Turbocharger (B235R)

| Turbocharger (B235R) |

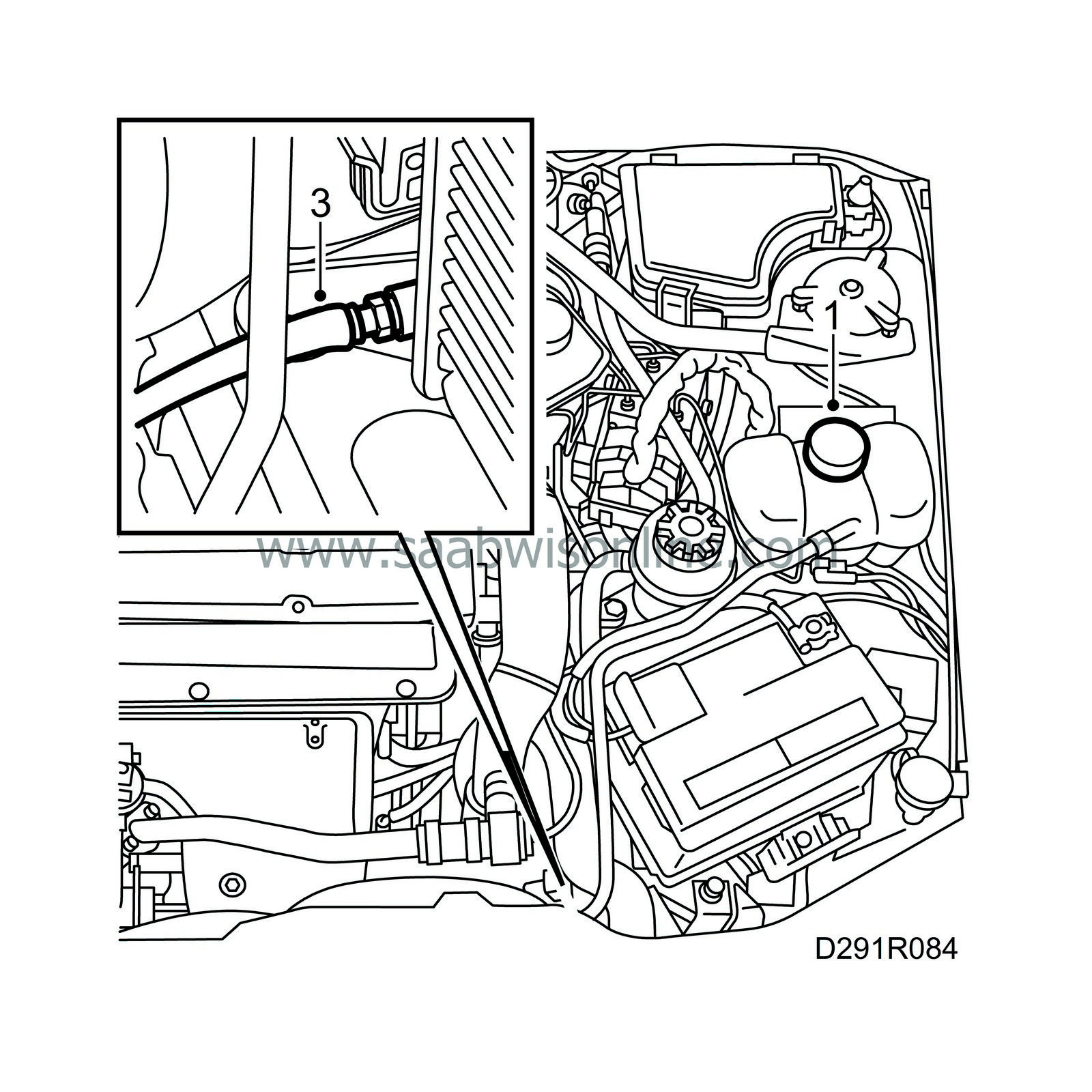

| 1. |

Open the expansion tank cap to release system pressure.

|

|

| 2. |

Raise the car.

|

|

| 3. |

Drain the engine coolant by connecting a hose and opening the drain plug. Collect the coolant in a receptacle.

