Power steering pump, diesel engine

| Power steering pump, diesel engine |

|

|||||||

| Note | ||

|

For changing the power steering pump with bracket , see Power steering pump with bracket, diesel engine . |

| To remove |

| 1. |

Raise the car and remove the sound insulation, right-hand spoiler lower section and the right-hand lower wing liner.

|

|

| 2. |

Relieve the tension on the belt tensioner, lift off the belt and remove the pulley from the pump. Prise the engine slightly to the left to enable the removal of the pulley.

|

|

| 3. |

Lower the car

|

|

| 4. |

Remove the cover on the engine.

|

|

| 5. |

Remove the air filter assembly.

|

|

| 6. |

Place a container under the car.

|

|

| 7. |

Clean and detach the inlet hose from the pump and let the fluid run down into the container. Point the hose at the container.

|

|||||||||

| 8. |

Undo the delivery hose retaining screw (also securing the dipstick pipe) from the engine

|

|

| 9. |

Detach the connection from the pump using special tool 89 96 803. See 1:3 Special tools.

|

|

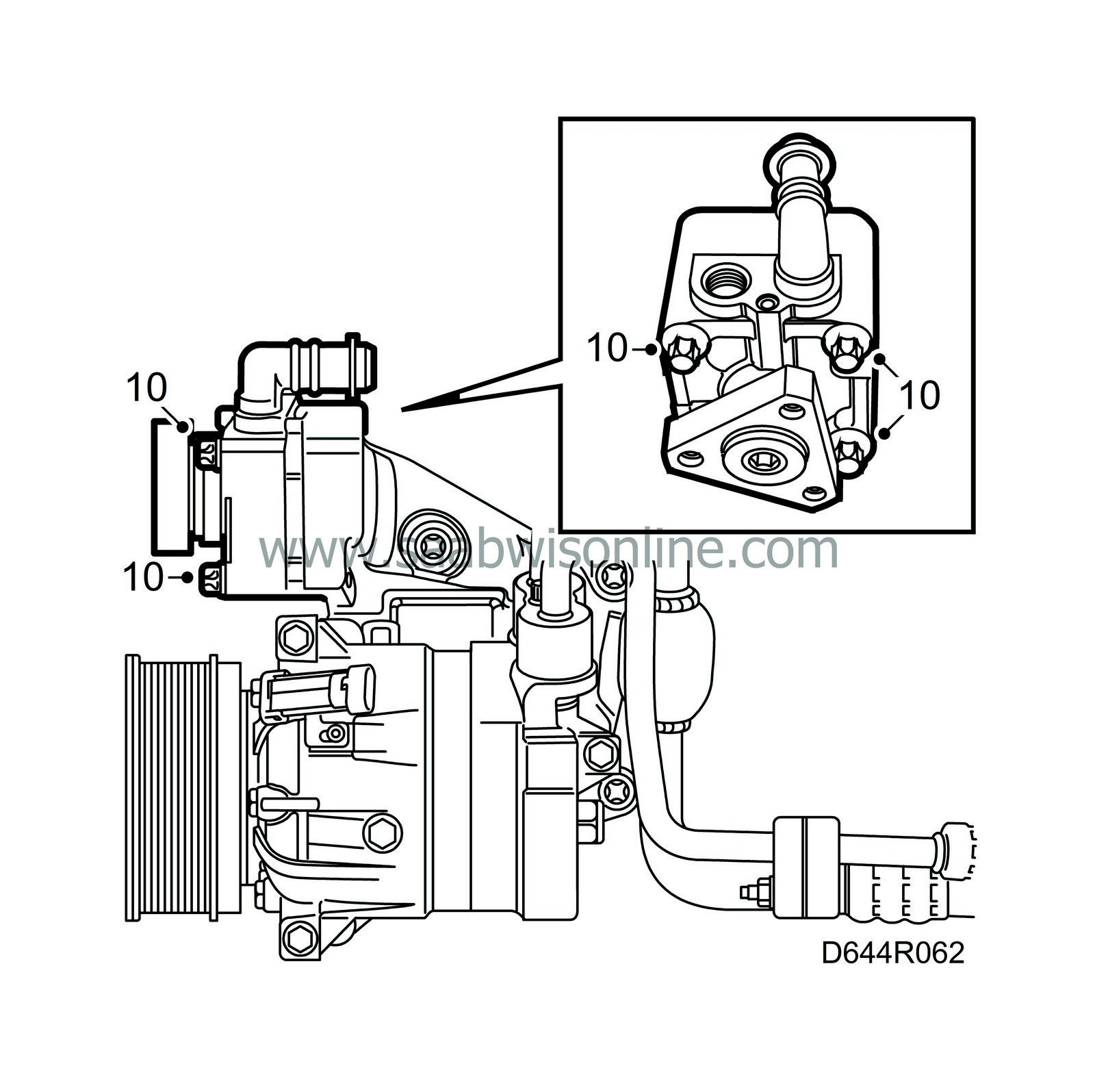

| 10. |

Remove the power steering servo pump carefully so that none of the loose pump components fall out.

|

|

| To fit |

| 1. |

Remove the transport protection from the pump.

|

|

| 2. |

Fit the sealing ring on the pump with petroleum jelly. Fit the two top bolts loosely in the pump.

|

|

| 3. |

Fit the pump carefully so that it does not come apart.

|

|

| 4. |

Press the pump against the contact surface and tighten the bolts (four pieces).

Tightening torque: 20 Nm (15 lbf ft) |

|

| 5. |

Connect and tighten the delivery pipe to the power steering pump with special tool 89 96 803. See 1:3 Special tools. Fit a new seal on the nipple.

Tightening torque: 25 Nm (18 lbf ft) |

|

| 6. |

Tighten the screw for the dipstick pipe together with the delivery pipe mounting on the engine block.

|

|

| 7. |

Connect the inlet hose to the power steering pump.

|

|

| 8. |

Fit the air filter.

|

|

| 9. |

Fit the cover on the engine.

|

|

| 10. |

Raise the car.

|

|

| 11. |

Fit and secure the belt pulley. Prise the engine slightly to the left to enable the fitting of the belt pulley.

Tightening torque: 9.5 Nm (7.0 lbf ft) |

|

| 12. |

Relieve the tension on the belt tensioner and fit the belt. Make sure it is correctly positioned on all the pulleys.

|

|

| 13. |

Fit the wheel arch liner, spoiler bottom and sound insulation.

|

|

| 14. |

Lower the car

|

|

| 15. |

Fill up the system with fresh fluid as per specification.

|

|||||||||||||

| 16. |

Run the engine for 5 seconds.

|

|||||||||

| 17. |

Check the fluid level in the reservoir and top up as necessary. At 20

°

C, it should be midway between the MAX and MIN marks.

|

|

| 18. |

Start the engine again and run it until the fluid in the reservoir stops bubbling. Use a torch to see properly.

An abnormally loud noise from the pump indicates that there is still some air in the system. |

|

| 19. |

Stop the engine and check the fluid level. Top up as necessary.

|

|

| 20. |

Check the pump connections for leaks.

|

|

Warning

Warning