Checking and adjusting basic charging pressure (B235R)

|

|

Checking and adjusting basic charging pressure (B235R)

|

|

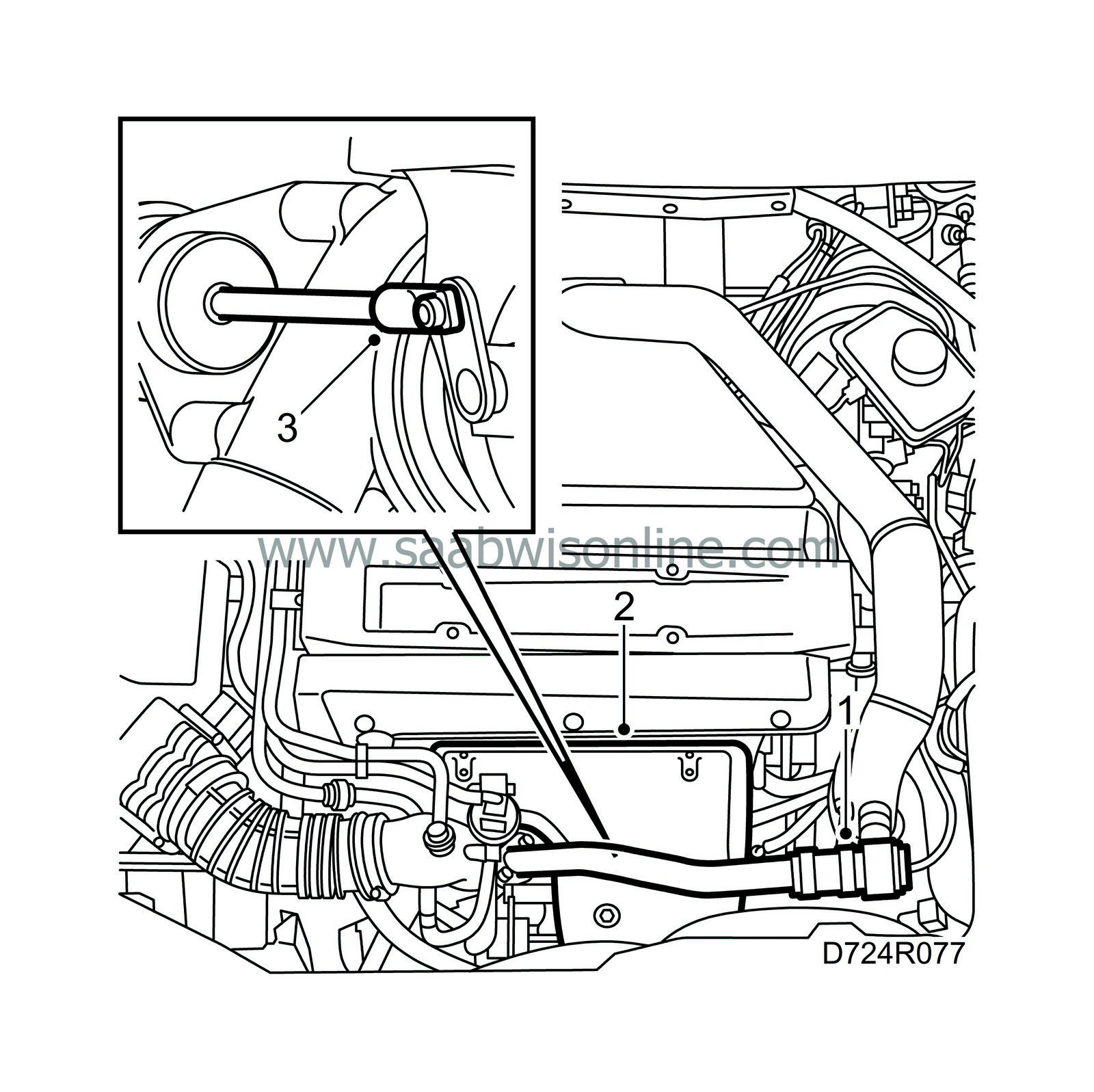

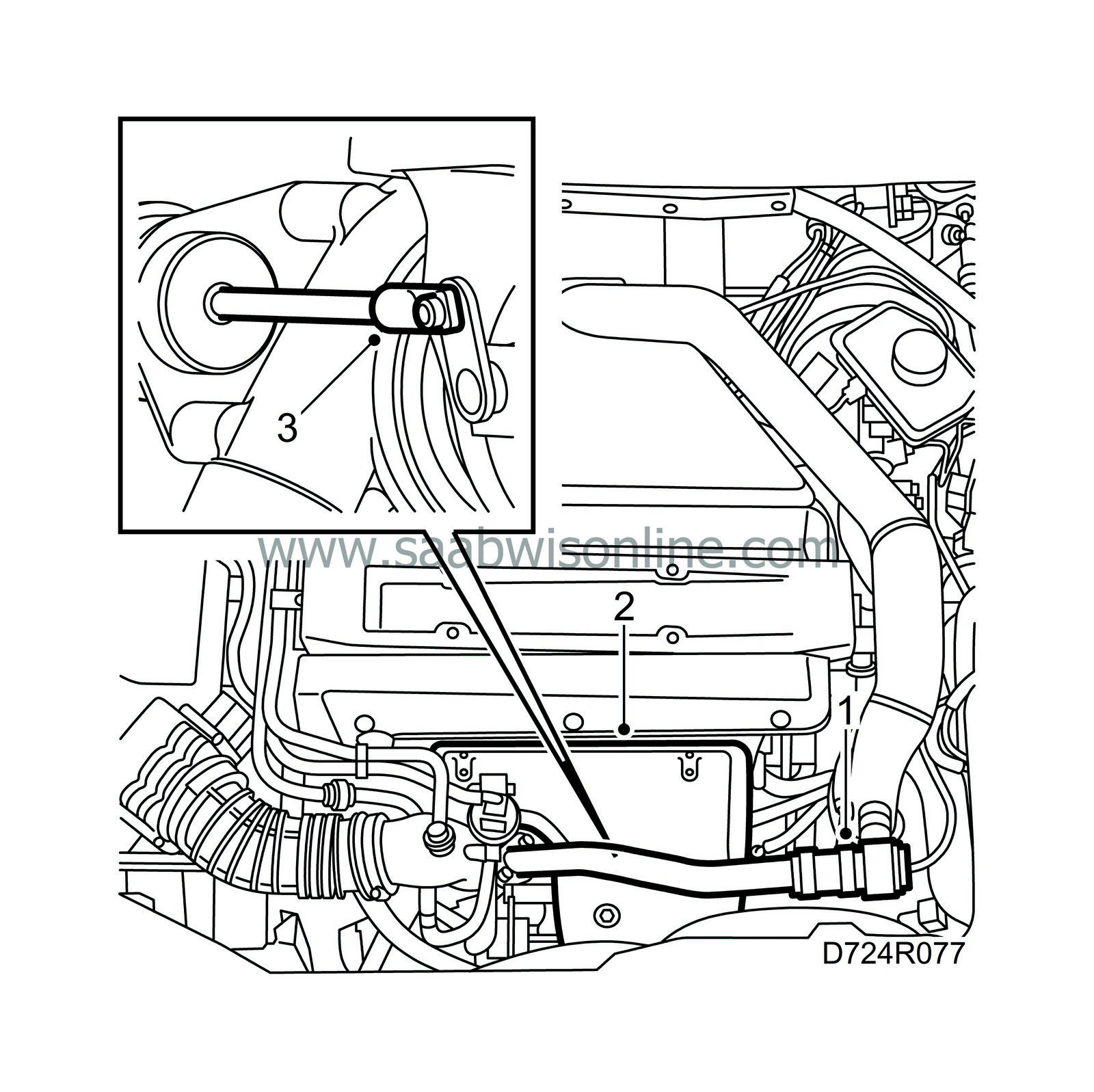

1.

|

Remove the bypass pipe with valve.

|

Note

|

|

There is an O-ring where the bypass pipe is fastened to the turbocharger inlet pipe.

|

|

|

2.

|

Remove the exhaust manifold heat shield. The heat shield is fastened with a nut and two clips underneath.

|

|

3.

|

Remove the locking clip on the operating arm with circlip pliers, part no. 83 94 538.

