Checking and adjusting basic charging pressure

| Checking and adjusting basic charging pressure |

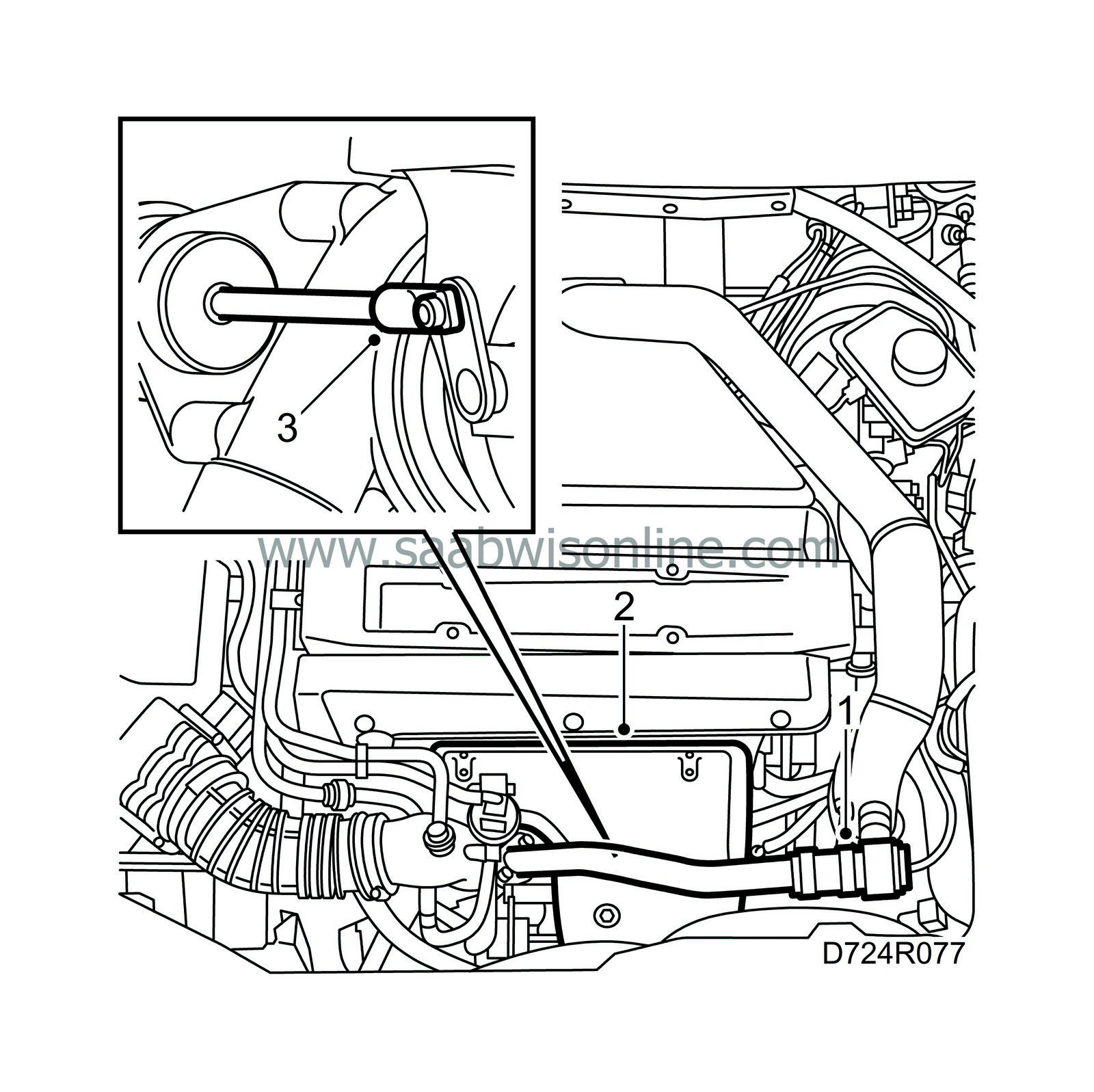

| 1. |

Remove the bypass pipe with valve.

|

|||||||

| 2. |

Remove the exhaust manifold heat shield.

|

|

| 3. |

Remove the operating arm clip with special tool (part no. 83 94 538).

