Front wheel housing and front frame member

|

|

Front wheel housing and front frame member

|

|

1.

|

Remove the door frame, see Section of door frame, three-door body; Door frame, three-door body or Section of door frame, five-door body.

|

|

2.

|

Position the car in an aligning bench and cross-measure if necessary.

|

|

3.

|

Position a door opening support between the floor and roof so that the roof does not sag when the wheel housing is removed.

|

|

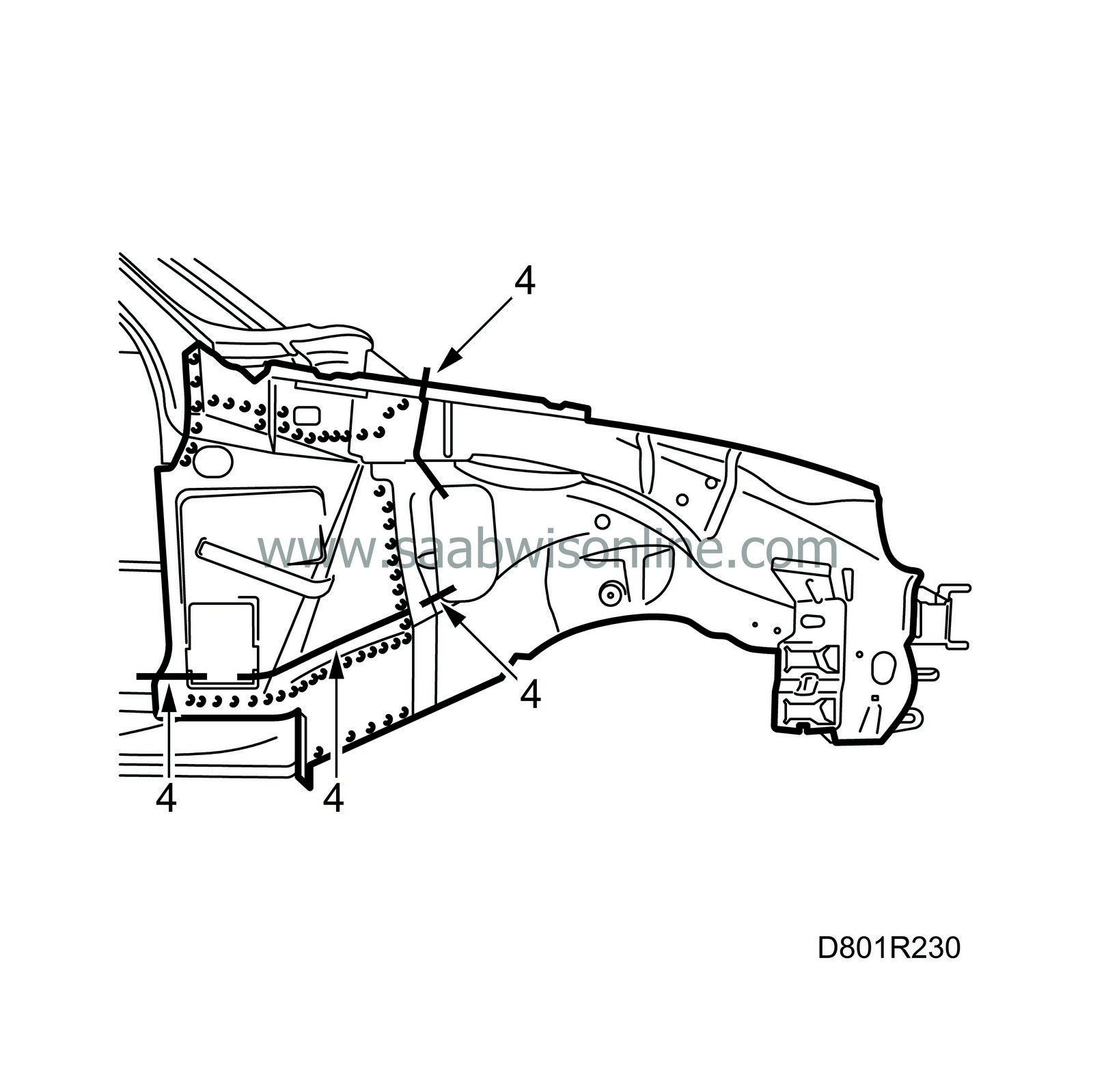

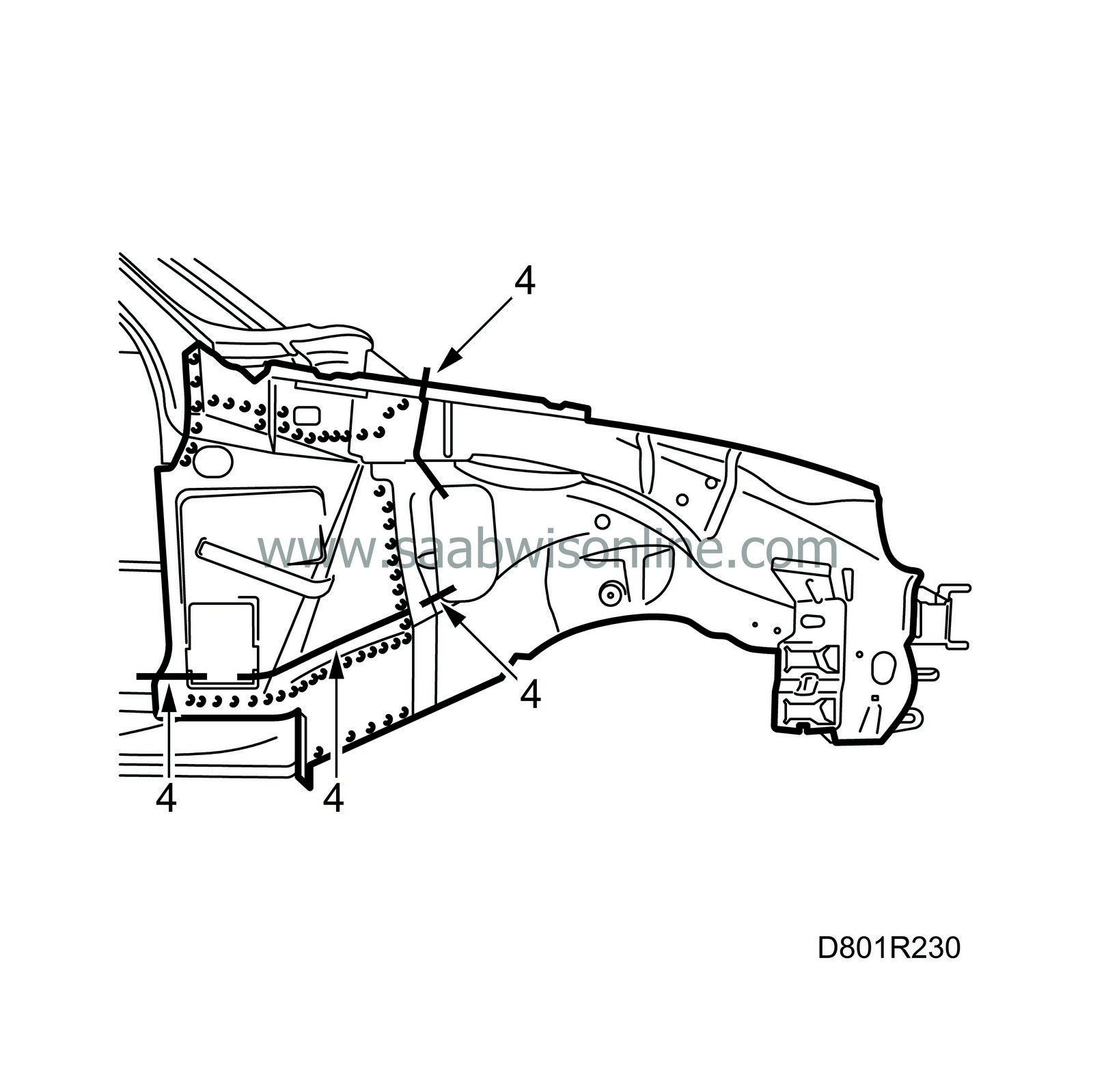

4.

|

Cut the wheel housing so that the welding points are accessible with a spot-weld drill.