|

|

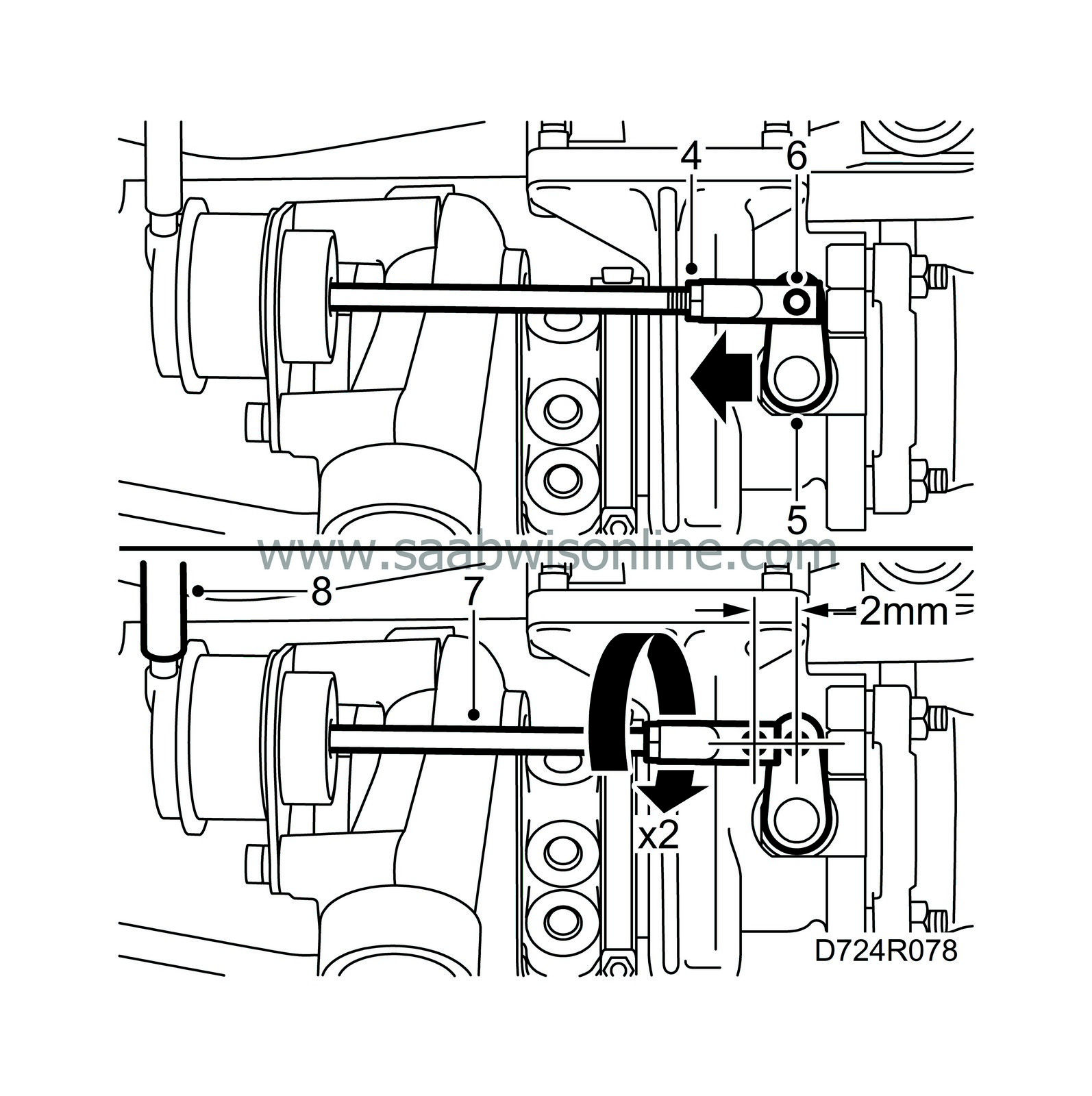

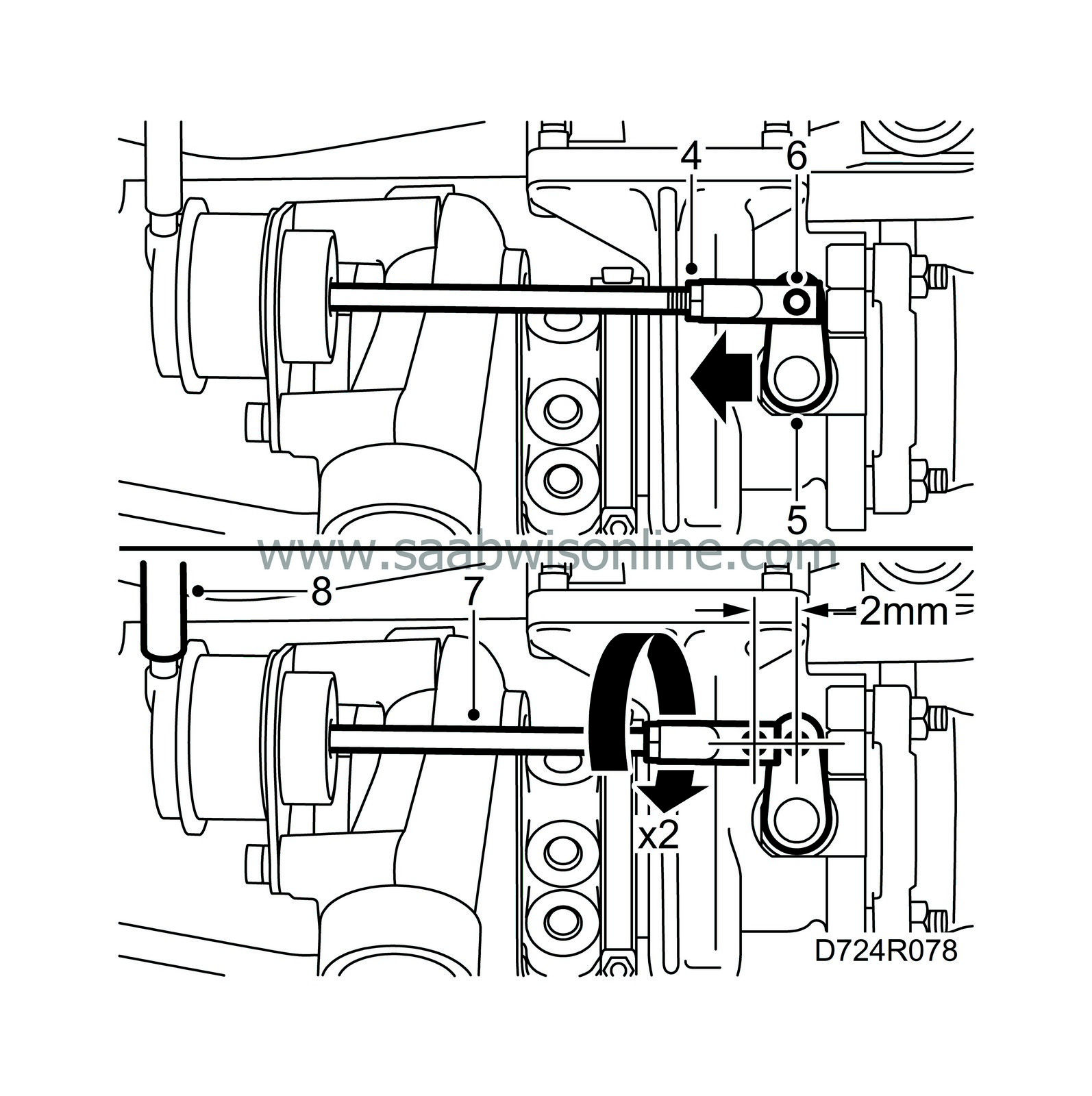

4.

|

Grip the pushrod with pliers, part no. 83 94 066 or similar tool. Undo the lock nut with spanner, part no. 83 94 520 or equivalent.

|

|

5.

|

Hold the operating arm and detach the pushrod. Secure the arm. Otherwise, the operating arm may ”jump over”.

|

|

6.

|

Move the operating arm on the boost pressure control valve towards ”Closed” and adjust the end piece so that the pushrod fits easily on the operating arm pin.

|

|

7.

|

Detach the pushrod from the control arm pin. Turn the end piece clockwise approx. 2 turns so that a 2 mm tension is achieved. Hook on the pushrod to the operating arm pin. Fit the locking ring.

