Description of operation, engine management system

| Description of operation, engine management system |

| Starting fuel quantity calculation |

The starting fuel quantity is the amount of fuel allowed when starting the engine. The function is activated when starting the engine is possible and is terminated at engine speeds above 750 rpm.

The fuel quantity is calculated using the following sub-functions:

Base value

A base value is retrieved from a file in which the starter motor speed and engine coolant temperature are the input values. The value from the file is corrected in the starting quantity correction function.Starting quantity correction

The starting quantity correction is calculated from the current engine speed. The max. correction is 5 mg/combustion and it decreases with the engine speed (0 mg/combustion at 750 rpm).Starting quantity enrichment

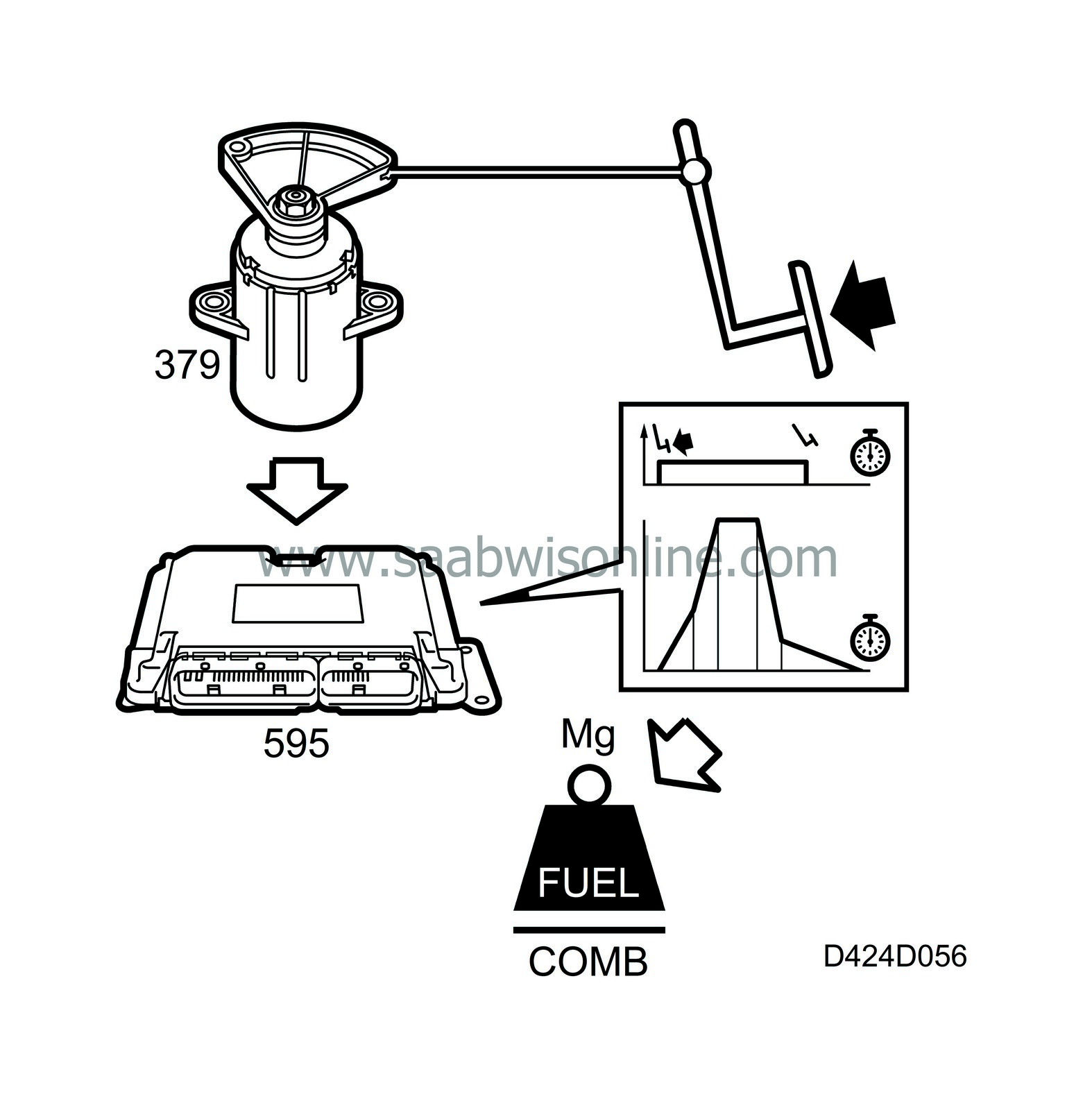

Starting quantity enrichment ensures problem-free starting at all temperatures. Enrichment is calculated from the pump temperature, engine speed and the time it takes for the engine to start. Different parameters are selected for cold starting enrichment depending on whether the pump temperature is above or below 10°C.The results of these calculations are totalled and form the total starting fuel quantity.

The starting fuel quantity can be decreased or increased by 5 mg/combustion with the diagnostic tool.

| Limit quantities |

The sub-functions under limit quantities calculate the largest permitted injection quantity in mg/combustion for the current operating conditions. The calculated limit quantity is used to limit the requested quantity from the pedal position sensor and the cruise control if it should be necessary. The calculation is performed at fixed time cycles, independent of the engine speed.

