Tart of rear floor

| Tart of rear floor |

The new floor should be plug-welded at the front edge around the edge towards the spare tire well as well as be all-welded edge-to-edge between the spare tire well and the wheel housing.

| 1. |

Position the car in an aligning bench and cross-measure if necessary.

|

|

| 2. |

Remove the rear bumper abutment, see

Rear bumper abutment

.

|

|

| 3. |

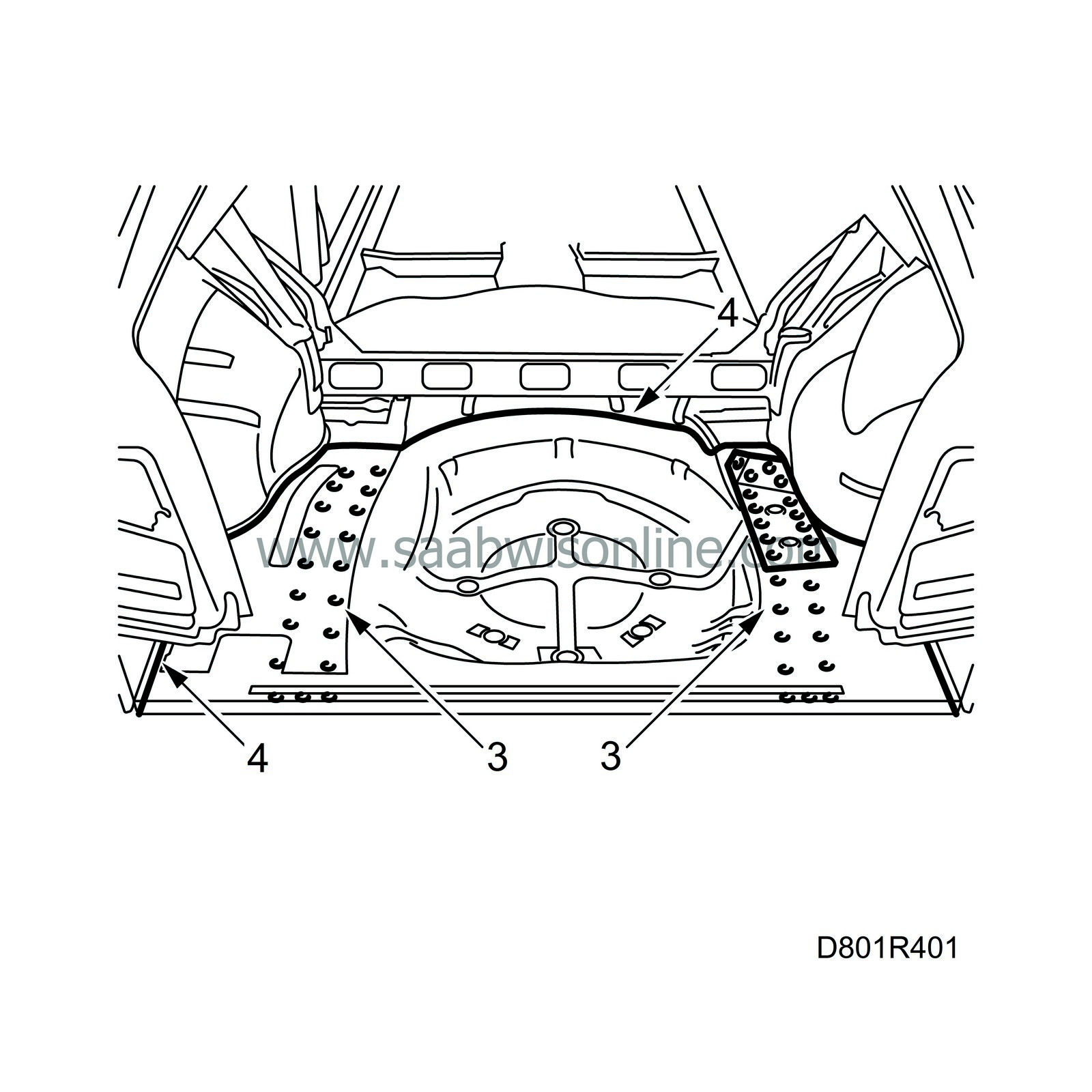

Drill out the spot-welds that secure the floor to the frame members.

