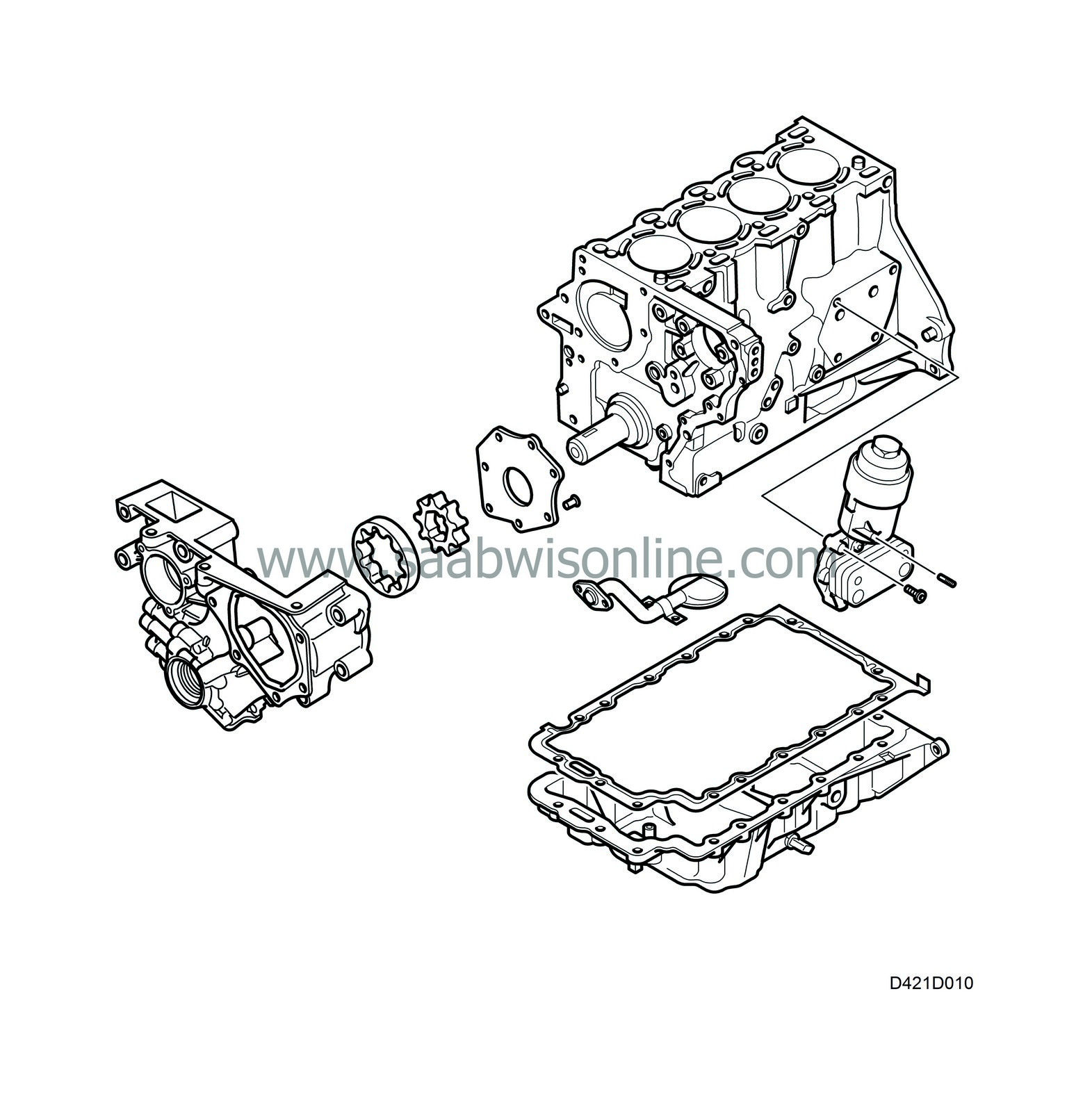

Lubricating system

| Lubricating system |

Oil is drawn up from the sump via a strainer and suction pipe to the oil pump. A pressure-reducing valve in the timing cover limits the oil pressure at the same time as excess oil is lead back to the suction side of the pump. The oil then passes via an oilway in the cylinder block to the oil filter.

The engine has a heat exchanger in which the engine coolant and oil temperatures affect each other, giving a more even engine temperature.

After filtering and cooling/heating the oil, it passes into the main oilway in the cylinder block where the engine oil pressure sensor is located. If the oil pressure drops below a certain level, the sensor will ground the circuit for the warning lamp in the main instrument unit.

The main and big-end bearing on the crankshaft are lubricated via oilways in the block and the crankshaft, while pistons and cylinder walls are lubricated by oil mist and splashes in the crankcase. Each cylinder also has a piston cooling nozzle, which directs a fine spray of oil towards the bottom of the piston.

The balancer shafts are supplied with oil via holes in the main bearings, which deliver oil down to the main bearing bridge. This also acts as the mounting point for the balancer shafts.

From the main oilway in the cylinder block there is also a relief channel leading via a relief valve to the cylinder head for lubricating the camshafts, valve mechanism and vacuum pump. The oil passes via a hole for one of the bolts in the cylinder head to drilled oilways to all the camshaft bearings and valve tappets.

| Oil sump |

The oil sump is adapted for the cylinder block and is sealed with a metal gasket with vulcanized rubber elements.

| Oil filter |

The oil filter is the insert type located in a filter housing. This is integrated with the heat exchanger on the cylinder block pointing towards the front of the car.