| 1. |

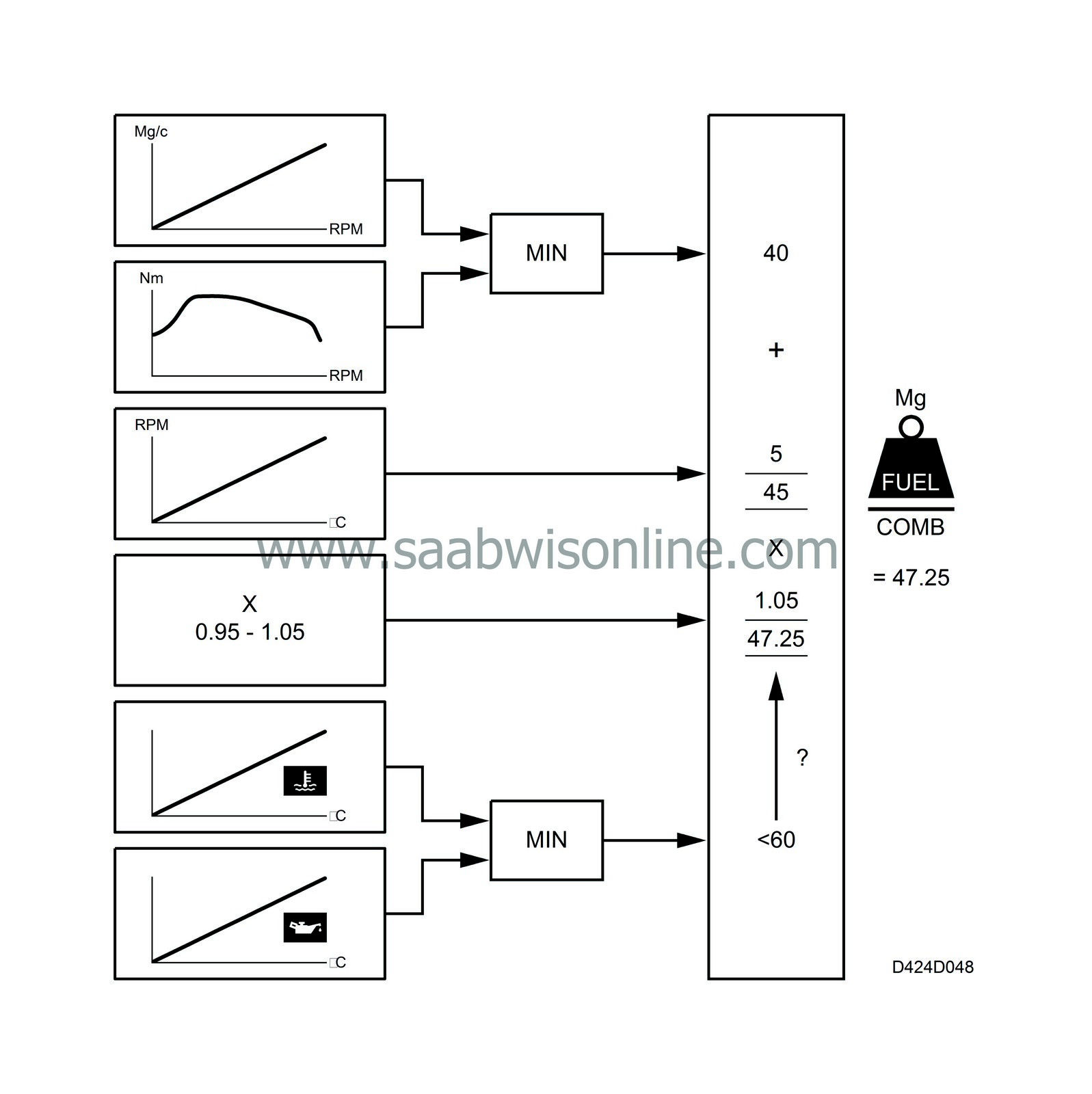

The result of the calculation in the smoke limitation and torque limitation sub-functions are compared and the function that gives the lowest injection quantity is the value that is carried forward.

Example: The result of the smoke limitation is 40 mg/combustion and the result of the torque limitation is 60 mg/combustion. This means that the value from the smoke limitation (40 mg/combustion) is carried forward. |

|

| 2. |

The result of the temperature compensation is added to the result of the calculation above.