|

|

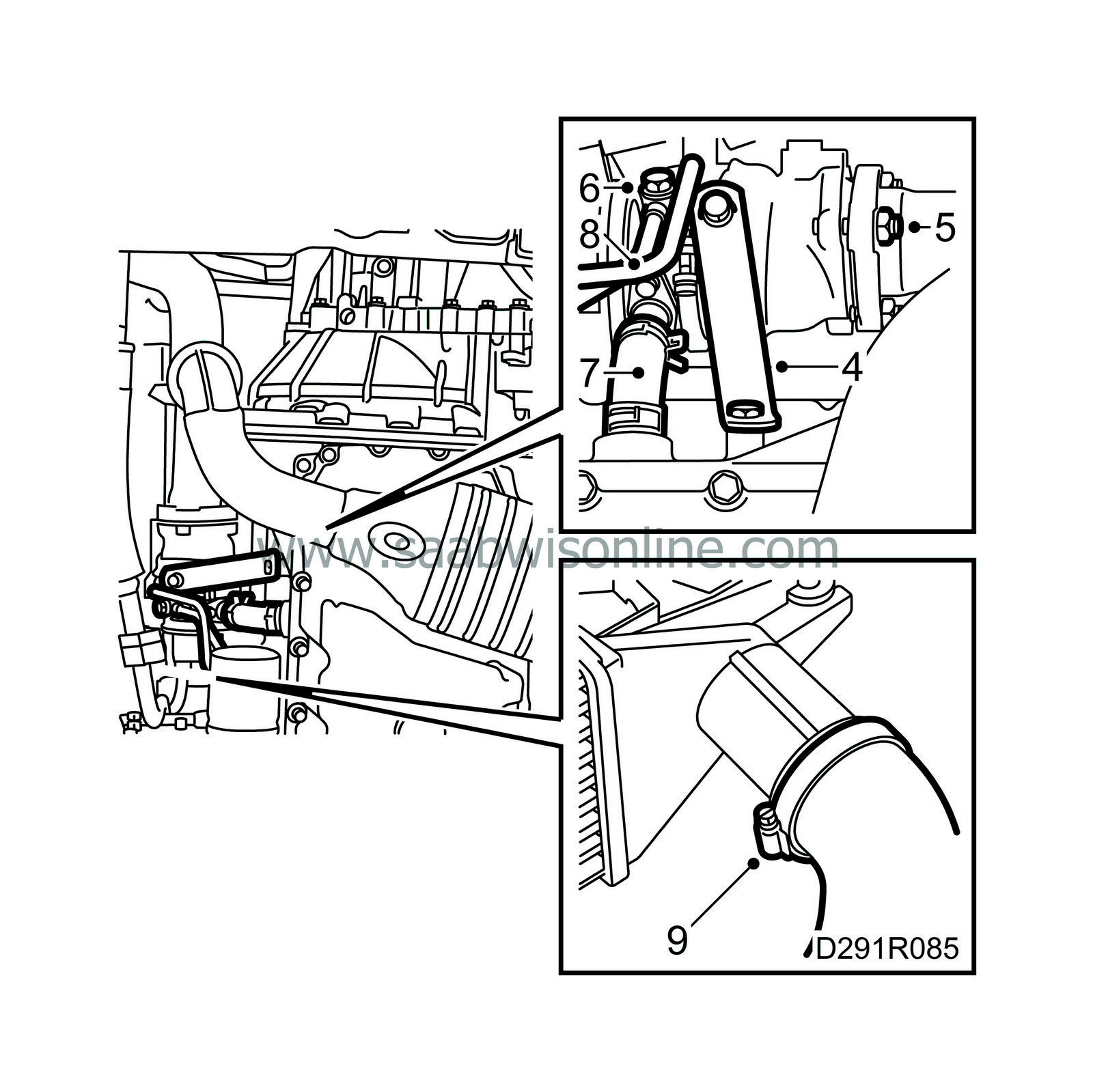

| 4. |

Remove the turbocharger stay.

|

|

| 5. |

Undo the bottom nut on the joint between the turbocharger and the front exhaust pipe.

