Input shaft

| Input shaft |

| 1. |

Mount the shaft in a vice with protective jaws.

|

|

| 2. |

Remove circlip.

|

|

| 3. |

Press the bearing off the shaft. Use

87 92 152 Puller

and

87 91 642 Basic tool

.

|

||||||||||

| 4. |

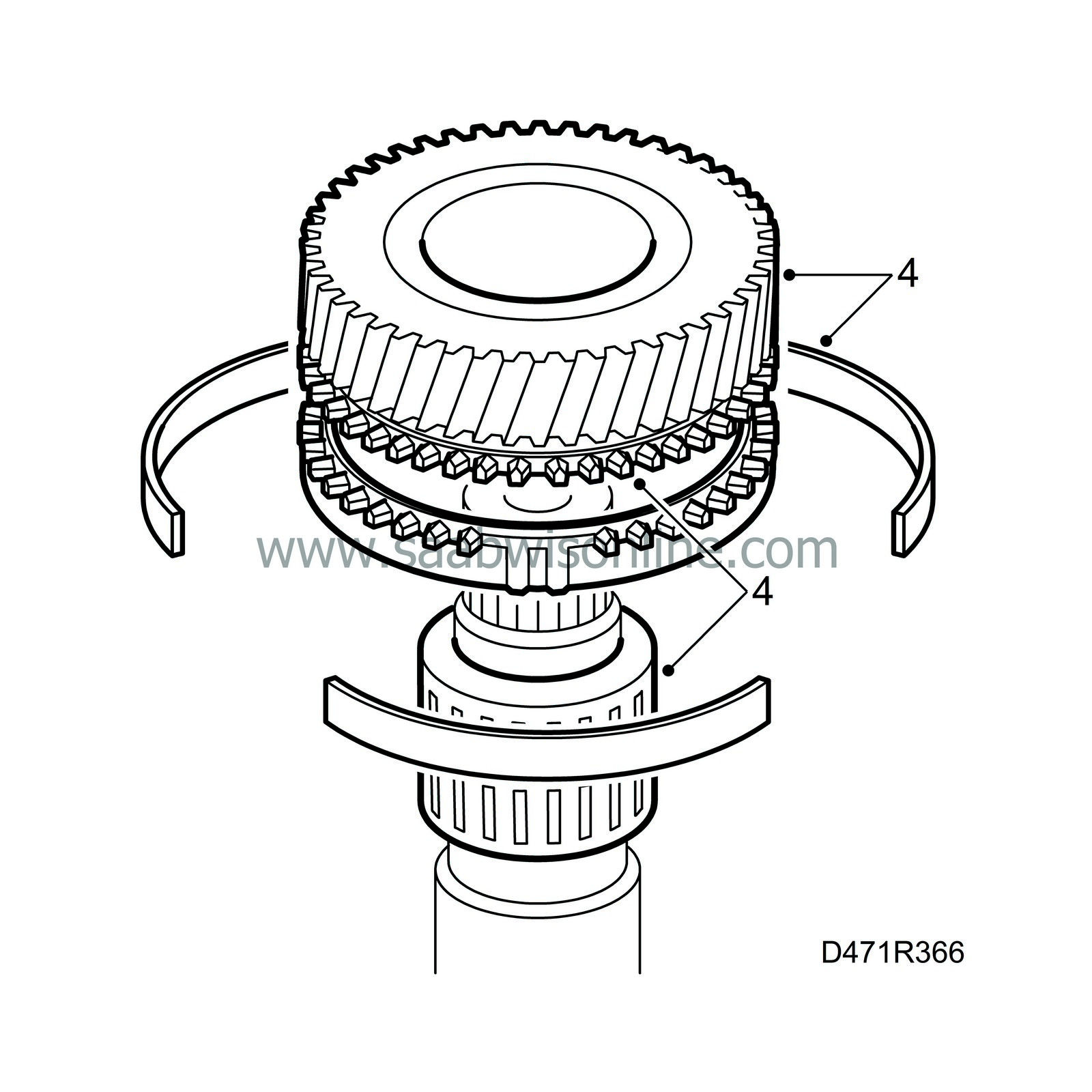

Lift off the 4th pinion, synchromesh and needle bearing. Keep the leaf springs in a safe place.

|

|

| 5. |

Slightly lift the synchromesh sleeve and hold with your hand so that the spring-loaded rollers do not come out. Keep the rollers in a safe place.