Example: 40 mg/combustion + 5 mg/combustion = 45 mg/combustion. |

|

| 4. |

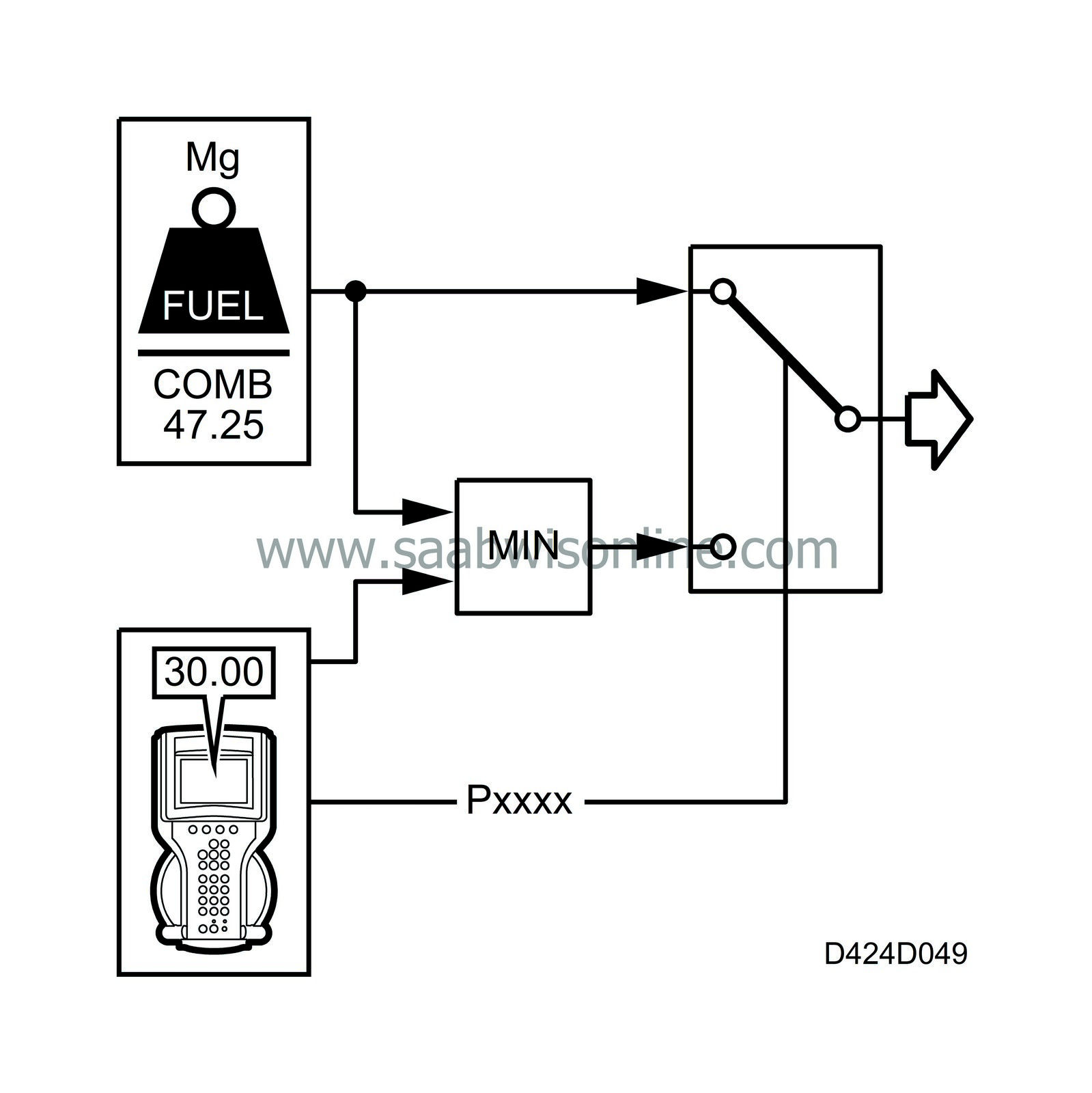

However, if there is a system fault, 45 mg/combustion is compared with the limit quantity on system fault (rpm dependent, max. 30 mg/combustion), and the lowest value is carried forward as the limit quantity.

|

|

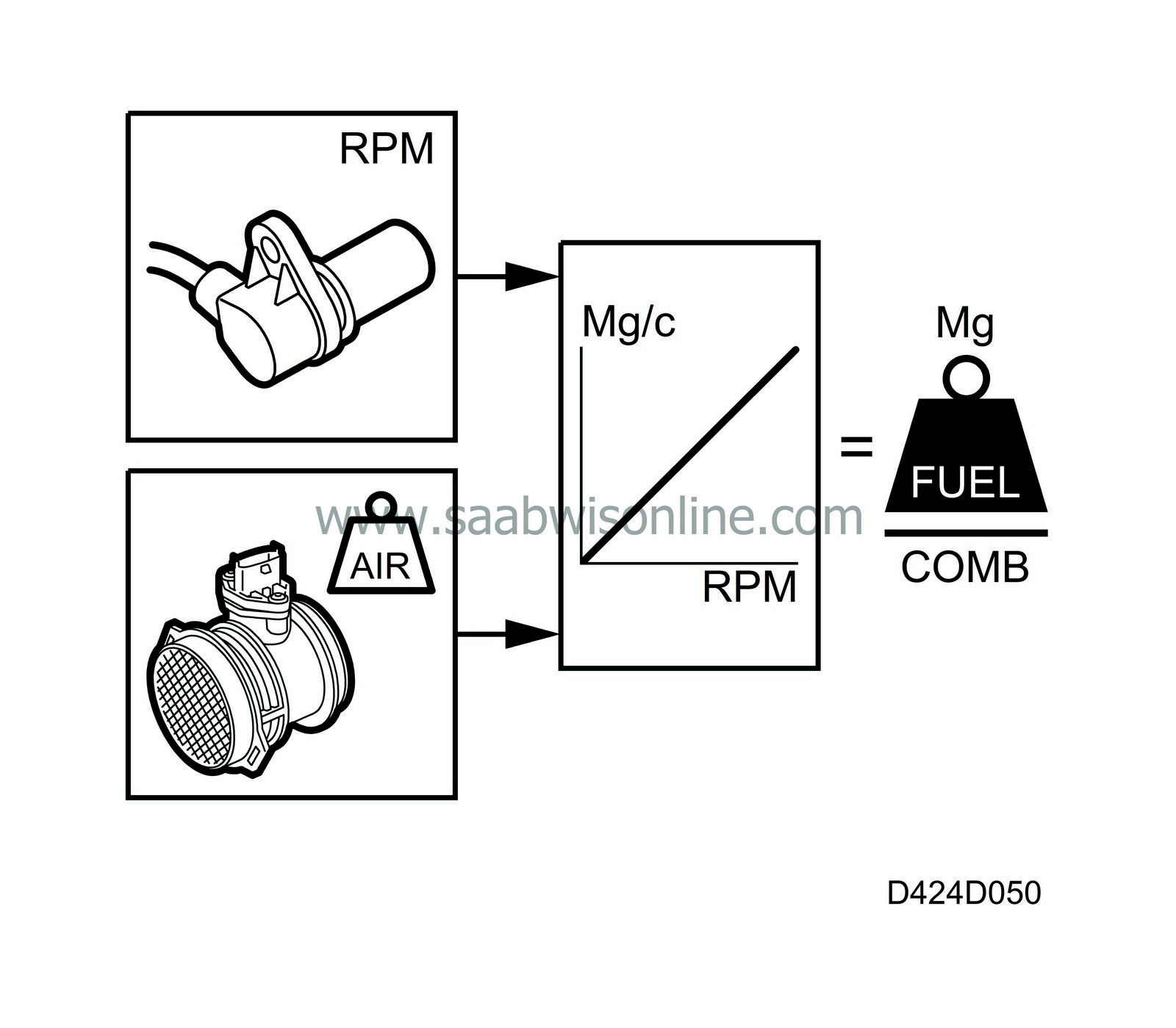

Smoke limitation

There is a smoke limitation function to prevent the formation of large amounts of smoke.Smoke limitation is calculated from the engine speed and the intake air mass in mg/combustion. The function is tested so that the fuel quantity in mg/combustion always has sufficient air mass/combustion, preventing smoke formation.

