Oxygen sensor, closed loop

| Oxygen sensor, closed loop |

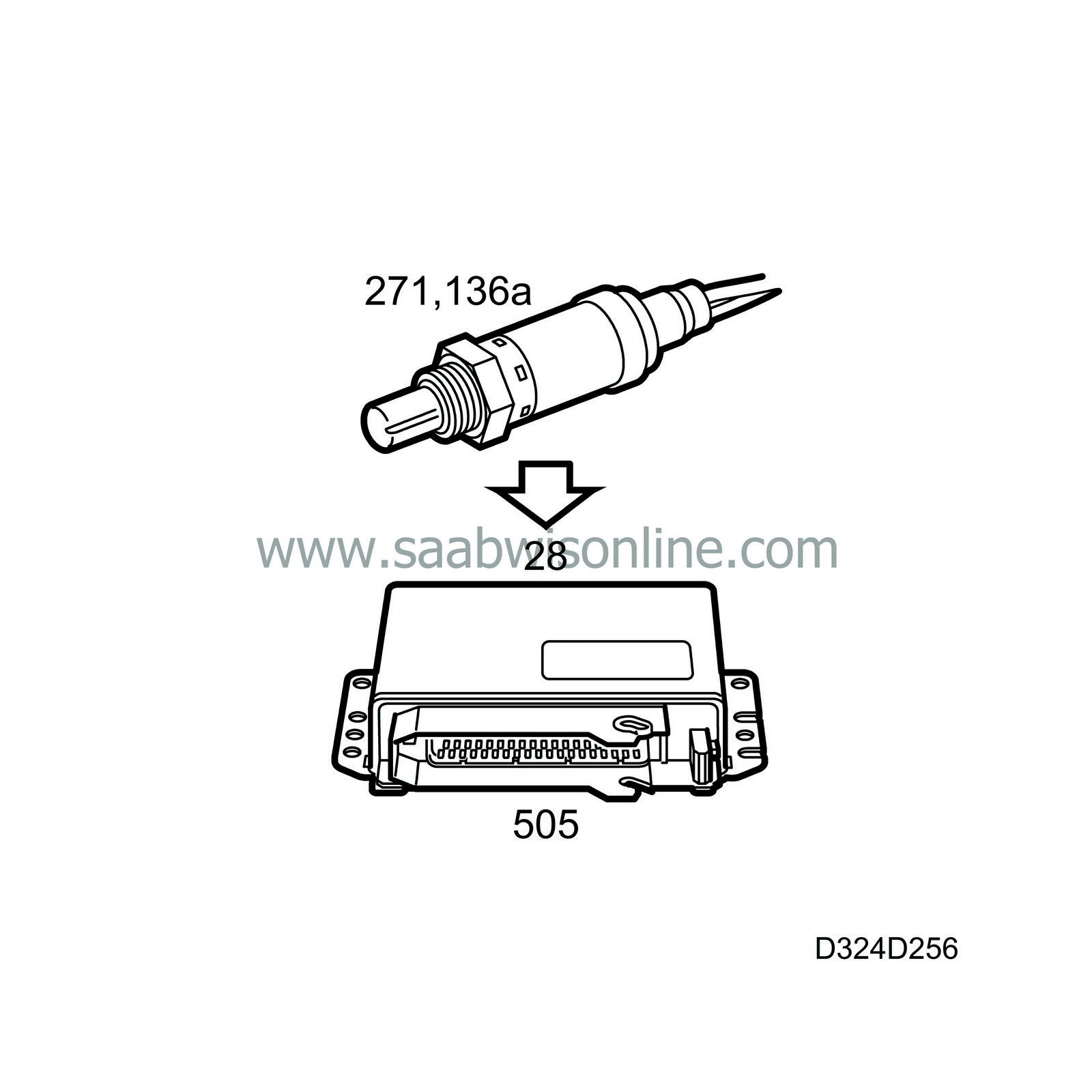

The oxygen sensor is mounted in the beginning of the exhaust pipe just behind the exhaust manifold and its task is to give the control module information about the exhaust gas composition (oxygen content).

The sensor consists of a primary cell with fixed ceramic electrolyte.

The inside of the ceramic element is in contact with the surrounding air while the outside of the element is in contact with the exhaust gases.

When the oxygen content in the exhaust gases increases, the pressure also increases on the ceramic element, which then emits a certain voltage.