|

|

| 4. |

Cut away the rear floor and remove it.

|

|

| 5. |

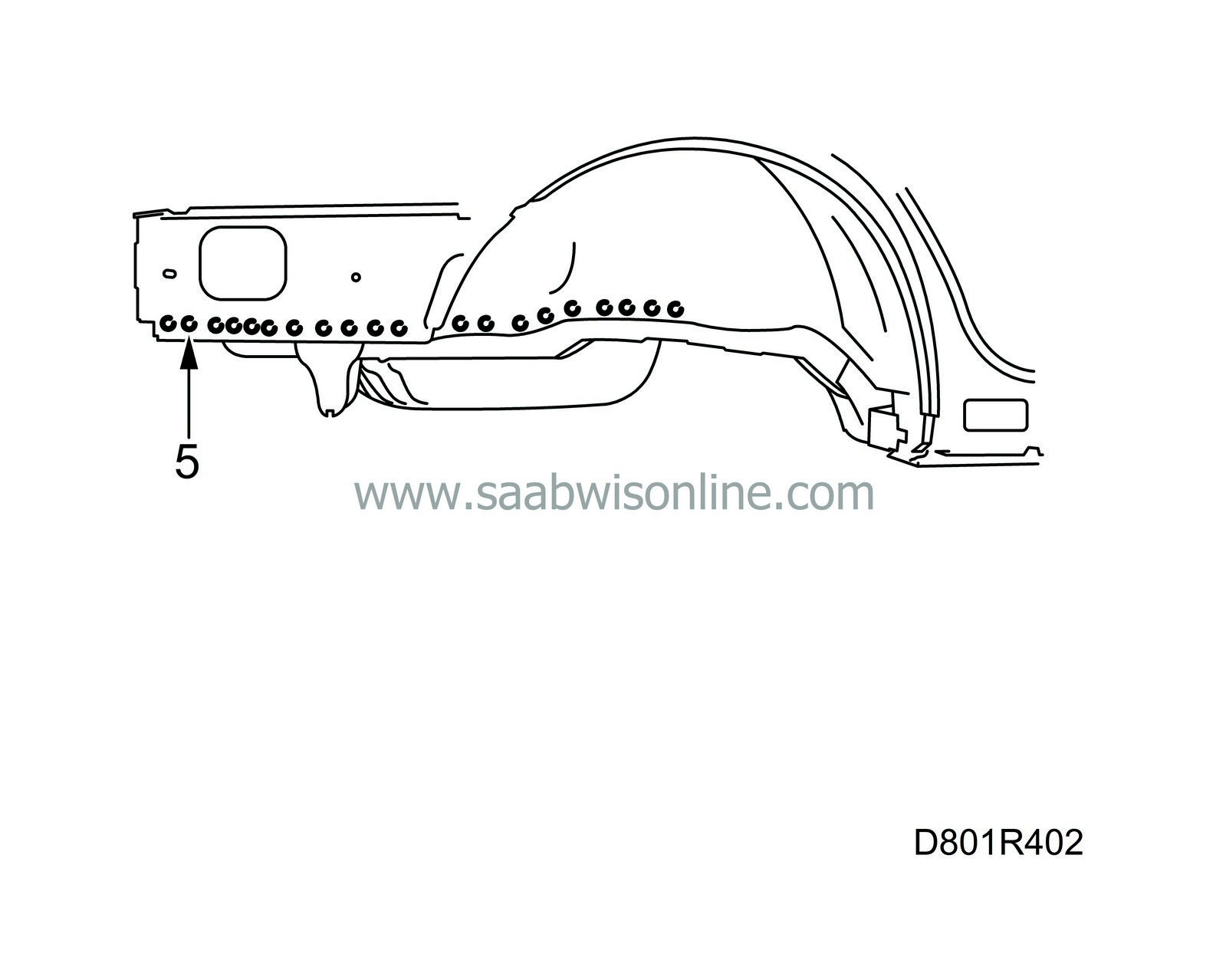

Drill out the spot-welds that secure the sides of the floor to the wheel housings and remove the remaining sheet metal sides.

|

|

| 6. |

Align any deformed sheet metal or panels.