If this is not the case, smoke limitation is activated and the fuel quantity is reduced to a level at which the available air mass is sufficient to burn the fuel without the formation of large amounts of smoke. This takes place when driving at high altitudes for example, as the proportion of oxygen in the air decreases at higher altitudes.

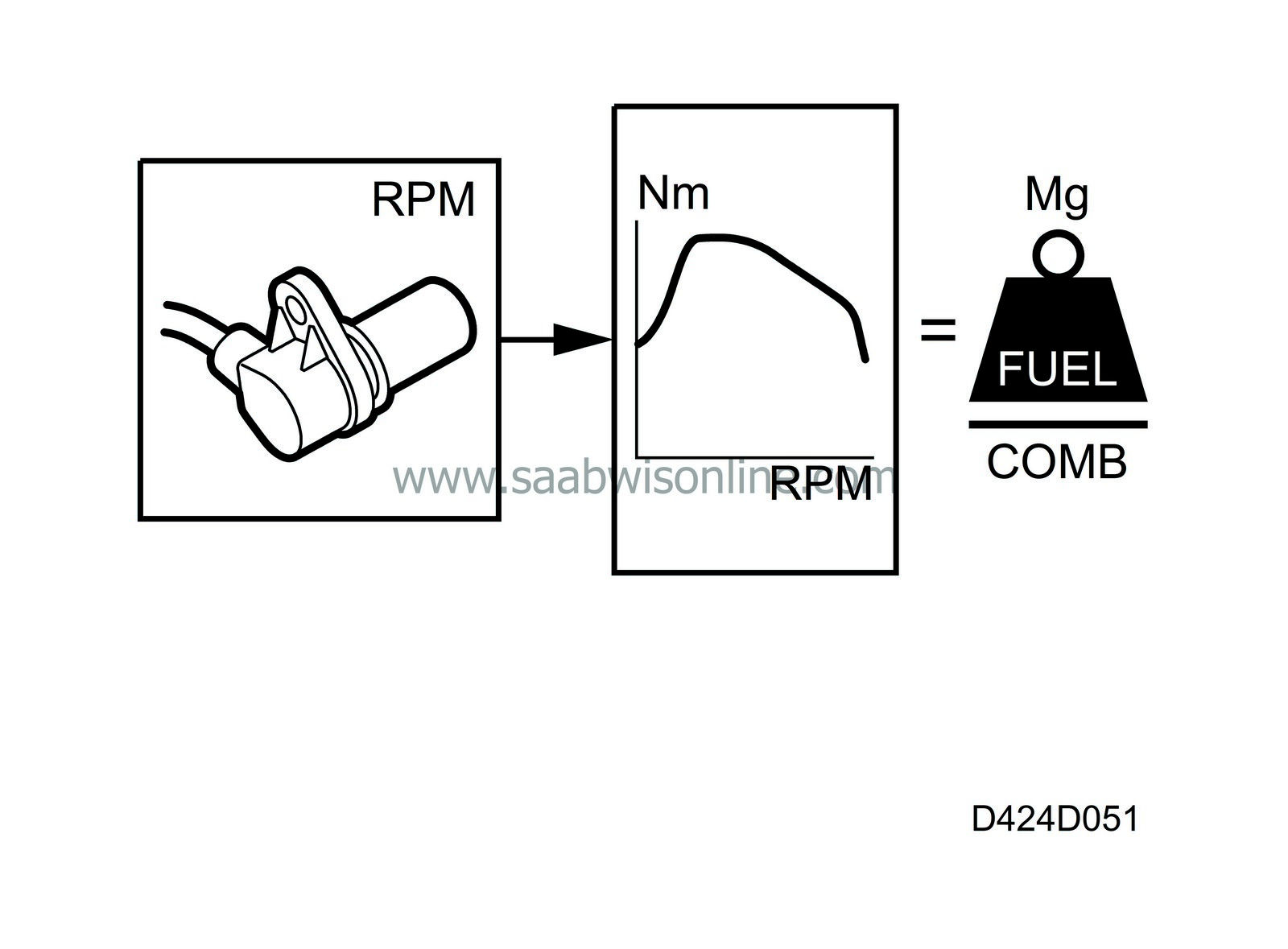

Torque limitation

To adapt the torque of the engine a torque limitation quantity based on the engine speed is obtained. If a diagnostic trouble code has been generated, the fuel quantity from “Quantity limitation on DTC” is used, see