|

|

| 6. |

Lift off the synchromesh sleeve.

|

||||||||||

| 7. |

Keep springs and plungers.

|

|

| 8. |

Remove the washer and circlip which secure the synchromesh hub. Remove the hub and keep the leaf springs.

|

|

| 9. |

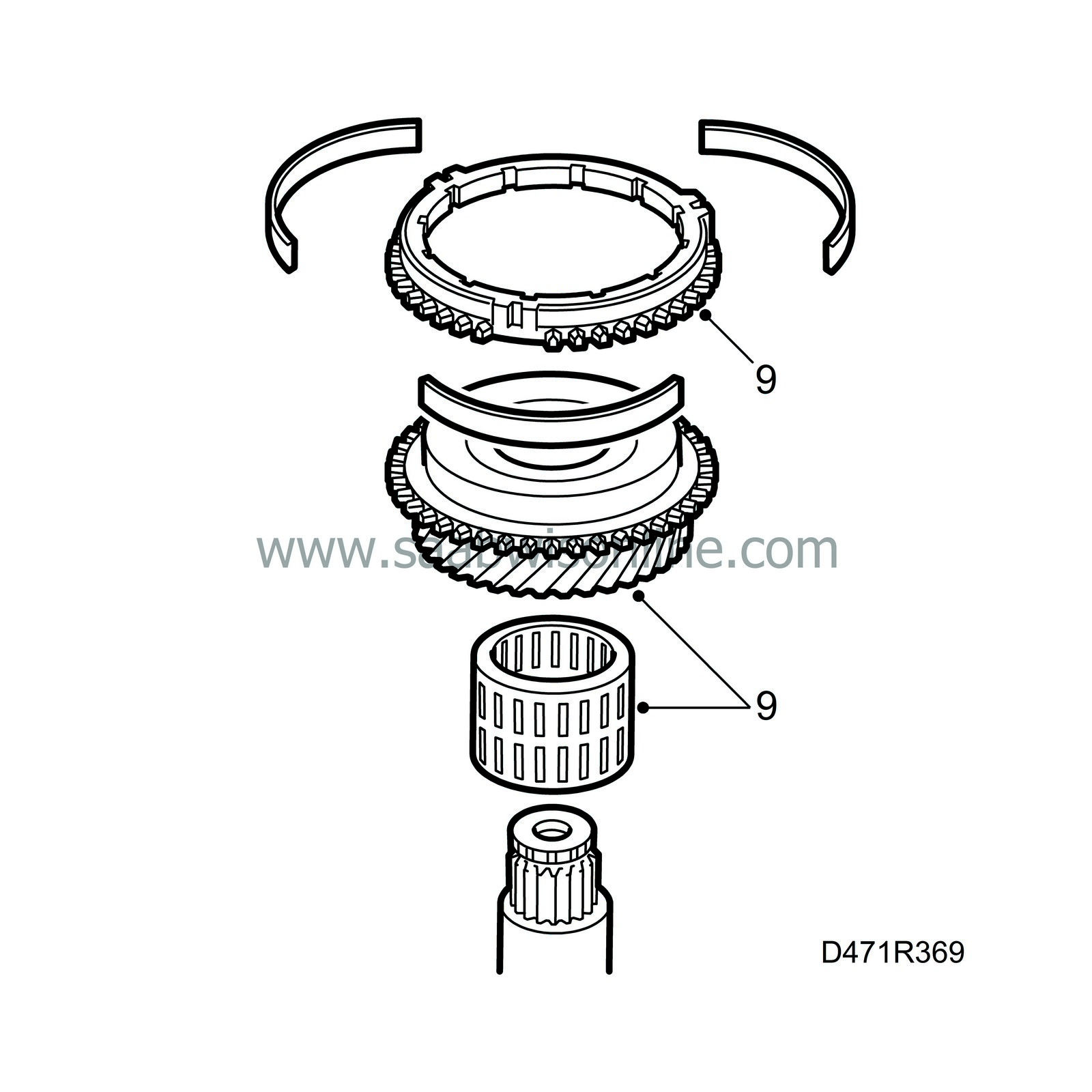

Lift off the 3rd synchromesh, pinion and needle bearing.

|

|

| 10. |

Check the condition of all parts as regards wear. Replace damaged or defective parts. Measure the wear on the synchromesh by fitting it in place. Measure with a feeler gauge in three places between the baulk ring and the pinion. Calculate an average of the readings. New synchromesh 0.8-1.1 mm. Min dimension is 0.5 mm. If the dimension is less, the synchromesh is worn out and must be replaced.

|

|

| To assemble |

Fit all the parts oiled with Saab synthetic manual gearbox oil, see

.