|

|

| 7. |

Grind the surfaces to be welded on the body.

|

|

| 8. |

Cut the new floor so that it overlaps the intended joint line by approximately three centimetres.

|

|

| 9. |

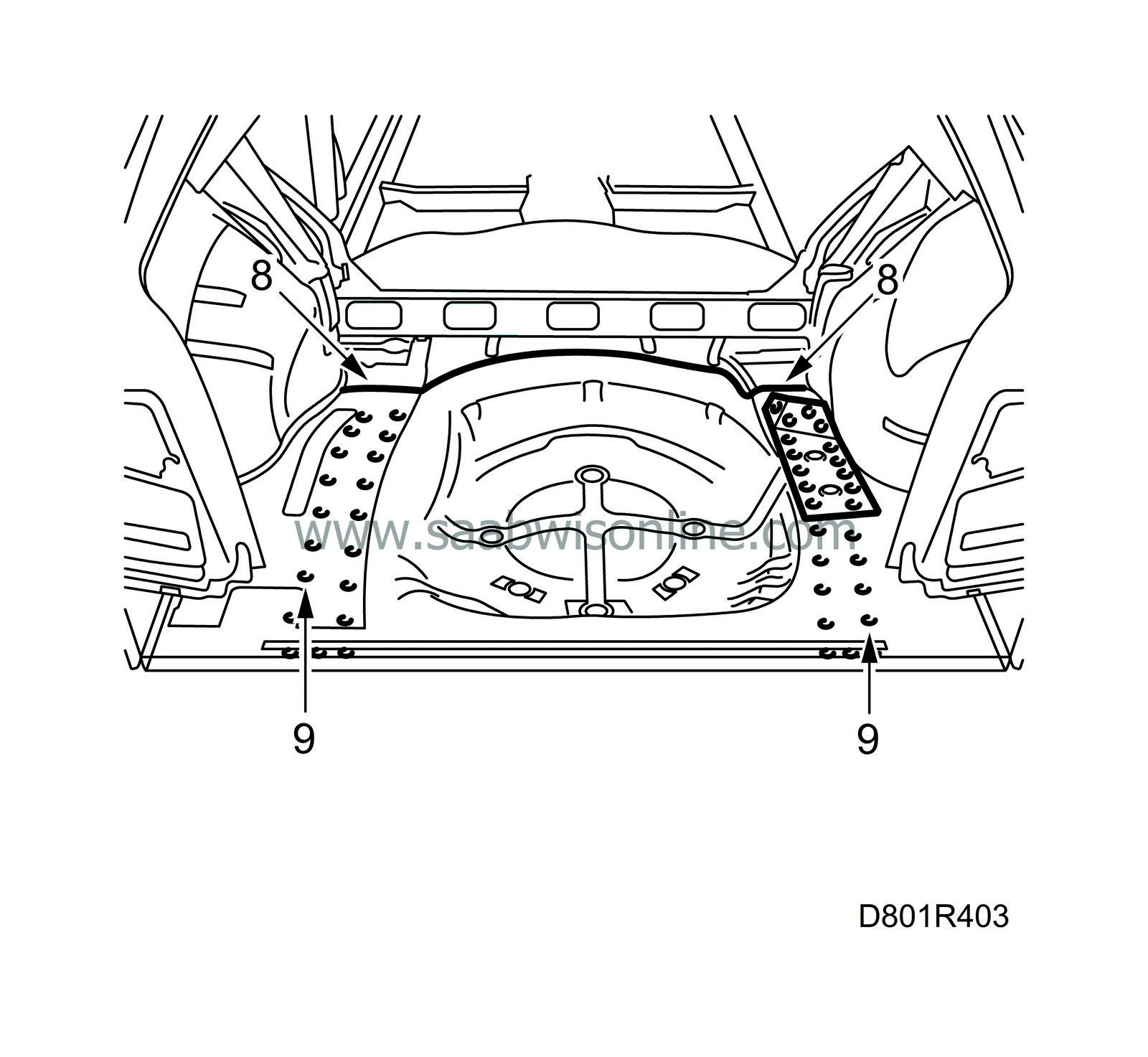

Punch holes for plug-welding where possible. Remaining holes are drilled using a 6 mm drill bit.