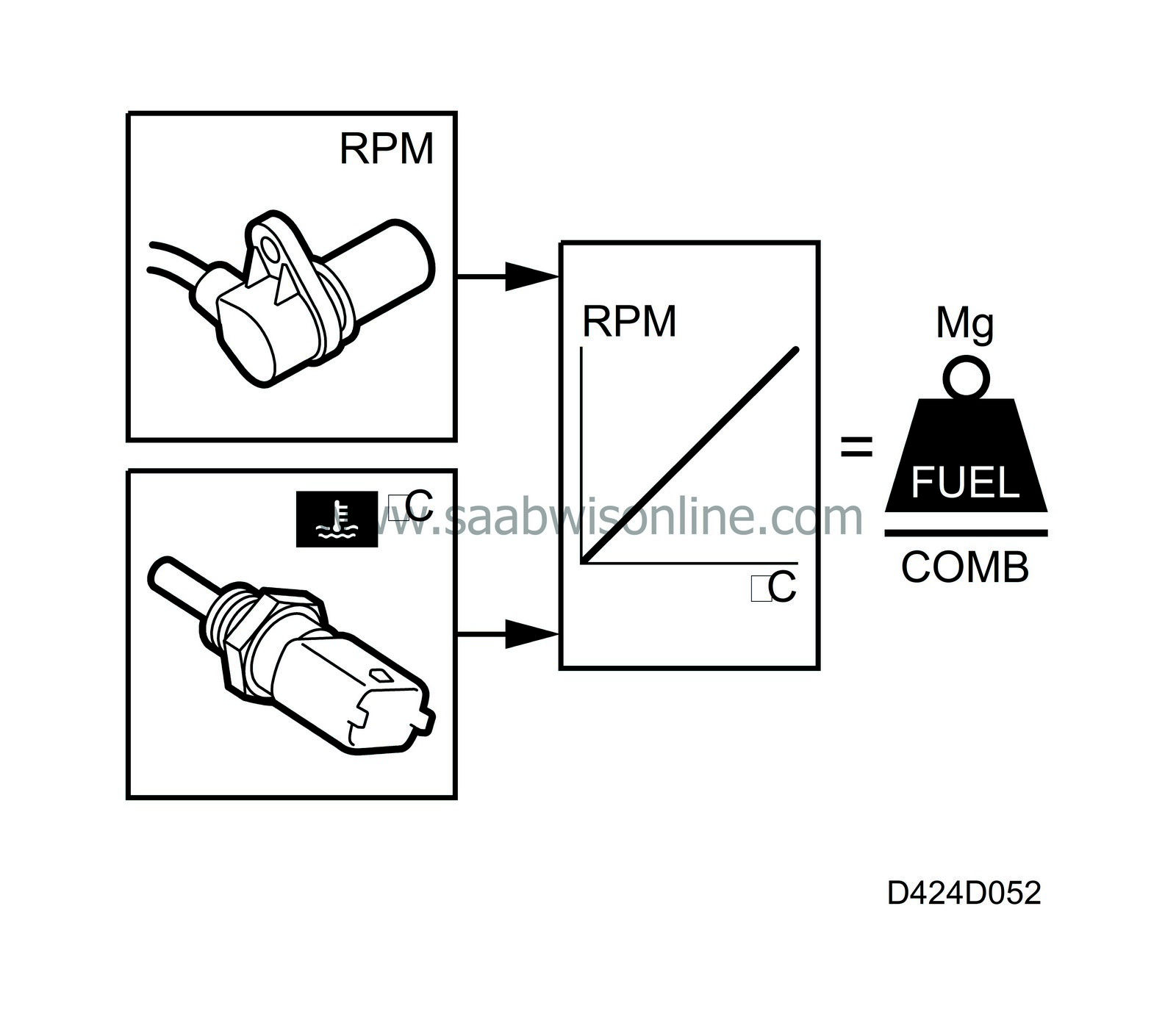

Temperature compensation

Enrichment is required when the engine is cold to ensure good driveability. On the other hand, if the engine is about to overheat, this function is activated to reduce the fuel quantity.