|

|

| 6. |

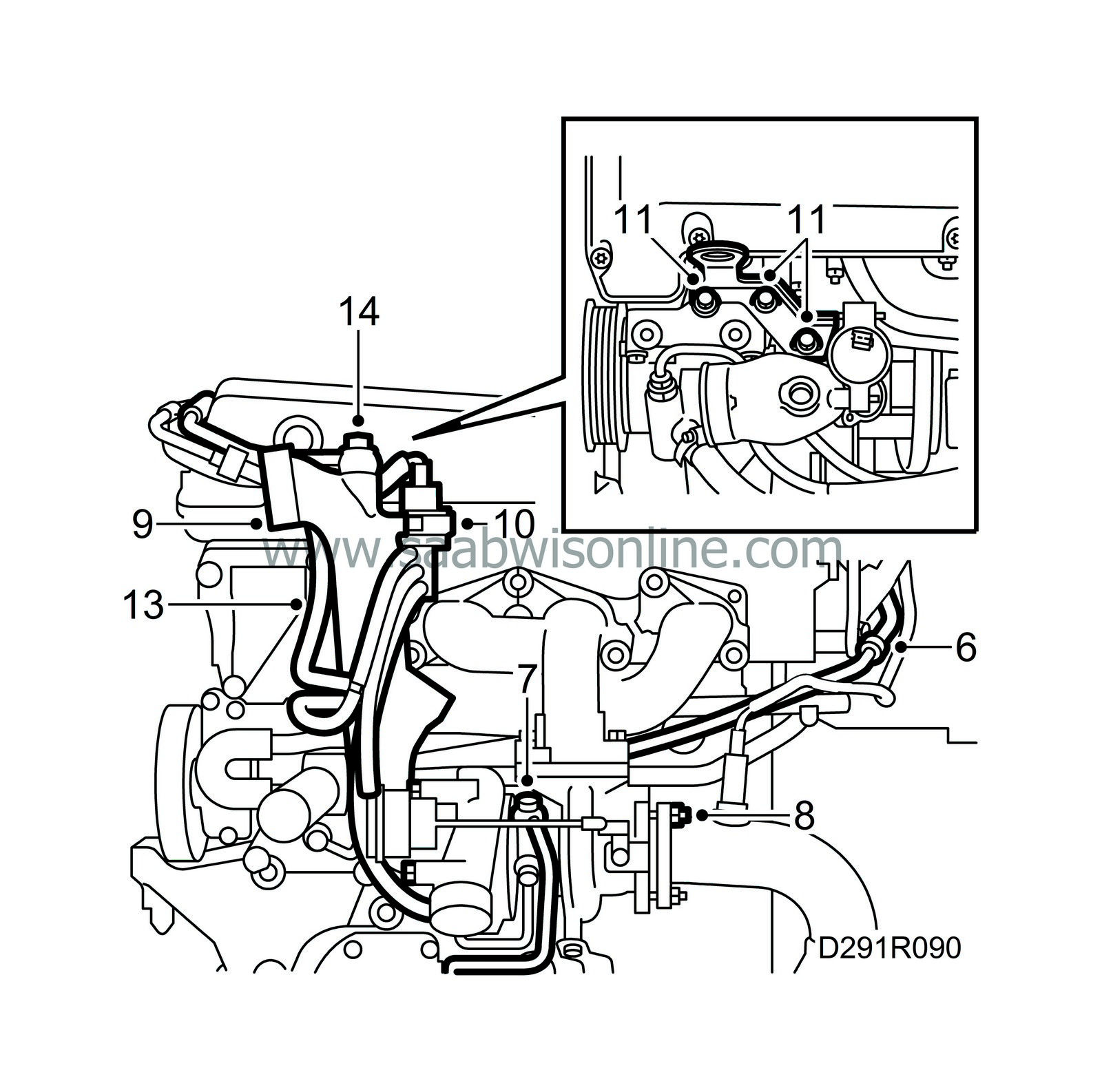

Detach the coolant pipe from the turbocharger.

|

|

| 7. |

Undo the oil return pipe between the turbocharger and the cylinder block. Plug the hole in the block.

|

|

| 8. |

Detach the oil pipe from the oil filter adapter.

|

|

| 9. |

Detach the turbocharger outlet hose from the charge air cooler, plugging the turbocharger outlet with plug no. 83 94 595 or similar.

|

|

| 10. |

Lower the car to the floor.