|

|

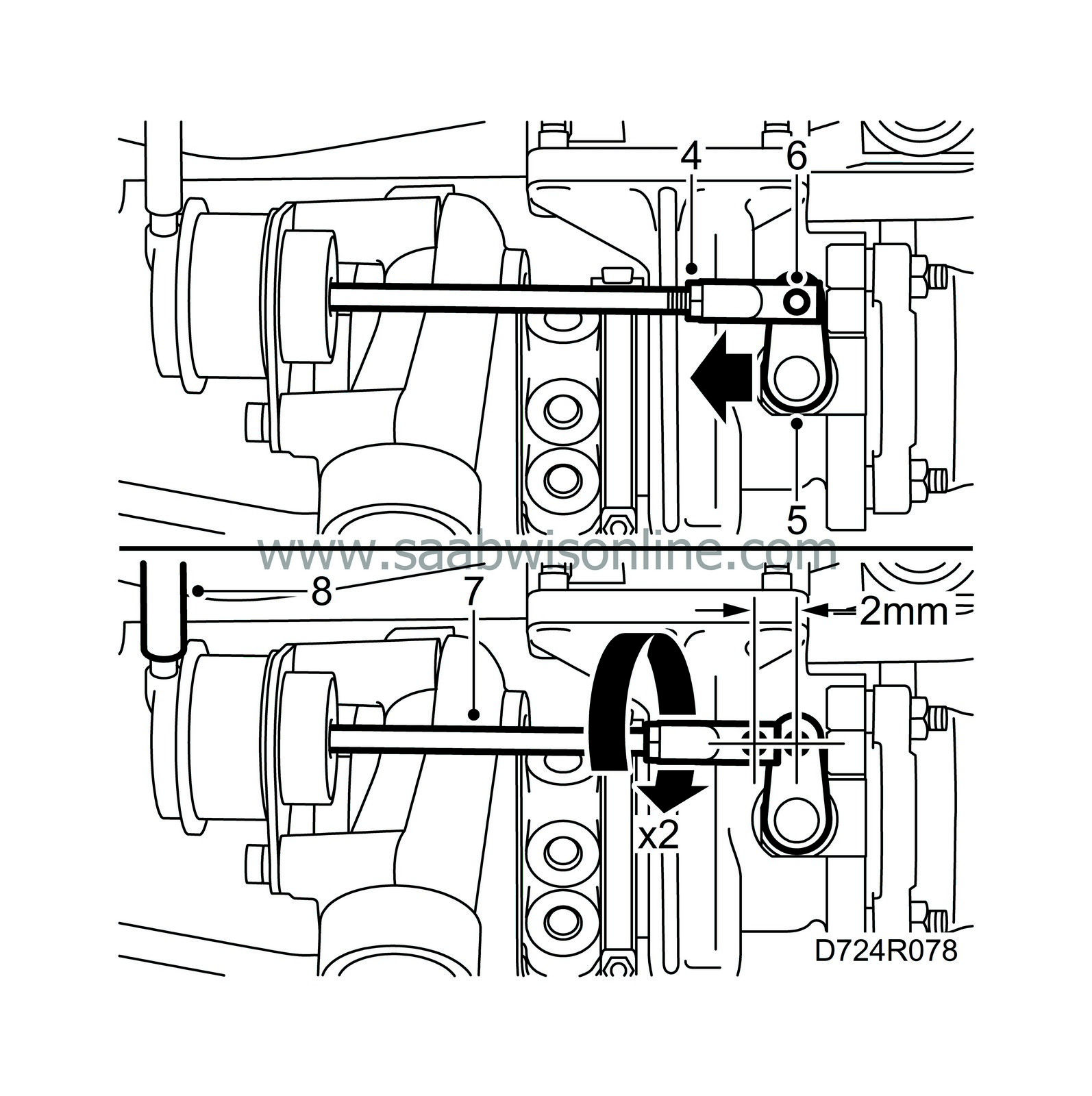

| 4. |

Grip the pushrod with pliers (part no. 83 94 066) or similar tool and undo the lock nut with special tool (part no. 83 94 520) or similar tool.

|

|

| 5. |

Hold the operating arm and undo the pushrod from the operating arm. Secure the control arm, otherwise there is risk of it “jumping over”.

|

|

| 6. |

Move the operating arm on the charge pressure control valve to the “Closed” position and adjust the end piece so that the pushrod can easily be fitted on the operating arm pin.

|

|

| 7. |

Detach the pushrod from the operating arm pin. Turn the end piece clockwise about 2 turns so that a prestress of 2 mm is obtained. Attach the pushrod to the operating arm pin. Fit the circlip.

|

|

| 8. |

Detach the hose marked “W” from the diaphragm.