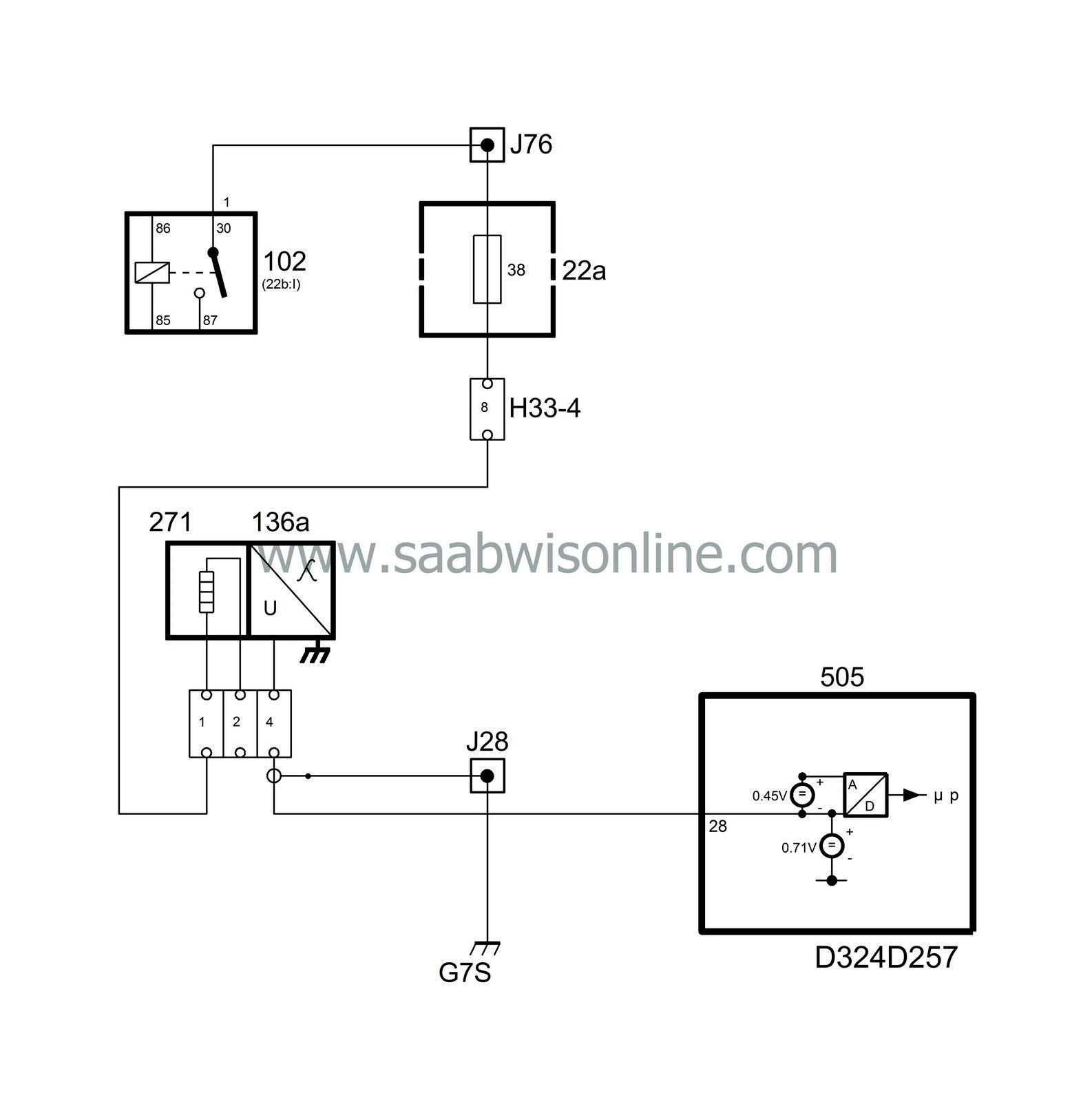

Information to the control module about the oxygen content in the exhaust gases goes from the control module pin 28. This information is handled very quickly by the control module, because it is one of the most important factors for determining the correct amount of fuel.

If the engine runs on a rich mixture, i.e. with a low oxygen content, the oxygen sensor emits a voltage up towards approx. 1 volt. On a lean mixture the voltage is very low or equal to 0 volts.

To work efficiently the sensor must be warm and to be able to quickly reach the ideal working temperature, the sensor is equipped with a heater element which receives its voltage from the fuel pump relay and is grounded at grounding point G7P.

When measuring with a voltmeter, the signal voltage can normally vary between 0.1-0.9 Volts.

If an open-circuit occurs in the sensor circuit, the control module sets a voltage value = 0.5 volts, which corresponds to lambda = 1.

| Markets with leaded petrol |

For markets with models adjusted to suit leaded petrol, an additional engine speed relay is fitted that breaks the oxygen sensors pre-heating circuit when the RPM output on the control module pin 6 indicates speeds above 3000 rpm. This is so the oxygen sensor will not overheat due to the powerful pre-heating output of 18 Watts.