|

|

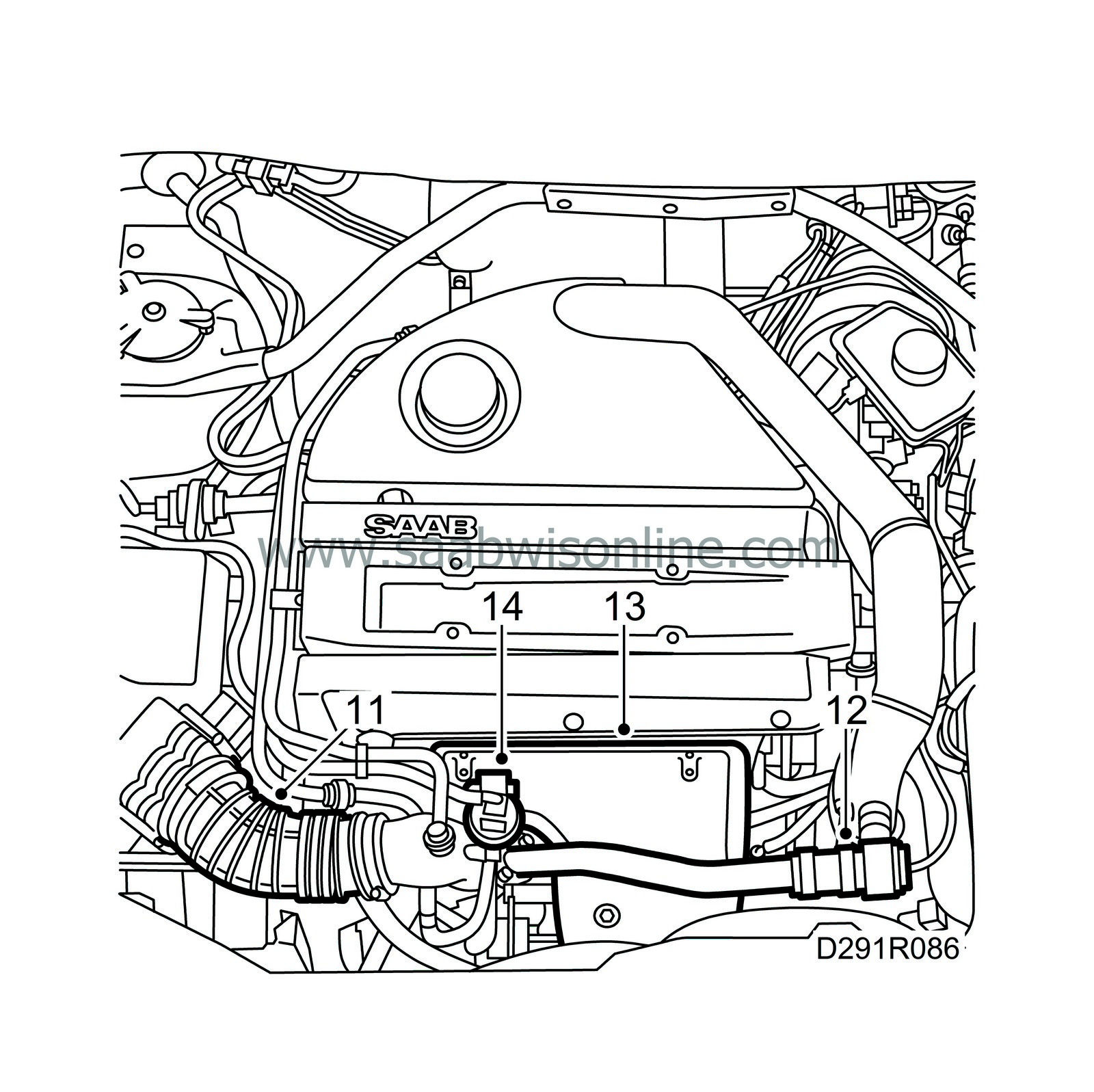

| 11. |

Remove the connecting hose between the mass air flow sensor and the turbocharger inlet pipe.

|

|

| 12. |

Remove the bypass pipe with valve, keeping the O-ring from the connector to the turbocharger inlet pipe.

|

|

| 13. |

Remove the heat shield over the exhaust manifold.

|

|

| 14. |

Unplug the solenoid valve connector.