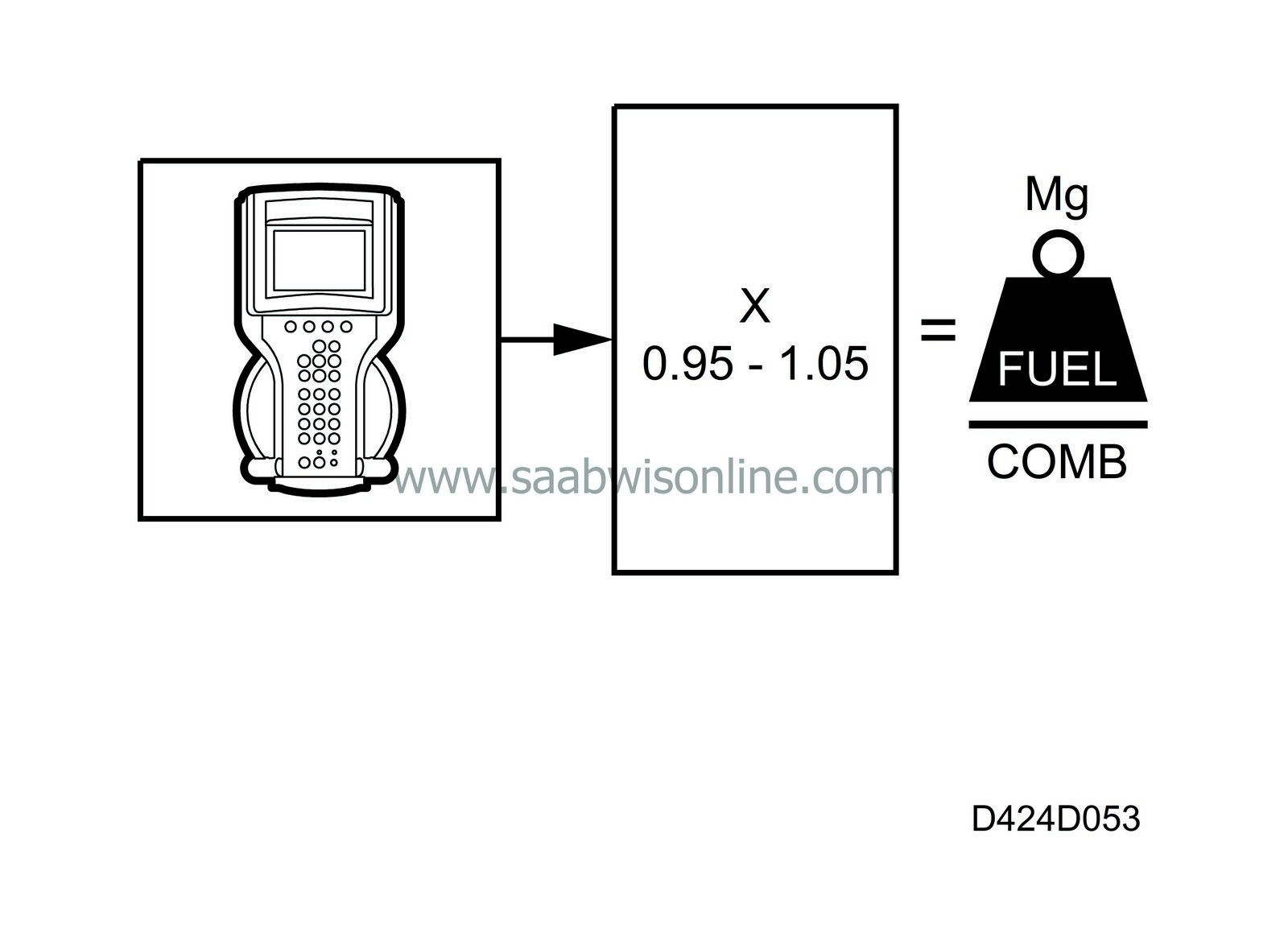

Quantity compensation

Due to variations in the diesel fuel, its density may vary. This means that at lower densities, the car will have less power than expected or, if the diesel fuel has a high density, the car will tend to issue more smoke from the exhaust. To compensate for this, there is a quantity compensation function that can be adjusted 5% using the diagnostic tool.The limits are quantity compensated by multiplying them by a value between 0.95 and 1.05 mg/combustion.

Boil protection

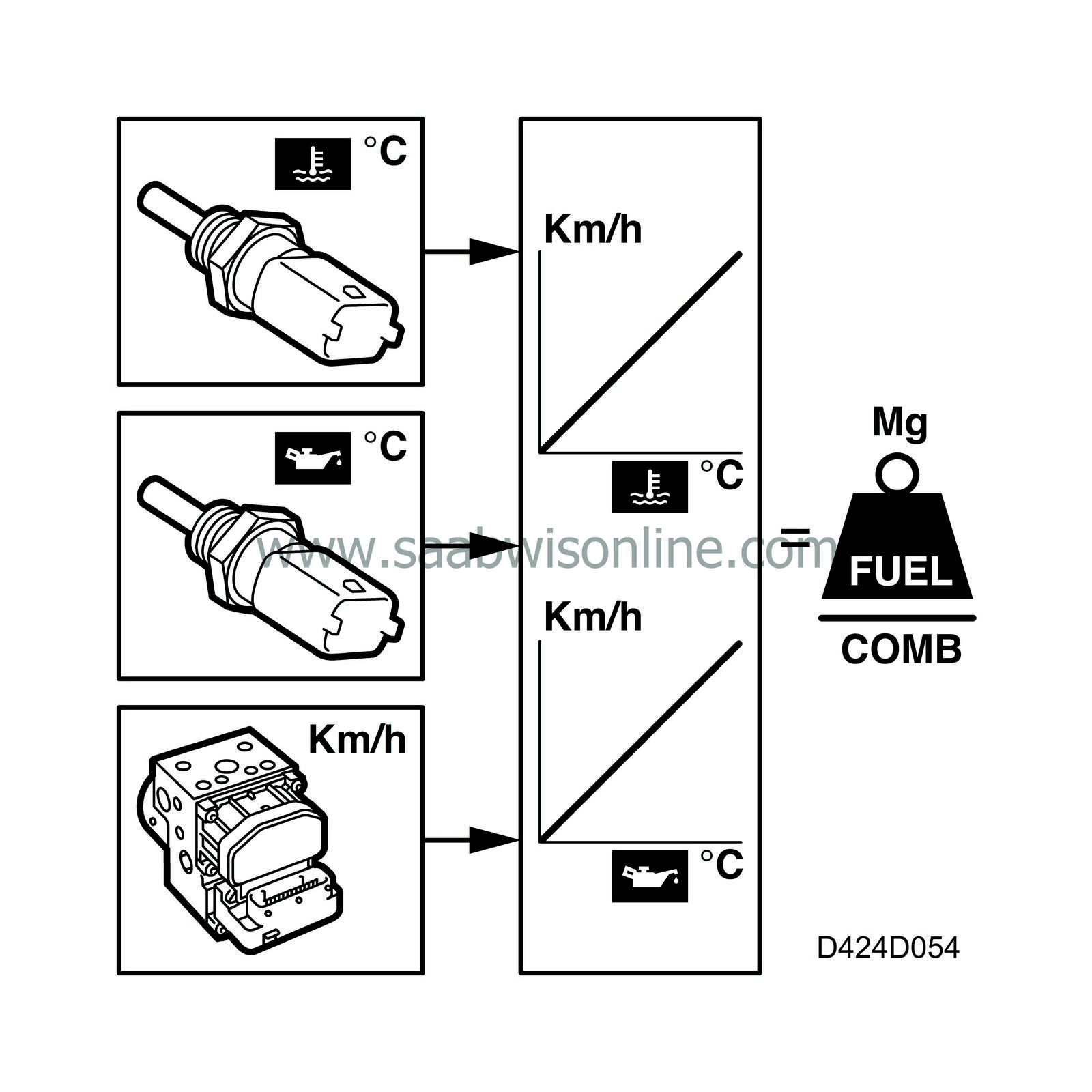

If the engine coolant temperature or engine oil temperature becomes too high, the boil protection is activated and the permitted fuel quantity is reduced.The boil protection function reduces the fuel quantity depending on the engine coolant temperature and the vehicle speed, or the engine oil temperature and the vehicle speed. The limit that results in the smallest injection quantity is the value that is applied.

The reduction is considerable and is clearly noticeable while driving. This occurs so that the engine temperature can be stabilized so that the engine is not damaged.

If boil protection has been activated, a diagnostic trouble code is generated that can be read on the diagnostic tool. The diagnostic trouble code is cleared after 60 starts with a fault-free system.

Requested quantity from accelerator position sensor

The value from the pedal position sensor is filtered in two stages during acceleration and deceleration respectively.A requested fuel quantity is read from a file based on the filtered pedal position value and the engine speed.