|

|

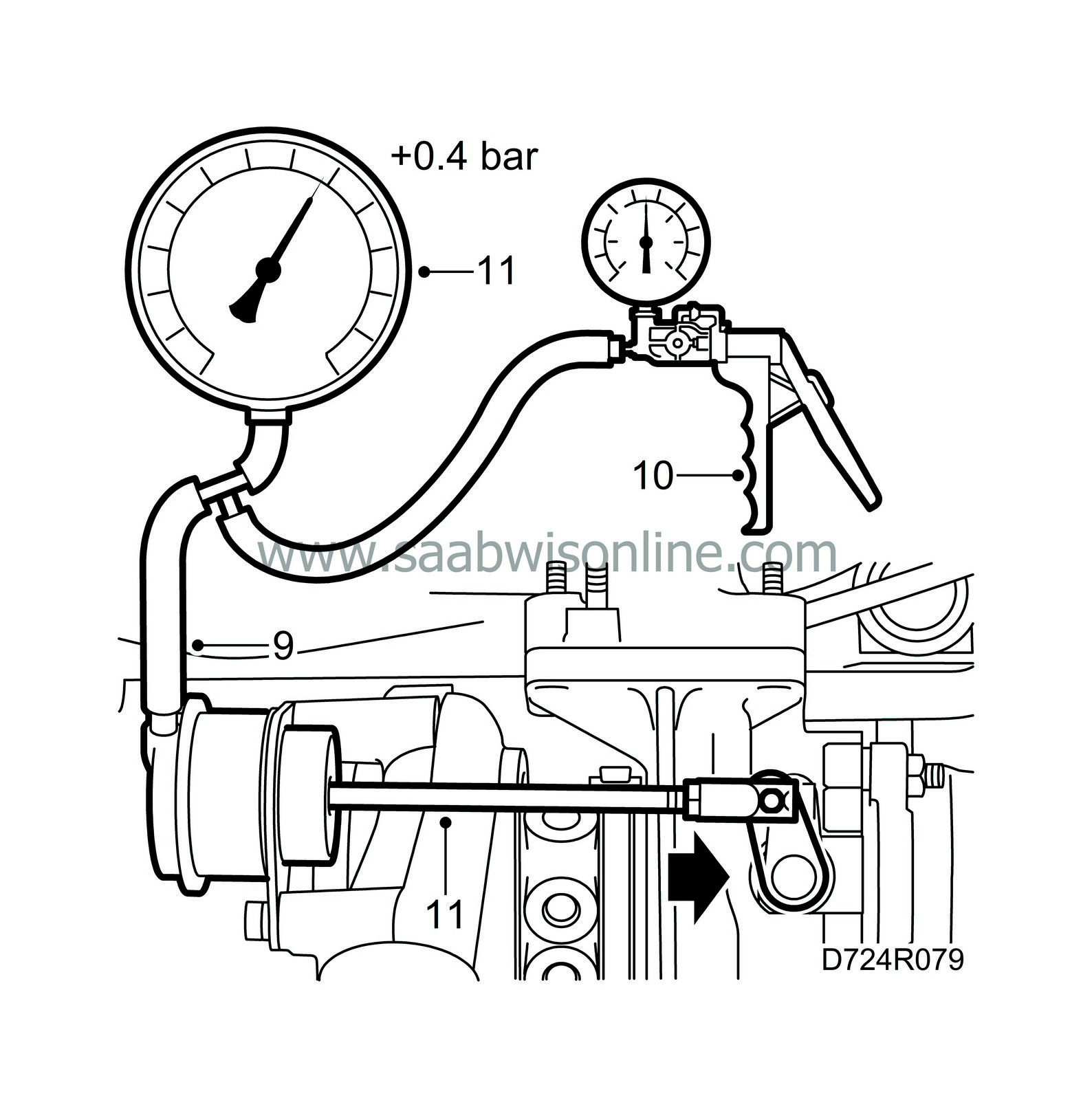

| 9. |

Connect the pressure/vacuum pump, part no. 30 14 883, to the diaphragm and the pressure gauge (part no. 83 93 514).

|

|

| 10. |

Carefully pump up pressure so that the control rod moves to regulate the charge pressure.

|

|

| 11. |

Read the pressure on the gauge scale just as the control rod starts to move. It should be at least 0.4 bar (but not abnormally high).

|

|

| 12. |

If the pressure is too low, shorten the rod until 0.4 bar is obtained.