|

|

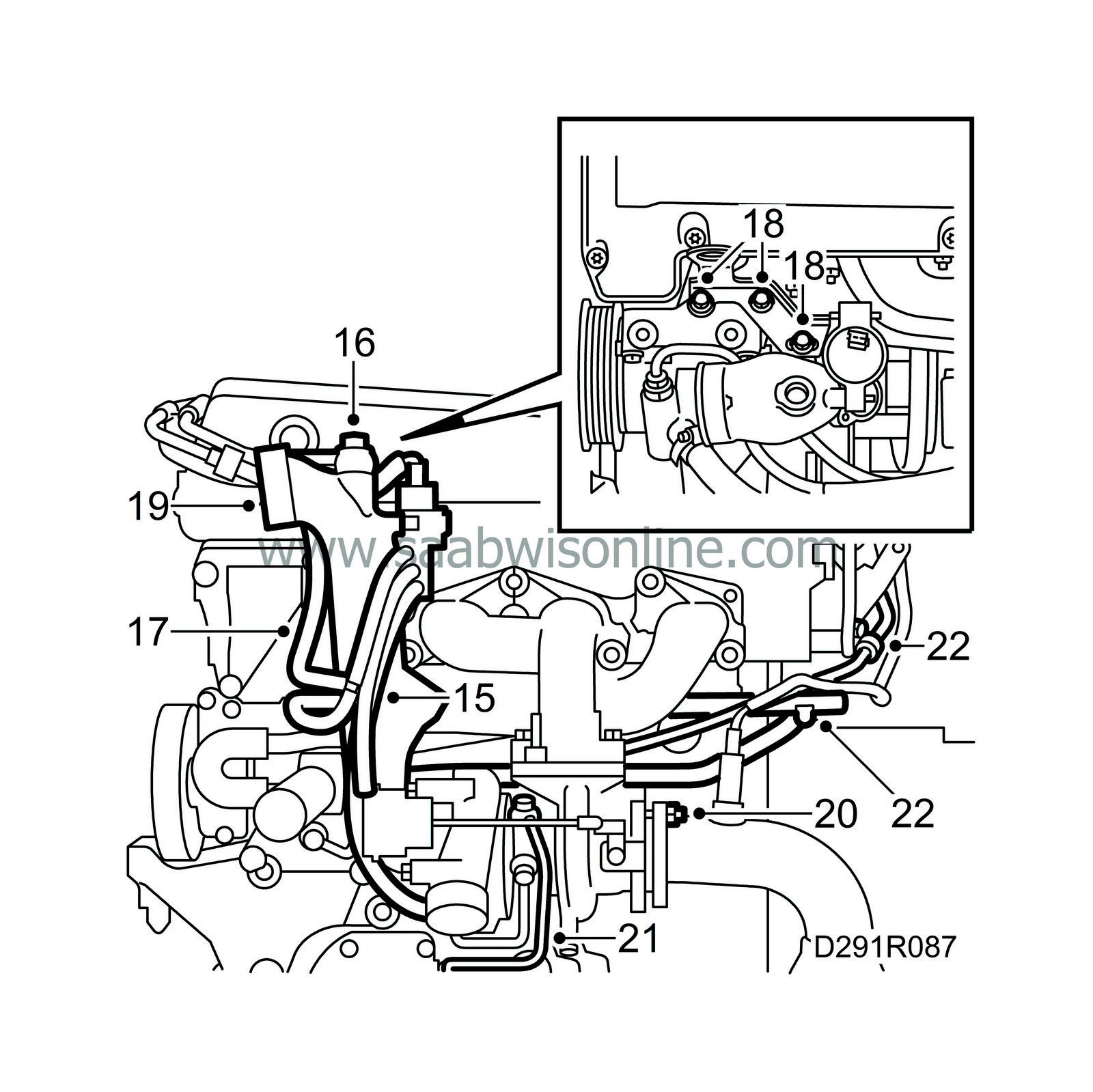

| 15. |

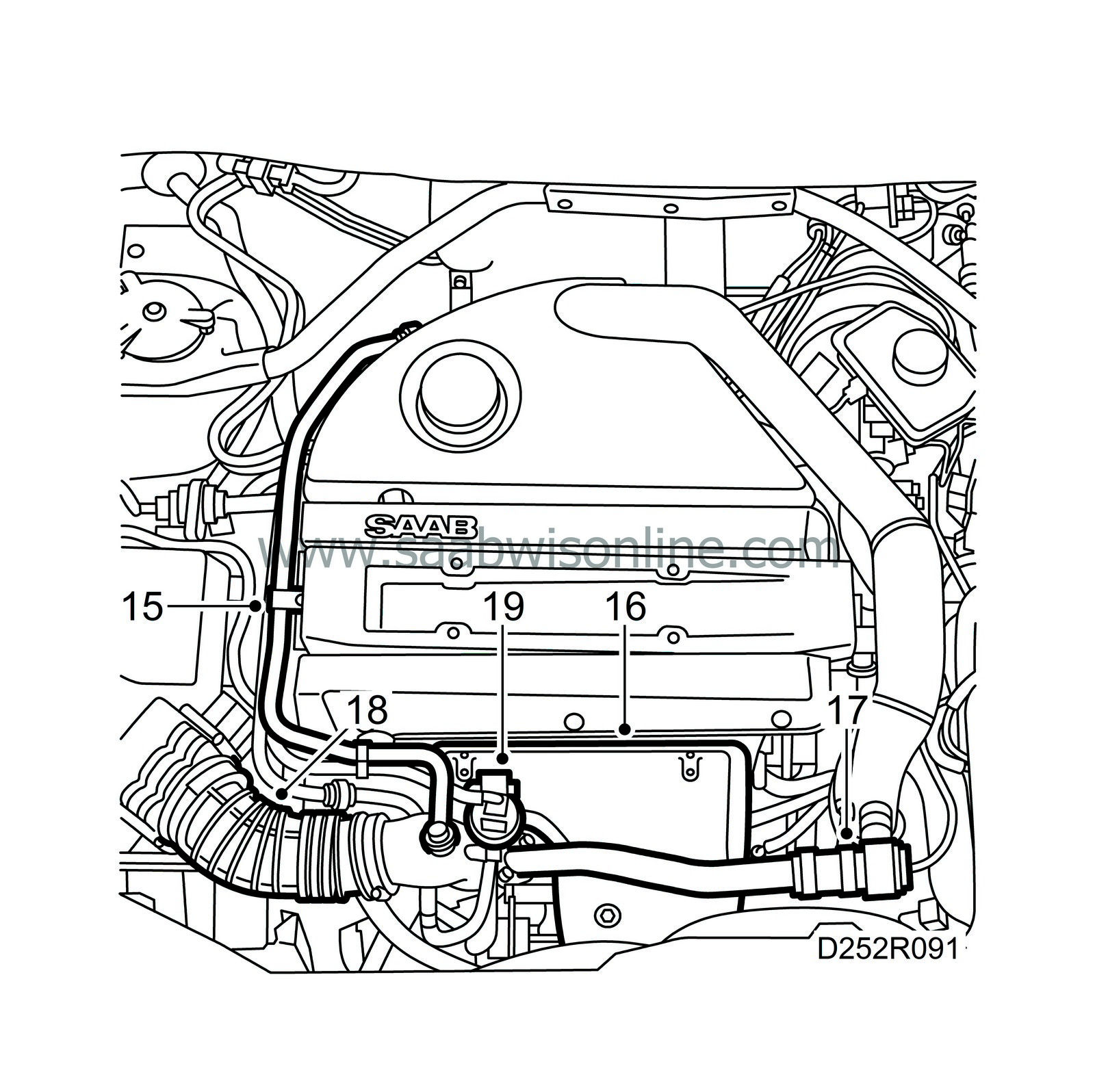

Remove the hoses to the solenoid valve, noting their locations.

|

|

| 16. |

Detach the crankcase ventilation pipe from the turbo inlet pipe and camshaft cover. Move the pipe to aside.

Keep track of the sealing washers. |

|

| 17. |

Detach the EVAP purge hose from the T-connector on the solenoid valve.

|

|

| 18. |

Remove the engine lifting eye.

|

|

| 19. |

Remove the turbocharger inlet pipe.

|

|

| 20. |

Remove the 2 top nuts on the joint between the turbocharger and the front exhaust pipe.

Carefully move away the exhaust pipe and secure it with a strap or similar.

|

|||||||||||||

| 21. |

Detach the oil pipe from the turbocharger.