|

|

8.

|

Detach the hose from the diaphragm box.

|

|

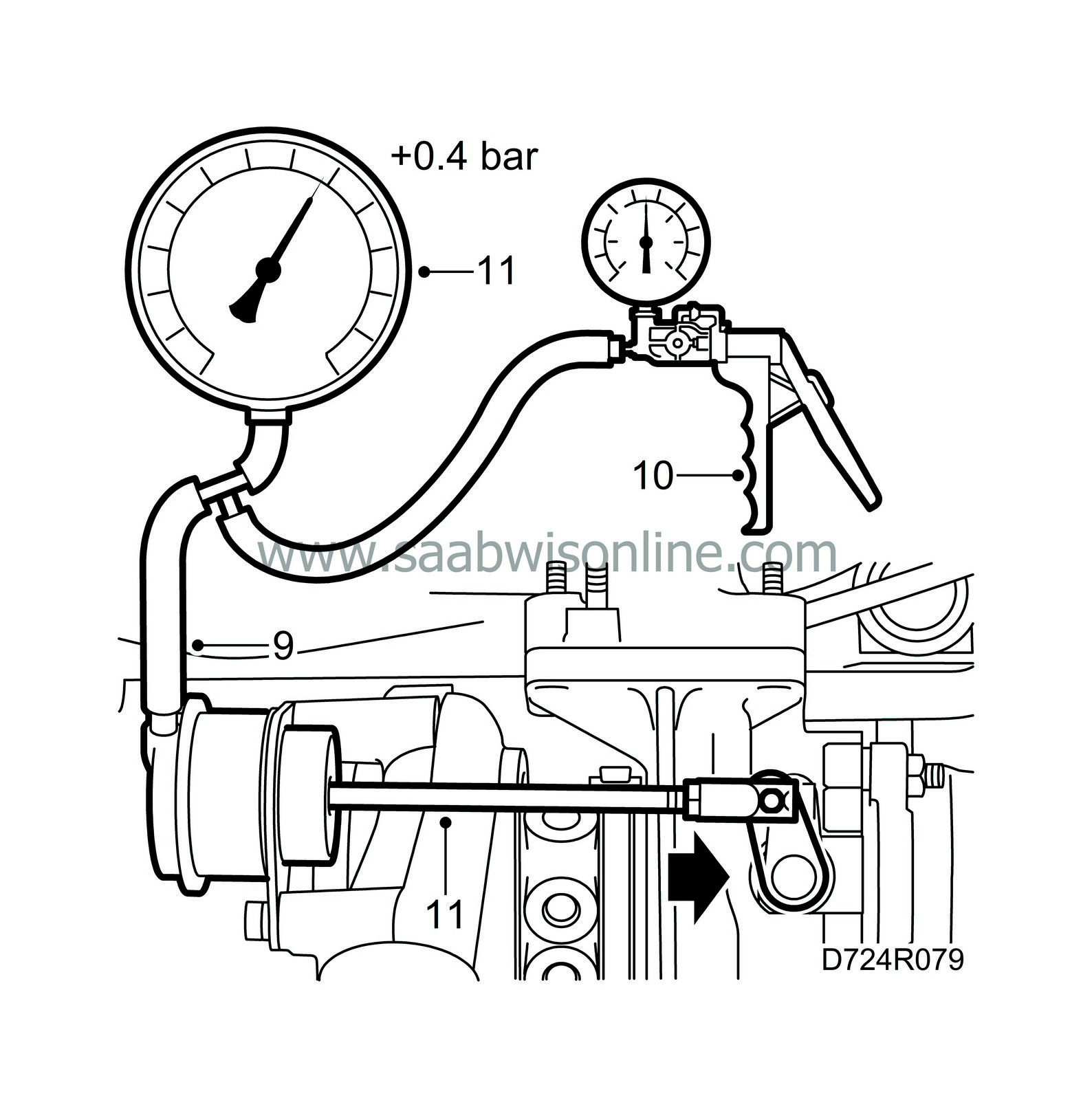

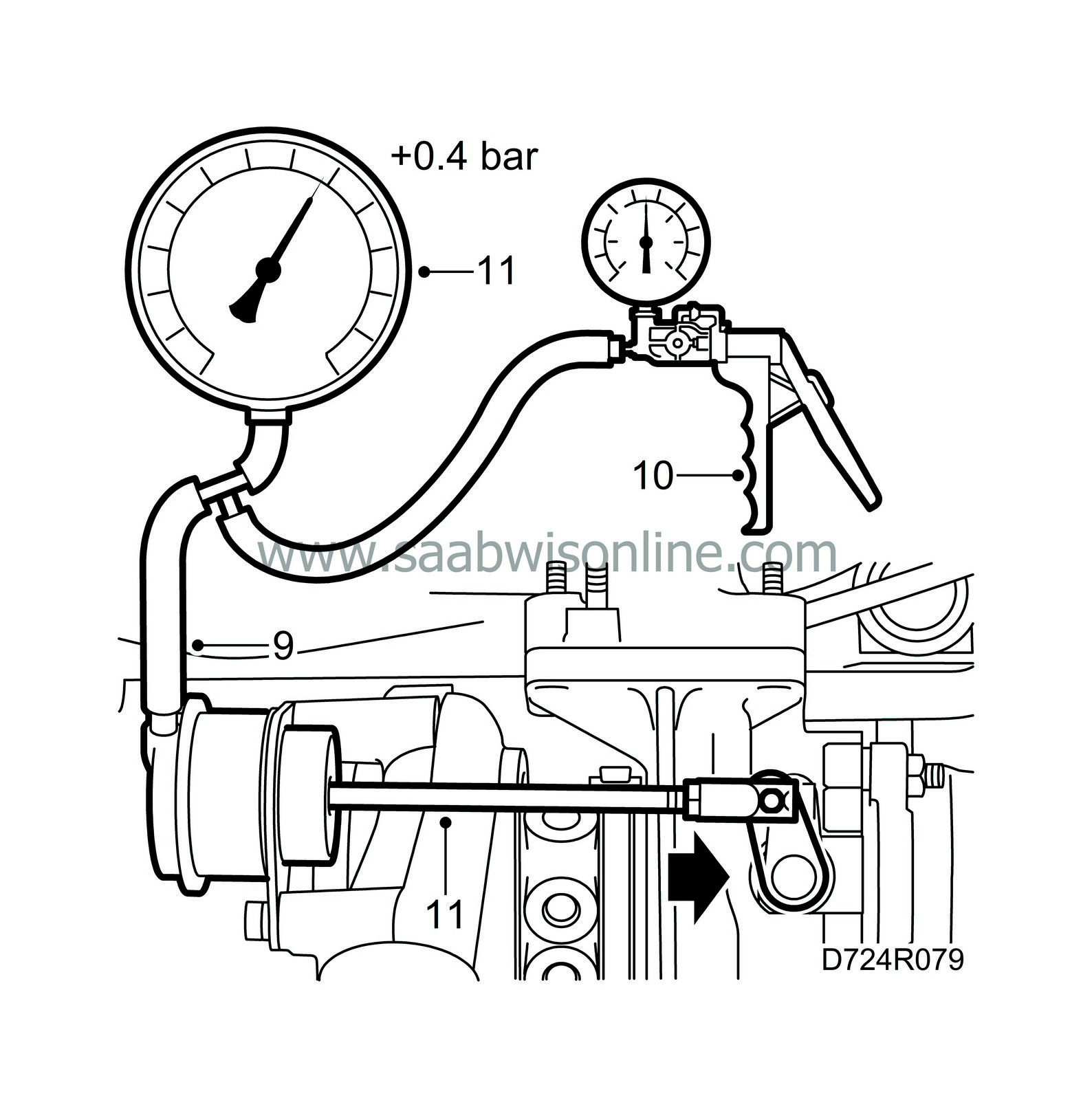

9.

|

Connect pressure/vacuum pump, part no. 30 14 883, to the diaphragm box and pressure gauge, part no. 83 93 514.

|

|

10.

|

Carefully pump up pressure until the control rod moves to regulate the boost pressure.

|

|

11.

|

Just as the control rod starts to move, read off the pressure on the pressure gauge. It should be 0.45 bar (±0.03 bar).