|

|

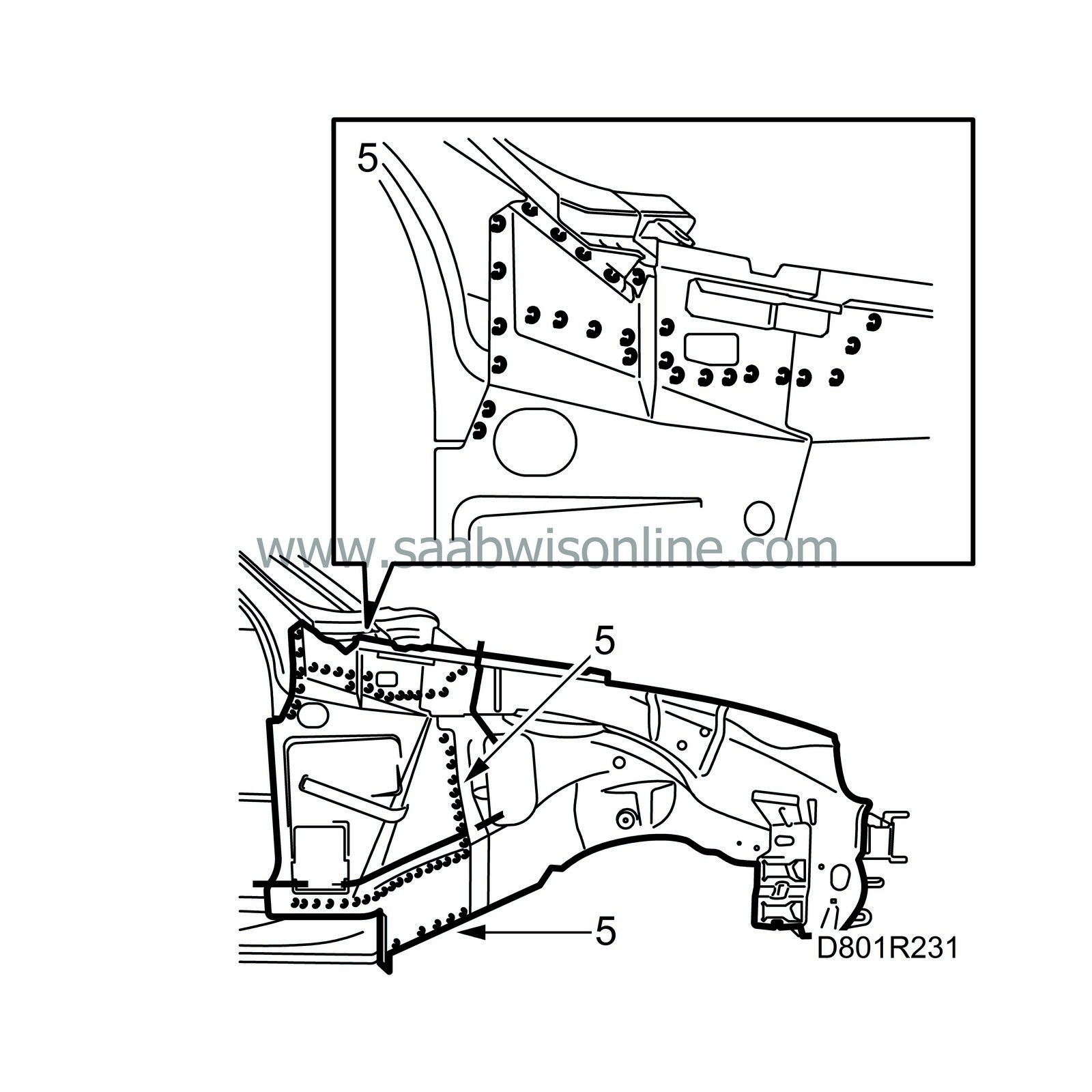

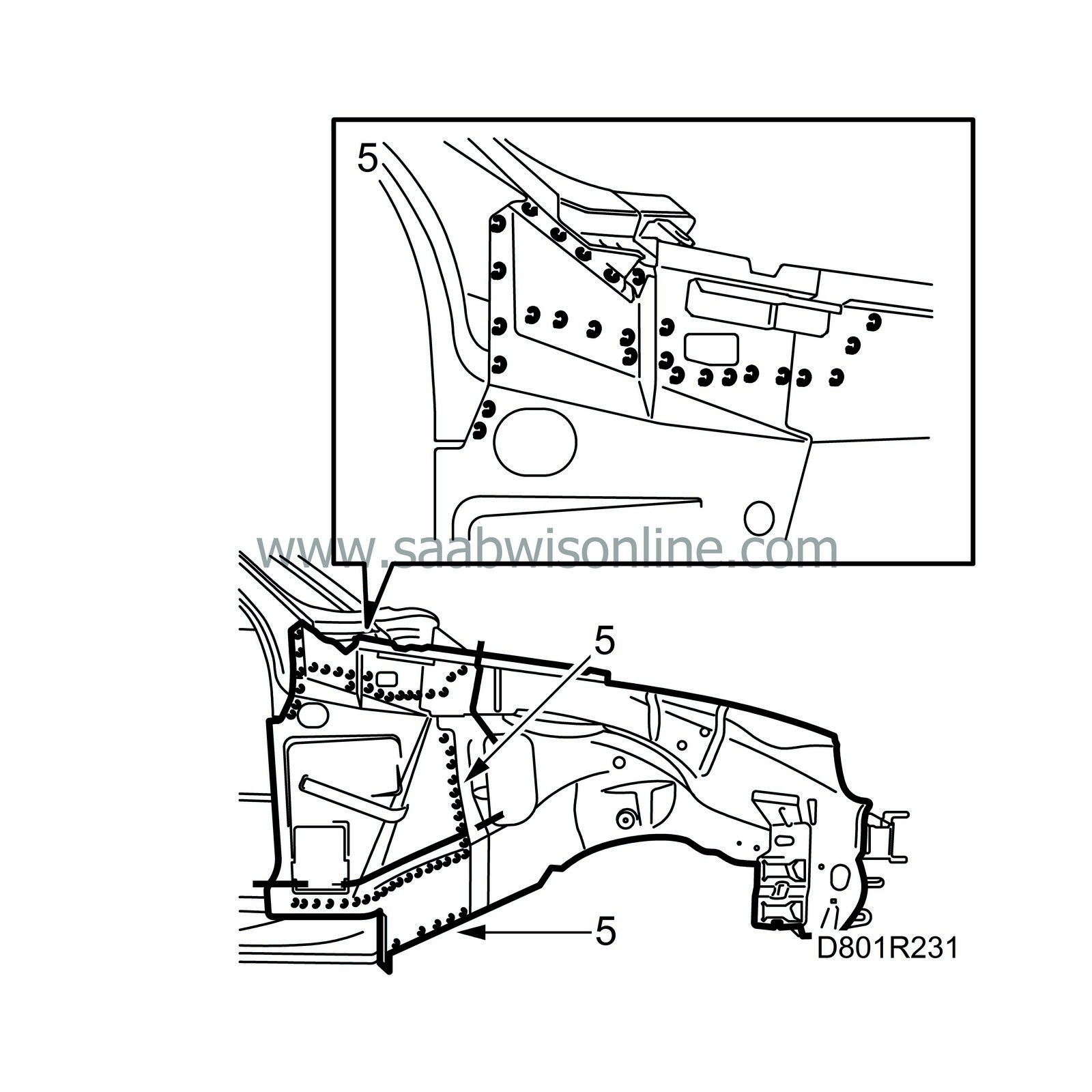

5.

|

Drill out the spot-welds and tap loose the remaining sections of the wheel housing.

|

|

6.

|

Cut the cross-member according to the markings shown on the illustration.

|

Important

|

|

The crossmember must only be joined according to the markings. If the damage extends beyond the marking, the entire crossmember must be replaced.

|

|

|

|

|

7.

|

Drill out the spot welds securing the cut section of frame member and crossmember. Drill through all the panels including the floor. Grind away the seam welds.

|

|

8.

|

Remove the cut sections of frame member and crossmember and align any sheet metal or panel damage.

|

|

9.

|

Drill holes in the body where the new frame member is to be welded.

|

|

10.

|

Grind clean the surfaces on the to be welded on the frame member and body.

|

|

11.

|

Remove grinding debris from the inside of the frame member, otherwise the risk for corrosion increases.

|

|

12.

|

Apply welding primer on the surfaces to be plug-welded. Use Teroson Zinkspray.

|

|

13.

|

Fit the frame member and secure it with a couple of welding clamps. Adjust the exact position using the aligning bench measuring system.