|

|

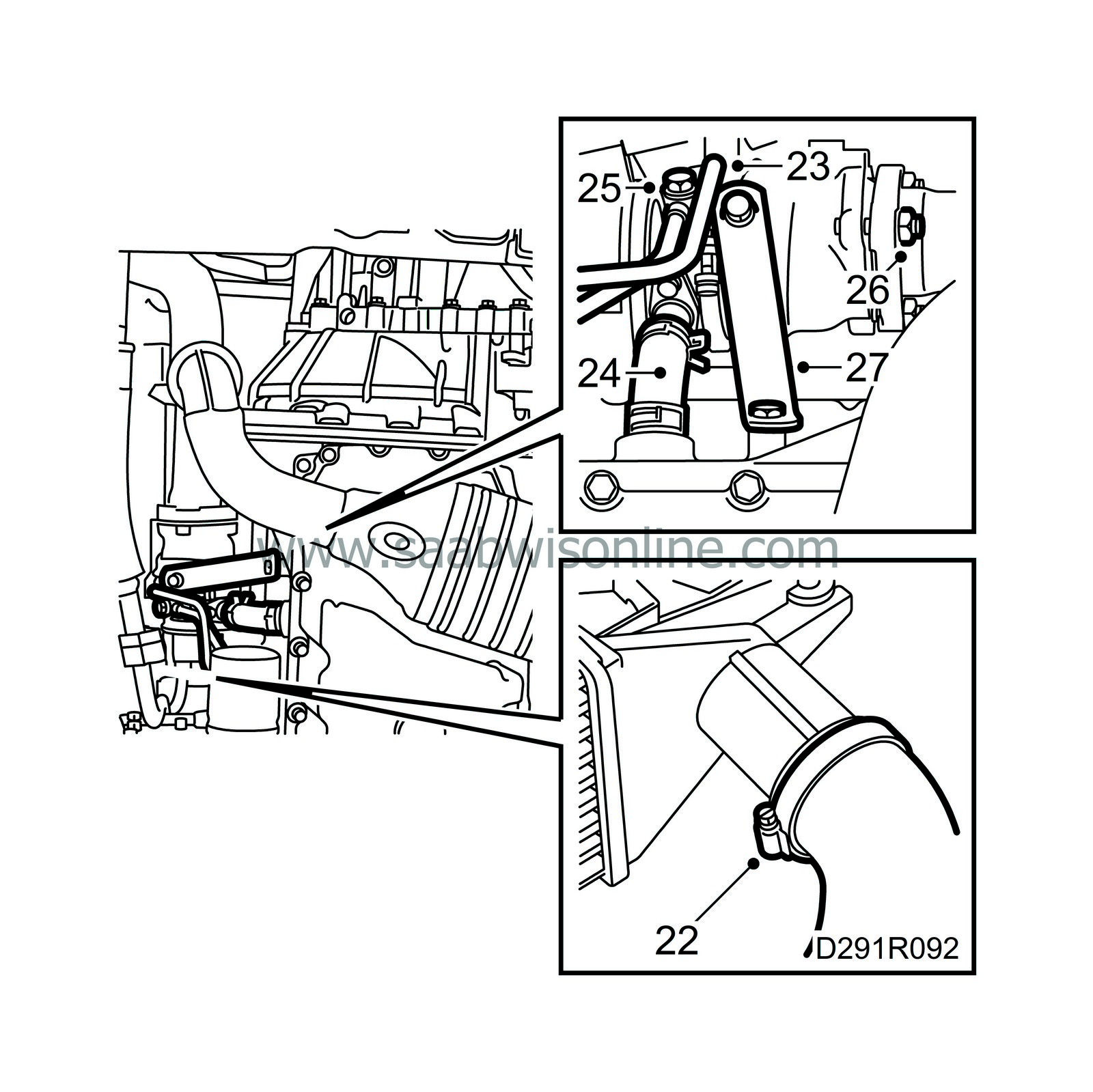

| 22. |

Detach both transverse coolant pipes from the cylinder head and pressure sensor mounting.