|

|

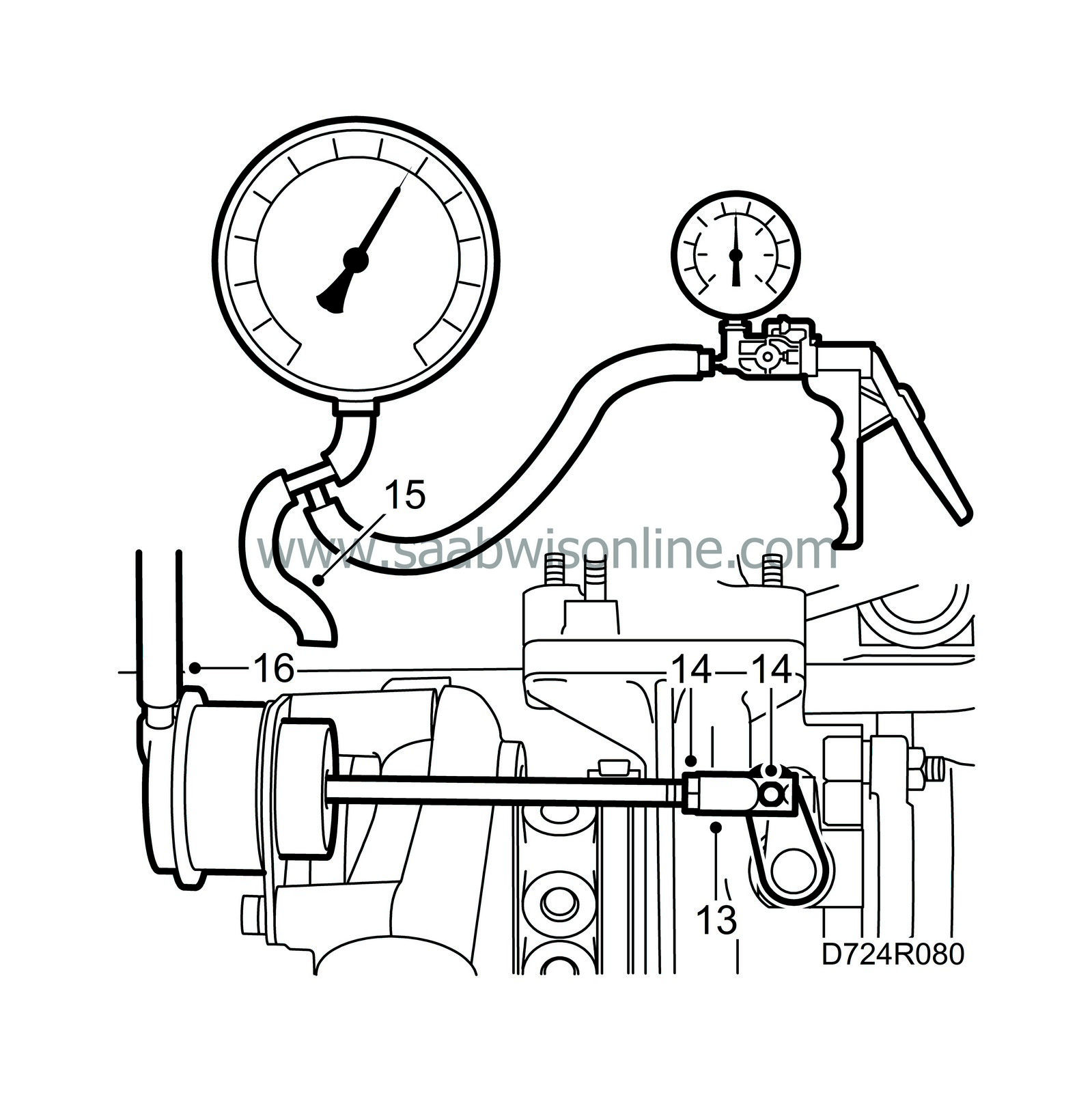

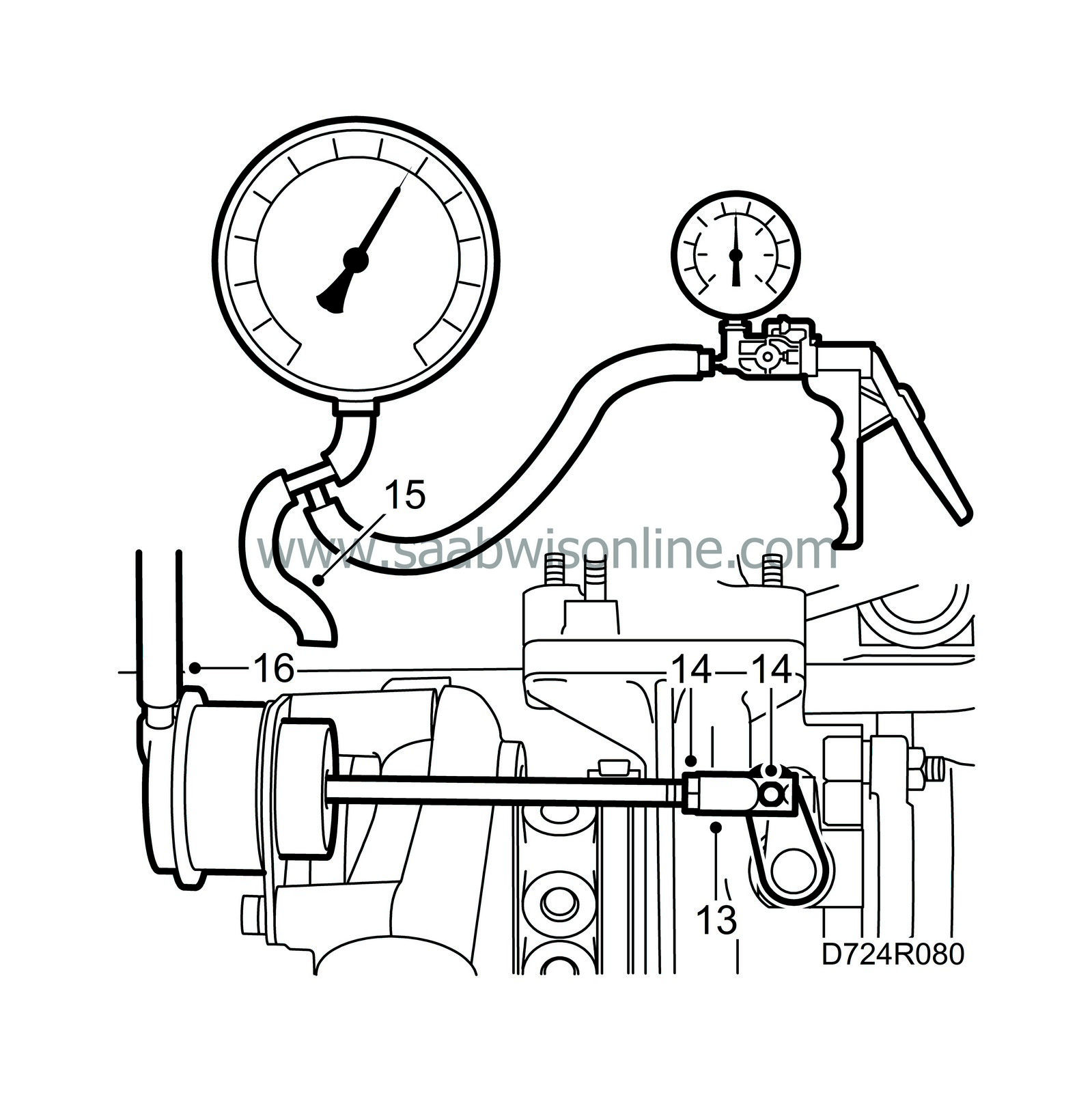

12.

|

Shorten the rod if the pressure is too low until 0.45 bar is obtained.

|

|

13.

|

Undo the pushrod and apply Molykote 1000, part no. 30 20 971, or equivalent to the pin on the operating arm.

|

|

14.

|

Fit the pushrod and clip, grip the pushrod with a pair of adjustable pliers and lock the nut.

|

|

15.

|

Remove the pressure gauge and pump.

|

|

16.

|

Reconnect the hose to the diaphragm box.

|

|

17.

|

Fit the heat shield.

|

|

18.

|

Lubricate the O-ring with acid-free petroleum jelly and fit the bypass pipe.

Tightening torque: 8 Nm (5.9 lbf ft)

|