.

| 1. |

Mount the input shaft in a vice with protective jaws.

|

|

| 2. |

Fit the 3rd pinion with needle bearing and baulk ring.

|

|

| 3. |

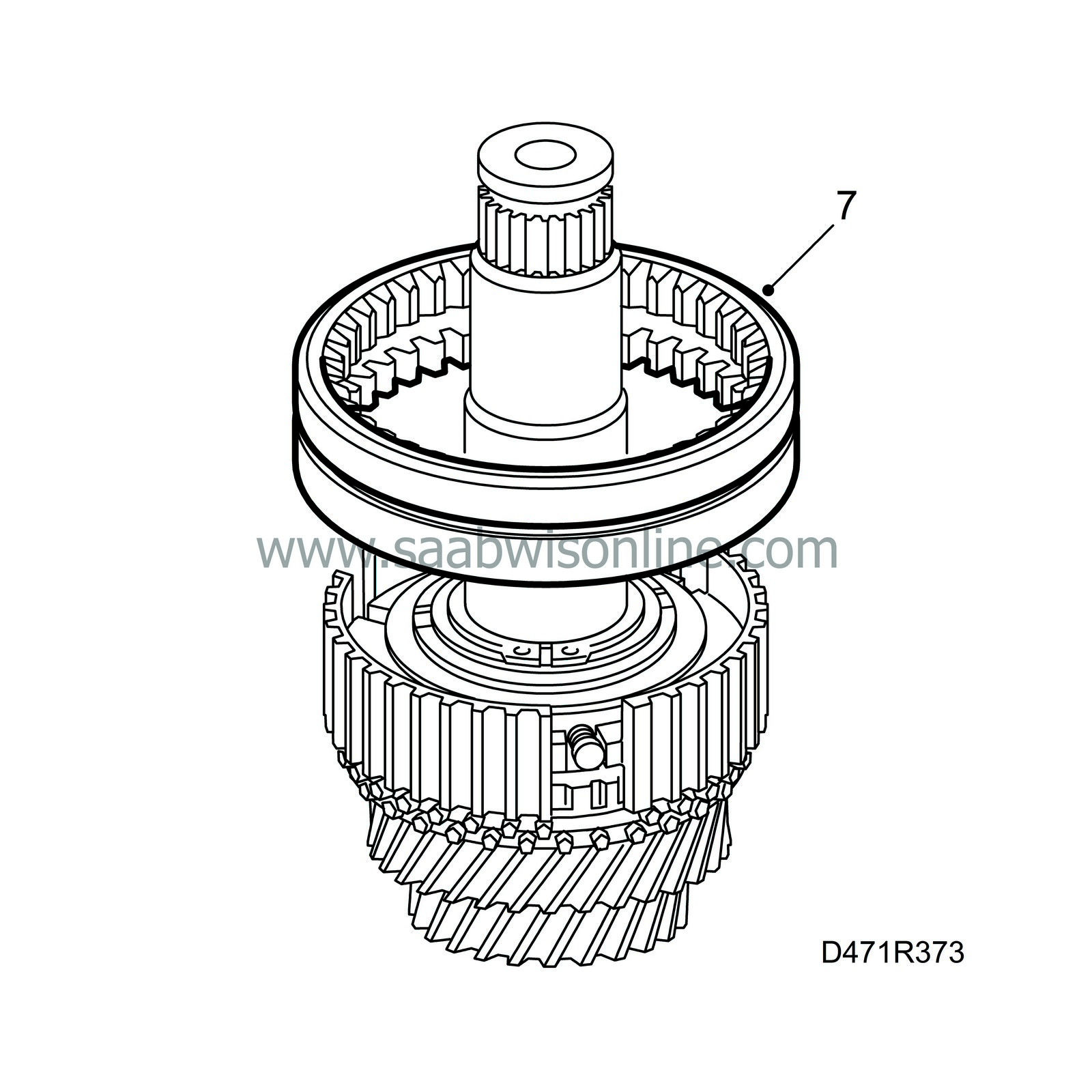

Fit the synchromesh hub and make sure that the recess for the circlip washer is facing up. Make sure that the hub goes over the baulk ring, fit the leaf springs. If needed, press with