|

|

| 10. |

Fit the floor and fixate with a few welding clamps.

|

|

| 11. |

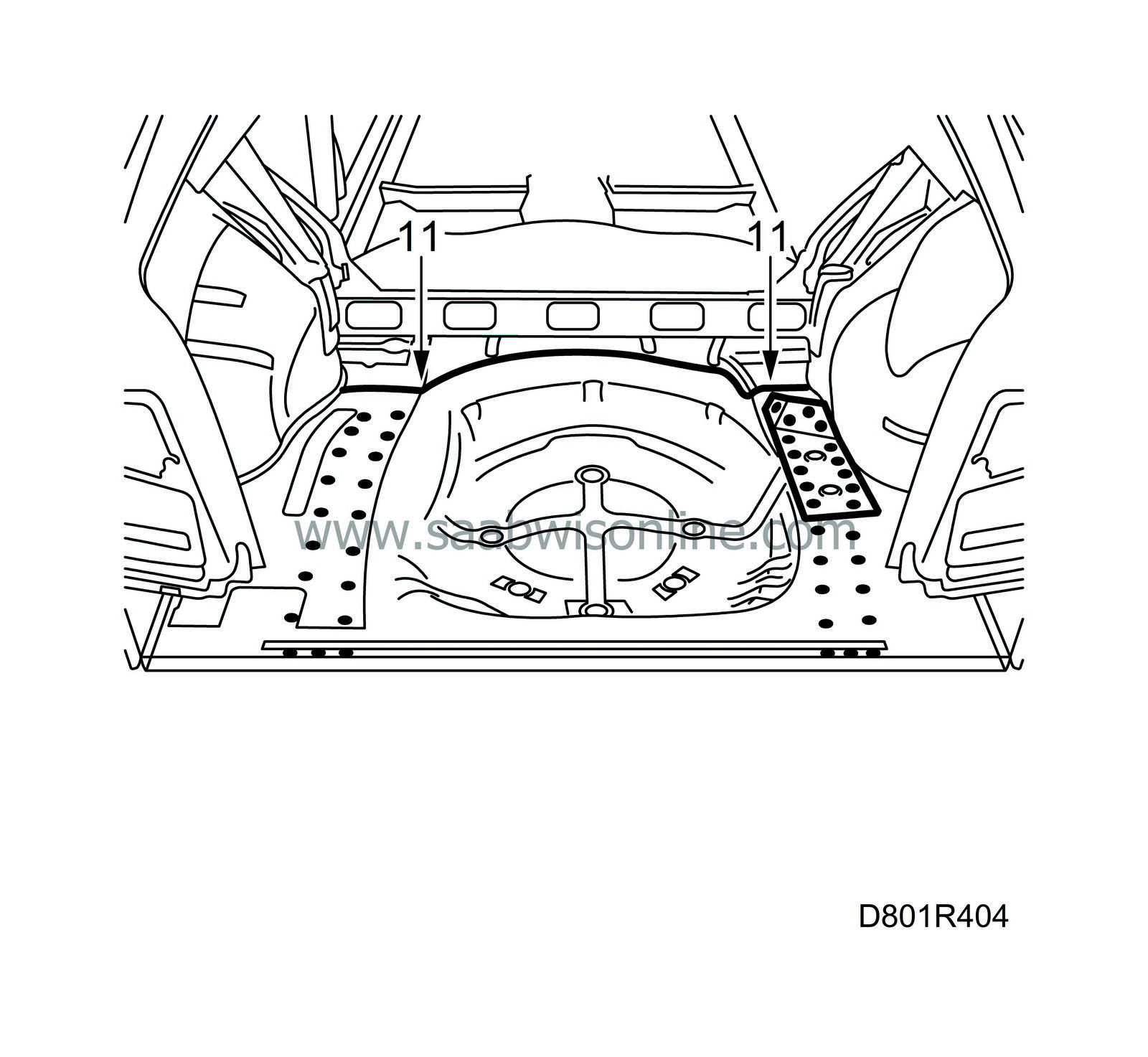

Cut through the new and old floor between the spare tire well and wheel housing at the same time so that the joints can be welded edge-to-edge.

|

|

| 12. |

Remove the floor and grind the surfaces to be welded.

