Toe-in

| Toe-in |

| Adjusting with the toe-in beam |

| 1. |

Roll the car slowly straight ahead on a level floor and let it come to a stop without using the brakes.

|

|

| 2. |

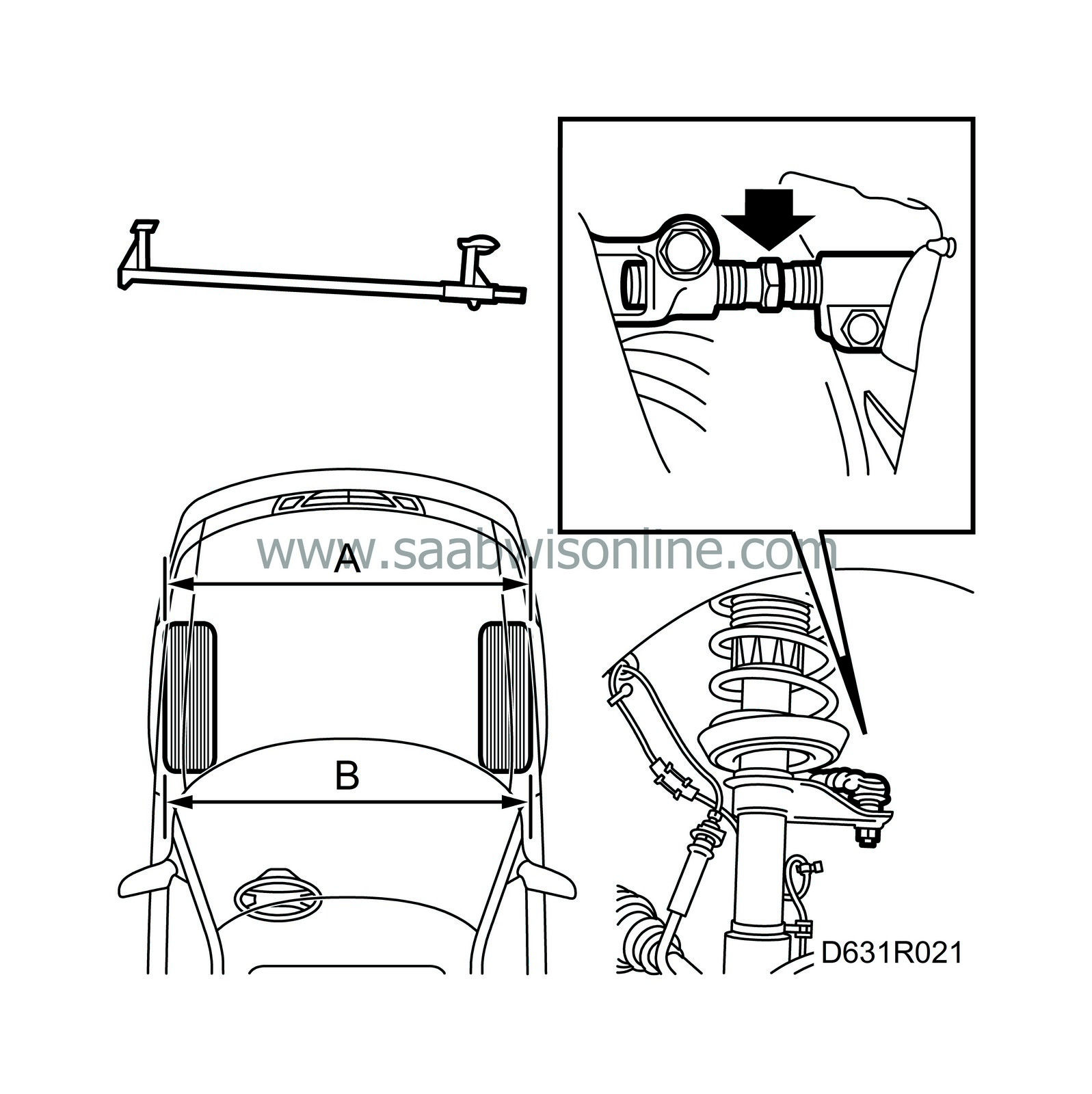

Measure A with the toe-in beam 88 19 031 between the edges of the rims at axle height. Make a chalk mark at the measuring points. Roll the car forwards until the chalk mark is again at axle height. Measure B. With this method, the toe-in beam 88 19 031 is at the same point relative to the floor when measuring both A and B. In this way, any unevenness in the floor surface will not affect the result.

|

|

| 3. |

If adjustment is necessary, adjust the distance between the track-rod ends and the track rod on both sides. Undo the lock bolts on the track rod and track-rod ends.

|

|

| 4. |

Turn the adjusting screw with a spanner to the right or left and as shown in the table, until the correct toe-in is obtained. Tighten the lock bolts with a torque wrench.