|

|

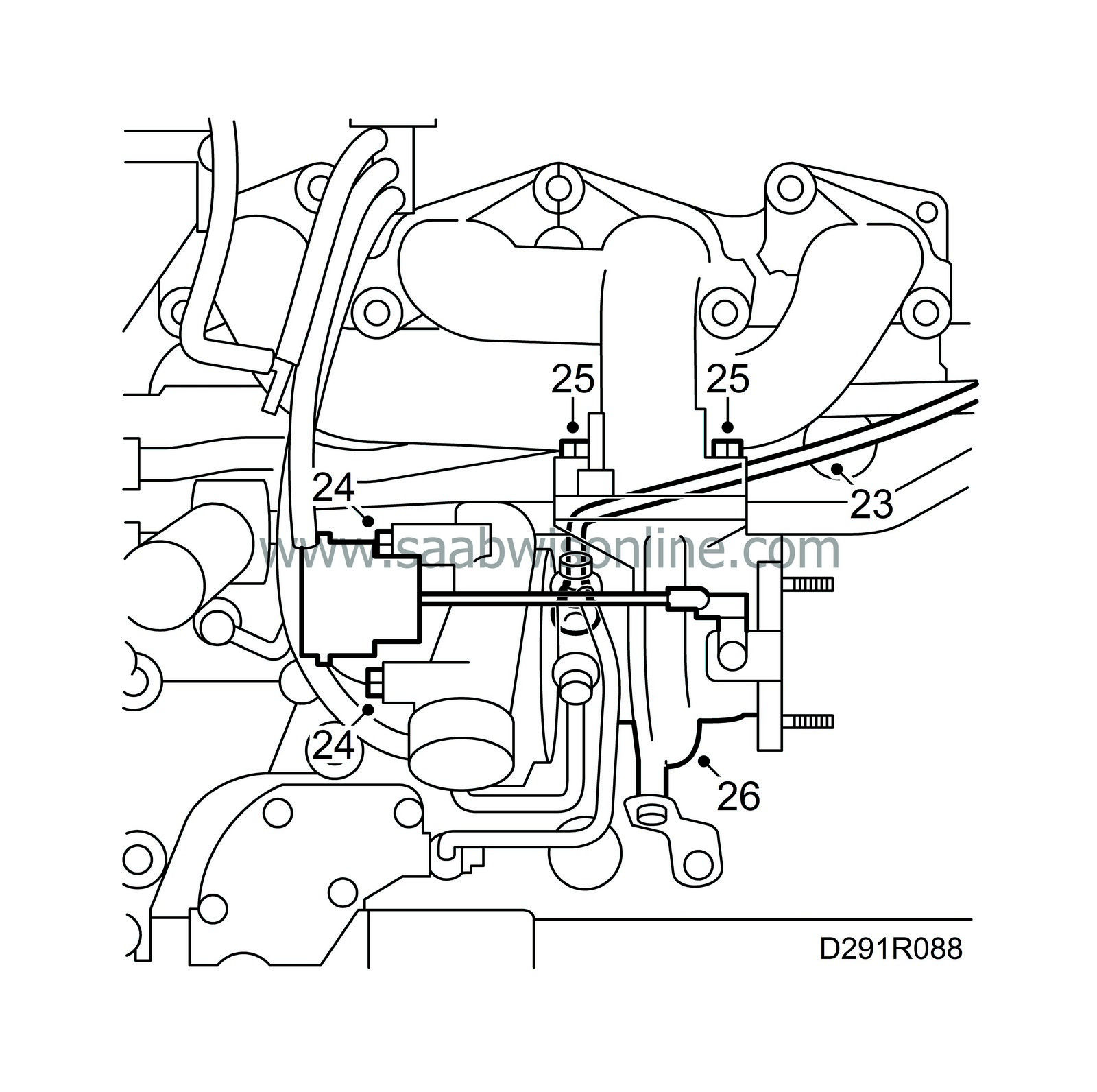

| 23. |

Detach the coolant hose from the turbocharger.

|

|

| 24. |

Remove the wastegate, 2 bolts and 1 clip.

|

|

| 25. |

Undo the nuts securing the turbocharger to the exhaust manifold.

|

|

| 26. |

Carefully lower the turbocharger.

|

||||||||||

| 27. |

Raise the car.

|

|

| 28. |

Carefully lift out the turbocharger.

|

|

| To fit |

| Important | ||

|

It is essential that there is oil in the turbocharger bearing housing when the engine is started, especially after a new turbocharger has been fitted. |

||

|

Fill the turbocharger oil inlet with oil from an oil can. Spin the compressor wheel a number of times to lubricate the bearings. |

||

| Note | ||

|

Apply a thin coat of Molykote 1000, part no. 30 20 971, or equivalent to the studs. |

||

|

Make sure the sealing surfaces are clean before fitting |

The wastegate must be removed from the turbocharger first if a new turbocharger is being fitted.

| 1. |

Fit a new gasket and carefully lift the turbocharger in place from below.

|

|

| 2. |

Lower the car to the floor.

