Boost pressure control

| Boost pressure control |

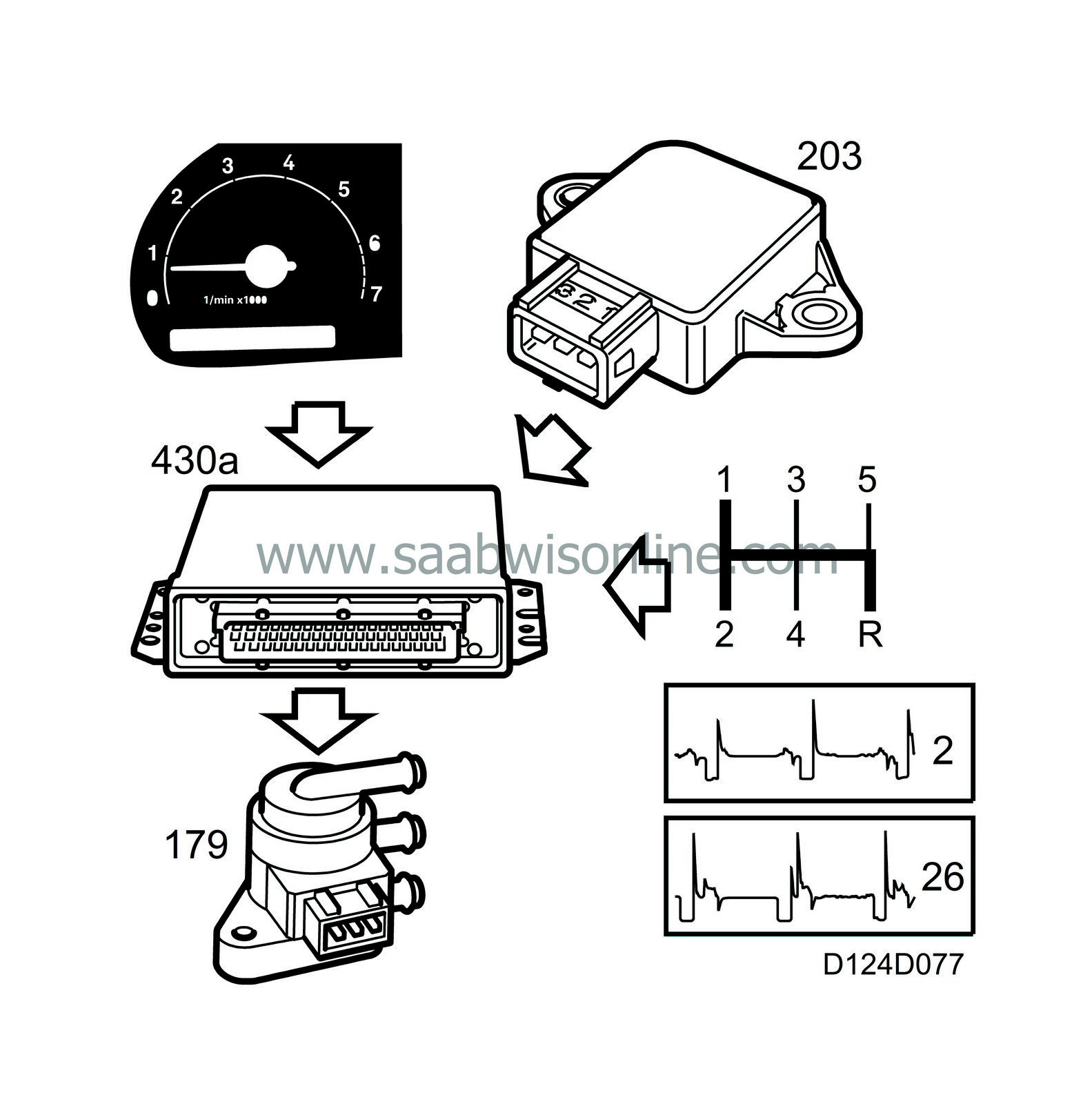

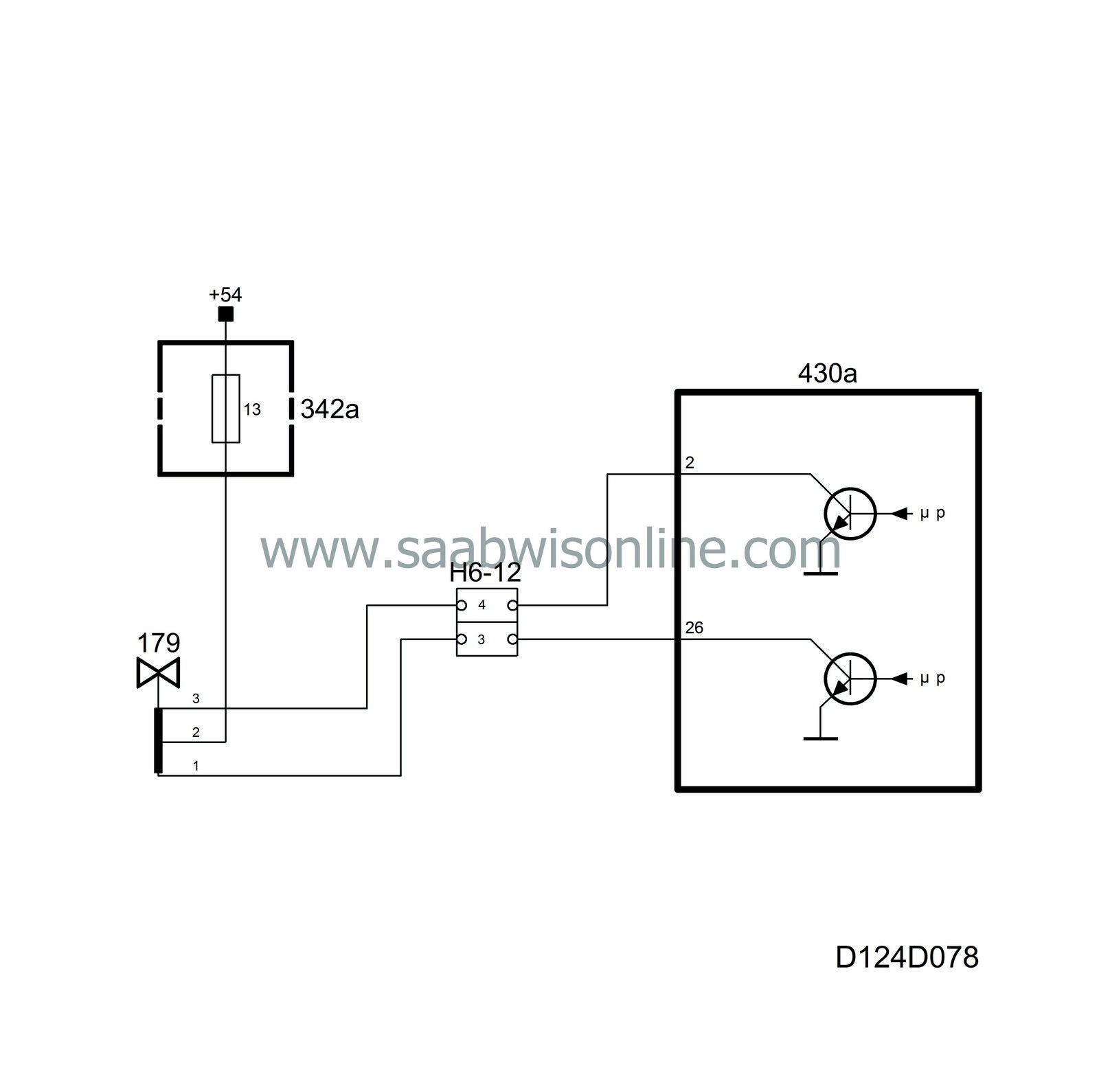

Boost pressure control takes place using a 2-coil, 3-way solenoid valve connected with hoses to the turbo wastegate, compressor outlet and compressor inlet.

The control valve is powered from +54 via fuse 24 and is controlled from control module pin 26 and pin 2. The control current is a PWM at 90 Hz below 2500 rpm and 70 Hz above 2500 rpm. The change in frequency at 2500 rpm is to avoid resonance in the air hoses.

By grounding pin 2 for longer than pin 26, the boost pressure will drop and vice versa, by grounding pin 26 for longer than pin 2, the boost pressure will rise.

To be able to regulate the boost pressure, the control module must first calculate a requested pressure, i.e. a value the system should try to attain. This is done as follows:

A requested boost pressure for every engine speed and throttle position is programmed in the control module memory. The pressure for each engine speed is chosen so that the desired torque curve is applied to the engine at wide open throttle.

The requested pressure will be limited in the following cases:

| • |

There is a maximum value for 1st, 2nd and reverse gear that is engine speed dependent. The control module calculates the gear position by comparing vehicle speed with engine speed.

|

|

| • |

A maximum value is set when knocking occurs that is dependent on the average ignition retardation on all cylinders.

|

|

| • |

When vehicle speed reaches 230 km/h (235 km/h for B204R).

|

|

In the following cases, there will be no boost pressure request at all (basic charging pressure):

| • |

When the brake pedal is depressed and the control module receives B+ on pin 15.

|

|

| • |

If certain DTCs are generated (throttle position sensor, pressure sensor or knock signal).

|

|

| • |

The following function is not implemented in the software at present: When cruise control is active and control module pin 36 is grounded.

|

|

Once the requested boost pressure is finally calculated, it is converted to a PWM to govern the boost pressure control valve.

The control module then makes sure the current pressure reading from the pressure sensor corresponds with the requested. If necessary, the PWM ratio will be adjusted by multiplying it with a correction factor.

The correction factor (adaptation) is stored in the control module memory and is always included in the calculation of the PWM ratio.

This is done so that the current pressure will equal the requested as soon as possible after a change in load.

| Diagnosis |

| • |

There is no diagnosis for a break or short in the circuit to the boost pressure control valve.

|

|

| • |

|

||||||||||||||||||||||||||||||||||||||||||||||