87 92 202 Sleeve

.

|

|

| 4. |

Fit the washer and a new circlip. Fit the circlip with the sharper edge facing up.

|

|

| 5. |

Check the axial play between the 2nd and 3rd gear pinions. The play should be between 0.05-0.40 mm.

|

|

| 6. |

Fit springs and plungers.

|

|

| 7. |

Fit the synchromesh sleeve.

|

||||||||||

| 8. |

Fit the rollers. They are fitted by pressing in the springs. A small screwdriver can be used to press in the springs.

|

|

| 9. |

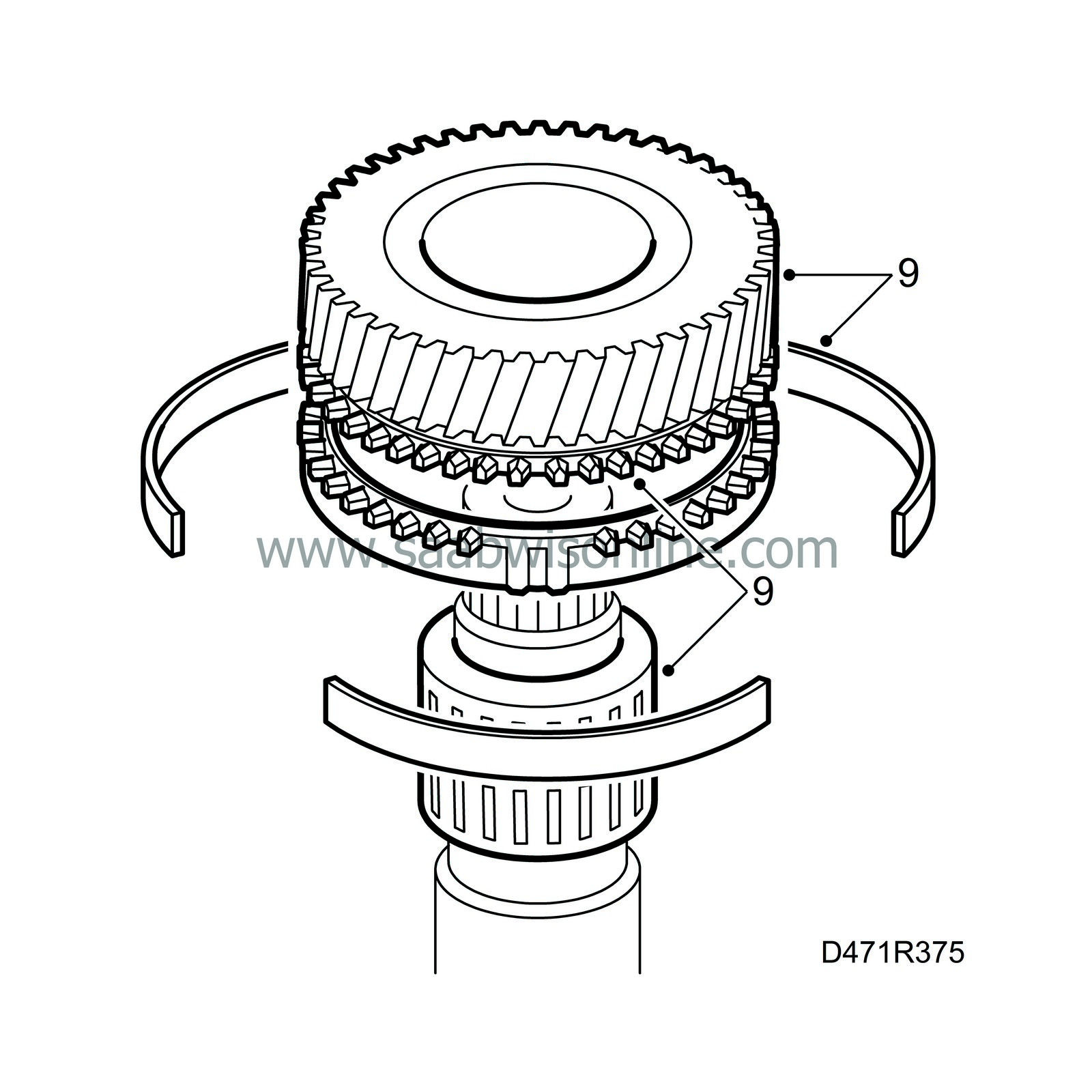

Fit the 4th baulk ring, leaf springs, needle bearing and pinion.