|

|

| 13. |

Apply welding primer on the surfaces to be welded. Use Teroson Zinkspray.

|

|

| 14. |

Fit the floor in the car and fixate with a few welding clamps.

|

|

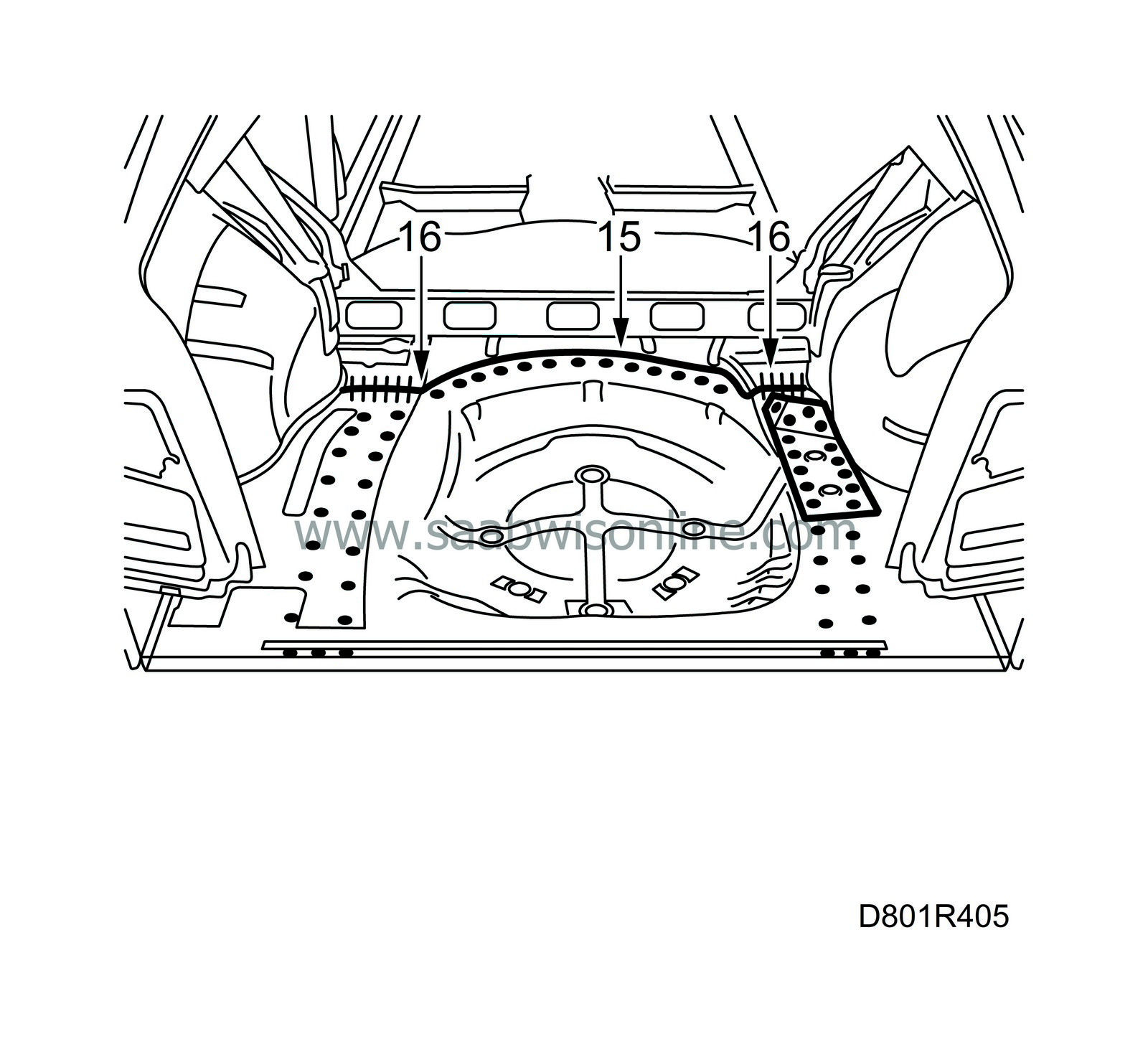

| 15. |

Plug-weld the new floor along the edge towards the spare tire well.