Tightening torque: 22 Nm (16 lbf ft).

|

||||||||||

| 5. |

Check the length of the track rod, see

.

.

|

|

| 6. |

Test drive and check that the steering wheel position is correct.

|

|

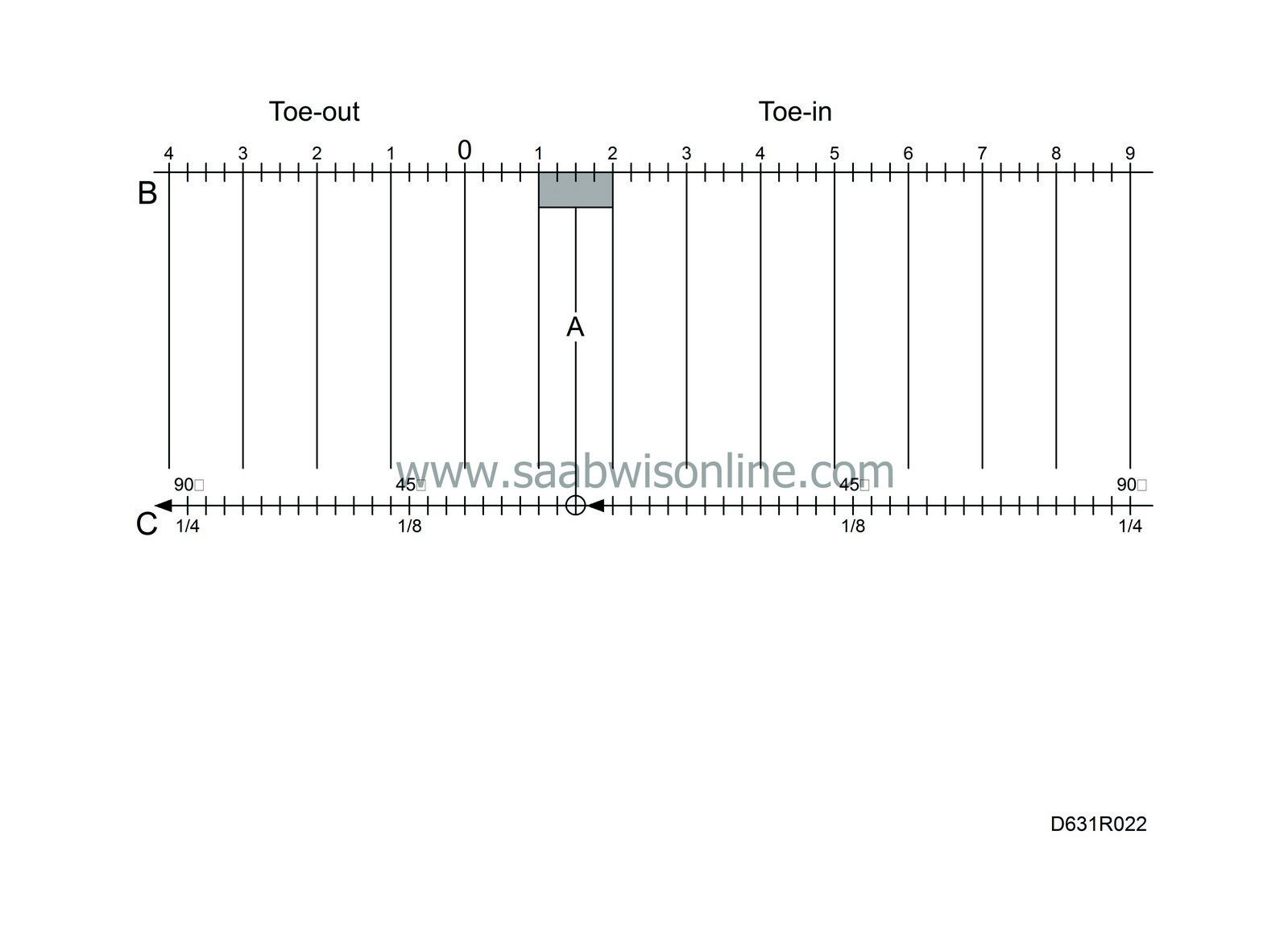

| Toe-in at edge of wheel rim |

| A. |

= nominal value (15” wheel)

|

|

| B. |

= mm

|

|

| C. |

= no. of turns

|

|

Example of how to use the table.

| 1. |

Secure the steering wheel in the straight-ahead position.

|

|

| 2. |

When checking toe-in, read “0.5 toe-out”.

|

|

| 3. |

Follow the top line of the table to “0.5 toe-out”. An imaginary line perpendicular to “0.5 toe-out” gives a reading of just under 1/8 turn. Turn the adjusting screw this amount on both sides.

Tightening torques: Adjusting screw 22 Nm (16 lbf ft)

|

||||||||||