|

|

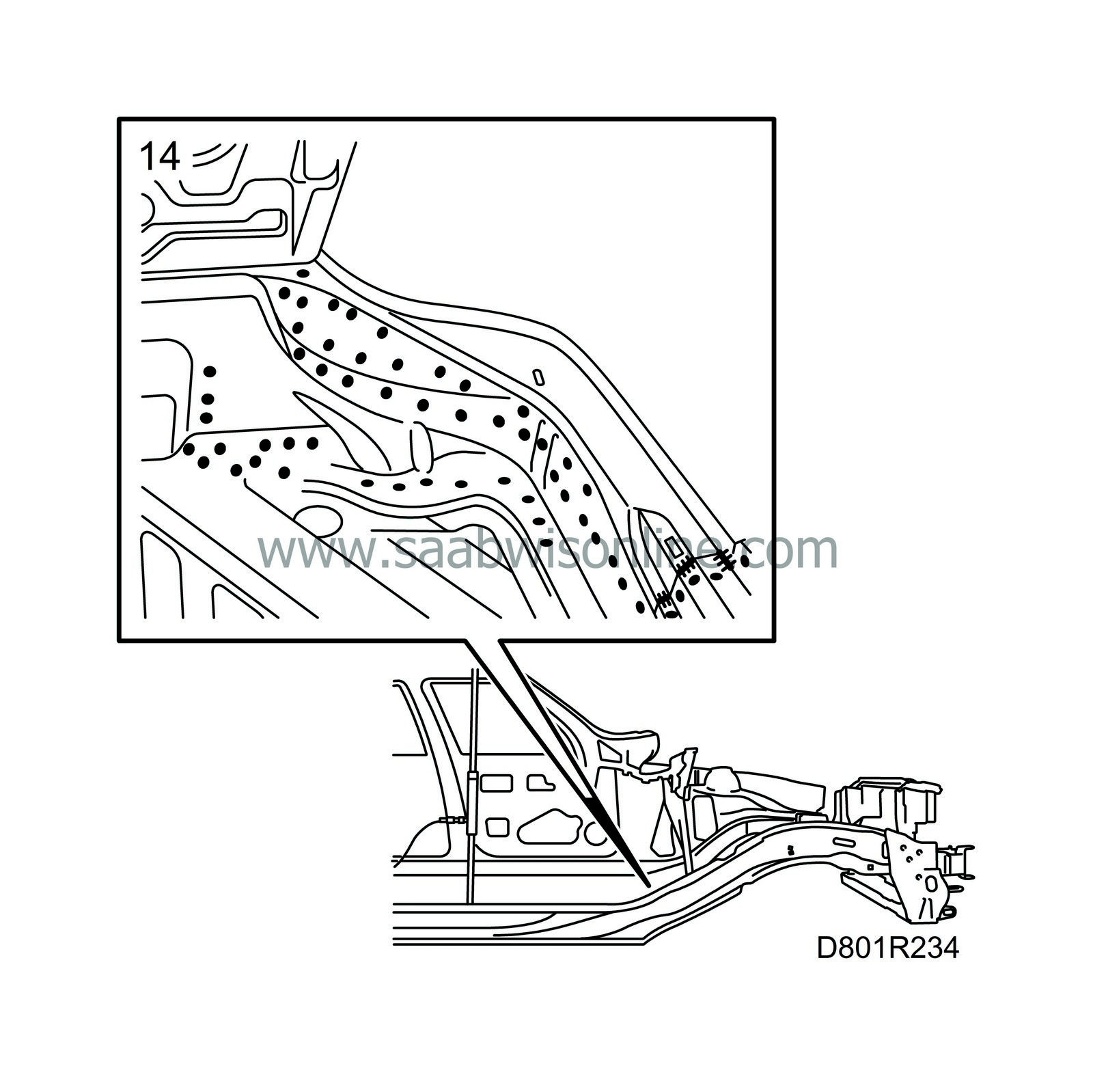

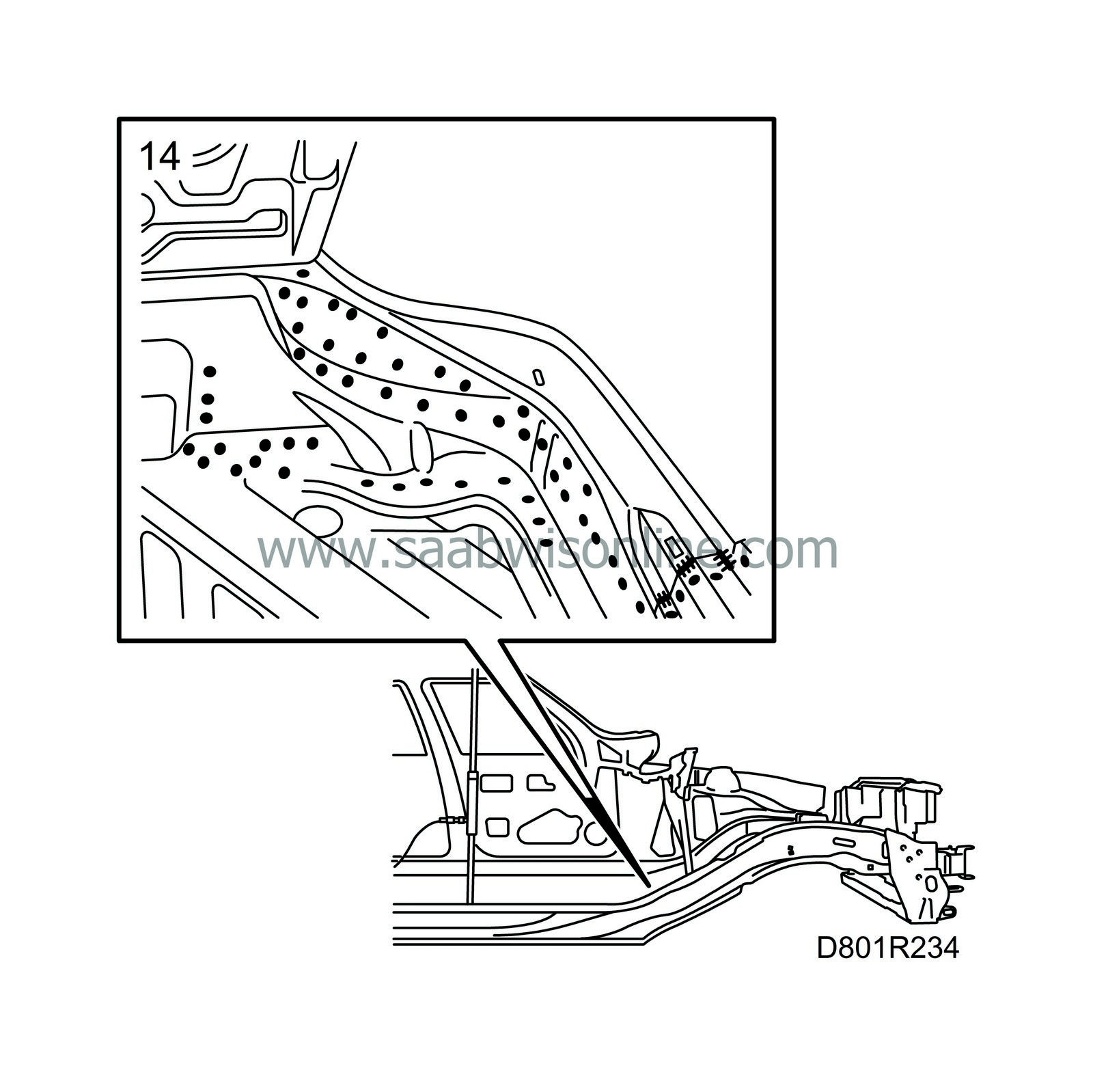

14.

|

Plug-weld and seam-weld on the frame member.

|

|

15.

|

Cut the crossmember and align it.

|

|

16.

|

Fit the crossmember and secure it with a couple of welding clamps.

|

|

17.

|

Remove the crossmember and drill holes for plug-welding in the crossmember.

|

|

18.

|

Grind clean the surfaces to be welded on the cross-member and the body.

|

|

19.

|

Apply welding primer on the surfaces to be plug-welded. Use Teroson Zinkspray.

|

|

20.

|

Fit the crossmember and secure it with a couple of welding clamps.

|

|

21.

|

Plug-weld the cross-member.

|

|

22.

|

All-weld the joint on the cross-member.

|

|

23.

|

Drill holes for plug-welding in the new wheel housing where it is not possible to reach with a spot-welder.

|

|

24.

|

Grind clean the surfaces to be welded on the body and in the new wheel housing.

|

|

25.

|

Apply welding primer on the surfaces to be plug and spot-welded on the wheel housing and on the body. Use Teroson Zinkspray.

|

|

26.

|

Fit the new wheel housing and secure with a few welding clamps.

|

|

27.

|

Measure in the wheel housing using the aligning bench measuring system.

|

|

28.

|

Fasten the wheel housing with a couple of welds.

|

|

29.

|

Fit the front wing and the bonnet, check the fit of the wheel housing.

|

|

30.

|

Remove the front wing and bonnet.