|

|

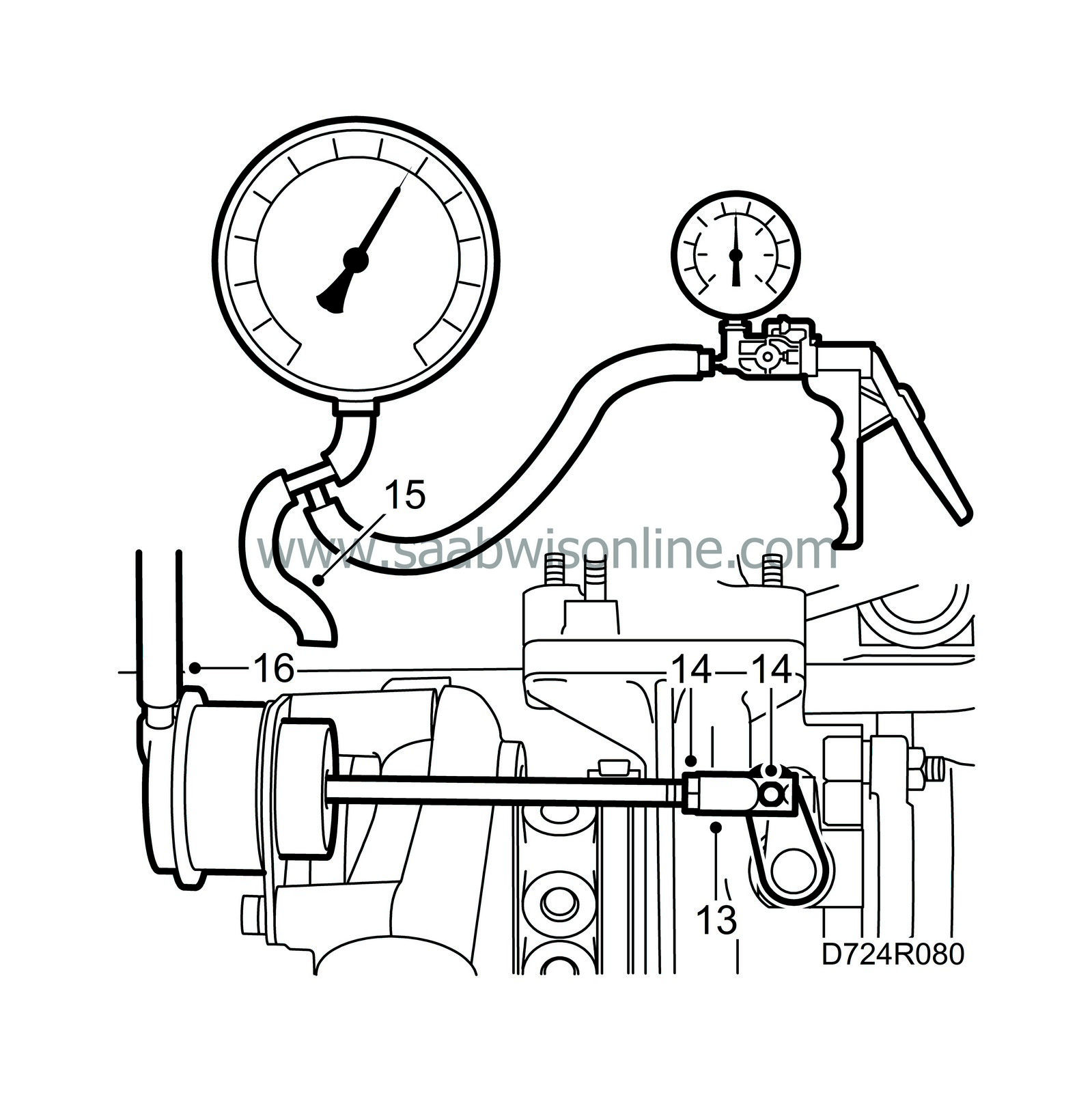

| 13. |

Undo the pushrod and apply a thin coat of Molykote 1000 (part no. 30 20 971) or equivalent to the pin on the operating arm.

|

|

| 14. |

Fit the pushrod and clip, grip the pushrod and lock the nut.

|

|

| 15. |

Disconnect the pressure gauge and pump.

|

|

| 16. |

Reconnect the hose to the diaphragm.

|

|

| 17. |

Fit the heat shield.

|

|

| 18. |

Lubricate the O-ring with non-acidic vaseline and fit the bypass pipe.

Tightening torque 8 Nm (5.9 lbf ft) |

|