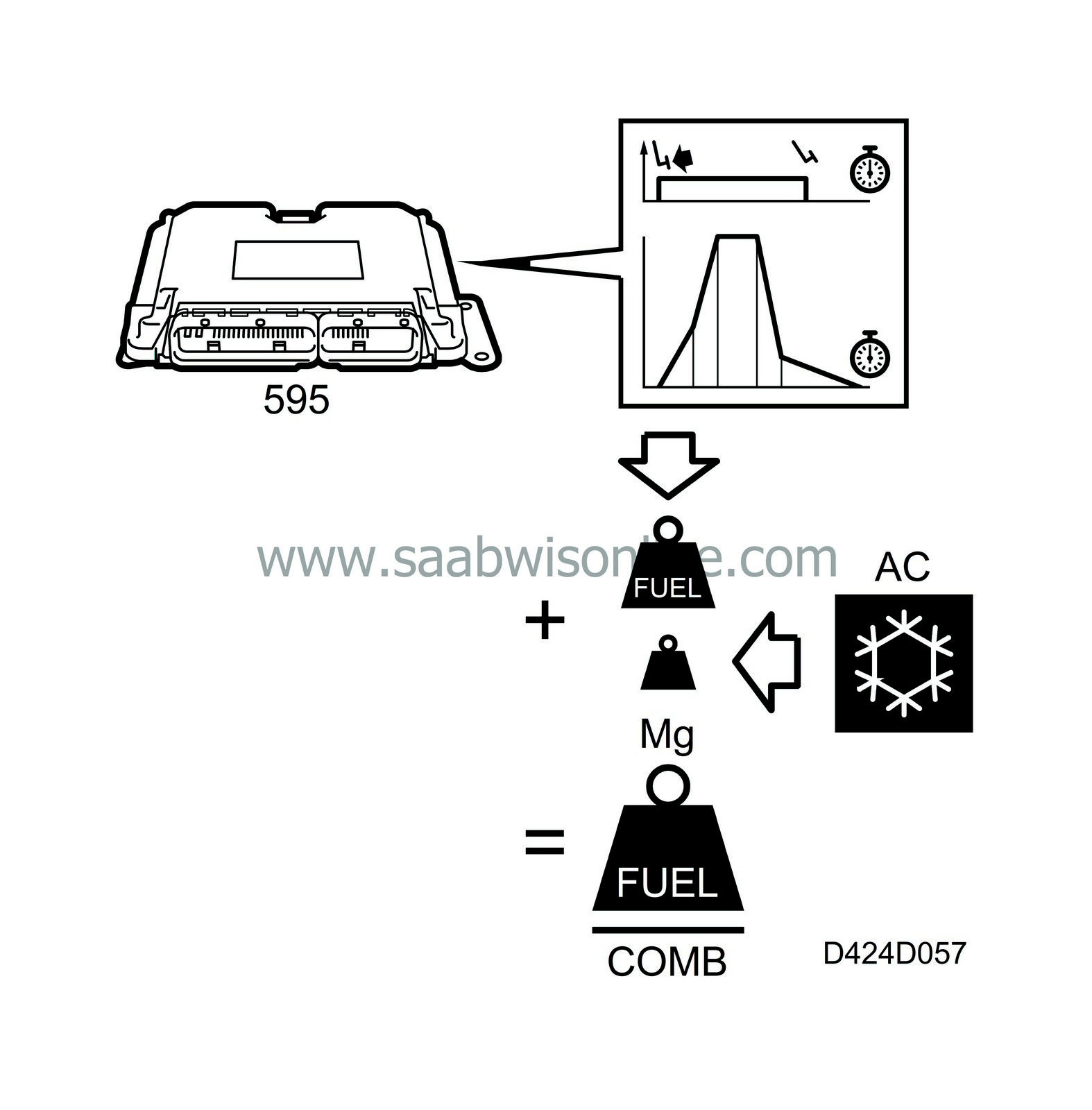

Compensation for A/C compressor operation

This function is activated when the A/C compressor starts, compensating for the extra torque that the A/C compressor takes from the engine with an extra fuel quantity/combustion.The compensation quantity from the "compensation A/C compressor operation" function is added to the value "requested quantity from pedal position sensor". The compensation fuel quantity depends on the pressure in the A/C system and is approx. 2-3 mg/combustion.

EDC 15 reads the A/C pressure on the bus.