|

|

| 16. |

All-weld the joints between the spare tire well and the wheel housings.

|

|

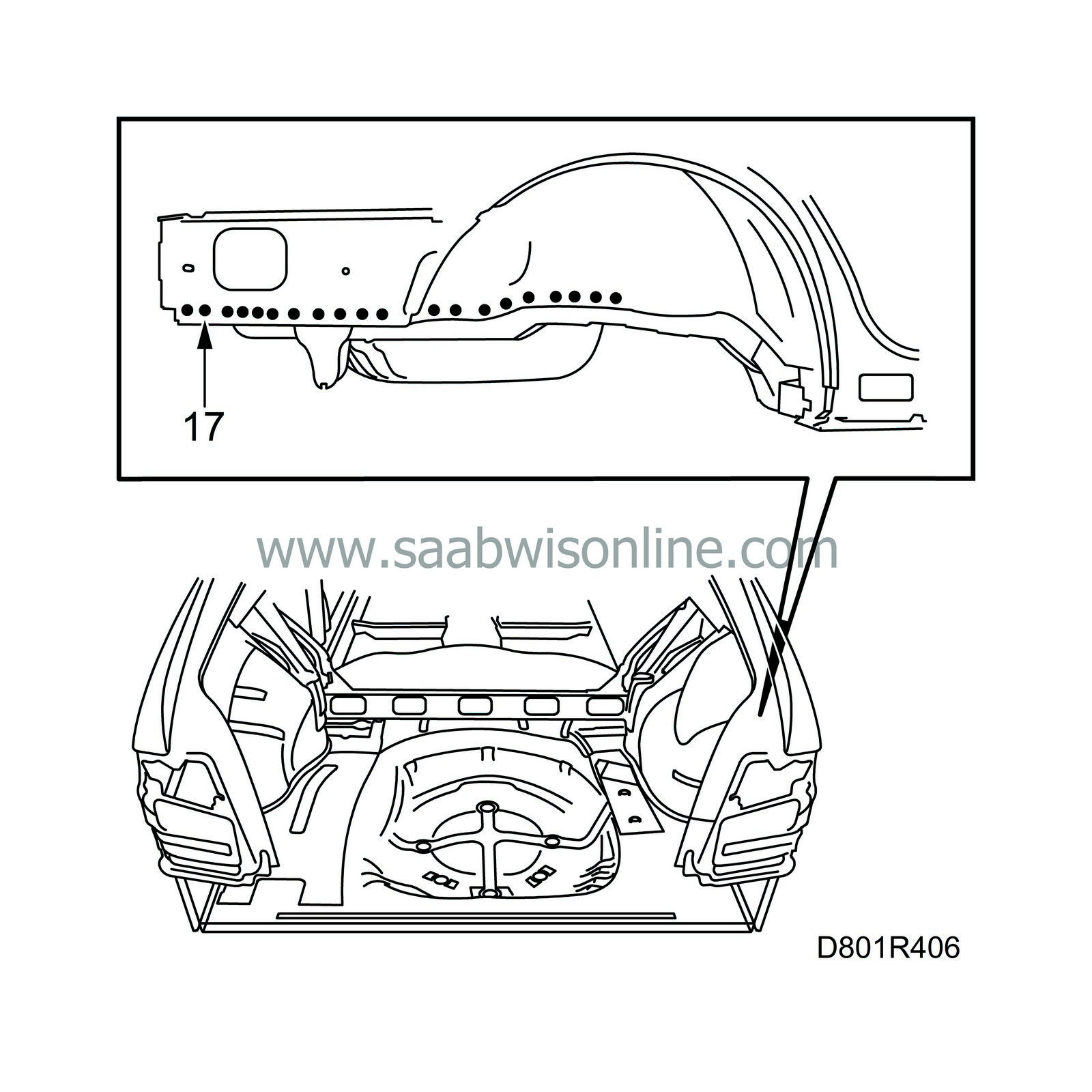

| 17. |

Spot-weld the edges of the new floor.