|

|

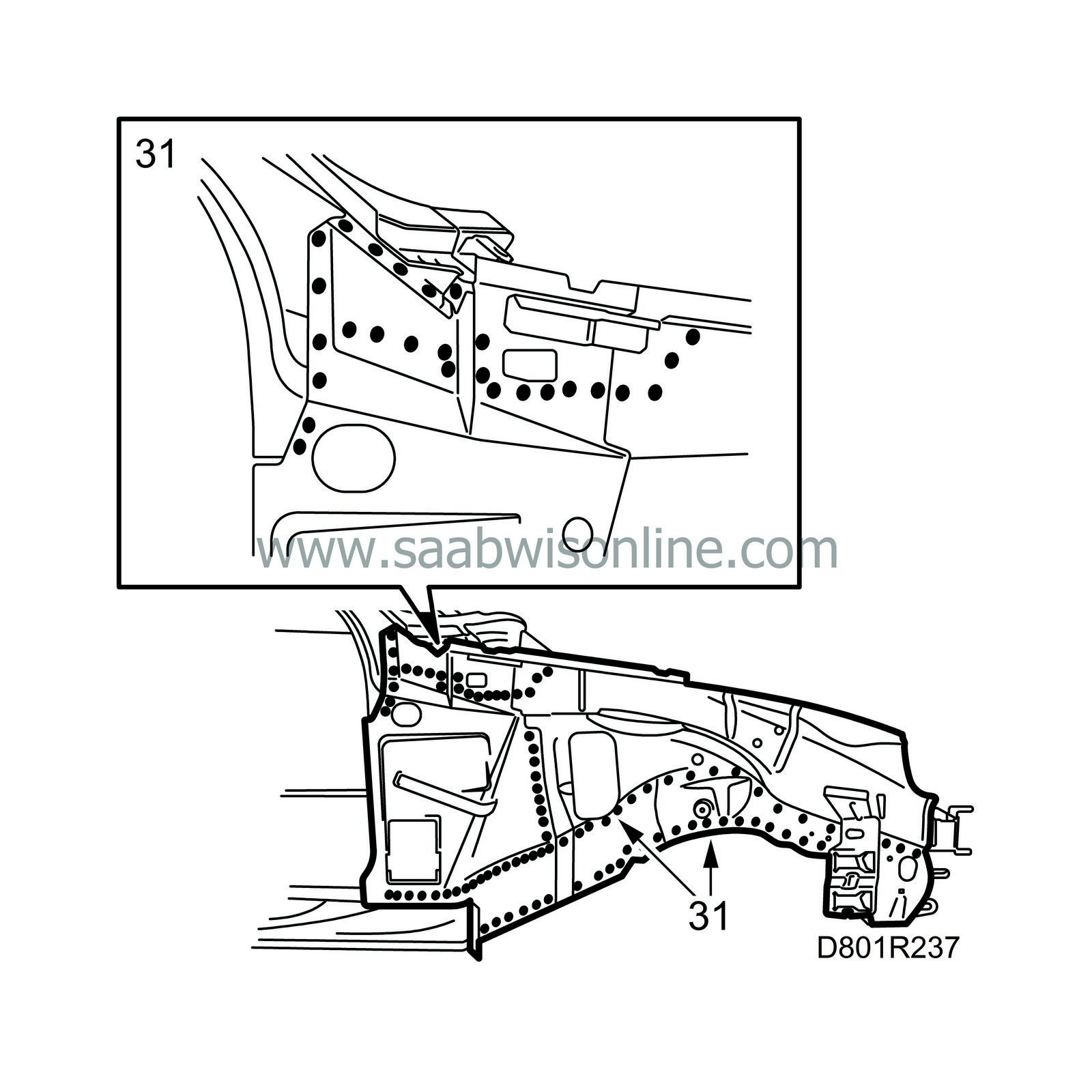

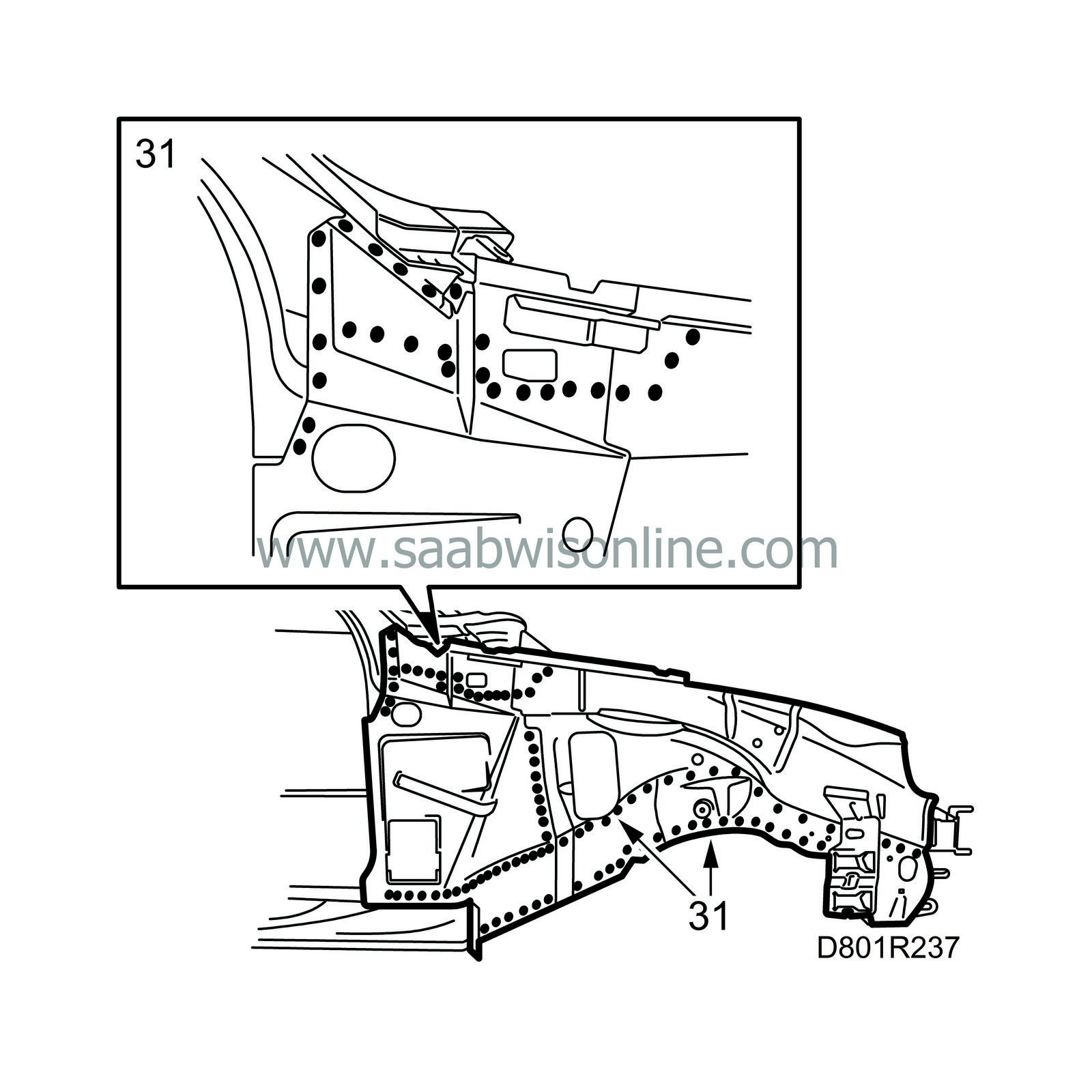

31.

|

Spot and plug-weld the housing into place.

|

|

33.

|

Grind clean the surfaces to be welded on the body and reinforcements that are to be fitted on the outside of the wheel housing.

|

|

34.

|

Apply welding primer on the surfaces to be spot-welded. Use Teroson Zinkspray.

|

|

35.

|

Weld on the reinforcement on the outside of the wheel housing.

|

|

36.

|

Remove any remaining welding primer. Welding primer reduces adhesion of paint, filler and sealant.

|

|

37.

|

Saab 9-3 Viggen:

The two lower bolts in the wheel housing behind the front wheel should be cut to give clearance for the wheel. Cut them to a maximum length of 10 -12 mm. Then use the nuts, part no. 47 41 203, when fitting the wing liner.

|

|

38.

|

Apply primer to all ground surfaces. Use Standox 1K Primer.

|

|

39.

|

Seal folds and panel edges with sealant. Use Terostat 1K-PUR.

|

|

40.

|

Apply underseal to the bottom of the frame and crossmember. Use Terostat 9320.

|

|

41.

|

Apply anti-corrosion agent to internal surfaces after painting. Use Terotex HV 400 or Mercasol 1.

|