Closed loop fuel injection system

| Closed loop fuel injection system |

| General |

The system is controlled electronically by means of an oxygen sensor located in the exhaust pipe ahead of a catalytic converter. The catalytic converter contains a ceramic or metal insert, the walls of which are coated with the catalytic materials platinum and rhodium. The catalytic converter is highly efficient within extremely narrow limits. If the fuel-air mixture is not maintained within these limits, one or more gases will unfailingly exceed permissible values. A closed loop fuel injection system ensures that the fuel-air mixture will be correct at all times.

Provided that the closed-loop fuel injection system maintains the fuel-air mixture at an optimum level, at which carbon monoxide (CO) and hydrocarbons (HC) are oxidized, the three-way catalytic converter can also reduce the amount of nitrous oxides (NOx). The end products will then be carbon dioxide (CO 2 ), water (H 2 O) and nitrogen (N 2 ). The ability of the catalytic converter to reduce emissions is conditional on the car being run on unleaded petrol. This is because lead destroys the active components in the catalytic converter.

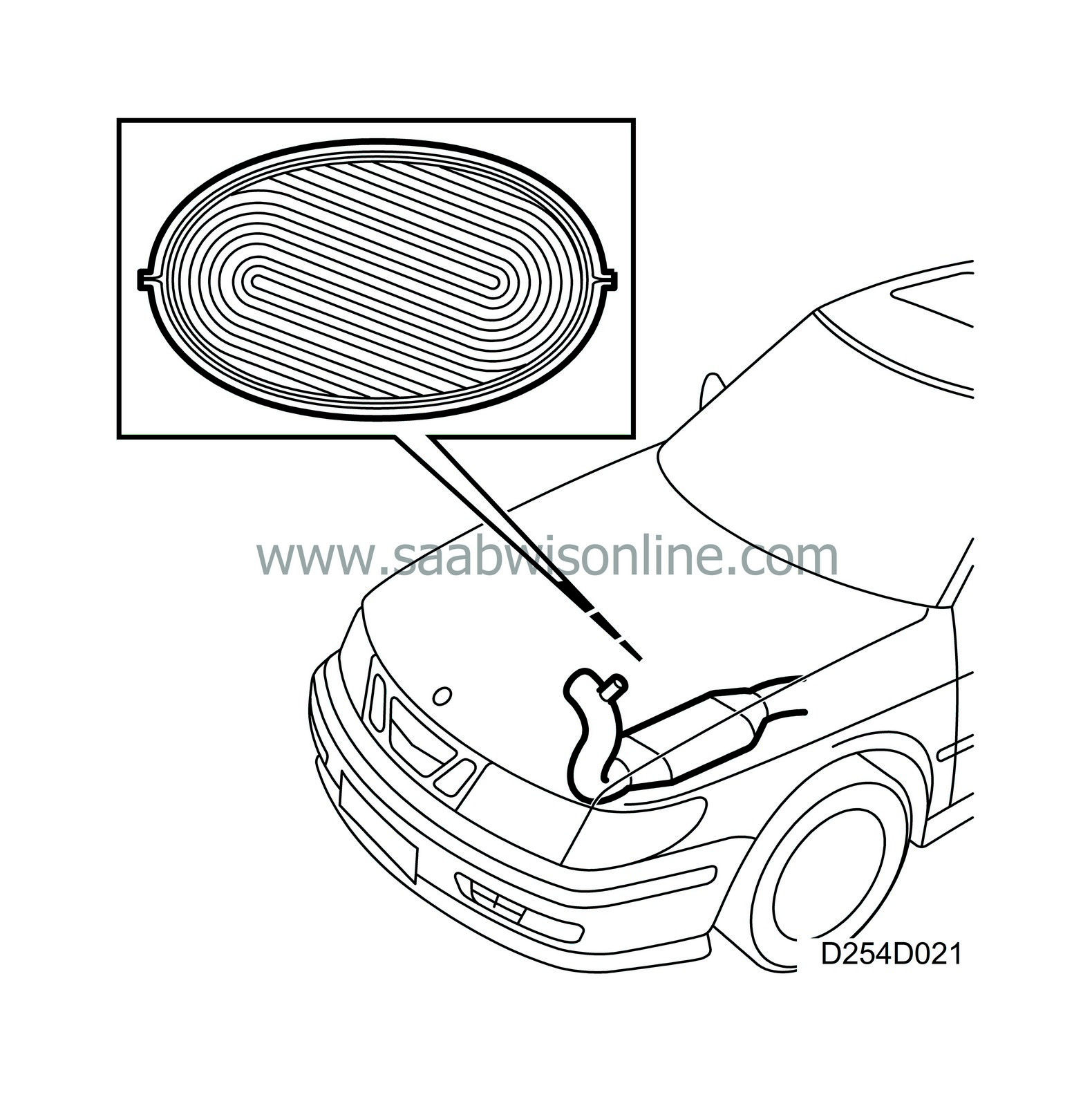

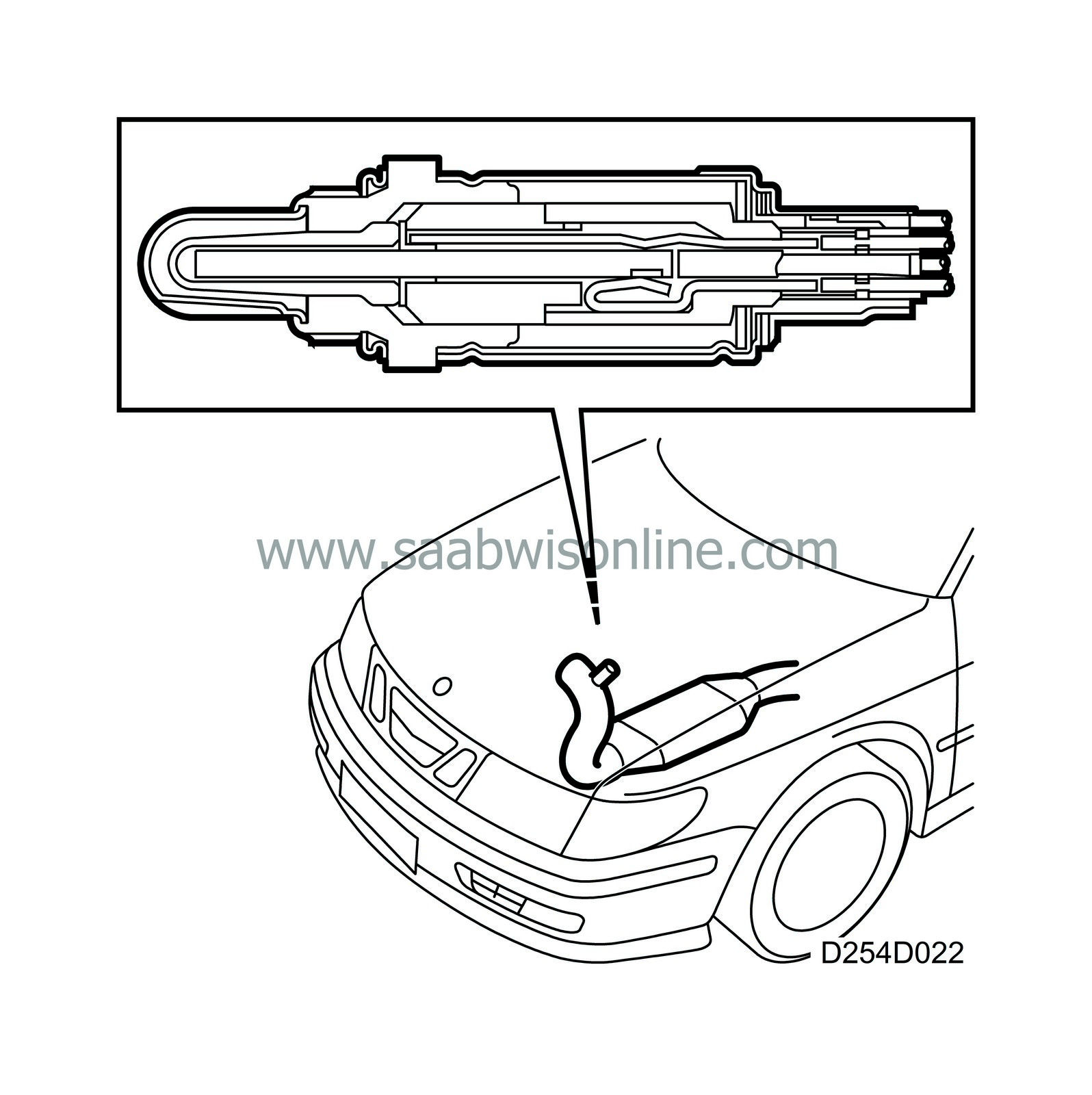

| Oxygen sensor |

The oxygen sensor consists of a primary cell with solid electrolyte. The electrolyte consists of ceramic zirconium oxide and is temperature-stabilized through the addition of a minor quantity of yttrium oxide. The electrolyte is tubular and hollowed out at one end. The casing is coated with titanium and therefore electrically conductive.

When the motor runs on a lean mixture the oxygen content of the exhaust gases increases. The oxygen sensor voltage then drops and the engine control module reacts by extending the injection time. At a closed-loop value of 1.0 the voltage is about 0.45 V.

Since the oxygen sensor does not become effective until its operating temperature exceeds 600°C (1120°F), it is preheated electrically. On cars with TRIONIC, oxygen sensor preheating is controlled by the system's control module. In certain markets the system incorporates a relay which disconnects preheating when engine speed exceeds 3000 rpm because the exhaust gases then heat the oxygen sensor. The output signals weaken as the oxygen sensor ages and it must be changed after 160,000 km (100,000 miles).