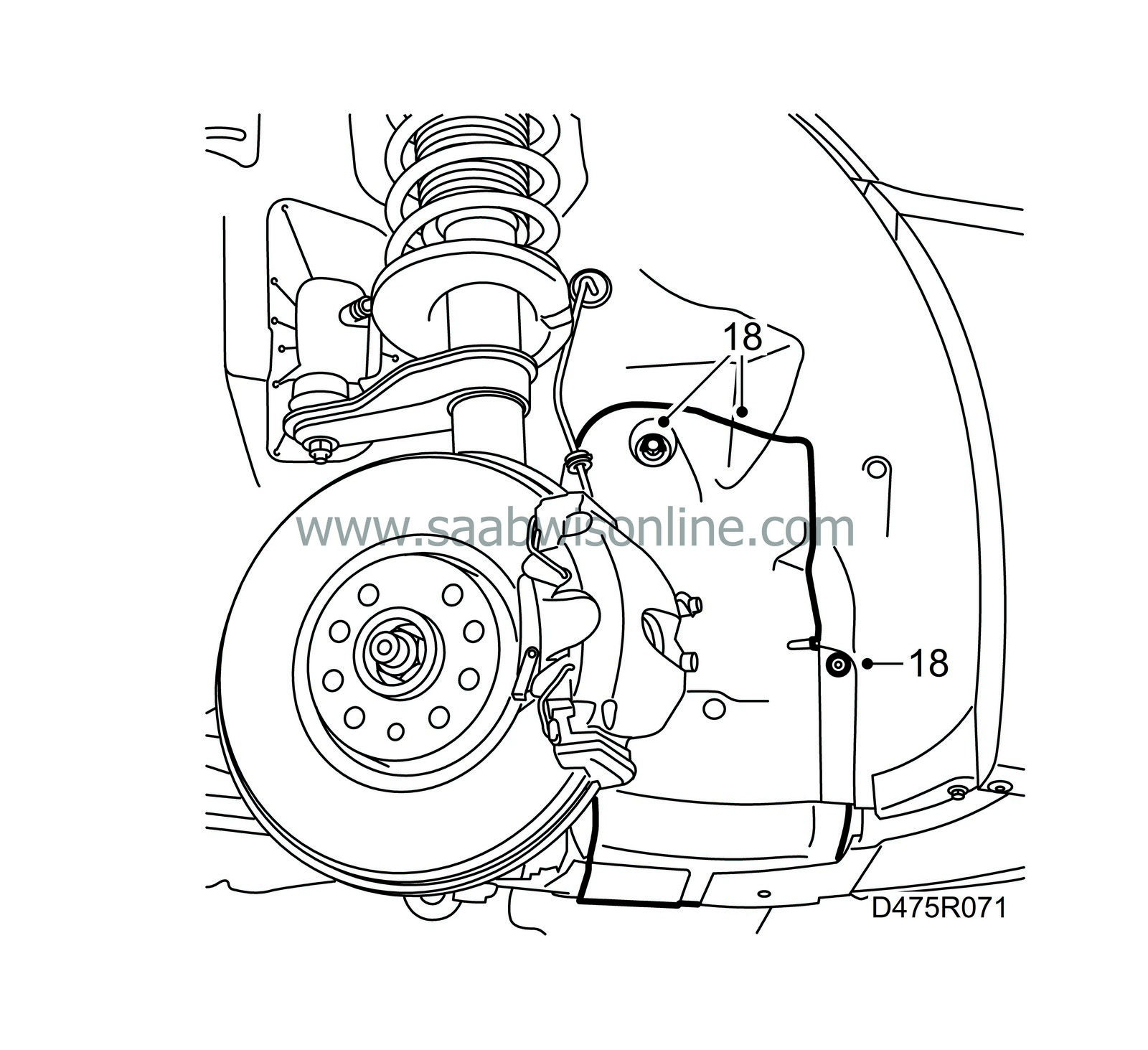

7.