|

|

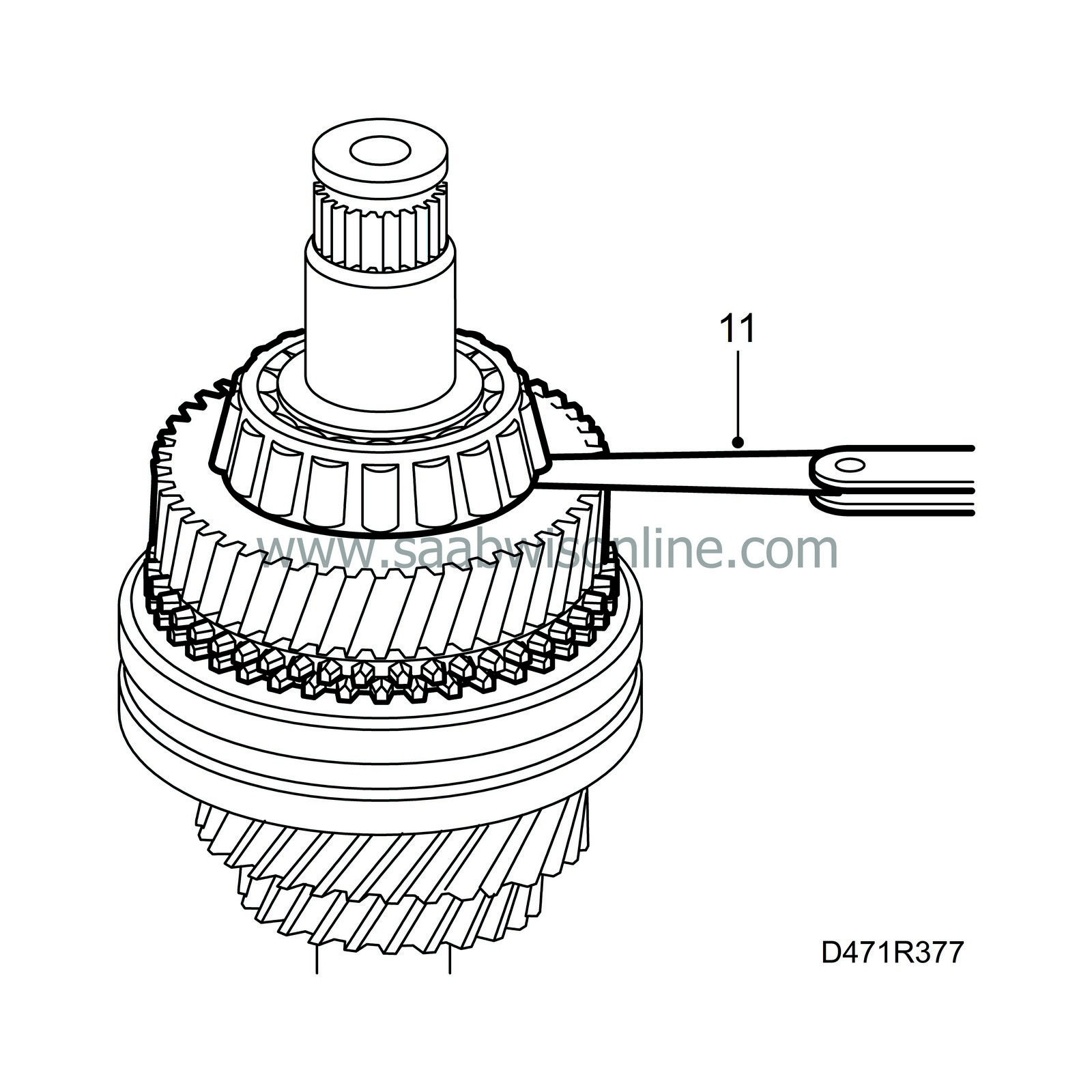

| 10. |

Check that the bearing is facing correctly and press on a new bearing closest to 4th gear pinion. Use the sleeve from

87 91 261 Puller, pinion

. Fit a new circlip with the bevelled edge facing up.

Carefully tap the circlip into the shaft groove using a drift. |

||||||||||

| 11. |

Check the play between bearing and 4th pinion to ensure that the input shaft is correctly fitted. Play should be 0.05-0.40 mm.

|

|