Inner sill

| Inner sill |

| 1. |

The door frame must be removed.

|

|

| 2. |

Position the car in an aligning bench and cross-measure if necessary.

|

|

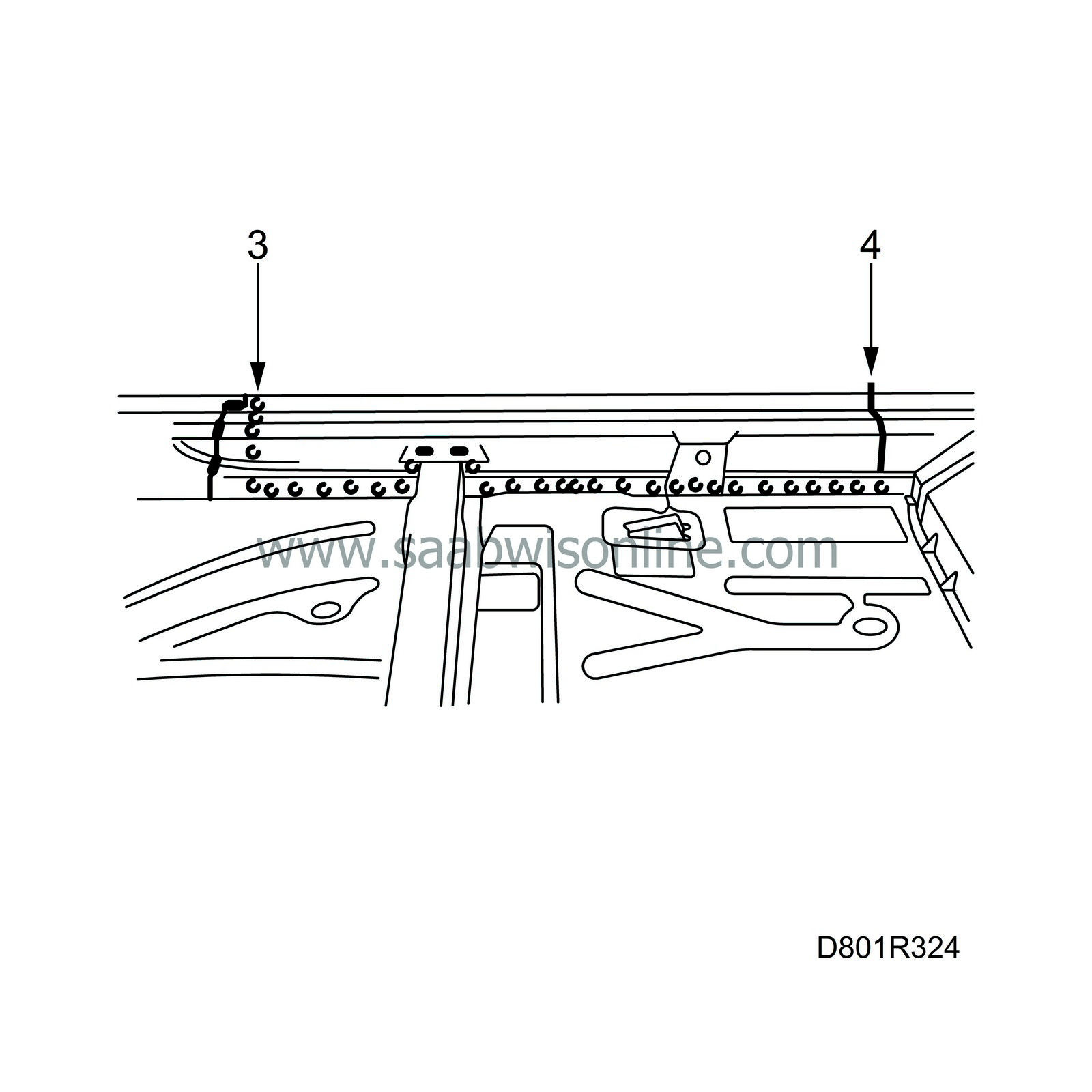

| 3. |

Drill out the spot-welds.

|

|

| 4. |

Cut the back edge of the inner sill.

|

|

| 5. |

Tap away the inner sill.

|

|

| 6. |

Align any deformed sheet metal or panels.

|

|

| 7. |

Cut the spare part so that it overlaps the intended joint line at the rear by approximately three centimetres.

|

|

| 8. |

Fit the spare part and fixate with a couple of welding clamps.

|

|

| 9. |

Cut through the spare part and body at the same time so that the joint can be welded edge-to-edge.