|

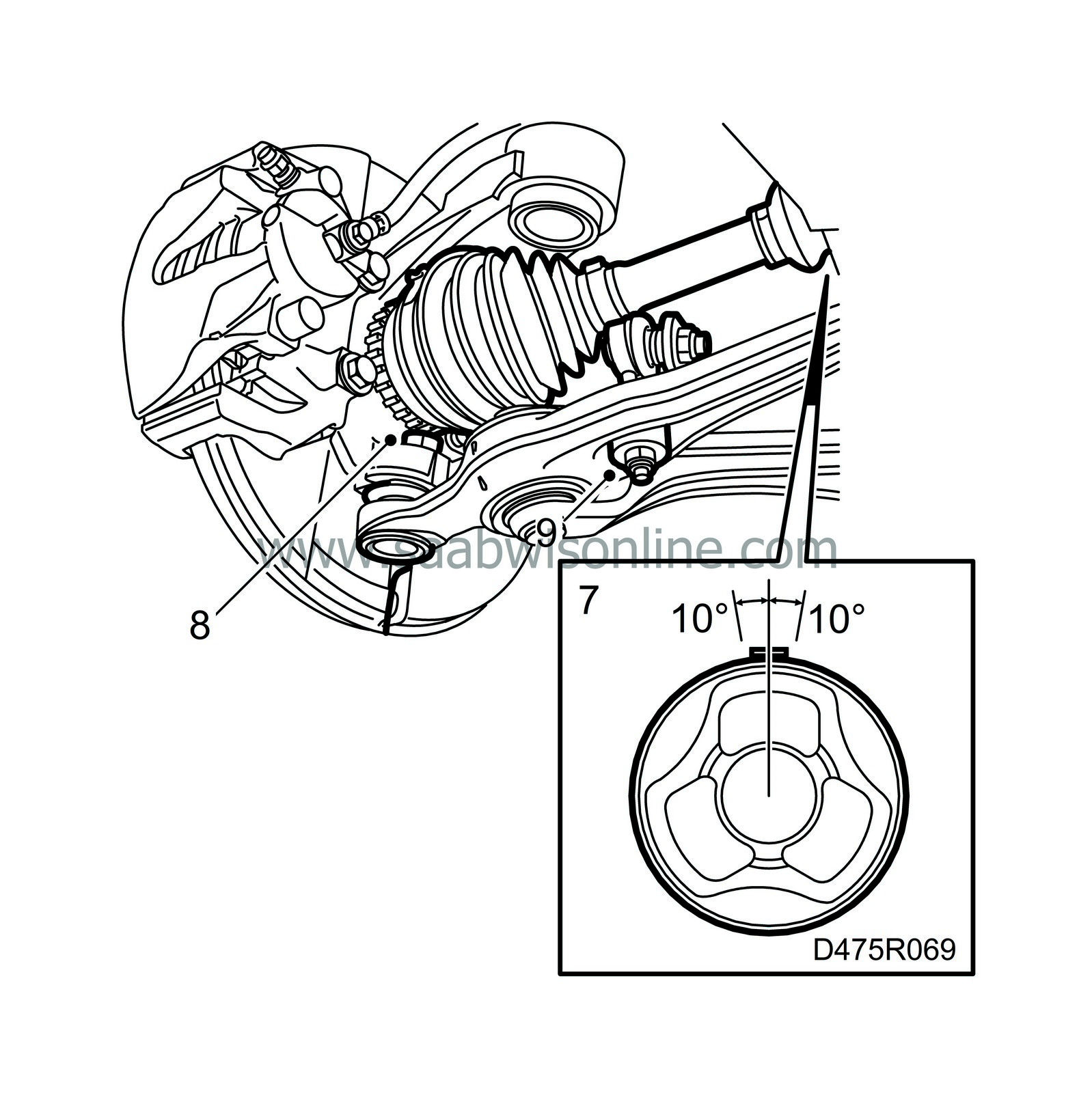

Fill grease, (16) 87 92 624, in the gaiter and driver and connect the universal joint to the driver. Fit a new clamp on the gaiter and wipe away excess grease. It is important that the clamp is fitted as illustrated.

|

|

8.

|

Remove the wooden block, swing the suspension arm back and connect it to the steering swivel member. Fit the bolt and tighten it.

Tightening torque 75 Nm (55 lbf ft).

|

|

9.

|

Secure the anti-roll bar.

|

|

10.

|

Lower the car to the floor.

|

|

11.

|

Tighten the generator's upper bolt.

Tightening torque 47 Nm (35 lbf ft).

|

|

12.

|

Fit the belt tensioner.

|

|

14.

|

Fit the stay between the suspension strut towers and press the protective caps in place

(RHD only)

.