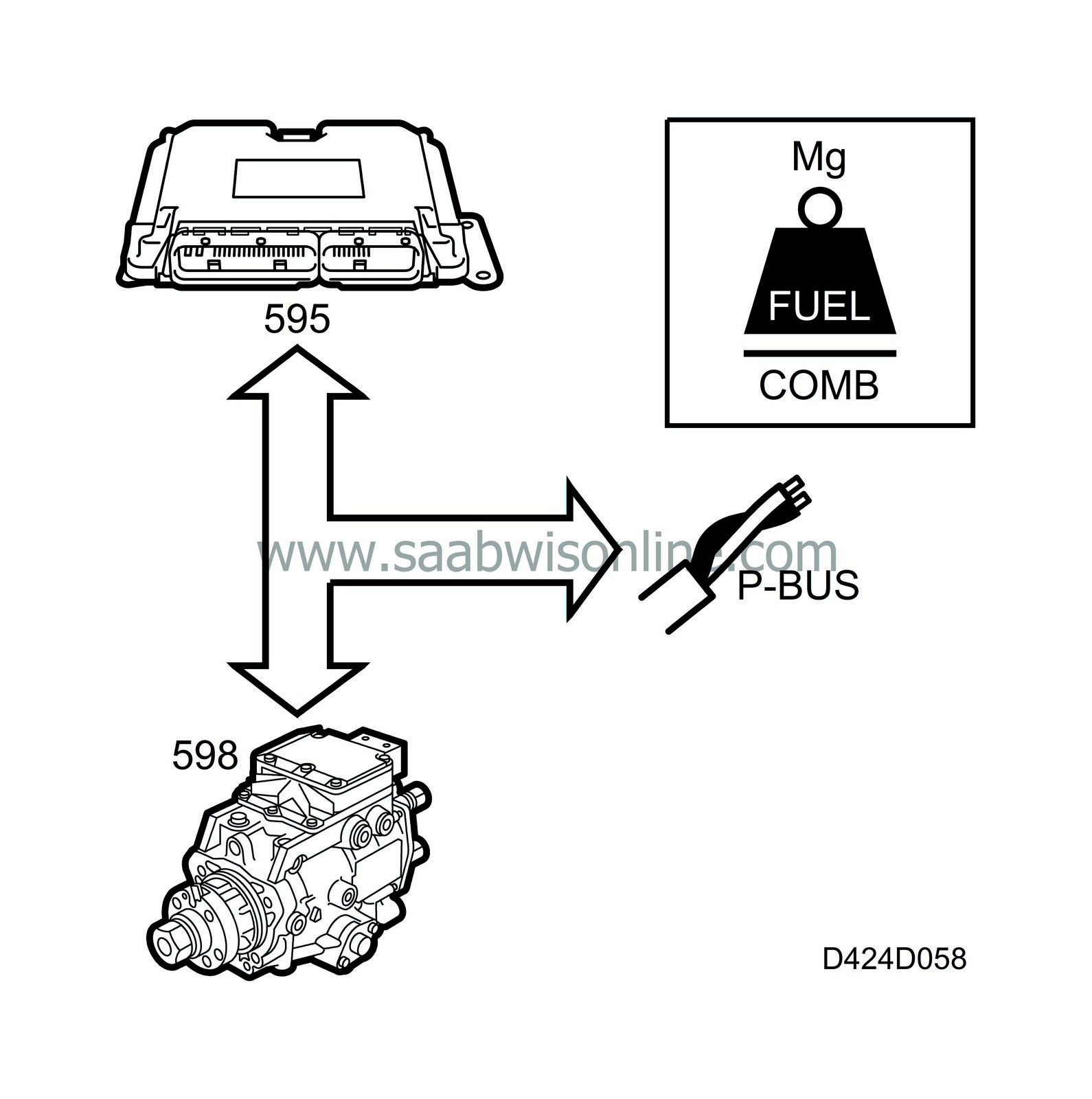

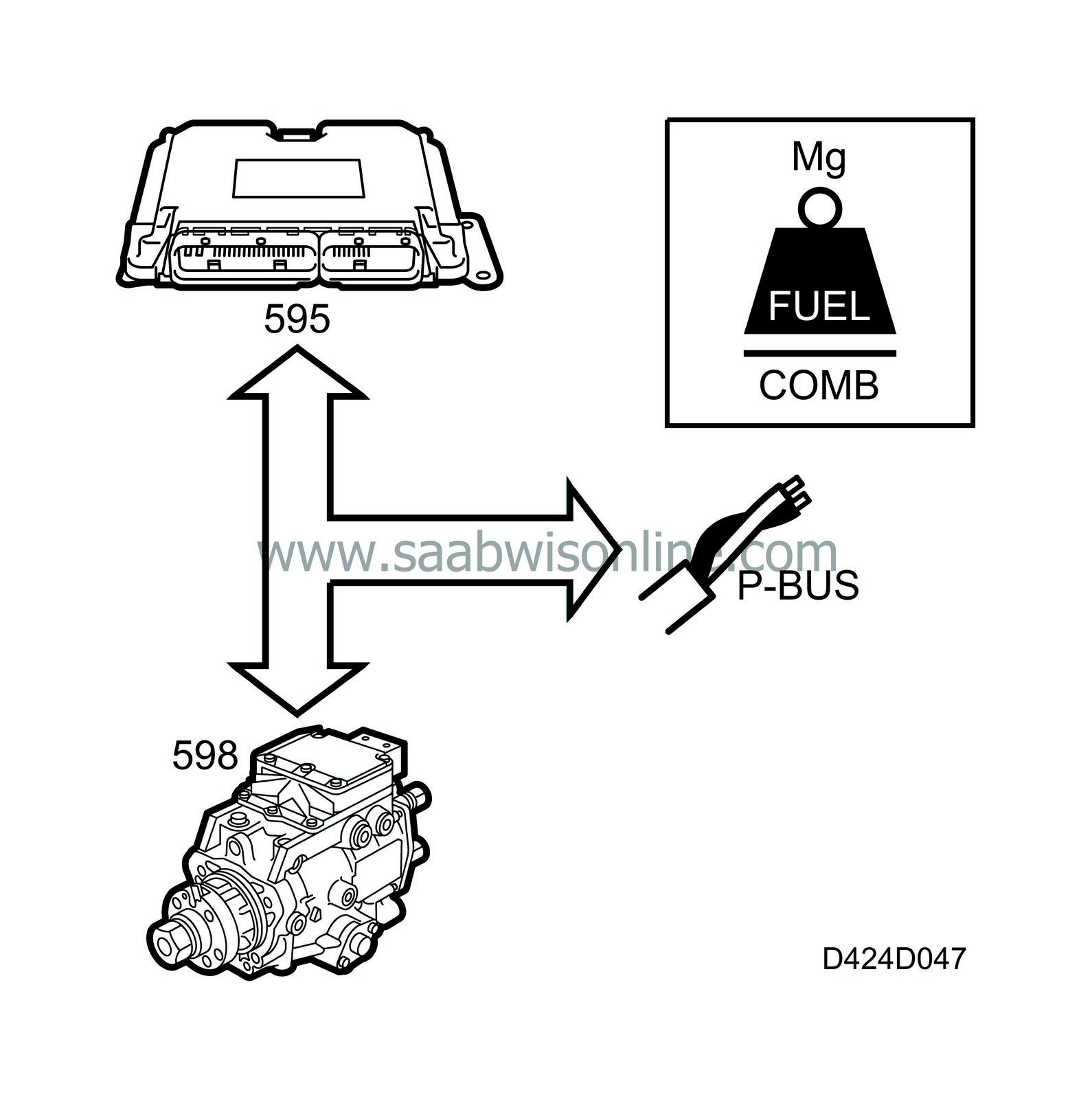

Control module calculations

The result from the calculations performed by the engine control module is sent on the P-bus and is read by the diesel pump control module, which processes the information as stated in the diesel pump description.