|

|

| 10. |

Grind clean the surfaces that are to be welded on the spare part and body.

|

|

| 11. |

Apply welding primer on the surfaces to be spot-welded. Use Teroson Zinkspray.

|

|

| 12. |

Fit the spare part and fixate with a couple of welding clamps.

|

|

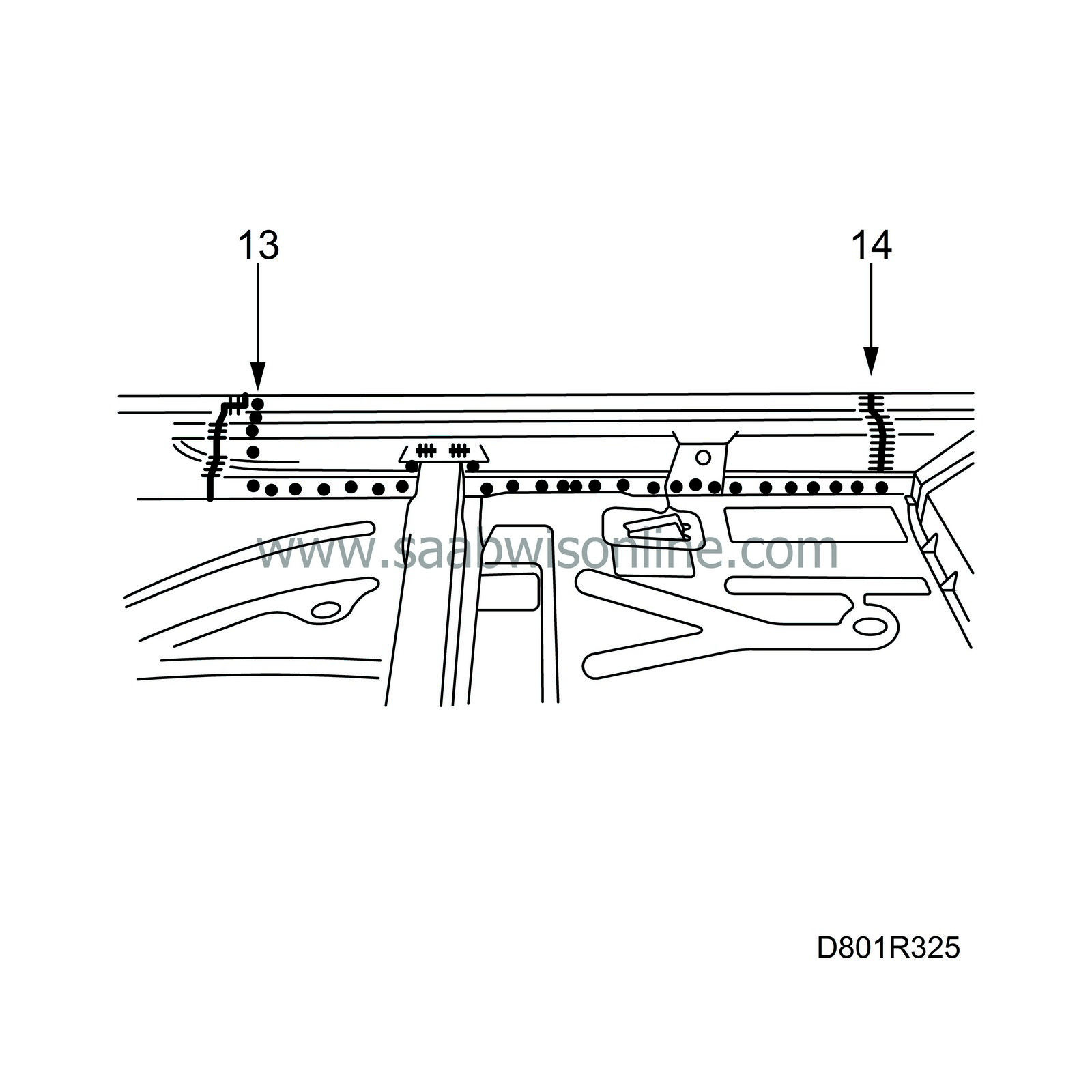

| 13. |

Spot-weld the spare part.

|

|

| 14. |

All-weld the joint at the rear edge of the sill.

|

|

| 15. |

Grind the welds.

|

|

| 16. |

Remove any remaining welding primer. Welding primer reduces adhesion of paint, filler and sealant.

|

|

| 17. |

Apply primer to all ground surfaces. Use Standox 1K Primer.

|

|

| 18. |

Seal joints and sheet metal flanges with sealant. Use Terostat 1K-PUR.

|

|