Tightening torque 24 Nm (18 lbf ft)

|

|

15.

|

Press the cover over the intake manifold into place.

|

|

16.

|

Connect the negative lead to the battery.

|

|

17.

|

Fill the gearbox with oil to the correct level.

|

|

18.

|

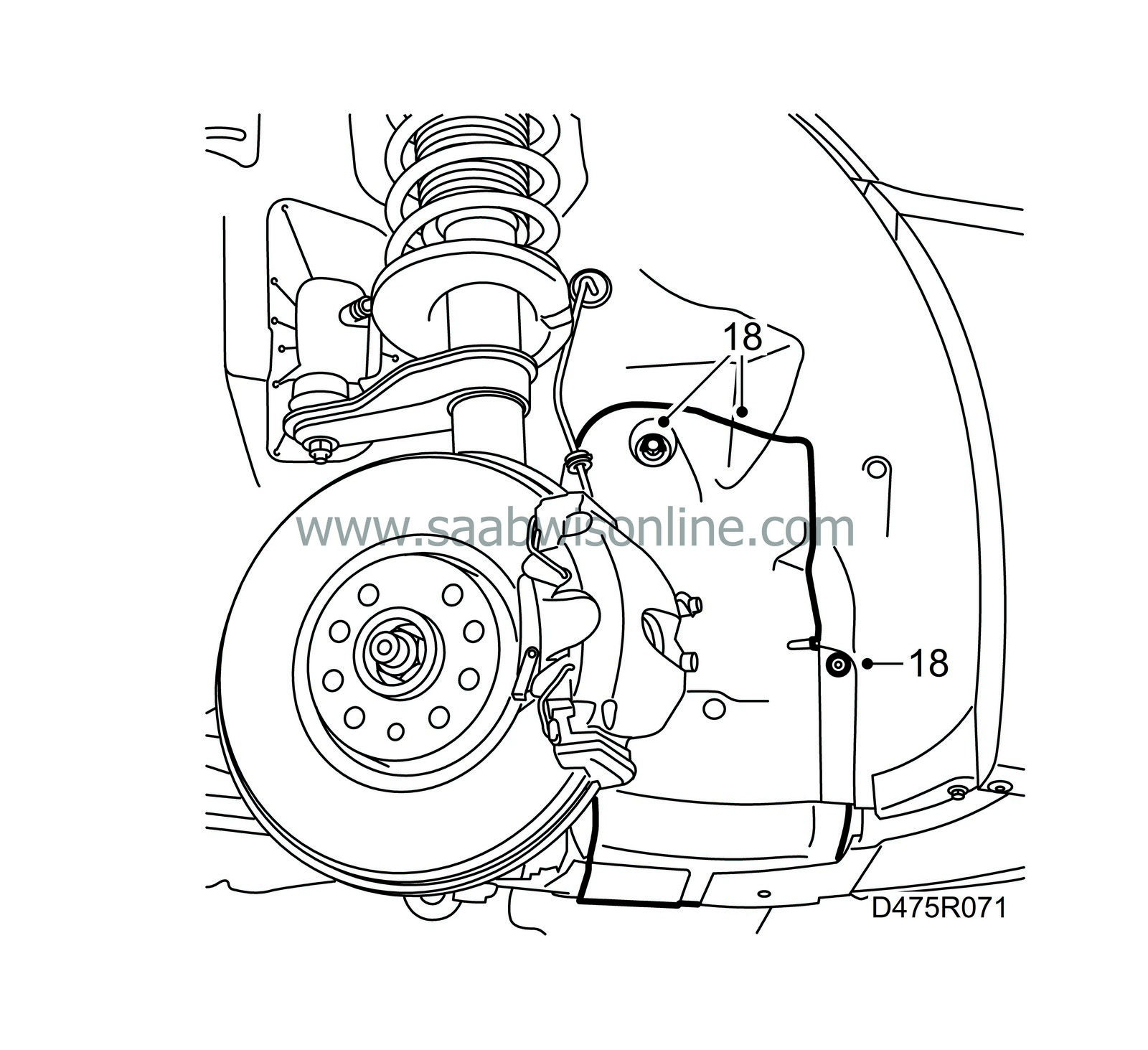

Raise the car and fit the cover over the belt circuit.

|

|

19.

|

Fit the wheel.

Tightening torque 110 Nm (81 lbf ft)

|

Important

|

|

The wheel should hang freely when the wheel bolts are tightened.

|

|

|

|

|

20.

|

Lower the car to the floor.

|

|

21.

|

Set the clock and any radio code.

|