|

|

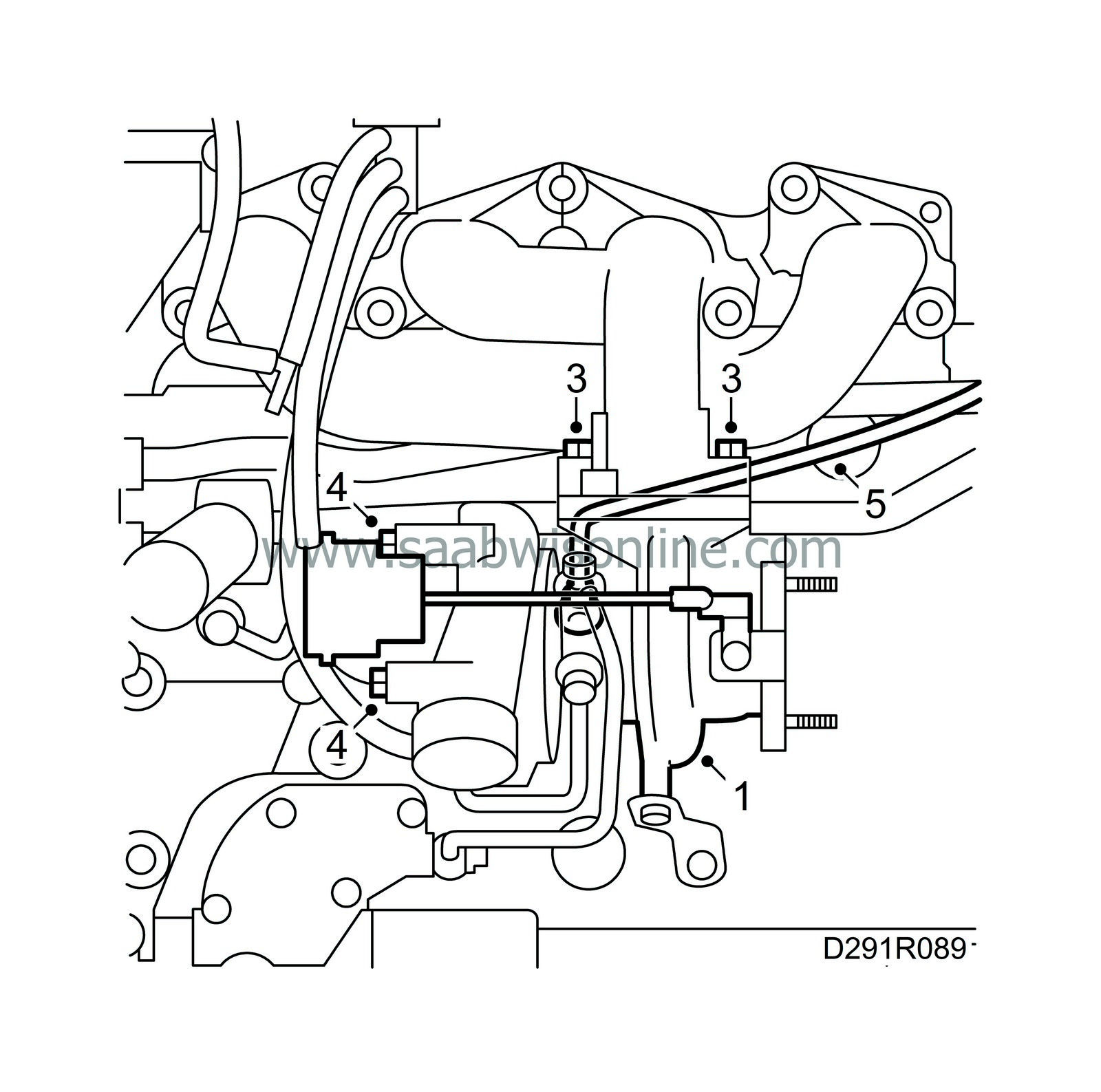

| 3. |

Fit the nuts securing the turbocharger to the exhaust manifold.

Tightening torque: 24 Nm (18 lbf ft) |

|

| 4. |

Fit the wastegate, 2 bolts and 1 clip.

|

|

| 5. |

Fit the coolant pipe to the turbocharger. Use new sealing washers.

Tightening torque: 25 Nm (18 lbf ft) |

|

| 6. |

Fit the coolant pipe with new banjo bolt and new gaskets to the cylinder head and to the pressure sensor mounting.

Tightening torque: 25 Nm (18 lbf ft) |

|

| 7. |

Fit the oil pipe to the turbocharger with new sealing washers.

Tightening torque: 20 Nm (15 lbf ft) |

|

| 8. |

Release the front exhaust pipe and move it to its correct location. Tighten the 2 top nuts on the joint to the turbocharger.

Tightening torques: Lock nuts: 24 Nm (18 lbf ft)

|

||||||||||

| 9. |

Remove the plug in the turbocharger air intake. Check O-rings and apply acid-free Vaseline, part no. 30 06 665, or equivalent. Fit the turbocharger inlet pipe without tightening the V-clamp.

|

|

| 10. |

Connect the hoses to the solenoid valve, noting the markings on the hoses and connections, and fit the solenoid valve on the engine lifting eye.

|

|

| 11. |

Fit the engine lifting eye.

|

|

| 12. |

Tighten the turbocharger's intake pipe, V-clamp.

|

|

| 13. |

Connect the purge hose to the T-connection.

|

|

| 14. |

Fit the crankcase ventilation pipe to the turbocharger inlet pipe with new sealing washers.

Tightening torque: 24 Nm (18 lbf ft) |

|

| 15. |

Fasten the crankcase ventilation pipe to the camshaft cover.

|

|

| 16. |

Fit the heat shield over the exhaust manifold.

|

|

| 17. |

Fit the bypass pipe and valve, using a new O-ring for the connection to the turbocharger inlet pipe.

Tightening torque 8 Nm (6 lbf ft)

|

||||||||||

| 18. |

Fit the connecting hose between the mass air flow sensor and the turbocharger inlet pipe.

|

|

| 19. |

Spray the solenoid valve connector with Kontakt 61, part no. 30 04 520, and plug it in.

|

|

| 20. |

Raise the car.

|

|

| 21. |

Remove the plug from the charge air cooler inlet pipe.

|

|

| 22. |

Connect the charge air cooler inlet pipe to the turbocharger.

Tightening torque: 8 Nm (6 lbf ft) |

|

| 23. |

Fit the oil pipe from the turbocharger to the oil filter adapter with new copper washers.

Tightening torque: 25 Nm (18 lbf ft)

|

||||||||||

| 24. |

Fit the oil return pipe from the turbocharger to the cylinder block.

|

|

| 25. |

Fit the coolant pipe on the turbocharger with new sealing washers.

Tightening torque: 25 Nm (18 lbf ft) |

|

| 26. |

Fit the bottom nut on the joint between the turbocharger and the front exhaust pipe.

Tightening torques: Lock nuts: 24 Nm (18 lbf ft) |

|

| 27. |

Fit the turbocharger stay.

Tightening torque: 24 Nm (18 lbf ft) |

|

| 28. |

Check that the cooling system's drain plug is closed.

Lower the car to the floor. |

|

| 29. |

Fill up with coolant. For the correct mixture, see

Cooling system

.

Close the filler cap. |

|

| 30. |

Bleed the system; see

Coolant (B235R)

.

|

|

| 31. |

Raise the car to check for any oil or coolant leaks.

|

|

| 32. |

Lower the car and top up the oil and/or coolant as necessary.

|

|