|

|

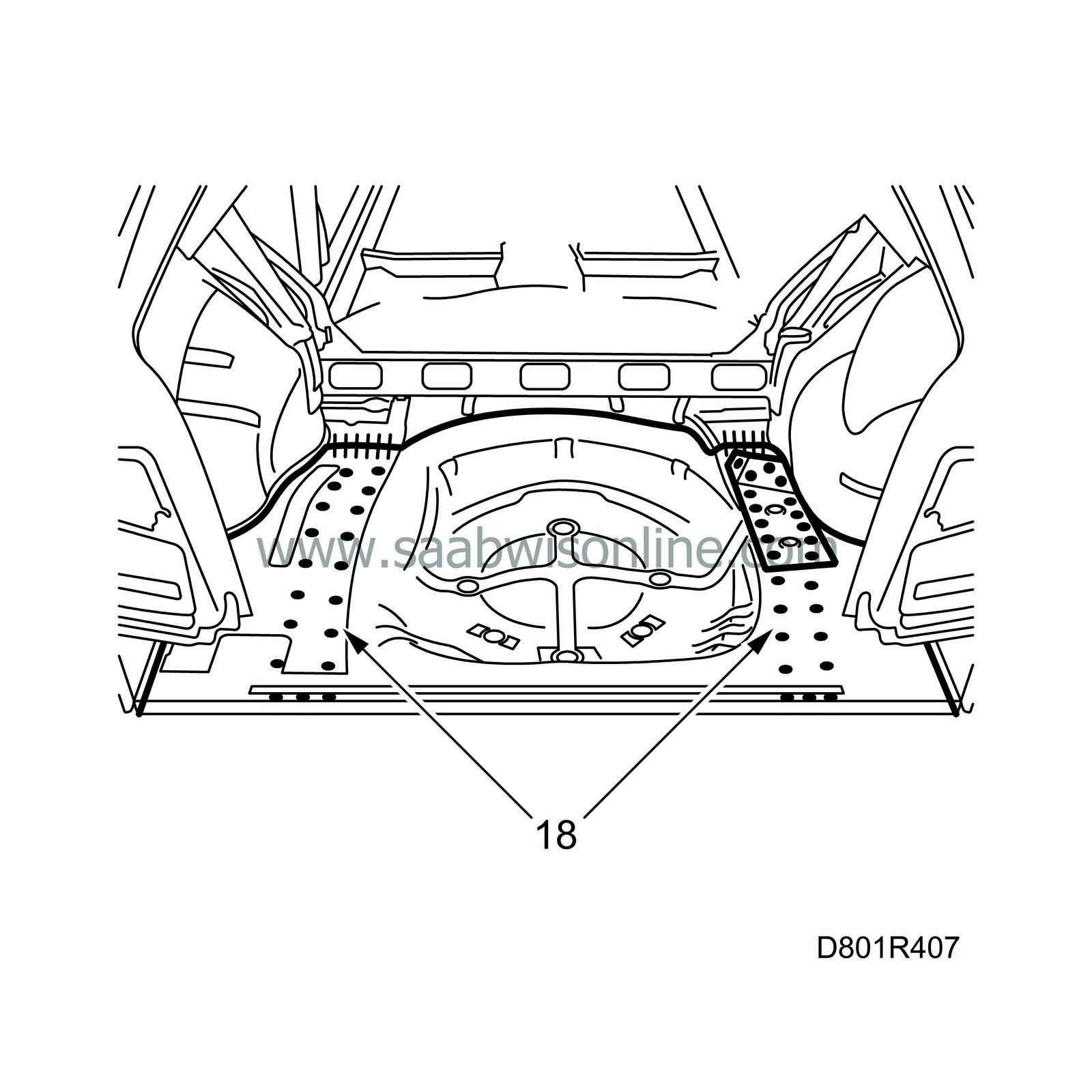

| 18. |

Plug weld the floor to the frame members and a new reinforcement on the right-hand side.

|

|

| 19. |

Fit the rear bumper abutment, see

Rear bumper abutment

.

|

|

| 20. |

Remove remaining welding primer. Welding primer will reduce adhesion for paint, filler and sealant.

|

|

| 21. |

Apply primer to all ground surfaces. Use Standox 1K Primer.

|

|

| 22. |

Seal joints and sheet metal flanges with sealant. Use Terostat 1K-PUR.

|

|

| 23. |

Apply PVC substitute on the underside of the floor. Use Terostat 9320.

|

|